Balcony plasterboard finishing

Easy installation, safety and durability - the main advantages of drywall. This building material is suitable for lining internal surfaces. Finishing the balcony plasterboard is practical, high aesthetic characteristics, you can do it yourself.

Advantages and disadvantages

Drywall is popular with professional builders and newbies. It is easy to use, suitable for finishing different surfaces and has a large number of positive properties. The material consists of a solid panel, covered with construction paper on both sides.

Distinctive features of drywall:

- Low weight.Panels are easy to transport due to their compactness. This feature also simplifies the installation of parts.

- Environmental friendliness. The absence of harmful emissions makes the material safe for human health.

- Ease of processing. Drywall is easy to cut, so you can get parts of any size. This is especially important when rooms with a non-standard area are sheathed.

- Incombustible. The material is resistant to high temperatures, almost does not burn.

- Thermal insulation. This feature allows you to create a comfortable microclimate on the balcony and maintain a comfortable temperature for a person.

- Soundproofing. It will be quiet on the balcony covered with plasterboard, noises from the street and from the apartment will not reach it.

- Affordable price. Drywall is lower than the panels of natural wood, however, is of high quality and has a decent appearance.

Despite the high functionality, the material has several disadvantages. Drywall is fragile and can be affected by external mechanical stress, so care should be taken when transporting and storing the panels.It absorbs moisture easily and is not well suited for use in humid places. To eliminate this minute, it is recommended to leave drywall in the open form for several days before repairing it.

Kinds

Modern drywall has improved performance. Depending on its properties, there are several types of materials used for finishing different rooms.

- Usual. Cheap material that does not have additional properties. As a rule, it has a neutral color scheme and is used for covering rooms with a stable temperature regime and low humidity.

- Fire resistant The composition of drywall includes flame retardants that make the material less flammable. Such panels fully comply with fire safety requirements and are suitable for finishing practically any premises.

- Moistureproof. The most suitable option for a balcony due to precipitation and temperature fluctuations. Sheets are coated with a special moisture-absorbing coating; anti-fungal solutions are also applied to them to prevent the appearance of mold.

The panels differ in size from each other, which is also taken into account when purchasing building materials. Before proceeding to repair, calculate the area of the room, the required number of sheets of drywall. To do this, you need to know in advance the sizes of the sheets, which can be specified on the manufacturers website or directly in the store.

Required tools

Repair work does not require professional knowledge, and standard equipment is sufficient for them. Its preparation or acquisition is one of the stages of preparation for repair. What tools are needed:

- Perforator. Used for direct mounting of panels.

- Drill, shrovovert. Needed when installing screws, dowels and other fasteners.

- Construction level, plumb. They are used to align the panels relative to each other and located on the balcony surfaces.

- Putty knife. Required for applying putty on walls.

- Tape measure and pencil. They are taken during the measurement work.

In addition to the above equipment, you need to purchase drywall and the following materials:

- Insulation - to prepare surfaces for installation.

- Hydro and vapor barrier. Required when laying insulation.

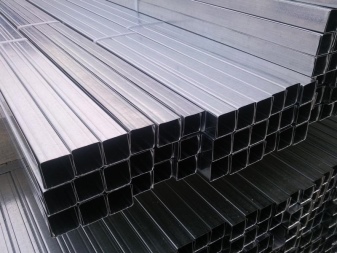

- Profiles. Need to install crates.

- Dowel, screws. Fasteners are required at all stages of work.

- Primer, putty. They are used for processing joints between sheets of foam.

- Hacksaw for wood and metal. If necessary, it can be replaced by a grinder. It is required to process parts of the batten.

If it is required to process materials additionally, purchase paint separately. It is suitable for both cardinal change in the color of drywall and for emphasizing the natural tint of the panels. At the stage of final finishing impregnation is applied to protect against high humidity, high temperatures.

Preparatory stages

The balcony is finished with drywall only after the glazing of the room, otherwise the panels will not stick and may be deformed due to precipitation or excessively high temperatures. Here are some other steps required for preparation:

- Before covering, all objects are removed from the loggia, they rid the walls of the traces of the old decoration.

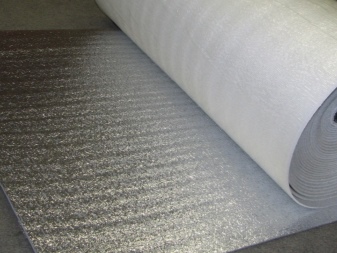

- Further recommended to install steam and moisture protection. For this purpose, suitable foil or plastic film, acting as a barrier. In addition, special membranes can be used.

- Warming is necessary not only to maintain a comfortable microclimate and constant temperature, but also to extend the life of the panels. Because this procedure is also required to conduct before covering.

It should be borne in mind that you need to process all surfaces on the balcony: not only the walls, but also the floor and the ceiling. Insulation should be resistant to rot, moisture and the effects of pathogenic microorganisms.

Materials used for loggia insulation:

- glass wool;

- mineral wool;

- polystyrene foam.

The thickness of the material should be at least 50 mm, so that there is no draft on the balcony. When operating in difficult climatic conditions, the insulation is additionally treated to increase resistance to high and low temperatures. It is placed between the elements of the batten, pre-covered with foil for waterproofing. For installation the construction stapler is used.

Sheathing plasterboard balcony requires installation of crates on which the panels will be mounted. The frame is made of horizontal and vertical profiles, which are both wooden and metal.The latter are characterized by increased strength and ease of installation, because they are used more often.

When using wood, the bars are further processed.

Mounting steps for crates:

- Creating a drawing and marking the walls in accordance with it. Due to this, the profiles will be located exactly, which means that they will last longer.

- Installation of support profiles. The first bars are installed on the floor, the following elements are aligned along them.

- Installation of parts in accordance with the markup. To make them as smooth as possible, it is recommended to use the building level.

- Fastener parts. For these purposes, dowels or screws are used, they are installed every 25 cm.

- Installation of cross bars. They are made of rack profiles and have a view of the congestion of the walls. If you want the crate to withstand a lot of weight, jumpers are fixed as often as possible.

Fixing suspensions will make the frame more durable and tough. A heater may be placed between the cells of the batten; on the site of future joints it is recommended to arrange a double batten. In the next stage, drywall is directly attached to the batten.

In the next video, we suggest that you visually review all the above steps on the example of ceiling lathing.

How can I sheathe your own hands: a sequence of works

Cladding start from the ceiling, and then go to the walls. First of all, you need to cut the plasterboard panels of the desired size, if necessary, leave room for lighting.

The simplicity of the filler joints between the panels is provided by the bevelled edges - chamfer. If not, the surface is prepared independently.

The first plasterboard panels are installed on the ceiling. It is most convenient to use screws as fasteners - they are recommended to drown their caps inside the material. The distance between the elements is 20-25 cm, for convenience, they make marks for future holes before work. The remaining panels are installed in the same way. If necessary, the last details are trimmed.

What is taken into account when covering the balcony:

- Wiring and screws should not be in contact.

- Metal lathing is most effective in humid climates.

- Wooden bars are polished, covered with protective solutions.

- Fasteners can not be very tightly twist: the material is brittle and can be deformed.

- When installing ceiling profiles around the edges and the middle, it is recommended to use anchors.

By complying with these recommendations, it will be possible to extend the life of the structure, simplify and speed up the installation process.

Video instructions for finishing the balcony plasterboard, see below.

Final finish

Facing allows to realize any design ideas of the owner of a balcony. It is at this stage that the design ideas are realized, the comfort is created:

- First of all, the gaps between the panels are sealed with a serpyanka or a primer, then a paper tape or grid is placed on the seams. To level the surface, put two layers of putty on it. The operation is similar for walls and ceiling.

- Versatility is one of the advantages of drywall. It can be painted, covered with wallpaper or tiles. Only lining is not suitable for finishing, since its installation requires the use of self-tapping screws, which can deform the panels.

- As for the colors, for decorating the balcony, you can use both natural and calm shades, as well as contrasting, aggressive colors.In the first case, you can create an interior in the style of country, the latter option is suitable for modern design.