Water tank in the bath: types and installation options

Bath procedures have a very positive effect on human health. They perfectly warm up the muscles, joints, prevents the appearance of colds, improve blood circulation. But for a comfortable and healthy holiday bath should be properly equipped.

Usually in the standard model of the Russian bath there are two water tanks. One of them is designed for cold and the other, respectively, for hot. Comfortable rest in the bath directly depends on what kind of hot water tank is selected, how it is installed and what volume it has. Treat these issues should be carefully and responsibly.

Special features

Although today there are a variety of heating devices for water, but the usual hot water tank in the bath still remains relevant. Quite a significant advantage of this device is a decent savings on water heating from gas or from electrical appliances. Also one of the positive aspects of a hot water tank in a steam room is that it increases the level of humidity in the air.

The main thing before buying a tank is not to miscalculate with its volume. Some important rules will help you to choose the tank correctly for its subsequent reliable and long-term operation. In particular, it is worth considering that per person in the bath will need from 20 to 25 liters of hot water. Therefore, if the sauna steam room is small and designed for two people, then the standard fifty-liter capacity is enough. And in the case when the bath area allows you to relax in it as a whole company, then there is an indispensable one-hundred-meter tank.

Kinds

Tanks for hot water are presented by various models. Among the most common types of structures emit built-in tank, portable and tank on the pipe.Each of the models presented has its own positive and negative sides.

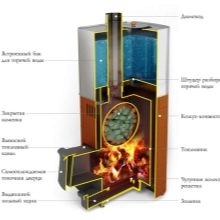

Built

Previously, the built-in type structures were made in baths immediately during their construction. The lower part of the water tank was connected to the furnace, and then the liquid was heated from the fire in the stove. This is a familiar and standard design that has been used for a long time. Its great advantage is that the water in the tank heats up quite quickly and it does not have much trouble with the option of heating the water. Liquid from such a reservoir is taken using a scoop, lifting the lid or mounting a tap in the barrel. However, such a tank may have a small capacity. The volume in this case directly depends on the dimensions of the heater or the boiler. As well as most of the heat from the furnace goes exactly to the heating of the tank with liquid, which reduces the level of heat transfer in the steam room.

Portable

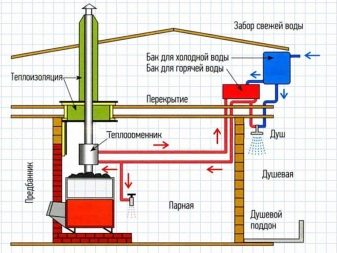

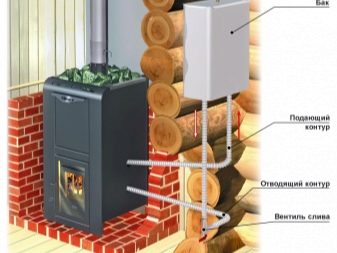

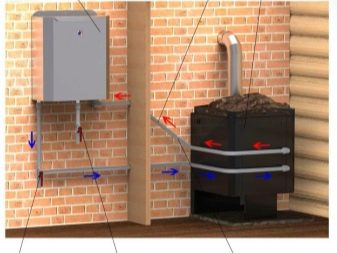

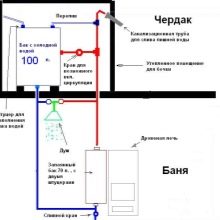

The main convenience of this type of design is that the tank can be installed anywhere, depending on convenience. Placed such a container most often in the sink or in the shower near the steam room. As a heating device, a heat exchanger is used here, which is located in the stove, which is connected to the tank by means of copper and brass pipes.The principle of operation lies in the fact that cold water is supplied through the heat exchanger, and the hot water rises back.

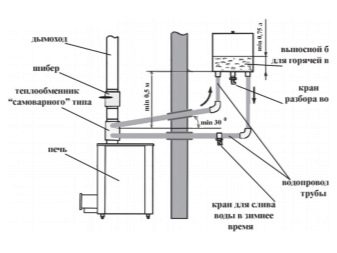

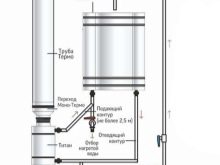

On the tube

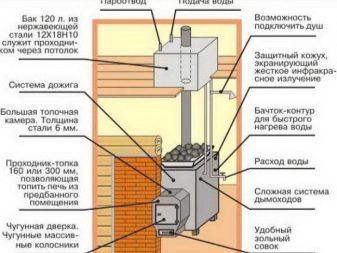

These models should be used when the steam room is used for quite a long time. In this case, the water tank is above the pipe. Installation of this design is more difficult than others, but it has more advantages. Water tank is usually installed in the attic. The heated water retains its heat for a long time, even after the furnace has stopped. The design itself does not clutter up the space in the bath, as it is in the attic. This design is good to use in a bath with a large number of people.because the tank contains a large volume of water, and its warming up is carried out in an extremely short time.

Another hot water tank on the pipe is called samovar because of its working principle. Usually, stainless steel is used for the production of samovar systems. Thanks to this material, the water in the tank warms up very quickly. But it is extremely important not to allow boiling liquid in the tank. This rule applies to all types of systems.

Also quite popular model tanks are mounted type. This is a very convenient design that is installed directly above the stove, which allows you to warm the water. This tank is very convenient to use in a small bath, as the water tank takes up little space. But their most typical disadvantage is that people in a steam room can accidentally touch hot walls of the tank and get serious burns. In addition, the volume of such tanks is not always large and the water in them can quickly boil. To do this, it is recommended to periodically drain the water and pour cold. Moreover, such tanks are equipped with taps for draining water.

Corner water tank is installed in the corner of the steam room. This is a plus, since such a design does not clutter up the space in the bath.

Horizontal water tanks have an oval shape and are more like a barrel.

There are also tanks with the so-called TENG. TENY are the heating elements providing heating of water from electricity. TENY recently also gained particular popularity. Even many bath stoves are now working not with wood, but with the help of these devices.Their leading manufacturers are firms. "Harvia", Helo, and from domestic manufacturers the campaign is popular "Ermak". In addition, there are complex apparatuses, the water in which can be heated both from the mains and from the heat of the stove.

Another worth mentioning is such a model as expansion tanks. The main function of such a device is to compensate for the overpressure in the heating system. This always happens when the water temperature increases. That is, the point is that such a cumulative tank helps maintain optimal pressure in the system. Often expansion tanks used for large heating systemsFor example, for public baths.

The added hot water tank is also considered one of the most sought after. To heat the water, the tank is simply attached to the furnace wall, and the water in it is heated.

Materials

When choosing a tank in a bathhouse or when it is independently manufactured, it is extremely important to choose the material for its manufacture without fail. From this will depend on the time of heating the fluid, the period of its cooling and the duration of operation of the apparatus itself.Among the most widely used materials, cast iron, stainless steel and enameled steel are massively used.

Previously, only cast iron tanks were used for hot water tanks. Cast iron tanks tested by time and have a number of positives. In particular, the cast iron tank will keep the water hot for a long time. There is no corrosion on them and the water in this tank will always be clean. Such material is very resistant to temperature changes. And, finally, the shelf life of a cast iron tank is very long, since this material is not subject to corrosion. Currently, not many manufacturers are engaged in the manufacture of cast iron tanks. But it is possible to buy a used tank at a lower price. In this case, you will need to make its processing and give it a nice appearance.

Of the minuses you can emphasize quite a long time to heat the water in the tank. Cast iron tanks are heavy and sometimes need to be installed on a special foundation. If the tank is above the stove, its attachment requires additional reinforcement. To make such a tank yourself will also be a very problematic event.

Stainless steel tanks now used quite often. This material has replaced the cast iron tanks. The owners of the baths appreciated their high positive qualities. These tanks do not require additional protection from high humidity. The water in the stainless steel tank is heated in an extremely short period of time. Stainless steel has good resistance to rapid temperature changes and, accordingly, does not rust, which already follows from its name. Of the minuses, it can only be noted that the water in it cools quickly.

Enamelled steel tanks - also a popular version of this design. Special enamel coating on these tanks reliably protects them from the effects of corrosion. The main thing - to prevent damage to the enamel, otherwise the tank may begin to rust. Although it is quite problematic to damage the enamel layer, since such a coating is resistant to all kinds of damage. If necessary, the tank of such a material can be very easily cleaned. Enamel of various colors is represented on the market.

For cold water, individual tanks are now used infrequently, as it most often enters the room through the water supply system.But if it became necessary to supply the tank for cold water, then much less hassle arises with it than with a hot water tank, since there are no particularly strict requirements for it. You can even use wooden tanks, such as oak barrels. Popular and enjoy plastic containers for cold water. But such containers should not be placed in the steam room, and especially near the stove, because plastic is sensitive to high temperatures and can become deformed when heated. Also, such a tank can be completely made with your own hands.

Self-made capacity can be welded from several sheets of aluminum. Galvanized surfaces can also be used, which will additionally protect the tank against the effects of corrosion.

Making your own hands

Quite a few bath attendants with experience recommend making stainless steel containers. Most of its advantages were listed above and they all indicate a great convenience in the use of such material. But it is worth considering that there are different brands of stainless steel, and not everyone can be suitable for the manufacture of containers with water in the bath. One of the best options is the brand 08 X 17 (430) and 812 X 18Н10 (304).These are very reliable surfaces that do not require special care and will last a long time.

Usually purchased tanks have a wall thickness of 1 mm. But in the manufacture of capacity is best to use metal sheets slightly thicker. Sheet sizes are selected according to the tank capacity.

Often craftsmen use a stainless steel pipe. In this case, the capacity is similar to a barrel. And this is quite a convenient option, because you do not have to spend a lot of time calculating the size and joining the sheets. For the manufacture of such an iron barrel, you must perform the following steps:

- First you need to cut off the necessary piece of pipe grinder.

- Places of cutting pipes must be carefully processed. For this you can use a regular file. To ease the task and save a lot of time will help the drill with special nozzles.

- Then you need to proceed with the installation of the bottom and the top cover of the container. Actually, for this you need to find a sheet of stainless steel. Usually the thickness of the upper and lower parts is larger than the walls of the tank itself. On the sheet you need to draw a flat circle in accordance with the diameter of the pipe. Necessary circles are cut and again processed.If a chimney passes through the tank, then additional holes are made in the lower and upper parts according to the diameter of the pipe from the stove.

- The next stage of work is the connection of the cut parts with the main part of the future container. For this, a welding machine or soldering method is used (which is much more complicated and longer). After the connection, again, you need to process the welds well. By the way, if necessary, and for convenience, the upper part is not necessarily welded. It can be bolted to the case or made in the form of a cover so that it can be removed. This is done when the tank is not connected to the water supply and the water is poured manually.

- The next stage of work is the most painstaking. It is necessary to install a crane and nozzles on the container. To do this, stainless steel need to drill from the bottom and top in places where there will be taps. Sometimes the pipes are simply welded to the container in order not to make a special thread.

- Then work on the installation capacity. More about them below.

How to install and connect?

In the process of installing and connecting the tank in the bath, one of the main priorities is to decide how the water in the tank will be heated.The water in the tank can be heated either from the heat of the furnace in the steam room or with the help of heating elements. Here the main factor is the number of people visiting the steam room and their need for hot water. The thickness of the tank will also affect the rate of water heating.

Water tank connection schemes may vary. If there is a water supply in the room, it is necessary to use a closed-type water supply system. For this purpose, it is best to use a furnace that has a coil, and which, in turn, will connect to the water tank and heat the liquid. Capacity itself can be equipped on the wall. Sometimes tanks are mounted directly above the furnaces, but with this type of installation it is best to use lighter and smaller structures. For tanks that have a water circuit, stainless steel or galvanized tin is often used.

You need to connect using the following instructions:

- The tank itself should be installed in the steam room and connected to the pipes with a coil.

- To achieve good circulation, it is necessary to connect the upper part of the tank with the upper branch of the coil, and the lower part of the tank, respectively, with the bottom.For this reason, cold water will flow from the bottom, and hot water will flow from the top.

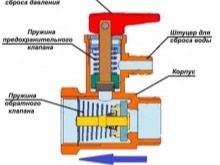

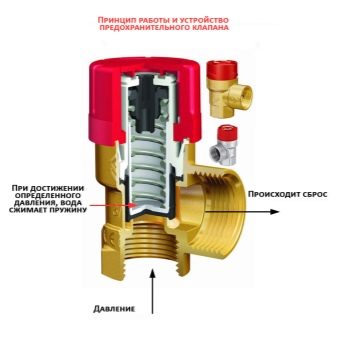

- At the place where cold water will flow into the tank, a safety and check valve is used.

- After that, it is necessary to set for valves the threshold pressure at which they will operate. The drawings are presented below.

Due to this principle of operation, the liquid in the tank will be heated with a coil. And after it is used, the tank will be filled with cold water again.

If the hot water will be in the tank for a long time, then it increases the pressure. But in this case, the so-called "shooter" is installed on the tanks, which releases pressure automatically.

Useful recommendations

Many owners of baths there is a need to paint the water tank. Especially if this is a handmade product, then you definitely need to give it a beautiful and presentable look. To begin with, it is recommended to thoroughly clean the surface of the container before painting both inside and outside. For this you can use a variety of abrasives. Also, the surface must be degreased so that during subsequent painting a good adhesion of the surface and paint is ensured.If an old container is used, then surely it will contain rust residues. You can handle this by using a metal brush or an electric drill with a special nozzle. Drilling can save time, effort, and clean the rust more thoroughly.

Immediately before painting, it is necessary to ensure that the surface of the tank is completely dry and that primer is performed. For painting it is necessary to prepare a respirator and rubber gloves in advance for safety reasons. For the process itself, you can take a brush or spray.

Paint should be applied in several layers. This will protect the surface from the penetration of water into its structure.

Currently, manufacturers offer a wide range of different paints for all surfaces. Many paints also contain substances that help protect the container from corrosion. Therefore, painting the tank provides him with additional protection and increases the service life. It is better for the bath to choose a paint with heat-resistant properties. Such paints create a special layer on the surface of the tank, which provides it with protection against high temperatures and the appearance of rust.Therefore, to choose a paint for a tank will not be a problem and their prices are quite reasonable.

For cold water, an accumulation tank is often used, which pumps water inwards on the principle of a pump. When the tank is full, the pump shuts off automatically. It is important to note that such structures create noise during operation. Therefore, for a comfortable stay is not recommended to install cumulative tanks in the steam room. Especially since high humidity can harm such a system.

A very important factor for the tank is the correct equipment for water extraction. He should pay special attention and choose pipes from quality material so that they do not leak. Otherwise, the water will drain constantly and will not have time to heat up well.

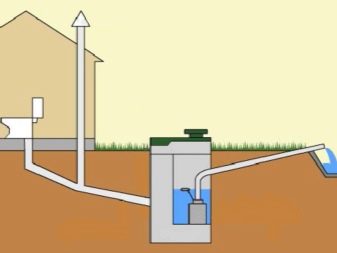

Also it is necessary to properly install the drain water from the steam room. To do this, they usually make a drain hole on the street, and a drain pipe is installed in the bath. The floor in the washing room is made at a slight angle so that all the water flows into the pipe.

Between the furnace and the metal tank is best to make a small partition. You can use a sheet of asbestos. This will not damage the walls of the tank with high temperature from the stove, thanks to which the metal's service life will last significantly.

If the weight of the furnace and the tank is large, you must first prepare a special foundation. It is usually done when the weight of the structure exceeds 600 kg. For the masonry of the furnaces is not used cement solution. Sand and clay are used instead. Clay is soaked in water, and then sand is added to it.

So, above were considered various models of water tanks in the bath. Each design has its own advantages and disadvantages. Therefore, the choice of design depends on the individual preferences of the owner of the bath. To choose the right water tank in the bath room, you need to decide on the design and volume of the tank. They can be built-in, remote and samovar on the pipe. Among the materials popular are cast iron and stainless steel. It is quite possible to make a container by yourself, without making a lot of effort and time and money.

To learn how to make a portable water tank, see the following video.