Baths of expanded clay blocks: advantages and disadvantages

For decades and even centuries, baths have been associated with wooden and brick buildings. But this does not mean that it is impossible to consider other materials (for example, ceramic blocks), choose them properly and apply. One of the most modern and practical options is claydite, which has a number of positive aspects.

Special features

The traditional idea of a bath as a chopped structure using wooden beams is still popular. In fact, the bath can be made of any material that meets the following requirements:

- heat retention;

- slight water absorption;

- decent fire properties;

- environmental Safety.

Ceramsite concrete blocks fully meet these requirements, and even exceed specially treated wood in terms of fire protection.

The basis of this material is laid, as the name implies, expanded clay, that is, clay balls subjected to firing. The building blocks are formed by connecting the expanded clay with the cement-sand mixture; the combination of substances then needs to be moistened, given a certain configuration and passed through vibrating presses. The choice between the fine and coarse fractions of the material is determined primarily by how light blocks should be created: if the size of the balls is large, lightweight ceramsite-concrete structures are obtained from it.

Advantages and disadvantages

Expanded clay almost does not absorb water, which makes it possible to consider it one of the best options for buildings with a high level of humidity inside or outside. The undoubted advantage is that this material is stronger than foam concrete, aerated concrete, ceramic blocks and perfectly stabilizes wall fixings. Expanded clay multislit blocks (these should be used in baths) are supposed to be lubricated with mortar only along the external contour. To ensure the tightness of internal voids, it is advisable to use a jute-based insulation.This allows you to automatically remove the problem of external insulation of the steam room.

It is possible to build a bath of expanded clay blocks much faster than from other materials. After all, each block replaces an average of 12 rows of bricks, depending on the size of the construction that the developer chooses. Importantly, the cycle of construction work is not interrupted, because the claydite does not sit down, unlike wood, which requires to wait from three months to six months.

Installation is extremely simple, even for those who know very little about stacking blocks. And very few tools are required.

There is no need for the use of masonry mix; the wall will be very flat, no finishing is needed before the beginning of the facade works. The total cost of all work, even if projects are taken into account, will be 1.5–2 times lower than when using wood. Bath will last at least a quarter of a century.

In expanded clay concrete there are several weak points that all developers should be aware of:

- it is impossible to build a bath above two floors;

- the material is very poorly tolerated by mechanical damage;

- must be facing both internal and external planes.

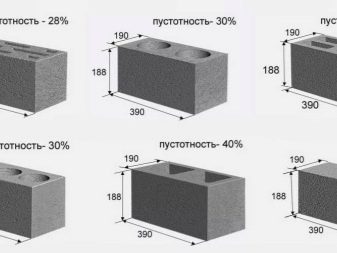

Kinds

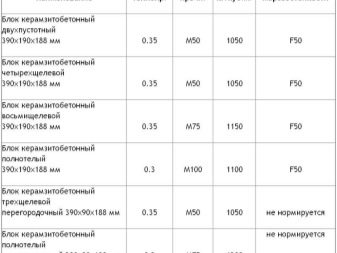

Ceramsite blocks are quite diverse in their performance. So, modern versions of them are able to transfer up to 300 cycles of heating and freezing, which is very decent even for a sauna room. But, of course, this does not eliminate the need for good insulation and waterproofing, both inside and outside. Brand strength varies from M25 to M100, this figure expresses a calmly tolerable impact (in kg per 1 cm). For the needs of housing, you can use only blocks not weaker than M50, all the rest are suitable only for outbuildings.

It is important to consider that the stronger the type of block, the denser and heavier it will be. Sometimes, even a small thickness of the walls, made of dense claydite concrete, does not allow them to significantly facilitate. The specific weight of a concrete block can reach 400 kg per 1 cu. m

It is also customary to divide clay block on:

- wall;

- used for partitions;

- ventilation (in which the holes for air passage and for the passage of air pipes) are initially prepared;

- foundation (the most durable and heavy, it is undesirable to use for the formation of the walls of the 2nd floor of the bath).

Due to the elimination of cavities, full-weight ceramsit concrete products are more mechanically stable, but hollow versions are easier and can drastically improve the thermal insulation of the bath. The properties of the voids can be very different, in some cases, blocks with two voids are best suited, in others with seven slots, and so on. The differences are manifested in the number of facing planes: in separate structures there is not one, but two such planes.

It is useful to choose a variant with a facial trimmed layer when there is an intention to abandon the finishing of the outside of the bath.

The texture of clay blocks is often divided into:

- smooth (there should not be even insignificant traces of machining);

- subjected to grinding;

- corrugated (with a geometrically accurate distribution of cavities and grooves on the surface of the block);

- chipped, or Besser (the most commonly used variety).

Color can be almost any: modern technology allows customers to get the desired result in a relatively short time.

What projects to choose?

When choosing a bathhouse project of expanded clay blocks, you need to give preference to those options that do not contain bends, arched structures and other uneven shapes.You can use them, but it immediately increases the cost of work and makes the structure of the building less robust. In typical projects, it is often provided for a single-pitch roof over a 6x4 or 6x6 m structure, although anyone can revise these values and remake the project to fit their tastes or characteristics of the site.

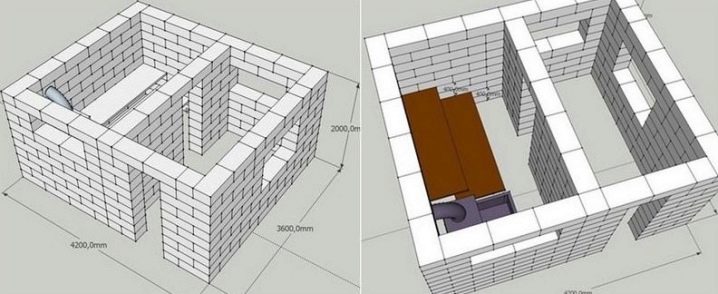

Judging by the reviews, it is best to work out projects using computer programs. The three-dimensional model of the future construction shows it much better and more accurately than any schemes drawn on paper. In this way, it is possible to facilitate the calculation of the location of window and door units, or more accurately calculate the need for building materials.

Construction process

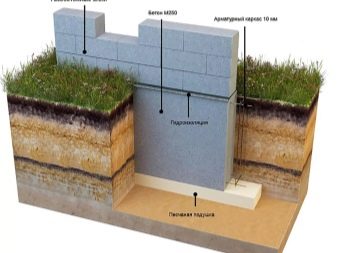

Any step-by-step instruction can not ignore such a moment as the construction of the foundation. Since keramsit concrete is relatively light, it is possible to form a tape base with a shallow depth. This is very economical, but when there is no complete certainty that the ground will be stable enough, you will need to contact geologists to investigate the territory. With the slightest doubts, it is worthwhile to deepen the basis of the structure under the boundary of soil freezing.Strictly according to the drawing space is spaced for the creation of future walls and internal partitions.

Further construction is as follows:

- digging pit;

- sand and rubble pillow is filled;

- formwork is made under the monolithic foundation, reinforcement is placed and the solution is poured over it;

- as a replacement, a set of lightweight aggregate with small grain can be used;

- wait until the foundation settles (monolithic option - not less than 30 days, and laying of expanded clay blocks - at least 7 days);

- the base is covered with a layer of waterproofing - not only the top, but also the side.

Strengthening the bearing qualities of the foundation is achieved by reinforcing mesh, and one or two layers of roofing material will help to ensure an adequate level of waterproofing.

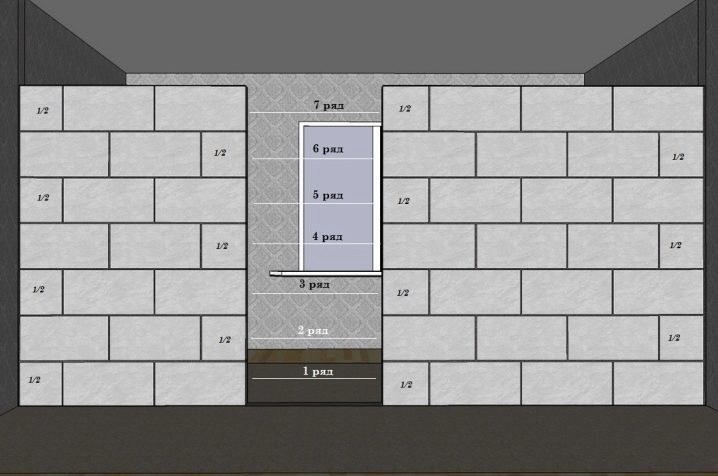

Next, build a box that starts to mount from the highest corner of the base. Immediately after the placement of the first row of parts, their level is carefully checked, and if any deformations are detected, it is necessary to correct them with wedges. Working with your own hands or hiring builders, you can not divide the construction of the box into stages. The shorter the time between consecutive stacking of blocks, the better the result achieved and the lower the risk of making a serious mistake.In the same way, remove the excess concentration of solutions and sew the seams immediately.

The most durable construction is created if every 4th or 6th row is reinforced. In large baths, the uppermost row is sometimes reinforced with a reinforced concrete belt.

The construction of roof systems and roofs does not have significant differences from the construction of similar parts of a residential house:

- first beams are laid;

- rafters are placed on them;

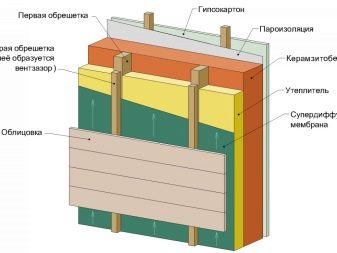

- a layer of waterproofing, vapor barrier and heat insulation is created;

- a roof is formed (the choice of slate, tile, metal or any other solution is determined by the specific conditions).

Exterior finishes, although not necessary for technical reasons, are very useful., because it increases the evenness of the walls and their resistance to external influences. In this case, the costs are relatively small, and the building will be much more aesthetic. Brick cladding is not the only option, the use of embossed plaster, plastered surfaces for painting, curtain walls and many other solutions has been worked out. If a decision has been made to add additional weatherization of the bath, it is advisable to choose the most environmentally friendly materials, the same requirement applies to productswhich bath buildings circled inside.

Before the start of finishing works it is necessary to carry out all communications. Among all natural materials, the first place in finishing is to give high-quality wood, since it best corresponds to the traditional bath. After finishing, it will be right to install the stove right away, to buy (or make it yourself) the sun loungers and the rest of the furniture.

Tips and tricks

- In the very top row of the walls, niches for beams are necessarily provided. Given the selected roofing material, determine the step of stuffing crates. The niches separating the rafters are filled with insulating materials, above which the vapor barrier is placed. Among all the rooms, the steam room needs the most insulation, where floor insulation is laid with an overlap on the walls of about 0.2 m. Only then the walls themselves are insulated, the pitch of the crate is made the same width of the insulation material. Reflector put overlap and glue it on top.

- The optimal laying of the walls - in half a block, that is 30 cm thick. Rows are laid in a “ligation” pattern, which allows you to successively close the seams.For the preparation of solutions recommend cement-sand mixture (1 share of cement and 3 shares of sand in the volume of dry powder). Water is added just enough to knit the properties and density of the material to be balanced. The width of the seam is 20 mm, for partitions, you can use both standard blocks and thinner ones.

- To protect the external walls from wind, precipitation and giving them a pleasant appearance, it is best to use cement plaster, which is kneaded from one part of cement and four parts of sand. When finishing, two layers are applied with an interval of 24 hours, each layer immediately after application is rubbed down to complete homogeneity with a special construction float. Paint for facades based on acrylic resins has become widespread as a topcoat.

On how to build a bath of claydite concrete blocks on their own, see below.