Foam blocks bath: design features

No one can deny the benefits of a bath for a person’s physical and emotional health. Baths have been popular with different nations for many centuries. And now she enjoys well-deserved popularity. Many people want to have a bath complex in their personal use, on their site. Unfortunately, the construction of a classic bath because of the relatively high cost of wood is not affordable for everyone. In this case, the option of a modern material - foam blocks will help.

Special features

To build a small bath of foam blocks can almost anyone. By virtue of its light weight, at the same time, quite large size to lay out the walls of foam blocks will not take much time. Observing all the technology of construction, the time that will be spent on it will take about a crescent, while the structure will be of high quality and have durability.

Foam blocks are a building material made from a mixture of a specific proportion of cement and sand with the addition of an air-forming substance mixed with water.

Cavities in the body of foam blocks are an additional source of high heat capacity.

It should be borne in mind that the bath is an object that uses high temperature and humidity. Taking into account these factors, foam blocks should be purchased of the brand M25, while it is desirable that their density was D700. Their cost is somewhat more expensive, but this is offset by the durability and strength of the bath being built. To minimize the destructive effect of water on the building material, the walls of it must be very well waterproofed from the inner and outer sides.

To the positive features of the use of foam blocks in the construction of baths are, as previously mentioned, the cost of building materials. To comparison: the cost of a wooden frame is twice as high as the value of a structure built from foam blocks.

The strength of this building material is different in a positive way. From it you can build a bath in two or even three floors.The thermal conductivity of foam blocks can be compared with the thermal conductivity of wood, in contrast to bricks, whose performance is three times worse.

Due to the ease of foam blocks due to air cavities in concrete, the construction can be carried out without the assistance of outside assistance and special equipment - with his own hands and relatively quickly.

A considerable advantage is also the environmental friendliness of the material used.

In comparison with most types of wood, foam blocks are non-radioactive, have no hazardous or toxic inclusions.

Wooden baths are characterized by increased fire hazard, while the foam concrete bath, on the contrary, does not burn, cannot sustain combustion and ignite. It also does not rot, rodents and insects do not breed in foam concrete buildings, foam concrete is not affected by fungus.

Due to the ease of processing, foam blocks are perfectly sawn with a simple saw, installation is practically not difficult. Any elements of the building is easy to cut out of any shape and size, after which they are glued together with a suitable mixture for this purpose.

A distinctive feature is the resistance of the material to deformation., the blocks do not warp and crack, do not swell under the influence of temperature fluctuations and high humidity.

Unfortunately, the pores of the material absorb moisture; therefore, it is necessary for such structures to acquire blocks that are treated with a special compound in the form of a water-repellent primer. The cost of this material will be more expensive, but it will pay off due to the durability of the building.

There are also some disadvantages. These include the low strength in the case of material bending, the heterogeneity of the pore structure, which creates certain problems of holding the fasteners. In such cases, it is desirable to use hardware (dowels, anchors) designed specifically for mounting in porous structures.

There may be deviations in the density of the material due to the different technologies used for their manufacture and the violation of proportions, as well as insufficient mixing of the mixture.

Construction is recommended at positive temperatures. due to the fact that the properties of the adhesive composition are significantly weakened or completely lost under frosty conditions. If you follow all the recommendations, even after 10 years, the structure will look like new, and the minuses will be invisible.

Since, because of their porous structure, the blocks absorb moisture, it is necessary to further waterproof the erected walls and partitions, as well as apply the appropriate finishing of the building.

Project

Just like for any construction, before you start building a bath, you need to choose a place, carefully plan, select and calculate the necessary material. Also find out what the roof will be, for example, shed.

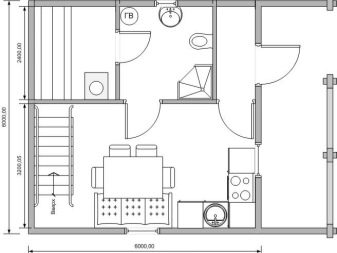

It is advisable to immediately imagine what you want to see in the planning of your bath. In the classic version, in the drawings of almost all the baths there is a steam room and a sink, a rest room is also desirable. The areas in different cases are distributed according to the arising requests. There may be options with a large steam room and a small sink, also with a reverse distribution, a large relaxation room and many other options are possible.

Choose the appropriate option is not difficult. Each person has his own idea of the functionality, proper use and organization of the premises of the structure being built.

Particular attention should be paid to the construction of the vestibule.if you plan to use the bath for its intended purpose in winter. Also, the location of the doors is important, they need to be planned taking into account not to take too much space.

The stove must be selected taking into account the volume of the steam room, not forgetting that it is usually heated from the waiting room, therefore, some of the heat is spent on its heating. Based on these parameters, select the capacity of the furnace.

Currently, the bath is not only for washing, it is often used for emotional and psychological relief. Based on the requirements, the construction project is selected and implemented.

It may include not only the classic set: steam room, washing room, dressing room, but this may include rooms for rest rooms, terraces, attic, pool.

The most economical option would be to implement a bath construction project with three rooms.

The size of this bath is approximately 400x400 cm.

There are a great number of bath projects, among them the most common are those where the rest room is combined with a dressing room.It is desirable to make it more than other rooms, in connection with the placement of the necessary furniture in it.

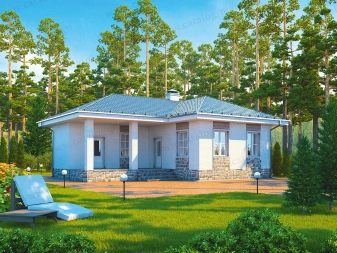

Very common plans for baths with terraces. Terraces are equipped with necessary furniture in the form of chairs and tables, barbecues and barbecue stoves are installed. The structure is performed under a single roof and the corresponding design. It is possible to add instead of a terrace, for example, a garage or another annex. The original idea is a country house, combined with a bath building.

Quite often the attic is built as a second or third floor. This two-storey building can be as living or guest rooms or for relaxing after the procedures. Such facilities may be single-storey. The most commonly used dimensions are 6 by 4, 3 by 5, and also 6x6 meters.

With all the responsibility you need to approach the choice of the site for construction. The site must comply with all fire safety regulations and the requirements of SNiP 30-02-97.

Based on these requirements, the building should be at a distance of one meter from the fence, while the neighboring house should be at least eight meters, including five meters to the border of the site.

The site should be chosen on a dry, preferably flat, place due to the fact that the foam blocks are hygroscopic.

Materials

Depending on what material is used in the construction, it depends on how functional and durable it will be. One should pay close attention to the time when the blocks were manufactured. The required strength of foam blocks is set after 28 days from the time of their manufacture. Accordingly, the use of blocks that have not passed the curing period is not recommended.

There are several factors to consider.

- It is advisable to purchase products of proven companies that value their authority. These enterprises carry out laboratory tests of their products and then implement them, accompanied by appropriate quality certificates.

- The cost of purchased materials should not differ significantly from the market average. Otherwise, you should find out the reason for the discount, so as not to purchase poor-quality material.

- Pay attention to the tightness of the packaging and storage conditions in a dry place.

It is also desirable to conduct a visual inspection of the purchased material, while it is necessary to determine what the structure of the pores of the blocks is, this is clearly seen on the split block.The quality of the material inner and outer surface is the same, while the pores are insulated and small in size. If the pores are connected, the foam blocks are hygroscopic, with a large pore size, the strength of the product is reduced.

Material need to buy gray, which corresponds to GOST 25485-89If the color is light, it may signal a violation of proportions and a decrease in quality. You also need to check how the correct shape of the purchased products. To do this, two or three sides dock and check for gaps between them. If there are gaps, then an increased consumption of adhesive mass is required.

You can calculate the required amount of material for construction by yourself. This will require data on the dimensions of the future bath and the unit sizes of the applicable material.

To calculate the total number of foam blocks, the number of blocks in the wall is calculated first. The width of the wall is divided by the size of the block length, the height of the bath is divided by the size of the height of the foam block, then both results are multiplied. Based on the result obtained, the perimeter is calculated.Accordingly, the number of foam blocks in partitions is calculated. Next, you need to calculate how many foam blocks contain window and door openings and openings for the furnace, subtract them from the total result, all walls and partitions. So it turns out the exact amount of material needed for the construction of the bath.

Separately, the calculation of the required number of bars for rafters and floors, plywood, Mauerlat, fasteners, necessary insulation and finishing materials.

The foam block can always be replaced by a gas block, as evidenced by the testimonials of builders. The main thing - that the thickness of the material was chosen correctly. Also do not forget to warm the building.

How to build with your own hands?

Once you have decided on the amount of the necessary material and the necessary tools, proceed to the construction. This requires step by step instructions. Such a construction can be done by yourself, even if you do not have any special skills.

Due to the fact that the foam blocks are lightweight material, it is possible to make a not very expensive strip foundation, and this will be enough.

First of all, we determine the density of the soil at the construction site, depending on this we count on the depth of the foundation: the looser the soil, the deeper the foundation.

The durability and functionality of the bath depends on the strength of the foundation.

The width of the lay a little more than the width of the foam block. When the depth is taken into account sand and gravel pad, which is placed directly under the concrete.

When it was determined what the depth should be the foundation, it is necessary to make the markup of the future bath with the help of twine and stakes. Further, a trench is being excavated depending on the ground: up to a meter deep and about 40 cm wide. A sand cushion is tamped and gravel is poured on top, laid with boiled reinforcement.

Rolling formwork from scrap materials, not forgetting about the ventilation holes. Pour the prepared concrete, preferably using a brand of not lower than M200. We need to wait for the concrete to fully set. If there is a possibility, the waterproofing in the form of roofing felt or roofing material is laid in advance on the bottom of the dug trench, which will prevent the foundation tape from getting wet from the ground.

For a high-quality foundation, a bay of concrete is made at one time, interrupted during work for no more than three hours. During the first two days, the concrete is wetted with water up to three times a day in order to avoid the appearance of cracks; it should also be covered from sunlight.

The formwork is removed after three days.

Full cure of concrete can take up to six weeks under adverse weather conditions.

Next, you need to fill the base for the installation of the furnace and the wiring of engineering networks to organize the discharge of used water. To do this, prepare the drain or equip a special pit, if possible, the sewer tap is connected to the central sewer system. In any case, a special channel is created inside the enclosed foundation area, which has a slight slope. When the floor is built, a special hole will be built into it to divert used water from the premises. Do not forget that the pit or other devices for the outflow of water is equipped for the contours of the building being built baths.

Before building walls, you need to isolate the foundation with polyethylene, roofing felt or roofing felt.You can also make coating with bitumen mastic.

To lay out the first row, you need to tighten a fishing line or twine on the level, then begin to lay out foam blocks with the help of cement mortar, a similar one is used for brickwork. It is important to lay out the first row correctly, the quality of the whole building depends on it. In order to avoid irregularities and differences in the height of the blocks, a rubber mallet is used with which they are knocked to the required height.

Starting the second row, it will be easier to work. Here begins the use of special glue. Glue preparation is simple; to do this, simply mix the mixture with water and stir. The adhesive is applied in an even thin layer, about 0.5 cm.

To make the walls more durable, every few rows fit reinforcement or reinforced mesh. If the height and size of the bath are rather large, then metal reinforcement is used, which is placed in special grooves in the blocks, when reinforcing the corners and partitions, the reinforcement is rounded off without cutting. When removing window and door openings, special mortgages are used, which are sold with foam blocks.

Upon completion of the construction of the wall, you need to withstand up to five days so that they are completely dry, after covering the entire structure with a special film. During this time, the strength of the box increases, and you can begin to make the roof.

For buildings that are built from foam blocks, usually make an ordinary dual-slope roof. Choosing truss legs, you need to take into account the width of the bath, the intended slope of the slopes. The feet in the skate are joined by a thorn-groove joint. In this case, the roof overhang above the walls is desirable to arrange about 50 cm.

The roof is built of wooden elements and covered with corrugated flooring. The ends are sewn up with roofing felt or roofing felt. The overlap between the ceiling and the immediate roofing space from the inside is insulated using foam plastic due to its lightness and non-hygroscopicity. For removal of excess steam in the ceilings holes are made so that there is good ventilation, it is necessary to install vents and grates. For data owners, the facility should not forget about all these nuances.

Interior finish

Due to the moisture capacity of the foam blocks, special attention should be paid to the finishing of the walls of the bath. For this you need to make a steam removal.Isolation of the inner surface of foam blocks is carried out in order to avoid the condensation of warm steam. Aluminum foil in the form of a reflecting screen for heat or a special vapor-permeable membrane is used for insulation. Pre-blocks need to be impregnated with a water-repellent agent and dried.

It is necessary to conduct a competent warming bath. Insulation is carried out in several stages. Pre-warmed foundation and the entire area of the underground. The foundation is insulated with mineral wool, while the basement is insulated by falling asleep with claydite and slag.

For the decoration of the walls in the baths used wooden material, it can be a board, wall paneling and other types of lumber. The wooden paneling is mounted on the installed frame, and the distance from the paneling to the wall should be at least five cm. Ceramic tile or plaster is also used for the finish, which is subsequently painted.

For the floor covering mainly use polished boards, as well as a special non-smooth tile for safety in order to avoid injury. In the case of the use of boards, they are stacked on the logs.The tile is laid on a concrete screed, then moisture-resistant grout is necessarily applied to the joints, otherwise the screed will be destroyed in the area of the joints, and the tile will move away from the base.

To maintain hot steam in the steam room, the floor level in it is made about 20 cm higher than in the rest of the bath.

For the decoration of the walls of the steam room is recommended to use only wood., and it is desirable that these were hardwood. Such wood species are resistant to rotting under conditions of high-temperature humidity, if possible, exotic wood species can be used, many of which form specific aromas when heated, and they can also be used to make floors or shelves in the steam room.

Exterior design

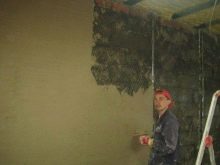

Pre-prepare the external walls by leveling and filling the chips, dents and irregularities with the solution used for stacking blocks, and rubbed with float.

Dust on the walls is removed and an initial layer of plaster is applied. A reinforcing mesh is applied and pressed into the fresh plaster using a metal trowel.

A primer layer is applied onto the depressed mesh, waiting for it to dry, and is completed with a thin decorative layer of plaster. If desired, it is given a certain texture using a trowel.

Exterior finish of the bath is equipped with mounted ventilated decorative facades. The use of such a finish contributes to the abstraction of excess moisture, it will help to reliably protect the walls of the steam room from adverse environmental conditions.

Bath built. It remains to install windows and doors outside, to make benches, shelves. Put the oven. Conduct the first test and enjoy the result.

Beautiful examples

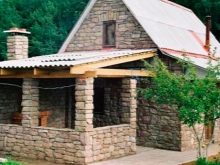

- Bath from foam blocks can be small. Such a structure does not take up much space, but will bring maximum pleasure.

- Such a structure may consist of the bath itself, as well as a beautiful veranda. On the terrace you can drink tea and cool down a bit.

- If space permits, then you can create a whole bath complex of foam blocks.

About the pros and cons of the foam block, see the following video.