The floor in the bath: the types and features of installation

The floor in the bath performs a number of functions that distinguish it from the coverage in living rooms. It not only provides free movement with constant moistening, but is also part of the sewer system. Therefore, before installing such a floor, you must be familiar with the features of its installation.

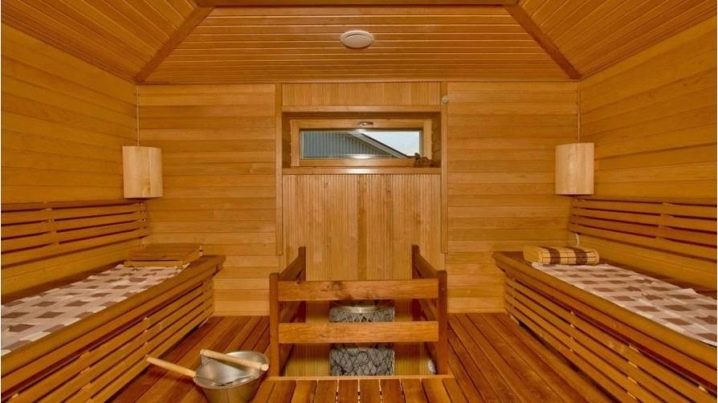

Special features

Before you choose the floor for a bath, you need to consider some of the nuances. The first thing that is important to consider is the season in which the room will be operated. If the bath is used all year round, it is usually placed in the shower, a waiting room, an additional steam room and rest rooms. A capital floor is installed in such a bath: a warmed floor with ventilation and drainage system.The floor in the summer sauna is enough to make leaking.

Installation of the flowing floor is carried out by laying boards of 1.5 meters in size by 50 millimeters. Boards are stacked on top of the logs - bars with a diameter of about 150 mm. When installing the lag, you must consider the type of base. For example, for a column base, logs must be supported on a mortgage bar. Lags are laid sequentially, starting from the shortest wall, the bars are placed at a distance of about 60 cm. The lag with the foundation is treated with bitumen mastic or roofing felt to provide insulation.

Next, a subfloor device is executed - a layer of soil is laid on top of the boards. The material and its amount is chosen based on the type of base soil. If the soil absorbs water well, then the flooring is carpeted with a layer of rubble about 25 centimeters thick. Clay soils that swell when wet and poorly conductive moisture must be covered with a material that provides water flow. After laying the floor boards, leaving a distance of 2 cm around the perimeter.

There should also be a small gap between the floorboards. The boards are fixed on the beams with the help of nails.To provide protection from dampness and prevent the development of the fungus, the coating is treated with linseed oil.

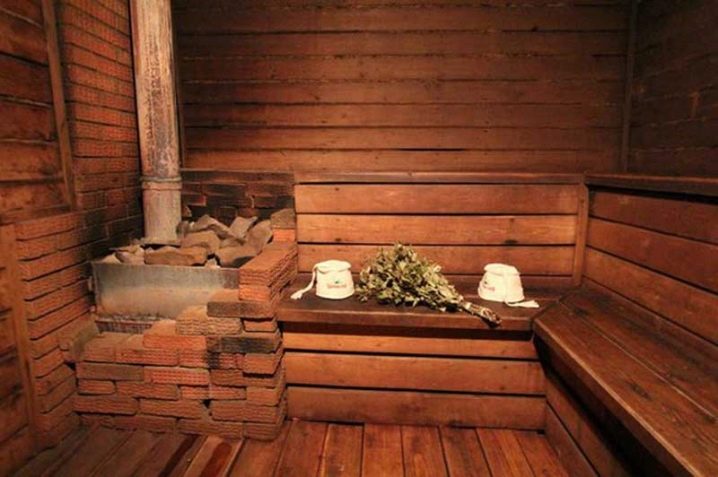

Flowing floor is also called "cold", because its temperature is always low. The disadvantages of such a coating - it is recommended to install it only in regions with a mild warm climate. Premises with such a floor is almost impossible to use in the cold season, because it cannot be insulated. However, there is the option of installing the stove below the floor level. This design allows you to warm the boards and better protect them from rotting.

The process of creating a non-leaking floor is technologically more complex and resource intensive. Before laying the lag is necessary installation of the subfloor. Next, the wooden flooring is covered with layers of waterproofing coating. To reduce heat leakage from the premises, the floor must be protected with mineral wool or fiberglass insulation boards. To ensure that natural insulation does not lose its properties under the influence of water, a moisture resistant coating is laid on top.

Draft floor is poured with a layer of bitumen and prepared for installation of floorboards. The technology of laying boards depends on the purpose of the room.The floorboards in the steam room should look in the direction of the falling beam of light. In the dressing room floor covering stele in the direction of travel. It is important to remember to leave a space of at least one centimeter along the contour of the room. This distance provides ventilation.

Russian bath with a warm floor on the drainage device resembles a pie. Boards have a small slope, which provides a drain of fluid in the built-in collection. Further, the moisture flows through the pipes and is removed outside the extension. The advantages of a warm floor is that the coating is additionally protected from cold, the system of moisture removal allows you to increase the shelf life of the boards.

What coverage to choose?

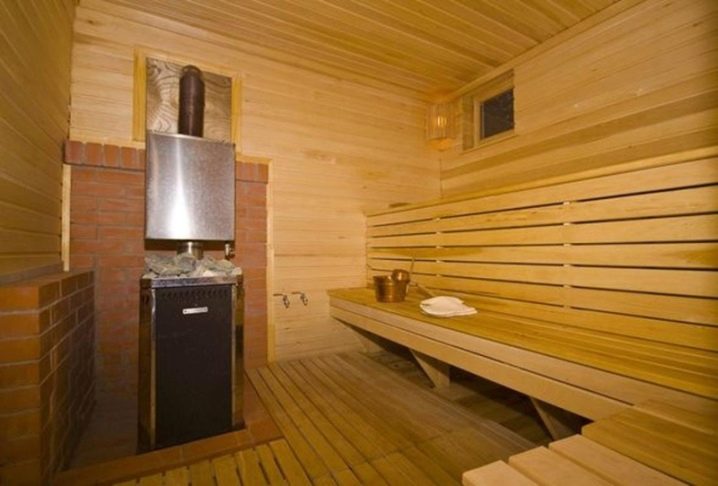

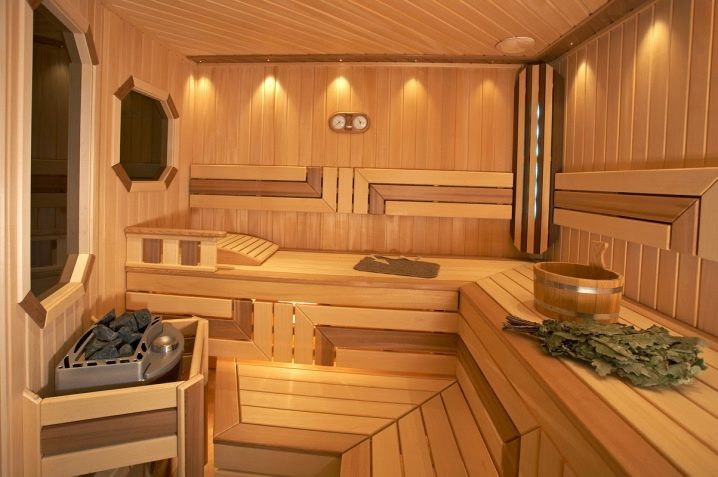

Indoors of a classical Russian bath are high humidity, and the temperature can reach 65 degrees. Under such conditions, there is a high probability of rotting the floor, especially of a wooden covering. It is important to understand that each bath room has different operating conditions and the coating material and operating technology can vary significantly in each room. In addition to individual characteristics, the floor should have some general physical and mechanical characteristics.

The coating must be resistant to critical temperature differences: from above the floor interacts with hot water, and from below it is affected by cold soil. Also, the flooring must withstand both mechanical stress and contact with chemical reagents of detergents. Obligatory characteristics of the coating - resistance to constant interaction with moisture and saturated water vapor. It is important to remember that floorboards must prevent slipping and do not require special care. In addition to the above mechanical properties, the floor in the bath should look aesthetic.

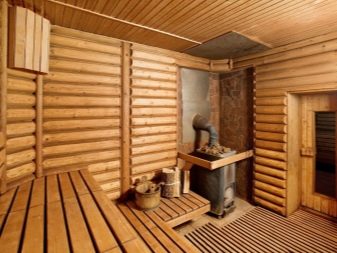

Classic flooring - wooden flooring. This method of laying the floor in the bath is used today. This is not only a tribute to the tradition - wood has a high heat capacity and beautiful appearance. A significant drawback of the boards is low moisture resistance: the coating is subject to decay and requires additional protection. Before making a decision on installing a wooden floor, you should be familiar with the characteristics of each tree species. For example, an oak becomes too slippery when exposed to moisture.

Concrete floor is not less popular compared to the board analog.Cement screed has a high mechanical strength, which ensures a long service life. It is important to understand that it is necessary to lay a finishing coating on the concrete base. Masters advise to use tiled masonry. Ceramics is easy to install and use. A significant disadvantage of the concrete floor is the need for thermal insulation devices. Also, such a floor must be laid under a slope to ensure the discharge of water.

During the construction of baths, they increasingly prefer laying stone and tile floors. Ceramics perfectly imitate natural stone and have a relatively low cost. In addition, this coating is durable and waterproof. An important point - the joints between the ceramic fragments require additional processing to protect against damp and prevent the formation of fungus.

To choose the right floor covering, you need to take into account all the operational features of the selected room. In the steam room you can lay the floors of concrete, stone or ceramics - these materials are able to withstand extreme conditions. Formaldehyde containing coatings should not be used.Under the influence of water and high temperature, such materials emit toxic substances.

If you want to paint the floor with paint or varnish, then you need to take into account some restrictions. The safest way to decorate a wooden coating is to use a water-based or dispersion acrylic paint. In the steam room is strictly prohibited the use of oil paint or alkyd composition.

Requirements for the floor in the sink are not as high as for the coating in the steam room. However, the pouring coating must withstand prolonged contact with water and detergents. Floors must also withstand critical temperature fluctuations. These requirements are fully satisfied with ceramics. Wood is also actively used in the washing room, but it needs to be treated with a special impregnation or varnished.

The floor in the dressing room is practically not in contact with water and steam, so there is no need to increase its water resistance. The firebox is located in the dressing room, so the floor should be protected from fire and overheating. As a rule, boards are laid here. A metal plate measuring 60 by 90 centimeters is mounted in front of the firebox.This device is necessary to protect the floor from sparks and fire.

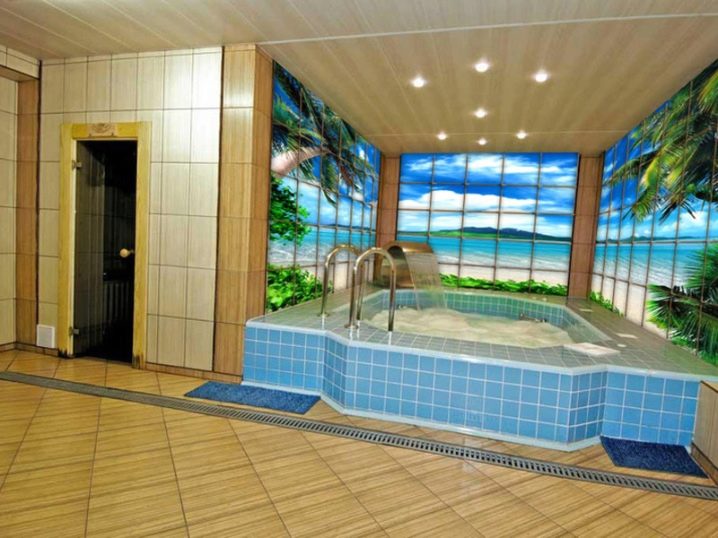

In the rest room, you can lay carpet or linoleum. Floors in this room should be comfortable and cozy. The main requirement for such a coating is that it should retain heat well. Since rest rooms do not come into contact with moisture and do not withstand temperature changes, they do not require additional protection. They can also be located on a hill height or shelves to accommodate the legs, which will add comfort.

Necessary tools and accessories

In order to obtain a high-quality floor with a long service life, it is necessary to follow the installation technique and technology for preparing materials. The success of the installation depends largely on the correct choice of tools. The floor can be installed under the guidance of a specialist or independently.

Some of the tools needed to make a concrete floor in a bath:

- The correct tie cannot be laid without the use of a special rake. These devices are leveling the concrete mass in the process of laying. It is important to understand that the coating should be as smooth as possible: violations in the technique canentail serious consequences.

- Laser or water level will help to obtain the surface of the required flatness. With it, you can also vary the angle of the boards. The grooves for running off water should be smooth: no level drop is allowed along the flow of the liquid. Such moments need to be corrected both at the initial stages of installation, and in the course of laying the plates.

- Trowels are needed to spread cement over the entire surface from the far corner of the room to the edges. With the help of trowels, impregnation or varnish is also applied during surface finishing. Trowels come in both with pointed and semi-circular edges. The rounded edges of the tool do not leave visible marks on the coupler.

- Grater for cement. This device is necessary to obtain a flat surface. It is necessary to make circular movements on the surface of the laid mass. With their help, excess material is also removed and an even coating is obtained.

- Smoothers are also needed to get a flat surface. Due to their design, they are able to cover and smooth a larger area than graters or trowels.Gladilki used for global work on the rolling of cement on the entire surface. Among such tools, angle-type flushers can be distinguished - they are used to obtain a smooth coating at the junction of the floor with the wall.

- To mix high-quality expanded clay or expanded clay concrete, a concrete mixer and container for the solution is necessary. The technology of mixing depends on its composition and method of installation. Before working directly with cement, you should be familiar with the technology and mode of preparation of the mixture. This process can be done manually, but there is a risk of getting a heterogeneous mass. Incorrectly mixed composition will not provide the desired performance properties of the floor.

- Also do not forget about simple tools. A shovel will greatly facilitate the process of spreading the concrete mass on the surface. Velcro towel or any other rag material is necessary for cleaning tools in the process. Smooth tie will work only when working with purified equipment. Also on hand, you must have a container of water.

A different set of tools is required for installing a wooden floor.

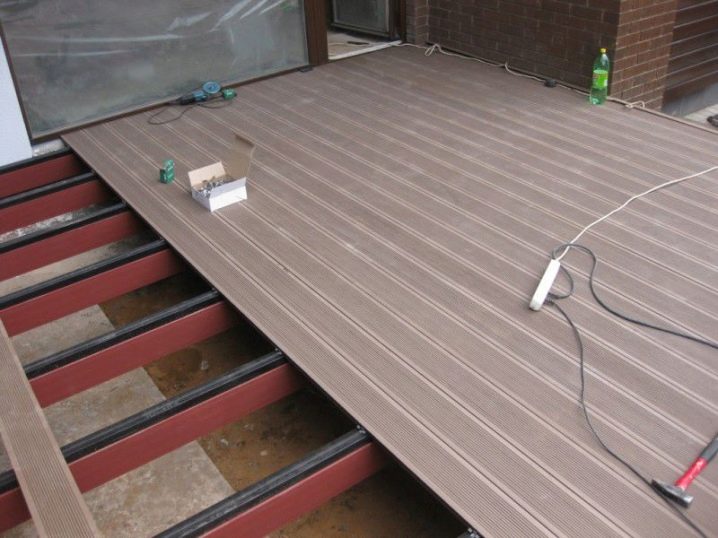

- Metal profile for laying boards.From small steel troughs mounted special grille on which the boards are laid. Such a frame is necessary for the floor of the sauna to be laid flat and firmly held. Profiles are sold complete with special fasteners.

- Electric screwdriver and drill are needed to fix the boards. They can be replaced with a metal hammer, but this will require a large investment of time and effort. In addition to the usual screws, brackets are used to fix the plates.

- To obtain the bars of the required size using an electric planer and a hacksaw for wood. The work of cutting wood is dusty enough, so the craftsmen recommend laying a mat or sheets of newspaper on the floor of the working area. This will significantly reduce the time for subsequent cleaning.

- In any work on laying the floor can not do without a level. The laser device is much easier to operate and helps to achieve a smooth coating or the desired slope.

- The finishing wood layer often needs to be varnished or painted. For this you need to stock up on rollers and brushes. Also, many materials are sticky and toxic, so all work must be carried out with gloves.

How to do it yourself?

The device of the flowing floor begins with the installation of lags. It can be wooden beams or metal beams. Before installing, lags should be treated with a special antiseptic that increases their corrosion resistance. The choice of antiseptics is great, but some prefer to use used engine oil as a counterpart. If for the device lag choose wood bars, then they must be dried. To do this, the wood is left for some time in a room with a humidity of 10 to 12 percent. To save time, you can buy ready-made wood after drying in the chamber.

Lags are laid from the smallest wall in parallel. If the room in the bath is large enough, it is recommended to create a stiffness frame. To do this, reinforced concrete piles are installed under the lags with a step of not more than one meter.

To properly lay the log there is a step by step guide:

- From the place of installation it is necessary to remove the top layer of soil. Next, lay out a layer of sand or gravel thickness from 10 to 15 centimeters and reinforce the system with a grid.

- Lay piles of bricks or fragments of reinforced concrete slabs.Such a construction will provide the foundation with the necessary bearing capacity.

- The system must be treated with bitumen mastic to protect against water.

The fixed piles are covered with two layers of waterproofing. Sheets should not be laid too close to the walls. It is necessary to leave a gap of at least 4 cm around the perimeter. This will provide ventilation of the resulting construction.

Next is the device drainage system. Moisture should be removed from the foundation. In order to properly equip the drainage system, it is necessary to become familiar with the characteristics of the foundation soil. If the soil absorbs moisture well, then it is necessary to remove the layer of earth from the entire area of the bath and cover the surface with rubble. On soils with a low throughput capacity, you need to dig a hole about 40 cm deep and carry the moisture removal system into it. Special clay backfill ensures uniform water flow. Floors with this method must be laid under a slope of 10 degrees in the direction of the water intake.

Warm floor boards are treated — trimmed from the front side and leveled. Between the masonry and the wall leave a gap of two centimeters for the implementation of natural ventilation.Boards laid at right angles to the location of the lag. This technology provides the necessary strength of the future floor. It is necessary to maintain the same distance between the boards: masters advise to use plywood fragments for these purposes.

Heated floors can also be laid on the logs. The previously described step-by-step actions are stacked bars or steel pipes. To obtain the slope of the surface in the logs make cuttings of four millimeters. It is not allowed to cut logs adjacent to the walls. The underfloor heating system is excellent. Between the two pillars they dig a pit with a depth of at least 300 millimeters and with dimensions of 400 to 400 millimeters.

The walls of the resulting pit must be strengthened with concrete and fluff bitumen. The installation of the drain pipe is carried out at the bottom of the pit with an indent of two centimeters. The drainage pipe should be at least 15 centimeters in diameter. For these purposes, perfect PVC.

Boards stack, starting with the draft layer. This is followed by a waterproof coating overlapped. Joints are coated with a small amount of bitumen mastic or taped.After fixing the waterproofing fit layer of insulation. In this case, the wizard advised to pay attention to the mineral or environmental wool, slabs of expanded clay. A more ecological type of insulation - a mixture of sawdust with PVA.

It is necessary to lay a vapor barrier between the finishing coating and insulation. It is also important to leave a gap of at least fifteen millimeters between the layers: through the hole is a chimney. The boards of the final layer should not have clefts in the joints, so builders prefer a tongue and groove board with a spike and groove. It is necessary not to forget about the installation of the drain system.

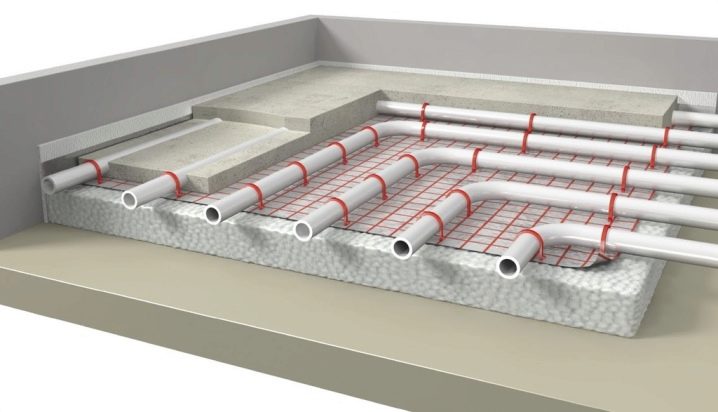

Laying concrete screed is carried out in several stages. The first concrete layer is poured with a height of not more than six centimeters and is not left to dry completely. Thermal insulation of standard thickness is laid on a slightly wet layer. In order to provide the necessary rigidity to the coating, the insulation is covered with a reinforced mesh. The last layer of the fill is placed at an angle of 10 to 15 degrees to ensure the flow.

The finishing layer, as a rule, does not exceed nine centimeters in thickness. Further, the surface can be decorated with ceramics or plank masonry.It is important not to forget that the coating must be resistant to temperature extremes and have a given strength. After installing the floor is polished walls.

Wooden

The board coating is perfect for the device leaking the floor in the steam room. Wood has good technical characteristics and requires relatively low labor costs. Masters advise absolutely novices to stop on the device of a cold floor. There is no need to create a warmed "cake" of the foundation and laying of utilities. A leaking steam room requires only simple drainage.

The flooring does not need to be fixed to logs, since the coating must be regularly disconnected and dried in the open air. This design helps to keep the material in proper condition even with frequent interaction of the floor with hot water. The board requires replacement 4-6 years after commissioning. If, nevertheless, there is a desire to fix the coating on the logs, then the boards must be carefully treated with an antiseptic. A cold floor of larch or pine is considered the most optimal of the price-quality ratio.Oak coating does not have sufficient roughness and can cause injury.

The leaky woody floor is suitable for year-round use. In the washing compartment and steam room, such a coating will last up to 10 years, if you correctly execute the design of the draft layer and do not neglect the laying of insulation materials. Boards are not recommended to paint. The chemical composition can clog wood pores, which will give the coating a lasting chemical aroma.

Also paint does not contribute to the protection of boards from rotting. Masters are advised to leave the surface clean, but polished well. Natural wood has a pleasant smell, and the aroma of pine needles is considered beneficial to health. In order to protect the coating from rotting, use special compounds. But an important point is the drainage device.

Concrete

Concrete has a long service life, which makes it the leader among the materials for floor installation in the bath. Properly laid coating can last up to 50 years, does not require special operating conditions. The screed of concrete is not predisposed to rotting, because the development of microorganisms in concrete is impossible.Caring for such a floor does not require special measures or the purchase of expensive funds.

The coupler can be poured and used as a finished floor covering or lay tile on top. It is laid on the ground or logs. To strengthen the foundation for the device of the warm floor is often used device screw piles. An insulating “pie” is already installed on these piles and a screed is poured. Concrete floor requires a lot of time and resources, because it is a complex multi-layer structure.

Before purchasing, you must be familiar with the composition of the product. Some species contain crushed stone or gravel, therefore they can cause difficulties in the kneading process. A homogeneous mass is obtained only with the use of a concrete mixer or perforator. If there are no such devices, then the masters recommend purchasing a mortar on a cement-sand base. This material is much easier to knead and pour.

The consistency and composition of the mortar largely depends on the conditions of further operation of the cement screed. If the concrete acts as a subfloor for laying boards, the mixture does not require special additives. If you wish to lay ceramic tile on the screed, you need to add gypsum mixed with anhydrate.Concrete floor is not recommended as a rough surface for installing a synthetic coating. When interacting with critical temperatures, synthetics emit complex chemical reagents that may be hazardous to health.

At installation of a covering from concrete the correct waterproofing is important. The floor is located under a slight slope, and a special pit with a sink is mounted under the foundation of the foundation. The water moves along the chute and the ground and is removed outside the bath. Technologically competent installation of this system will protect the foundation from corrosion and allow the cement screed to serve for a long time.

Tiled

Ceramics are widely used for laying a cold floor. This material is not subject to decomposition under the action of microorganisms and does not require special conditions of operation. Tile resistant to critical temperature extremes. The coating is also resistant to moisture, which allows you to lay it everywhere in the bath.

Designers note the wide color palette of this material, so they are often used to create a decor in a rest room. The tile is eco-friendly, does not emit harmful substances and does not possess a chemical smell.Ceramics are laid directly on the self-leveling concrete floor.

The screed does not always provide smooth coverage and requires additional measures. The surface roughness should be minimized, since this work requires time and effort. A tile laid on a screed with irregularities will not last long. Water may enter the voids, causing fungus to appear between the mosaic joints. The intervals between fragments must be treated with a special tool both during the laying process and during operation.

A significant disadvantage of tile is its high thermal conductivity. To the temperature in the steam room does not fall, you need proper insulation. Another major drawback is the risk of lacquer coating. It is necessary to purchase a tile with a rough surface so that it does not become slippery when in contact with water. To date, there are many ceramic tiles that mimic the stone coating.

Designers emit a mosaic, stylized pebbles. In addition to aesthetics and beauty, this coating has a massage effect.This tile will be a great solution when you design a rest room in a nautical style. Small stone particles are complemented with worn glass inserts. The sparkling inserts have a beautiful brilliance and reflect the light interestingly.

To increase the service life of the ceramic coating, it is coated with glaze and fired several times. In addition, craftsmen are advised to give preference to a thick tile. Such material is resistant to temperature fluctuations. Do not buy tiles with a large number of pores - it is less durable. Preference should be given to clinker mosaic or porcelain stoneware cladding. Watch the surface texture carefully: glossy shine must be avoided.

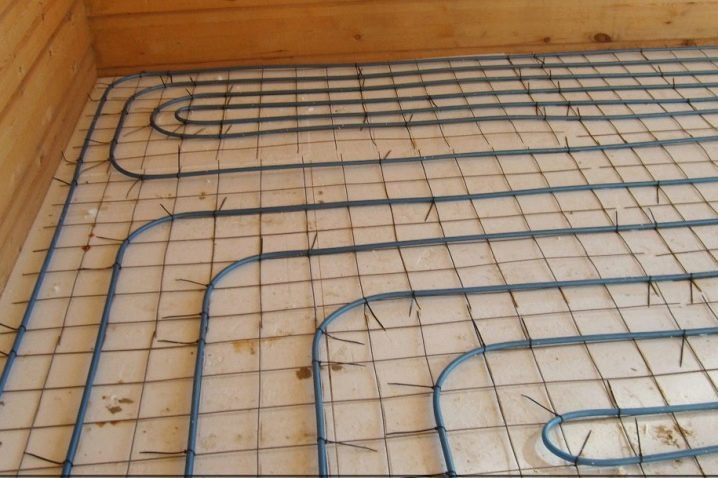

Heated

Heated concrete floor creates a comfortable microclimate. This option is necessary when setting up a cold floor, especially in a cool climate zone. Also, the system of heated floors heats the surface from the inside, drying the material. This system allows you to get rid of moisture and increase the life of the flooring. It is important to understand that such a heated floor is quite difficult to install for a beginner.Requires wizard instructions and control of the installation process.

Underfloor heating - a system of pipes or cables along which a warm fluid moves. Convection ensures uniform heating of the floor along the entire perimeter of the room, regardless of the location of the heating device. Pipes have a strong internal pressure, so the surface must be further reinforced. The contours themselves are easy to install, but require reliable attachment to the roughing surface. For the device of such heating it is necessary to get pipes without seams and joints.

The distance between the contours is called the laying step. It must be maintained in the process of laying. Violation of the step leads to uneven heating of the floor. Such a gradient is noticeable when in contact with the floor. You should also carefully choose the flooring in the case of the device warm floor. Ceramics have the ability to quickly heat up, so the craftsmen do not recommend using tiles as a finishing layer. Preference should be given to wood panels.

To date, there are two ways to install a heated floor. The water system is carried out by circulating a heating fluid from the pump.through the pipes. The coolant in this design can be both plain water and special non-freezing compositions. The water system consists of a boiler, a collector and pipes. It is difficult to install, and it is not cheap. However, such a system reduces heating costs. Water floor heating is often used as additional heating in apartments and houses.

Another way to install a heated floor is an electrical system. Such “cable” floors are easy to install, but their price depends entirely on energy tariffs. The cable converts electricity into heat and heats the surface evenly. To control the heating in the floor mounted temperature sensors. It is important to remember that such a system should not be combined with wooden materials, since there is a high probability of overheating of wood and the occurrence of fire.

Installing each type of heated floor requires master control. The floor is laid on the insulating material. Vapor barrier is an equally important layer when installing a heated floor. After laying the contours of the surface is poured cement screed.

All pipe joints should be additionally fixed.It is important to remember that after laying the cement layer, it will be impossible to make adjustments. Otherwise, you will need to completely remove the masonry, re-clean the surface and eliminate irregularities in the installation of circuits. It is important to lay the pipes on a perfectly cleaned surface. After making adjustments, the surface is filled with a new layer of cement mortar.

Before use, the floors are pre-tested and heated in accordance with the instructions. The problems are resolved and the system is checked again. The cycle must be resumed to obtain the required temperature. Only after the final test cement screed level and proceed to install the finishing floor covering. It is important to understand that each joint of the material requires careful processing. Water floor heating will last for a long time if all its features are taken into account in the process of installation, for example, steam insulation of the floor.

Professional Tips

For the manufacture of high-quality coatings masters advise to listen to some recommendations. The causes of the destruction of the sexes can be different, but many can be prevented if you do not violate the technology of laying the coating.The choice of quality material also plays an important role.

When installing the lag it is important to install a waterproofing between the pillars. This coating will protect the frame from rot and rapid destruction. In the opposite case, the foundation will quickly collapse upon contact with water. Bars should also be made of materials with high frost resistance and water resistance. Water may accumulate in the soil, which will lead to corrosion of the concrete and subsidence of the structure.

Wood flooring must not be installed without ventilation. Its scheme provides for gaps around the perimeter, all depending on the type of stacked layer. It is not always possible to correct the violation after the installation of the finishing coating, therefore it is necessary not to violate the technology at each stage of work.

Floor boards should not be less than 35 millimeters in thickness. Such a plate will withstand a critical load and will last for a long time, unlike the analog of a smaller thickness. All floor boards must be cut to the same size. This will not only simplify the installation, but also provide the necessary flatness and slope of the surface. In cold periods, such a coating will retain heat longer.

The installation of a wooden floor should only be done with stainless steel fasteners. Metal structures can be further processed to protect against rust. Since the coating is regularly exposed to the interaction with water, it is necessary to pay special attention to the choice of metal structures and fasteners.

The floor level of the washroom is always slightly below the level of other rooms. The steam room and the rest room should rise a few millimeters.

Before you start laying the boards, the coating must be processed. The material is impregnated not only with a mixture to protect against moisture, but also with a substance that protects against fire. The latter is especially important when installing a warm electric floor. All components of the floor must have protection against fire. These indicators are written in the regulatory documents and must be confirmed by certificates of materials.

Craftsmen are advised to give preference to a tiled floor. This combination reliably protects against natural phenomena and the negative effects of the bath room. Coverage is easy to install and use and will save on hiring workers.

At arrangement of a sweating room it is necessary to competently arrange a ventilation system. Otherwise, water vapor will accumulate and destroy the ceiling and walls covering. Rooms with poor ventilation require constant ventilation after use. Only in this case, the room bath will last a long time. To bring ventilation to the outside in the attic, it is necessary to pass a pipe through which water vapor and smoke will be removed from the room. With a monolithic foundation masters advise to make holes from the ventilation pipe to the outside.

To reduce the audibility while moving around the bath, it is necessary to lay a layer of fiberglass under the finishing floor covering on the waterproofing layer. Fiberglass can be purchased in roll, as the material is produced in the form of a wide ribbon. Cover joints can be joined with tape.

How to make a floor in the bath with your own hands, see the following video.