Stove for a bath of pipes: the details of manufacturing

Among lovers of outdoor recreation or fans of a healthy lifestyle, there is hardly anyone who does not like to take a steam bath. Today, many gardeners are eager to get their own bath. Recently independent creation of the bathing furnace from a cylinder or a pipe is gaining momentum. Building a solid brick furnace requires certain skills and abilities, among other things, such a furnace takes up more space, and you can buy it at a hardware store, but it costs a certain amount of money. While a metal furnace is a more economical option and it is much easier to do it yourself, not to mention the fact that you can entrust this work to a welder.

The oven, made independently with regard to safety regulations, does not carry a threat to human life and health, since its sealed case does not emit carbon monoxide during operation.

Features: pros and cons

The source material for a metal bath stove can serve not only a pipe or a cylinder, it also uses sheet steel.

Sheets are usually made into a case in the form of a rectangular parallelepiped, but this shape has its own characteristics:

- sheets must be pre-cut, cut and joined together with a welding machine;

- as a result, such a furnace will cost more;

- cylindrical firewood conducts heat better;

- based on the trajectory of the flue gases, a circular cross section is more preferable;

- flat walls are more susceptible to burning than pipes made of exactly the same material.

What are the advantages of metal furnaces:

- the cylinder only slightly loses its spherical shape due to its thermal conductivity;

- the thickness of the walls of water or gas pipes makes it possible to achieve high thermal conductivity;

- the stove can be moved, it is durable;

- the cost of manufacture of such a furnace is very low, because the trim pipe is often sold at low prices;

- Detailed instructions for manufacturing with dimensions and diameters of pipes will reduce the complexity of the process and save time;

- many factory products of this kind are made of exactly the same pipes, in the image and likeness of which it is easy to recreate the product in an artisanal way;

- In addition, such devices have heat resistance, are resistant to corrosion, durable and easily tolerate temperature extremes.

Of course, such furnaces have their drawbacks - the processing of a thick metal pipe requires both the application of physical force and the tools for a certain type of work.

Types and characteristics

The location in space of the furnace, made of pipes, are divided into the following types:

- vertical;

- horizontal.

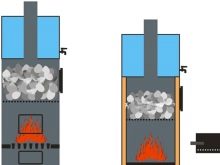

The vertical oven looks like a stove, but it has differences - an additional container for stones and a water tank.

Vertical homemade oven takes up less space, which is of great importance with small dimensions of the steam room, but for the same reason it is inferior to a horizontal furnace in terms of burning time and heat transfer rate. In the process of burning fuel, the heat goes up, the side walls do not have time to warm up much. In a horizontal furnace, the process goes differently - because heated air on the way to the chimney simultaneously heats and archenclosures. Based on this, it is clear that the efficiency of a horizontal furnace will be higher than the vertical one. The main disadvantage of this design is considered to be the location of the doors of the ash chamber and the firebox directly in the steam room.

The fuel in the vertical pipe will burn faster if you do not close the ash pan door, thereby suspending the access of oxygen to the fire. In such a pipe, the fire interacts immediately with the entire volume of firewood, while in the horizontal pipe the fuel is consumed gradually, which is more logical for heating the bath. Also in the horizontal form of the furnace more coverage of heating stones and higher convection of hot air, besides the door blew and firebox, which are located at the very end of the pipe, make it possible to remove them from the steam room. Both the first and second type can be made by hand.

Training

Of course, the stove, made by hand, will not have a sophisticated appearance or originality, but it performs its function no worse than the factory one and perfectly heats the steam room with an area of up to 20 m2.

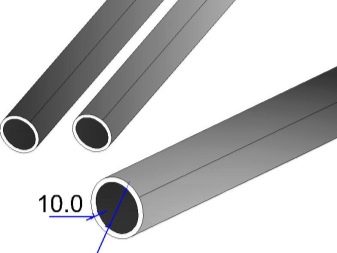

First of all, the pipe should provide its main functions., namely, to evenly pick up and release heat and at the same time have walls thick enough so that the furnace is not afraid of high temperatures and served for a long time.Speaking about the basic characteristics of pipes, it is necessary to take into account not only the diameter of the cross section and the thickness of the walls, but also the steel grade. It is clear that when using scraps such information is not always available.

Speaking of a standard bath, the following dimensions are considered optimal:

- section diameter - 0.5-0.55 m;

- wall thickness - 8-12 mm.

It should be noted that the larger the diameter, the higher the consumption of wood will be.

Pay close attention to the quality of the material: for the manufacture of the furnace in the bath fit only steel pipes, and the steel is not needed high carbon. It is not suitable for profile work, because its seams can easily get out of shape or even break up. High-carbon steel can be determined by sparks appearing during the interaction of metal and emery ring - white sparks will scatter in all directions. Low-carbon steel, in turn, gives sparks of a yellowish hue, which have a straight-line trajectory of motion, and stainless steel parts will not work either. The best option is steel with a carbon content of about 2%. Also, when choosing a metal, it is better to avoid alloy steel - it is also easy to calculate using an emery machine: the sparks from the interaction with the metal will be orange, red or bright white.

In no case can cast iron be used, as it becomes unusable upon contact with water.

Other advantages of steel pipes:

- resistance to mechanical damage, high heat transfer and low coefficient of expansion when heated;

- preservation of heat even after the complete combustion of firewood.

Pipes have their own characteristics in accordance with the specification. Consider this information in more detail.

Round tubes are classified by the size of the inner diameter. The second figure indicates the thickness of the walls, the subsequent report information about its type and other characteristics. As a unit of measurement, it is customary to take a millimeter. If the pipes are profiled, the first two characters indicate the maximum size of the section, the third digit - the wall thickness. The instructions “530 by 10” means that the diameter of the pipe along the inner wall is 530 mm, thickness - 10 mm, external diameter - 550 mm with an error of +/- 5 mm, taking into account the transverse tolerance, which is 10%. Advantageously, the flow tolerance applies to ellipticity.

The thickness of the pipe wall will also vary.

Water pipes are divided into the following subspecies:

- lightweight;

- ordinary;

- fortified.

Anyway, the most popular pipes have a diameter of 530 mm, their thickness is 6-12 mm, the nominal value is 6, 8 or 10 mm.

This information is needed in order to immediately prepare materials for the future stove. The best variant of the pipe diameter is 0.5 m, which implies both a good heat capacity and comfortable work. Pipes with nominal values of 500 mm have a pitch of 10 mm and are usually classified as large diameter pipes. It is much easier to immediately pick up pipes that match each other in cross-sectional diameter and wall thickness in order to facilitate the preparation of a concentric design and reduce the gaps between them.

Pipes are among the most frequently sought after products.therefore, it makes no sense to regulate them too scrupulously. Pipes in sizes from 250 to 400 mm have a wide space for selection. If possible, for the manufacture of a bath stove, give preference to scraps of spiral pipes (their designation is GOST 20295 85). Comparing them with longitudinal pipes (GOST 10704–91), they have lower ellipticity values, are more accurate and sell them at the same price as scrap metal. Seamless pipes without seams are an even better option, but are only suitable for making small parts,since their diameter is not more than 250 mm.

When preparing for work, equip yourself a workplace - this can be either a garage or a home workshop.

Materials

The following materials are required for the work:

- directly the pipe, which is needed to create a firebox and a water tank, its diameter should be from 500 to 600 mm (530 mm is considered optimal), wall thickness from 8 to 16 mm, length - from 1.2 to 1.5 m;

- a pipe that will become a container for stones - its diameter is about 400 mm;

- chimney-flue - diameter 120-150 mm, thickness 2-4 mm;

- sheets of metal in the amount of several pieces, dimensions about 600 by 800 mm, thickness about 8-12 mm;

- hinged metal hinges;

- a small part of the water pipe with a thread, diameter 1 / 2-3 / 4 inch, length 50-80 mm and a water tap with a thread inside the same diameter;

- pieces of rods from rebar - about 500 mm length, diameter from 12 to 18 mm, ready-made iron grates for solid types of fuel will fit;

- cement composition;

- bricks;

- sand.

Please note that the fuel compartment, chimney and boiler should not be made of ferrous metal, but of stainless steel. Although this is associated with some difficulties, since welding them will require electrodes made of the same stainless steel or special wires for welding.

Required tools:

- apparatus for welding elements;

- any strong metal carver;

- electrodes;

- Mortise valve;

- metal for legs;

- asbestos cord;

- door handles.

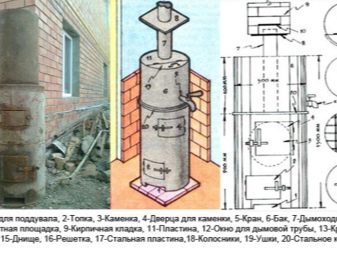

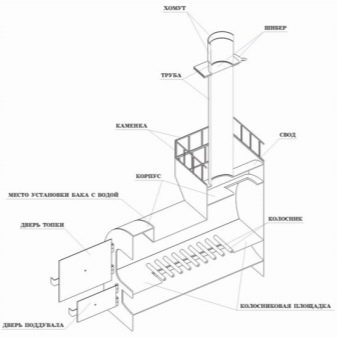

Schemes and drawings

Before starting work, you need to decide which type of furnace - vertical or horizontal, will be preferred. Then create a working drawing with all the parameters - the size of the device, the configuration of its components, dimensions.

In the event that this is the first experience of self-production of a stove, it is more logical to refer to ready-made drawings and diagrams for the manufacture of a typical model of the device, this will help to avoid errors and further incorrect operation of the unit. Moreover, improperly assembled oven can threaten the life and health of a person!

It is necessary to prepare the foundation on which the stove will be installed:

- In the area where the installation of the device is planned, a hole is dug with dimensions of 50 x 70 x 70 cm.

- The bottom of the pit is filled with fine gravel. Please note that the layer should be at least 30 cm thick. Next, you need to compact this layer as closely as possible.

- Next, you need to prepare a cement mortar based on the following ratio of components: for 1 part of cement, take 4-5 parts of sand, dilute with water to obtain a creamy homogeneous mixture. Pour a layer of rubble and let it harden - as a rule, this process takes 24 hours.

- In order to create a waterproofing on the hardened cement layer, roofing felt is laid in several layers.

- The layer of roofing material is finally filled with concrete: where 1 part of the cement mixture is 2 parts of sand, 4-5 parts of gravel and water. After that, you need to level the resulting layer.

After the foundation has dried, a clay platform is installed on which bricks are subsequently laid in the same dimensions - 0.7 m by 0.7 m. As a result, the brick platform must be about 15-20 cm in height. In order to protect the walls from overheating, intended for the location of the furnace, laid out a protective screen of bricks, which are laid edge and fastened with a clay composition. The best length for this structure is 120 cm, while the furnace is located not less than 20 cm from it.

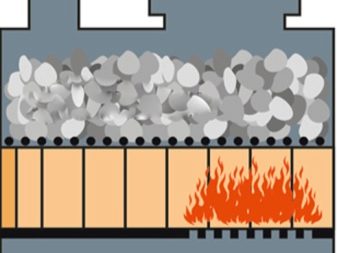

It does not matter what kind of stove the future bath will be equipped with - horizontal or vertical - in any case it will be equipped with a stove.In this article we will not deal with the topic of choosing stones (most recommend using river pebbles, balm, quartzite, talc chloride, or gabbrodiabase), anyway the heat capacity depends on the heater. It is simply impossible to fill up the stove with stones, because in this case the bath will not warm up and all the heat will settle into the pipe in the form of soot.

First you need to decide whether the stove will be flowing or open. In the first case, the stones will be washed with flue gases, in this case it is quite simple to set the mode - it is enough to select and place various stones during several stages until the desired effect is achieved. There are nuances - in this case, you can only bathe when using wood fuel of the highest quality and add steam only when using water. In the case of an open stove, these requirements do not exist, but its creation is more complicated in execution.

The simplest type of open stove is a tray mounted on the firebox. Such a device is suitable only for a horizontal view of the stove. But there are difficulties - carrying out preliminary calculations, as well as the study of prototypes, since the contact area between the stones and the walls of the firebox must be strictly observed.Another type of stove requires less accuracy, in which heating takes place by means of flue gases, but such a device is more difficult to make.

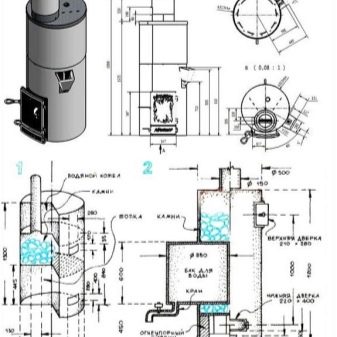

Without proper experience, it is best to give preference to a furnace with a vertical arrangement. - in it the heater and the water tank are heated in series. For more experienced people, it is better to make the oven of a parallel circuit; water in this case heats up faster. The most difficult to manufacture is a bell-type stove, in which the stove is also open.

Fabrication and installation

We must not forget that the interaction with the furnace is directly related to the risks of both possible burns and fire hazard, therefore, in order to avoid possible consequences, it is necessary to apply certain rules for installing the stove and take into account the peculiarities of its operation. In shape, it will not necessarily be round - there are other options. Different species have approximately the same properties, making them not so difficult. Regardless of the fact that the mounted furnace itself has a low weight, the heat exchanger must be installed on an elevation of at least 20 cm relative to the floor.The foundation can be either reinforced concrete or brick, or it can be assembled from concrete blocks.

A prerequisite is also the presence of a metal sheet with dimensions of 0.5 by 0.7 m in front of the door of the firebox and the blower. Doors must unravel inside the dressing room or steam room.

The smallest distance between the chimney, as well as other heated metal parts of the furnace, chimney and wood paneling of the walls and ceiling is 1 meter.

It is best to fill the tank with water before kindling the bath - the ingress of moisture into a hot dry metal container is fraught with burns from steam blow.

Carefully inspect all the details. Before you cook them together, when the installation is complete, do not forget to check its characteristics: Efficiency, operation of the coil by means of a trial. Go into the steam room, stay inside - appreciate the warming of the air around you.

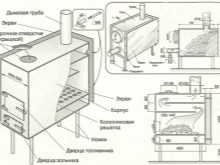

Horizontal oven

In the manufacture of the furnace horizontal arrangement of their own hands the procedure will be as follows:

- Cutting out the firebox with the help of a grinder is part of a pipe of the required format (in strict accordance with the scheme). As a rule, the length of the pipe will be from 0.7 to 0.9 m.

- The manufacture of grates from metal frames, as well as reinforcement bars welded to the frame in parallel, the distance between which should be about 50 cm.

- Grate bars are fixed inside the firebox. In the case of using ready-made metal structures, they are folded into small pieces of metal, pre-welded inside.

- A hole is cut from above, which will later perform the functions of a chimney, its size is 15 to 20 cm. It is best to indent 15 cm from the rear wall so that the hot air also takes part in the heat exchange, and not just be removed as soon as possible.

Some insist on cutting the hole directly in the very rear wall of the pipe, but it is not recommended to do this, because due to such manipulations, the efficiency of the furnace subsequently decreases, fuel consumption increases.

The next stage is to cut a sheet of metal with a size corresponding to the back wall, and it is welded to it. If the scheme indicates the presence of the heater, then the sheet belonging to the back wall of the stove should be larger in order for it to create a stone container with its upper part.In the front wall cut out the groove, which subsequently become the ash pan and firebox.

The facade is fastened by welding and the doors are hung at the end - as a rule, they are either made independently or purchased in a specialized shop.

That's all - the stove for a bath is ready. Before using the metal, it is necessary to treat it against corrosion and possible deposits, after all the manipulations it is necessary to test the capabilities of the unit, having carried out the first control firebox.

Vertical

The design of a vertical furnace is absolutely identical to the creation of a horizontal one, except for a few moments. A distinctive feature is the direct position of the pipe in space, when both ends form not the back and front surfaces, but the top and bottom, respectively. In such furnaces, the department for the location of stones is located directly in the furnace chamber, as a result, the manufacture of such a unit will be somewhat more difficult to perform, but the heated air will also be more saturated.

Stages of manufacturing.

- First, it is necessary to cut out a window in the pipe, which will be the groove of the blower for the supply of oxygen to the burning fuel, and will also collect the fuel decomposition product - ash.Move 40 mm away from the lower edge of the pipe and cut a parallelepiped-shaped groove with a grinder or hacksaw, which will then be approximately 80 mm by 240 mm.

- In the same axis, you need to cut another groove for stacking fuel in it - move away from the upper edge of the blowing hole from 180 to 200 mm. The cutting procedure needs to be done extremely carefully and as carefully as possible, since these cut segments will subsequently be the door of the firebox and the blower.

- Above the level of the firebox is a tray for laying stones. Measure from the front edge of the furnace from 120 to 180 mm, cut a groove in the shape of a circle with a diameter of about 350 mm. Please note that this groove must be shifted 90 degrees to the circumference of the pipe.

- The next pipe is cut so that it is equivalent in length to the outer diameter of the larger pipe. Next, you need to cut the apical part by three quarters to give the material the shape of a scoop.

- A hollow wall is welded to the rear part with a groove. A cap with a semicircle-shaped sliding door is attached to the frontal part, which will later be used as a container for stones and adding liquid to the stones in the process of soaring in the bath.

- This section is inserted into the base tube in such a way that its external indent is from 20 to 30 mm with the presence of free space around it. Next, the hole is carefully scalded around the perimeter. As required fastened from the inside with reinforcing bars.

- A circular disc is cut out of a sheet of metal, which is equal in diameter to the main tube by the diameter of the inner part. In the center of the disk is cut a rectangle - in size it should easily fit in the grate of cast iron. If they are not there, reinforcement bars are welded at the bottom, which form a grid of grates.

- To the base of the fuel tank you need to attach the base pipe 20 cm above the blower using a welding machine.

- Cut out a base for a blower from a sheet of steel. Below the stove is placed on small legs.

- The next step is the manufacture of a water tank, while the chimney must pass through it. The main pipe is used as side walls, the bottom is also the upper arch of the firebox.

- The bottom is cut from a sheet of steel in accordance with the diameter of the inside of the pipe, then a hole is cut into it in the form of a circle with a diameter of 30 to 50 mm, which will later become a chimney.

- A part of the chimney is inserted into this hole so that it extends beyond the edges by 100-120 mm.

- The bottom of the water tank is inserted into the chimney and brewed slightly above the stone container. Pipe for smoke should be on the side of the site in the form of a scoop.

- The water tank is brewed along the entire perimeter, a hole is made from the bottom into which the faucet is inserted.

- Hinges are welded to install the doors to the body. Check if the tank is leaking by filling it with water. Next you need to hold the first test furnace.

Useful recommendations

To make the furnace not only functional, but also to please the eye, you can paint it with fire-resistant paint - heat-resistant paint will not only give it the desired color, but also help protect the metal from the effects of corrosion.

You can also enclose it with bricks, which not only carries a decorative function, but also saves you from excessive infrared radiation, which carries heated metal. This type of rays does not soar, but burns.

How to cook the stove from the pipe with their own hands, see the video below.