How to make a stove for the garage?

Sometimes the purchase of some finished products may be financially difficult, so it may be necessary to manufacture them by hand. For example, at first glance, making a stove for a garage may seem like an impossible task, but if you follow all the rules, you can easily implement the idea.

Let us consider in more detail the features and types of garage furnaces, as well as learn about the intricacies of their own production.

Special features

Some motorists spend a lot of time in the garage, doing repairs or improvement of the car.A garage stove is not an ordinary product, as it is somewhat different from a classic stove in its appearance and functional characteristics. But besides this, the product has a lot of advantages, the main of which are efficiency and financial side of the issue.

Garage heating is important not only from the point of view of heating the air, it is also necessary to maintain an appropriate atmosphere in the room.

The fact is that in the garage, moisture is often observed, which can lead to mold and fungi, and uniform heating eliminates such problems.

And the minimum cost of materials for the manufacture and fuel will allow decent savings and will not cause a significant impact on the budget.

Primary requirements

Since mainly garage furnaces are used to heat small spaces, it is necessary to take into account some of the requirements that a particular product must meet.

Depending on the size of the room, it is necessary to choose the best design option. and decide which furnace heating is best suited and which model will be the most relevant and effective - a brick product or a variant from an empty cylinder.

It is important that the product has not only the highest efficiency, but also comply with all safety rules. In order to avoid the penetration of smoke into the room and the emergence of a threat to life, it is necessary to make sure that the chimney is arranged according to all the rules and carefully sealed. In no case should caustic fumes enter the room.

All flammable items and flammable substances must be kept at a safe distance from the product, so you should take care of the location of the furnace in advance. Do not use raw materials of dubious origin for kindling, as vapors and gases released may be harmful to health.

When using metal models, it is necessary to divide the time of the fire into several periods. It is better to melt the stove two or three times, rather than resorting to a long burning period. This is due to the fact that the metal can become extremely hot and its contact with any combustible materials will cause a fire.

Cleaning of the chimney and stove as a whole should be done, though infrequently, but regularly - up to three times a year.

During the kindling and throughout the entire combustion procedure, the raw materials must beto keep the door closed in order to avoid the ingress of fire to the outside and its spread throughout the space of the room.

It is strictly forbidden to leave young children alone with a melted product.

In addition, smoldering particles should not be thrown near buildings or in areas with abundant vegetation in the form of shrubs or dry grass. All rubbish must be burned to the ground or previously extinguished.

Types and materials for manufacturing

For a handwritten construction of furnaces of such a plan, there is no need to purchase specialized parts or manufacture individual particles. Sometimes even suitable materials will be suitable for work, which can be bought at a very low cost or even received for free. But absolutely certain are some of the requirements for metals and brick products used for the construction of structures.

For example, metal elements involved in the production process must be resistant to high temperatures. Heat-resistant properties of materials will not prevent incandescence of the metal, but will not allow its melting.

Let's take a closer look at all the varieties of designs and subtleties of the manufacture of various models.

Oven-stove

Perhaps the most common option for a garage stove is the stove. Such models were popular at the beginning of the 20th century and, being easy to use and very practical, could practically replace fireplaces. The stoves were popular in houses and apartments until the appearance of central heating, and then they were used only when necessary.

The framework of the entire furnace, including both the main part and the chimney, is made of metal, which, on the one hand, is a plus, and on the other, it is a rather significant disadvantage, since stopping the maintenance of the firebox and adding wood, the stove cools down very quickly and again getting cold.

The potbelly stove is a very economical product, since its production does not require any large expenditures. For manufacturing, you can use, for example, propane cylinders or large iron pipes with dense walls, which should have considerable strength.

Iron barrels are also suitable, but their choice should be given special attention. The barrel should not be too large, because the stove with too large dimensions will be cumbersome and not quite practical, but must have rather thick walls - from 2 to 5 mm.

There are types of potbelly with a water circuitwhich are slightly different from the classic models. Heating of this structure is carried out by increasing the temperature of the water, as well as evaporating a certain amount of it, therefore the walls remain hot longer and emit heat for a much longer time, heating the room.

The main advantage of this model lies in the duration of heat distribution, since the distribution and maintenance of heat can be enough even for heating a small country house. As for a small garage room, for those who spend most of their time working with a car, this is a great option for heating design.

Brick construction

In addition to the compact and easy to use stove, there is also a variant of brick structures, which has a number of advantages and disadvantages.

This model retains heat much longer because it needs a longer time to cool. Such heat capacity is provided both by the thermoregulatory properties of the brick, and by the rather large weight of the structure as a whole.

For a brick model, it is necessary to have a damper, which is also called the blower, through which you can adjust the temperature in the room. The main thing is to learn how to use such functions of this model, since improper use of the valve can even harm health.

With self-made brick kiln, you can save a lot, because the material is quite inexpensive, and the process is not so laborious as to interfere with third-party labor. The main thing is to calculate the required amount of bricks and cement, as well as to purchase the necessary cast-iron parts.

The heating force directly depends on the dimensions of the furnace, therefore, depending on the functional characteristics of the room itself, it is possible to make the appropriate size of the heating structure with an appropriate power.

In addition, the operation of such a product is also very economical, since kindling does not require any special means. Suitable as coal, and the most common firewood.

But, unfortunately, this product has some drawbacks, which can slightly darken the process of using the furnace.

Such a design cools for a long time, but it also heats up for quite a long time., therefore, with the rapid heating of the room may be some problems. In addition, in order to maintain a certain temperature in the room, it is necessary to melt the oven daily.

If you want to make the heating structure durable and reliable, you will most likely have to purchase a special brick with refractory properties, which has a cost that is many times greater than normal. Therefore, the issue of economy can be considered very controversial.

How to do it yourself?

For those who have no relation to the plumbing and construction business, making a furnace with your own hands can seem like a complicated and laborious process. But the designs are sometimes so simple that sometimes a unit for heating can even be built from improvised means.

But one should not do everything at random, for the manufacture of a self-made construction one should first draw up all the necessary drawings and foresee all the advantages and disadvantages.Let us consider in more detail which products have the highest efficiency and what you need to know to make them.

Vertical

The most common option for the manufacture of a furnace from a cylinder, barrel or pipe is a vertical model, since the design is very compact and does not take up much space in horizontal space.

First you need to choose a piece of cylindrical shape, suitable in size and parameters. Then it is necessary to divide the main part into two different sizes. The lower, narrower element will be intended for ash, and the upper space - for kindling using firewood.

Further in the resulting parts it is necessary to make square holes. The bottom can be small, but the top should be quite wide, allowing you to easily put the wood into the interior of the furnace.

Cut parts can not be thrown out, because they are useful for the manufacture of doors - it is only necessary to attach hinges to them.

Inside in the place where the stove is divided into two parts, it is necessary to weld a solid grid. You can purchase a finished part and adjust it in size or make it yourself. To do this, you will need steel rods of reinforcement, the thickness of which is from 12 to 16 mm.The rods must be cut into parts of certain sizes and welded to the base at a distance of two centimeters from each other.

If there is no bottom, it will need to be welded, and in the upper part of the cut hole, which will serve as a chimney. The pipe is fastened to the hole, then its separate parts are assembled and as a result a full-fledged chimney is obtained that is able to remove smoke from the room.

At this hand-built construction of the vertical stove ends and the product is ready for use.

Horizontal

Another option for the location of a homemade iron stove is a horizontal position. As already mentioned, the disadvantage of this design is cumbersome, because it occupies a fairly large space on the floor, so the horizontal version is categorically not suitable for small garage spaces.

So how do you make such a model of the furnace? It's pretty simple. For the manufacture of suitable as a large balloon, and a large rocket tube.

With a horizontal arrangement, there is no need to divide the main part into two parts, since the ash box is manufactured separately and welded to one of the roundedparties. The box should have a rectangular shape and even lower edges, which will also serve as a support.

In order for the ash not to remain in the casing, but to fall into the box, it is necessary to drill several holes along the entire perimeter of the wall that is directly above it. The openings should not be too large so that burning particles do not fall into them, but not too small.

The next stage in the manufacture of the furnace is the construction of the chimney. To do this, you need to pick up a pipe of not too large diameter and in the upper part of the body cut a corresponding hole under it to which the part will be welded.

Special attention should be paid to the place of welding, since the seam should be smooth, neat and without small holes - the smoke should in no case penetrate the room.

If necessary, you can make the legs separately. They will help the construction to stand straight and firm in place.

Next, a door is made - a hole is cut, hinges are welded to the iron part and all of this is attached to the body. It is not scary, if at the closure there are cracks - they will pass air, which will contribute to a better burning.

After the door is constructed, it is necessary to clean the casing of debris and you can start the kindling.

From two barrels

Sometimes the use of a classic stove or structures made of single-layer metal becomes impossible, because the walls are very hot and give too much heat radiation, overheating the room too much. To solve this problem, the construction of two barrels was invented.

First you need to pick up barrels of different sizes and put one in another. It is important that there is a sufficient distance between their walls in order to evenly cover it with pebbles, sand or clay (in some cases special mixtures are made).

Before falling asleep, it is necessary to ignite it on the fire, and then cool it.

The outer barrel is exclusively a body, but the inner one serves for kindling. In the barrels should also be all the necessary holes, a box for the ash and chimney. To build the door, it will be necessary to close the gap between the two parts with the help of welding and metal in order to prevent the eruption of the sand and pebble filler.

This design, although it heats up a little longer and does not immediately begin to generate heat, heating the room,but it allows you to maintain a more comfortable atmosphere in the garage and cools longer after the fire is completed.

Long burning

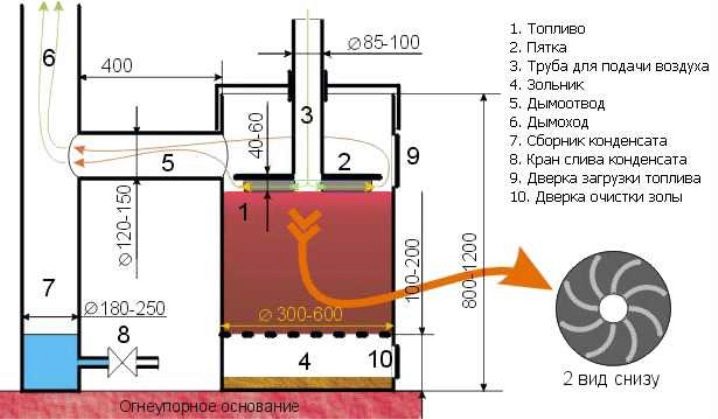

From an empty gas cylinder, you can build a structure that will serve as a heating device for long-term combustion. The idea, though not new, was consolidated among the masses relatively recently, when one of the forums had instructions for making the most reliable and safe construction.

A long-burning furnace has one feature, which is also a disadvantage of the product. - it does not have a separate ash drawer, so in order to clear the inside, you will have to turn the case over and shake it all out manually.

The advantage of the product is that the furnace is very easy to manufacture and, armed with a welding machine, it can be made in a few hours.

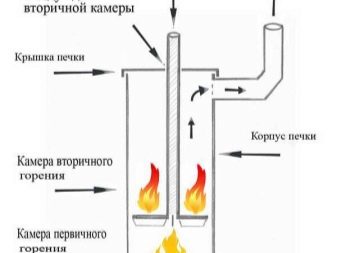

The design is constructed in such a way that the combustion process starts from the top and gradually spreads downwards. This is the reason for the long burning - the flame spreads gradually and rather slowly. But at the same time, the heating of the furnace and the space around it is also slightly slowed down.

This model must be cylindrical in shape and can be exclusively vertical. Therefore, for its manufacture fit both cylinders and wide iron pipes, and standard metal barrels.

The design has a movable part inside the cylinder, which is a small pipe and a metal circle that serves as a load. These parts must be welded together.

Due to this structure, air enters the inside of the product, providing more intense combustion.

This model of a garage stove has a removable cover and chimney at the top of the side. The size of the chimney is determined individually, based on the parameters of the room, but on average it is about 2-3 meters. It is important that the smoke does not enter the garage, as this may be unsafe for health and life.

The bulk of the wood and sawdust is laid in the lower part of the product - at the bottom, a certain amount of combustible material is added to the load. In the process of burning, it falls lower and lower, and the main tab gradually begins to burn. As soon as all the firewood burns out, the stove will start to cool down rather quickly and a new portion of fuel will be needed.

It is important to know that before starting the manufacture of the oven, the housing must be thoroughly rinsed from the inside.especially if it is an empty gas cylinder. After that, the upper part of the cylinder must be cut off - this part will serve as a cover. If a barrel or a pipe is used for manufacturing, the lid must be made separately according to individual parameters.

At the top of the lid, you need to make a hole for the pipe, and on the side - a flue outlet. Next, the inner tube is welded to the circle and installed inside, all parts are attached to each other and securely fixed.

And for ease of use, small handles can be attached to the lid and even the body itself.

For convenience of design, some improvements are introduced into the manufacturing process. For example, in the lower part of such a furnace, you can still build a special space for the ashes with a small door, from which it will be possible to easily scoop out the entire contents.

But in order to prevent a large amount of oxygen from entering through the lower door and the burning process to accelerate, it must be made airtight. Thus, the air will not be able to penetrate into the internal space due to tightly closedholes.

Another improvement is the installation of a certain number of edges of a special shape on a metal circle. Thanks to this innovation, the air will spread evenly across the stove, which will have a beneficial effect on the entire heating process.

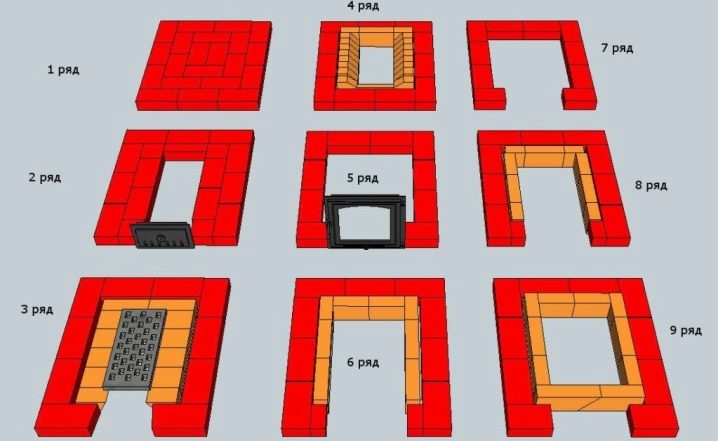

Brick

The construction of a brick structure is perhaps the most time-consuming and lengthy process, since there is no ready-made frame, but only consumables.

To make a small but functional model, we need:

- ceramic brick - about 300 pieces;

- special door for the furnace dimensions 250x180 mm;

- a lattice for ashes - 240х250 mm;

- blower door - 130x130 mm;

- gate valve - 130x130 mm;

- cast iron panel, which will serve as a cooking tile - 720x290 mm.

To make the construction quality and strong, it is necessary to lay the elements on the clay mortar, observing the thickness of the seams up to one and a half centimeters. You should know that for the construction of this furnace it is necessary to build a special foundation that will not only increase the service life of the product, but also help to comply with all fire prevention measures.

The laying of bricks is made in a special way - the bottom nine rows practically have no similarity to each other,The bricks are arranged in a special pattern to ensure maximum strength and product efficiency.

When laying it will be necessary to make holes where cast iron cast elements will be laid.

The place for casting should be slightly larger in size, since bricks tend to expand when heated, and because of too tight masonry, cracks may appear, thus the structure will quickly begin to crumble and fall apart.

In addition, you should know that to maintain the insulating properties may need a special material.serving as a heat exchanger. Particles of asbestos cord or heat-resistant mineral wool are perfect. And to adjust the heat transfer, you can use the valve, which also helps to control the temperature in the room, depending on the time of year.

Fuel types

To kindle any stove you will need the right fuel, and a homemade garage copy is no exception.

Stock up on diesel fuel - diesel fuel, much easier than buying wood raw materials for the garagebut it has a lot of flaws and is considered the most flammable.Combustion in the furnace when using this fuel occurs due to the heating of the liquid and the combustion of the evolved vapor.

The construction, working on waste oil, is no less dangerous and prone to the occurrence of unwanted fires. The fact is that the flame flashes at lightning speed and sparks can accidentally get on combustible substances and objects in the vicinity.

In addition, models of stoves operating on liquid fuel, have another drawback - an unpleasant oily odor that spreads in the combustion process. Otherwise, they are quite functional and economical.

Perhaps the most familiar and safest option is a heating product that runs on wood. But some users believe that the raw material inflames too slowly, which affects the distribution of heat. This problem is solved quite simply - you can equip the design with a mini-fan. If you put this element in the manufacturing process, it will contribute to the best air circulation, which has a beneficial effect on the process of burning and kindling.

It is also worth noting that, in some cases, a combined fuel variant is used for the long-burning furnace.

Tips

It is not enough just to make a quality product and determine its location, it is also necessary to properly install it and securely fasten it. Although some models have among the advantages of the ability to move and move the oven, yet the fixed position is important for safe use.

First of all, it should be noted that the installation of the product should be carried out exclusively on a flat surface. Even a minimum slope is unacceptable, since this can lead to an uneven distribution of fuel inside the firebox and its careless falling onto the floor during combustion.

In addition, the stove must be installed not just on the floor. It is best to use for this asbestos cement slab or brick surface. This nuance is not only a fire precautionary measure, but also allows you to protect this or that floor covering from damage.

Professionals also advise the use of metal sheets to fence products from all sides, where there are small holes, slots or lattice elements. If sparks or burning particles get out, the sheets will not allow them to get on household items,which will prevent the spread of fire.

For details on how to properly lay a brick stove, see the following video.