Stoves for bath "Vesuvius": an overview of the range

In the bath one of the most important elements is the stove. From the material from which it is made, depends on the time of heating water and steam room, the amount of spent fuel, service life. The article presents an overview of bath furnaces from the manufacturer Vesuvius.

Features and benefits

The company "Vesuvius" produces a large range of furnace products and related products, but the distinctive feature of furnaces is their special shape without angles for uniform distribution of heat.

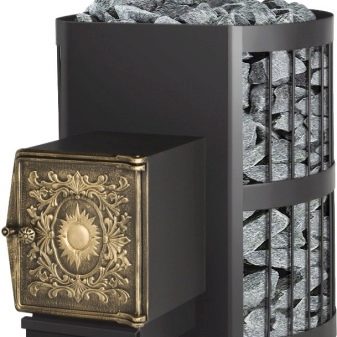

The range of stoves for a bath from the company "Vesuvius" is divided, depending on the material of manufacture, into iron and steel. In each case, there are several options for the manufacture of furnaces: with decoration (forged elements, serpentine stone or sandstone) or without it, open panoramic windows at the firebox or deaf, open heater or closed.

The sizes of furnaces are various, they can be picked up for rooms with the area from 6 to 40 m3.

The company catalog contains all the necessary elements to create a full range of heating from the furnace to the chimney and other components. All elements can be replaced if in the process of exploitation something has become unusable.

An extensive dealer network of partner companies allows you to purchase products in many cities of the Russian Federation, from the city of Kaliningrad to the city of Yuzhno-Sakhalinsk.

Design

Bath stoves can be classified according to the main characteristics - the material of the body and the method of obtaining thermal energy.

- Brick stove, heated by firewood. The most reliable and durable (provided quality brick laying), and the steam generated in the steam room from a brick stove, is considered optimal for Russian baths. The minus of these furnaces is a big weight and a long warm-up time.

- Metal stove, wood. Steel or cast iron alloy is used as the body material. The most common use for private saunas.

- Electric, heat comes from heating heaters. The advantage in this case is the absence of a chimney, which allows equipping small saunas in apartment buildings.

- Stoves on gas. The heat source in such stoves is gas, which is considered a cheap material, but its use requires great care and certain skills.

Despite the differences, the principle of operation and the design of the main components of the furnaces are the same.

Fuel (wood, gas) should be burned in a special compartment. For efficient fuel combustion, it is necessary to provide oxygen to the furnace through special channels (“primary” air flows, as a rule, from the “blowing door - ash box - grate” channel; an additional channel is also created to supply “secondary” air).

- Fuel during combustion gives heat in the form of gas and smoke, which, passing through special channels, give it to the stones and the walls of the water tank. For better heat transfer, channels for gas and smoke are made like labyrinths, so that they change direction several times and go a longer way to the chimney.

- Heated stones give off their heat more evenly, cool for a long time.

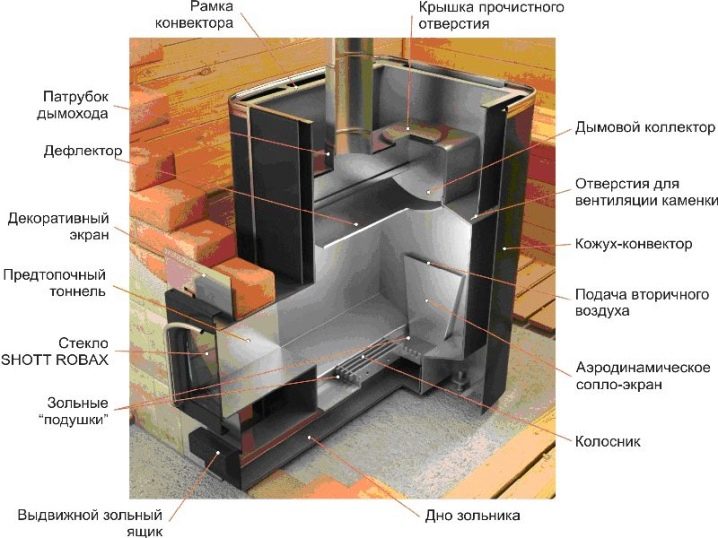

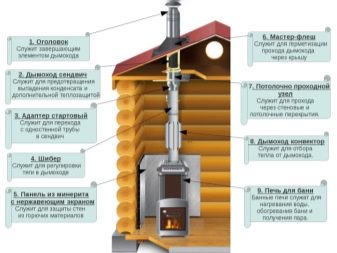

The device of the stove for a bath from "Vesuvius" is considered on the example of a model with a convection-ventilated casing. In the figure below, all major nodes are signed.

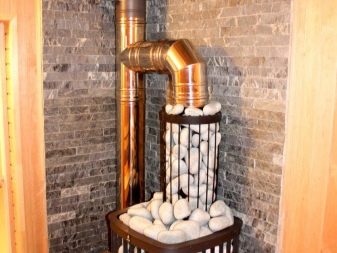

We should also describe the situation with heat exchangers, which provide hot water in the bath, They are used in two ways.

- By installing a water tank on the outlet of the stove chimney. Such heat exchangers are called "samovar" type.

- The water tank is attached directly to the wall of the firebox. Heating in this case occurs directly from the heated metal surface of the fuel compartment. Such heat exchangers are called “built-in”.

For the production of heat exchangers used high-alloy heat-resistant stainless steel with a thickness of 2 mm.

When selecting a model, keep in mind that only the built-in heat exchanger is included in the standard price. If a remote water tank is needed, then it must be purchased separately. Only in some models of steel furnaces of the Skif series there are tanks for the heat exchange circuit.

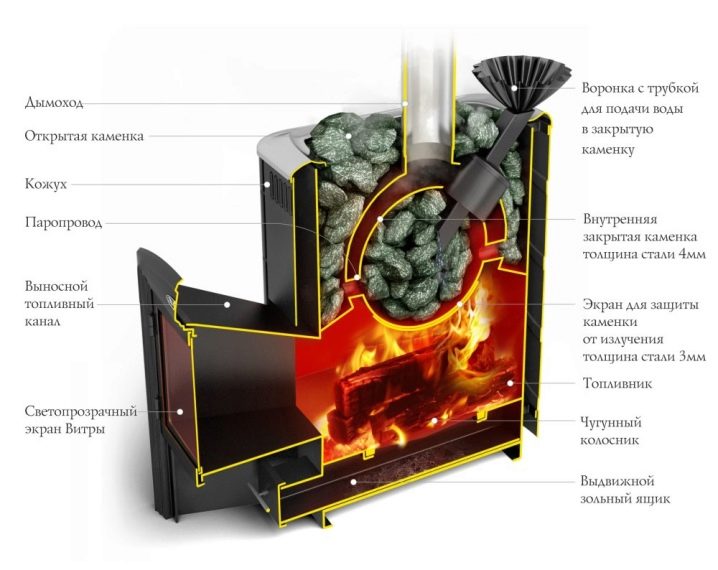

For special lovers of steam in the model range of furnaces from "Vesuvius" there are several modifications with the steam generator. The device of such a furnace is shown in the figure below.

The steam generator delivers water to the hottest stones that are in close proximity to the firebox and warm to a temperature of 550 °. The steam produced in this way is very fine and light.

How to install and flush?

It is permissible to install any furnace only on non-flammable resistant substrates (concrete, brick, steel, ceramic tile). The same applies to the walls adjacent to the furnace surface - they must be covered with refractory materials.

When choosing a place under the stove, consider the following minimum allowable distances:

- from the vertical surface of the furnace to flammable substances - 500 mm;

- from the flue window to the walls - 500 mm;

- the floor in front of the firebox door must also be protected by non-combustible materials (for this, it is necessary to stack a sheet of metal with dimensions of at least 1000x400 mm along the furnace);

- from the upper surface of the furnace to the ceiling should be at least 800 mm;

- nozzles without insulation must be within 1000-1200 mm from flammable substances in horizontal and vertical directions, respectively;

- the chimney should rise above the roof of the bath not less than 500 mm.

Sometimes in the conditions of small bath rooms there is a need to reduce the allowable distances. This is allowed to be done on the condition of creating fire-resistant brick screens for the back and side walls of the stove.

To comply with all fire safety regulations when installing the furnace, the manufacturer recommends that you refer to SNiP 2.04.05-91.

After installation, the furnace must be tested in order to ensure that all joints of structural elements are tight. A normal air draft should be created when the damper is opened.

Range

Cast iron stoves "Vesuvius" are reliable and durable. This factor is of key importance in the bath, where the metal is exposed to aggressive effects of water vapor, as well as high temperatures during the combustion of fuel. The efficiency of cast iron furnace is closest to brick. In addition, cast iron stoves do not burn oxygen in the steam room, and when heated, no hard infrared radiation is emitted. Therefore, the steam in the bath with a cast-iron stove is soft and light, which creates optimal air parameters for creating the effect of the “Russian bath”.

The higher cost of cast iron stoves than steel, is covered by their unlimited service life.

According to the manufacturer, the design features of cast iron furnaces are as follows.

- The furnace consists of 3 elements, which are interconnected by a ceramic cord. It can withstand temperatures up to 1200 degrees. Since in wood-burning stoves the temperature during the combustion of fuel does not exceed 1000-1100 degrees, it can be concluded that such stoves will be airtight.

- The furnace parts themselves are interconnected by means of a thread, which ensures absolutely safe operation.

- The developers of the company "Vesuvius" picked up the best alloy of cast iron and castings. Products from such an alloy do not lose their structural characteristics even when interacting with a large amount of water.

The table provides a brief overview of the models of cast iron furnaces by main characteristics at the beginning of 2018.

№ | Feature \ Series | "Sensation" | "Legend" | "Hurricane" | Premium |

1 | Feature | - the volume ventilated Kamenka; - there is an external convection-ventilated casing | -a open | - provides warming up of stones to 400 ° (for creation of a small-dispersion pair) | -The outer hull has a stone finish (sandstone or serpentine) |

2 | Allowable space for optimal heating, m3 | 6-14; 8-18; 12-24; 14-30 | 6-14; 8-18; 12-24; 14-30 | 8-18; 12-24; 14-30 | 8-18; 12-24; 14-30 |

3 | Types of furnace doors | - deaf tight; - deaf untight; - panoramic with heat-resistant glass is not hermetic; - panoramic with heat-resistant glass | - deaf tight; - deaf untight; - panoramic with heat-resistant glass is not hermetic; - panoramic with heat-resistant glass | - deaf tight; - deaf untight; - panoramic with heat-resistant glass is not hermetic; - panoramic with heat-resistant glass | - panoramic with heat-resistant glass; - fireplace self-cooled with heat-resistant glass and with a cleaning system |

4 | Kamenka (open / closed) | closed | open | open | closed |

5 | Price range, rub. | 17000 – 40430 | 15860 – 40430 | 27560 – 47650 | 36190 – 57980 |

6 | Number of models, pcs. | 29 | 32 | 18 | 12 |

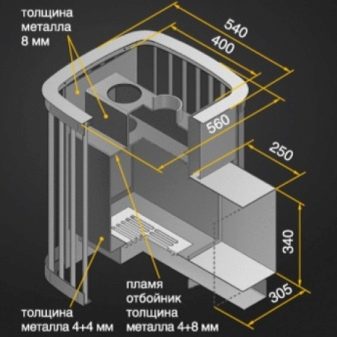

Steel furnaces for the bath more budget, but less durable than cast iron. However, according to the manufacturer, their furnaces are made of structural steel with a metal thickness of up to 8 mm and with a minimum number of welds.

Also, the stoves are equipped only with cast iron doors, which are not deformed during operation, and the glass in these doors do not burst.

For convenience, the review of the model range of steel furnaces is made according to the same characteristics as the cast iron furnaces.

№ | Feature \ Series | "Optimum" | "Scythian" | "Rusich" | "Lava" | Stove with closed stove | Premium | Furnaces with steam generator |

1 | Feature | - simplified structure of the furnace and the use of metal 5 mm thick provides low cost; - there is a model that needs to be heated from the steam room; -capacity of stones up to 110 kg | - the cover is convection-ventilated according to the “grid” type, with a stone capacity of 110 kg, 130 kg or 230 kg; - thickness of structural steel 6-8 mm; - in the decor of some models there are elements of decorative forging | - the cover is convection-ventilated, with a capacity of stones up to 50 kg; - thickness of structural steel 6-8 mm | - the cover is convection-ventilated, with a capacity of stones up to 50 kg; - thickness of structural steel 6-8 mm | - the furnace is suitable both for creation of effect of the Finnish sauna, and for the Russian bath; - in the upper part there is a compartment with a closed heater, where they are heated to 400 °; -The thickness of the steel in the most vulnerable places of the furnace reaches 12 mm; -Convection-ventilated, “grid” type, with a stone capacity of 170 kg | - the jacket is trimmed with a “coil” stone (it has healing properties, a large heat capacity); -capacity of stones from 60 to 80 kg, depending on the model | -the presence in the design of the steam generator furnace, which creates a soft steam; - capacity of stones is 180 kg |

2 | Allowable space for optimal heating, m3 | 6-14 | 6-14; 8-18; 12-24; 14-30; 24-40 | 6-14; 8-18; 12-24; 14-30 | 6-14; 8-18; 12-24; 14-30 | 12-24; 14-30 | 12-24; 14-30 | 14-24 |

3 | Types of furnace doors | - deaf untight | - deaf untight; - panoramic with heat-resistant glass | - deaf untight; - heat-resistant glass is not hermetic; - panoramic with heat-resistant glass | - deaf untight; - heat-resistant glass is not hermetic; - panoramic with heat-resistant glass | - deaf untight; - heat-resistant glass hermetic; - fireplace self-cooled with heat-resistant glass and with a cleaning system | - fireplace self-cooled with heat-resistant glass and with a cleaning system | |

4 | Kamenka (open / closed) | open | open | closed | closed | closed | closed | open |

5 | Price range, rub. | 9030 | 11700 – 47680 | 13180 – 28500 | 12680 – 27710 | 19190 – 40150 | 40380 – 51610 | 16480 – 23250 |

6 | Number of models, pcs. | 2 | 30 | 18 | 23 | 5 | 4 | 4 |

Owner reviews

Of the shortcomings, only a long heating time is noted and the risk of burning out after several years of operation. It cannot be said that furnace products from Vesuvius are ideal. However, a variety of model range with different characteristics and an acceptable price range created a decent army of fans of these recognizable stoves.

For information on how to assemble and disassemble the Legend furnace from Vesuvius, see the following video.