How to make a ventilation in the bath with your own hands?

During the construction and repair of baths, attention is paid primarily to structural materials, furnaces, insulation and waterproofing. It is assumed that the natural air circulation will be sufficient for high-quality ventilation of rooms in the bath. But this is absolutely not the case, and if one approaches the matter superficially, one may encounter serious problems.

Special features

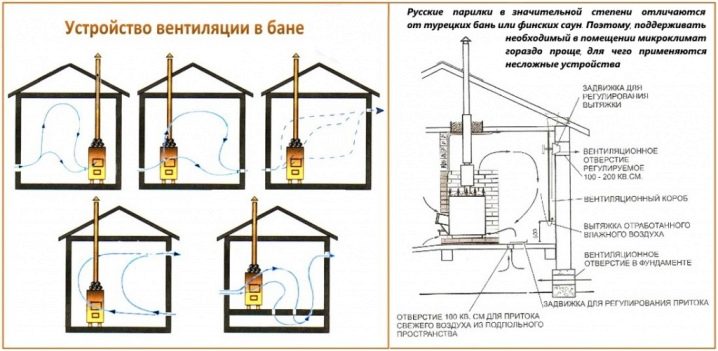

Ventilation in the bath can be performed in various ways.

From her presence depends:

- distribution of heat flux inside;

- comfort and safety washable;

- the period of operation of the building.

Water and steam are continuously concentrated there, the tree actively absorbs them. Even if you dry the building periodically, without adjusting the constant movement of air, the effect will not be strong enough.In order to avoid dampness, it is required to create a pair of ventilation windows - one serves to bring in fresh air from the outside, and the other helps the heated, absorbed a lot of water. By selecting the location of the openings, they change areas that are particularly intensively ventilated. The use of a pair of outlets in the steam room and the dressing room sometimes improves the orientation of the air flow in the desired direction.

Of course, the size of each window and the ability to adjust the clearance are of great importance. They put valves, fully or partially open. The calculation of the volume of ventilation holes is repelled, first of all, from the area of the bath rooms. If you make them too large, the mold will never appear on the floor and in the sink, but the steam room will heat up for a very long time, and an extraordinary amount of fuel or electrical energy will be consumed. Too narrow windows will not allow the air inside to cool or become drier.

All deviations from normal parameters are strictly unacceptable., which allow to exclude the occurrence of powerful temperature differences - this not only creates discomfort,but it can cause health problems. It is impossible to completely eliminate the difference in temperature of the streams, it is only necessary to limit their value. Normal ventilation systems are formed during the construction of the bath, while making channels and preparing openings. Windows are mounted only after the building paneling is completed. That is why it is necessary to enter into the project of a bath information on the device of ventilating channels.

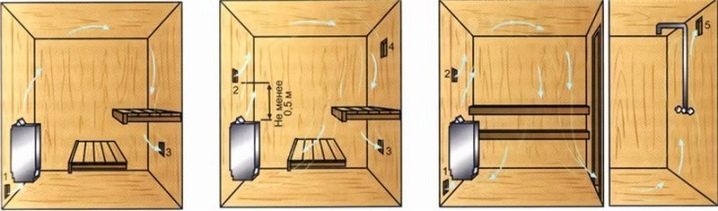

In most cases, the vents are made exactly the same. The outlet can be made larger than the inlet, but according to the safety rules it cannot be less than the first. For the same reasons, sometimes resort to paired output windows. As control elements, it is worthwhile to use not the doors, but valves, which, when closed, cannot preserve the gaps. When the steam room is heated for the first time, the valves are locked at 100% until the air reaches the desired temperature.

The use of elements with a controlled position is also useful because the amount of air flow must be adjusted according to the season. When there are negative temperatures outside, even a very small trickle of air brings a lot of cold. Therefore, it is not necessary to open the ventilation windows completely.The cross sections of such windows on average should be 24 square meters. cm to 1 cu. m internal volume. But these are only preliminary figures, and when in doubt about the result obtained, it is worth contacting qualified heat engineers for calculations.

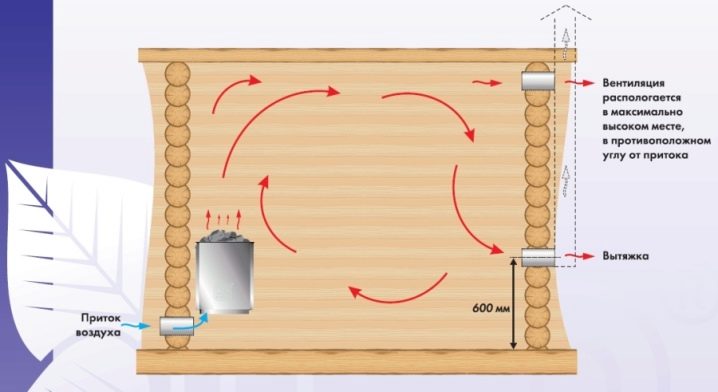

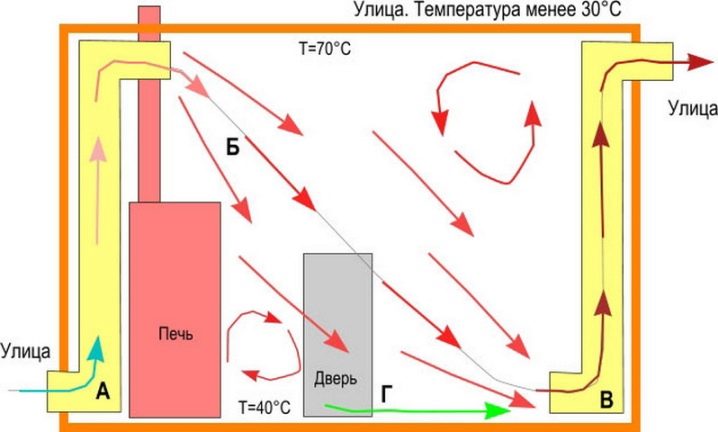

It is strictly impossible to place the ventilation windows at the same height or even directly opposite each other, as this will not allow to warm up all the air in the bath sufficiently. In addition, this design will not evenly mix air masses, and therefore, it will be necessary to thoroughly calculate the accuracy of the location of the ventilation elements. Exhaust windows are recommended to be placed just below the ceiling, because the air immediately after heating rushes up.

Types of ventilation systems

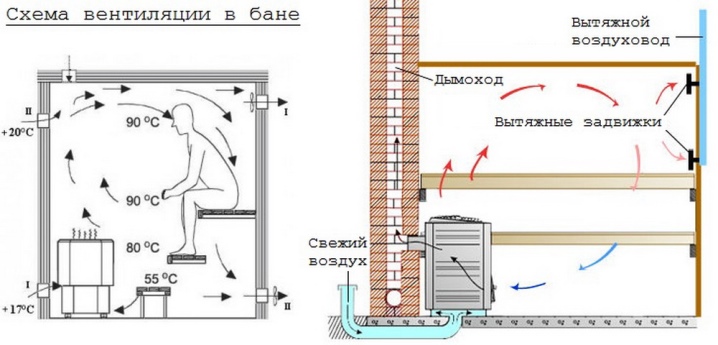

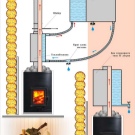

The device of ventilation in the bath varies according to the design of the room and its total volume. Natural ventilation is based on the difference in temperature and pressure inside and outside. To make it work efficiently, air intake will be organized near the furnace, at a level of 25-35 cm from the floor. The outlet is made on opposite walls about 15-25 cm below the ceiling.But it is important to bear in mind that such a scheme is not good enough for steam rooms, since it’s relatively cold down there and always hot above.

Natural air movement in such a situation is too difficult to organize., it will be necessary to position the components of the ventilation system very carefully and carefully. Forced circuit does not always require the use of electronic control systems, with complex panels and so on. There are simpler options when ventilating windows placed in a special way are supplemented with an exhaust fan. The combination of such components is especially effective when the bath is located inside the house, the windows are not placed inside the outer wall, but are connected to the exits by a long box for ventilation. Channel fans are required to select very carefully, because the conditions of their operation in the baths differ from the usual parameters.

The peculiarity of such devices consists in increased waterproofing of electrical circuits and main mechanical parts, in adapting to work at high temperature without consequences for equipment. The state of fresh air ventilation and its device in each room is adapted to the individual characteristics and to the type of bath.It follows that the time spent on calculations and thinking through the project is not wasted - it will save a lot of money and time, get the best result soon.

As already known, the bulk of the projects involves the location of the opening windows near the furnaces in the 0.25-0.35 m from the floor. With this design, the stove transfers heat to the air coming from the outside, and a flow arises, moving in the direction of the exhaust. Having covered the entire distance, the hot and street streams ultimately cover the entire volume of the steam room, and the section where the upper shelf is located is the most heated.

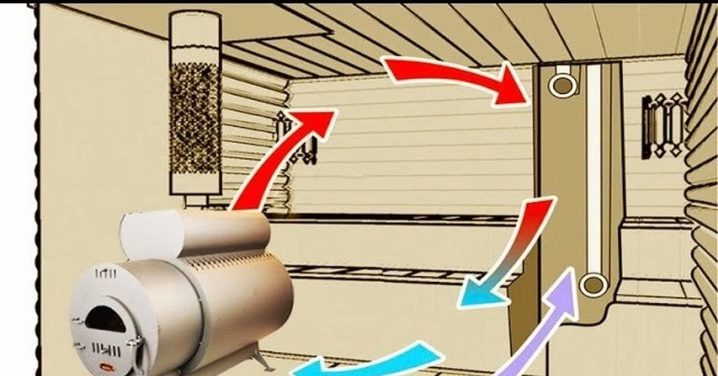

In the second version, by installing an exhaust fan, it is possible to mount the inlet and outlet openings on one wall. The air flow is directed first towards the heater. After receiving a heat pulse, he begins to rise to the ceiling and moves in a wide arc that covers the entire room. This approach will be effective if the bath is built into the house and has only one outer wall, while there is no need to arrange the ventilation duct.

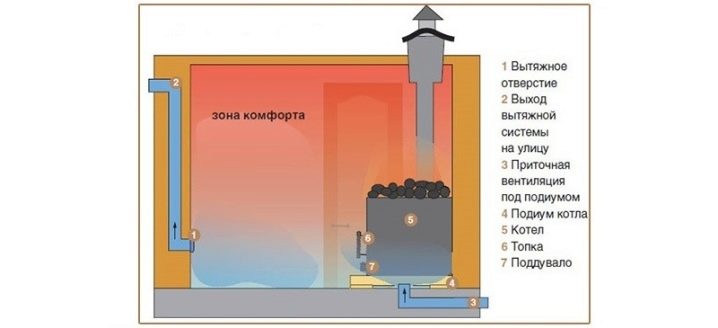

If a bath is created with a leaking floor, the introductory window is placed in the same place as in the first case.directly next to the stove.When the heated air gives off heat in the upper part of the steam room, it cools and falls to the floor, leaves through the holes in the flooring. This technique improves the evaporation of water accumulating at the bottom and allows you to delay the exit of the wooden floor from the system. The hood is placed either in the next room or in isolated ducts that do not allow air to return to the steam room. The complexity of the flow path makes the use of a fan mandatory. This option is used very rarely, because it is difficult to calculate everything accurately, to provide for the details properly.

Another type provides for a continuously operating furnace, the blower hole of which replaces the hood. For the inflow, a window is made under the shelf opposite to the furnace itself and at the same level. The cold air displaces the heated mass upwards, and when the heat that has given up heat flow down, they go into the blowing channel. There are even more complex systems when a pair of air inlets and a pair of outlet ventilation windows are placed (always with a forced type of circulation). It is rather difficult to adjust complicated complexes, but their efficiency is higher than in the simplest cases.

The Bastu system is the placement of the air inlets (with adjustable valves) behind the stove or under it. The organization of vents under the furnace is not required, although it is highly desirable. Through these openings, air penetrates into the room from the underground part of the bath, which is connected to the outside atmosphere by means of the foundation. When the bath is done in the previously prepared room, you need to choose a room with a pair of external walls; when preparing the basement, choose an angle that meets the same requirements. The dimensions of the inlet and outlet are calculated according to the general rules.

How to do?

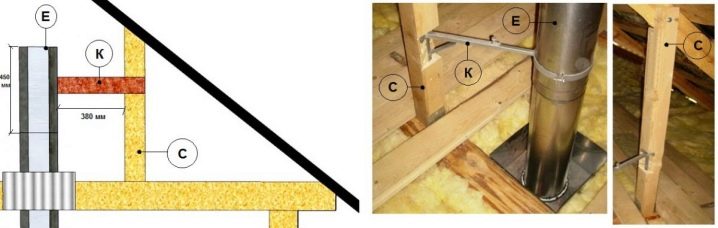

Installation of ventilation implies that when the pipe is brought outside it is protected from penetration of snow, mud, rainwater and melt water. When this does not work out, you can organize a ventilation duct or direct the pipe to the top, passing it through the ceiling and the roof. In the latter case, the canal is covered with an umbrella in order to prevent the penetration of the same sediments and falling leaves. Arrange high-level ventilation means ventilate and dry all rooms, structural parts of walls, floors, attics, and roofing spaces.

Step-by-step installation guide for ventilation in the bath is easy to find.However, the simplest option is the use of asbestos-cement pipes and grids, selected according to the diameter of the channel. If we talk about the technical performance, the most effective and convenient execution in the walls of the frame type is the use of inlet valves. First, the valve is disassembled and circled on the wall with a circle marker where future ventilation ducts will pass. To obtain holes in the casing, use a drill, and take a drill of large diameter, in which the jigsaw knife will quietly pass.

Further:

- using the jigsaw cut the circle;

- remove wooden parts;

- take out heat-insulating and paroizolyatsionny material;

- using a long drill pierce the outer casing (this should be done to avoid mistakes when placing the outer valve lobe);

- mark a suitable hole outside and make it using long drills;

- cut off the valve tube thickness of the wall.

Then you need to mount the tube in the hole with your own hands and fix the inner segment of the valve with self-tapping screws, only then you can put the outer part of the product. Installation of valves is recommended in the washing compartment and in the dressing room.

When preparing a new building, it is imperative to calculate both the size of the openings and the required power of the fans. Ventilation can be adjusted even when it was not originally made. A common mistake is to rely on salvo ventilation and the use of kiln traction to dehumidify the air. In principle, this scheme works, but it has serious drawbacks. So, when opening windows and doors, instead of lowering the temperature, steam is released into adjacent rooms.

He does not go out into the street, but turns into condensate. Air heating decreases only for a short time, and very soon in the bath again it becomes uncomfortable. To use the effect of stove draft for ventilation, holes are needed, but they should be done only at the bottom. This will ensure the flow of air from the neighboring rooms, where fresh portions will flow from outside. The gate and the door of the furnace itself help to adjust the ventilation, they are opened to the limit to increase the flow, and partially covered to loosen (to avoid carbon monoxide).

A simple calculation can only be made for forced ventilation.and the natural flow of air is much more complex and subject to a variety of different factors. Among them, special attention should be paid to the force and direction of the wind, which blow in a particular area. If the outlet is on the side from which strong winds are directed, this can lead to inflow of inlet mass to it (the so-called reverse thrust effect or its tilting).

Prevention of such a negative phenomenon seems simple - it is the lengthening of the channels that are drawn in the right direction or the use of turns in them. But each turn complicates the work and reduces the rate of release or entry of air. The solution will be the orientation of the inflow entrance to the side from which the wind mostly blows, when placing the outlet on the opposite side or on the roof (with a high pipe).

Do not use the ventilation channel in the block wallIn such cases, it is mounted on the inner wall and partition. According to experts, the best air duct is the one that is built from galvanized pipes. Plastic structures can be mounted with care, carefully evaluating the temperature range allowed for them.The gap from the pipe to the walls of the hole filled with mineral wool or more modern heaters. The assembly foam helps to eliminate gaps in the inlet and outlet.

The method of fastening the ventilation grilles is selected on the basis of the material. It is very easy to check the quality of the ventilation work - a fire or a smoking object is brought to the hole. This will further clarify how fast the air moves. In the dressing room often place only the hood, supplemented by a fan.

When the furnace stove is brought into the dressing room, a special ventilation channel must be made on the basis of galvanized steel, which is passed under the clean floor and air is supplied directly to the door of the furnace. It is necessary to create the channel before the finishing floor is laid. One edge of the pipe is introduced into the hole and is fixed in it with foam, is sealed with a grill. On the edge, suitable to the furnace, establish an adjustable cap.

Good ventilation is one that avoids condensation on the surface of the ceiling. As for the subfloor, work on it begins with the preparation of a cement screed,which is tilted toward the sewer. The foundation is equipped with a pair of holes (in opposite walls, but not directly opposite each other). Air flows should go under the floor along the most intricate paths. The holes are plugged with valves, which will allow you to adjust the rate of movement of the jet in accordance with the current season.

In the bath, which was originally built without floor ventilation, it is required to drill a concrete base down to the ground. This will be a decent replacement for full drainage, when there is no desire to work on the installation of drain pipes. The ventilated floor should be designed with bridges, which use pipes or a wooden bar with a section of 11x6 or 15x8 cm. The lags are covered with treated and well-polished oak boards.

How to choose?

In the Russian bath, in contrast to the usual washing, it is necessary to ensure with the help of ventilation the following conditions:

- temperature in the steam room - from 50 to 60 degrees;

- relative humidity is not lower than 70 and not higher than 90%;

- very fast drying of any wooden surface after washing;

- rapid reduction of humidity with the exclusion of drafts and opening doors;

- the same air quality in the steam room, as well as in the rest room, regardless of the season;

- preservation of all the traditional properties of the Russian bath.

No ventilation devices will help to escape from carbon monoxide.if there is a constant inflow. It is necessary to continuously monitor the completeness of combustion of firewood, and only after the damping of all coals to block the chimney. The organization of air flow in the chopped log bath occurs through the rims of the walls.

This approach, for obvious reasons, is not suitable for brick construction. When walls are sheathed with boards or clapboard, it is imperative to use air vents, otherwise the negative effect of dampness will be excessively strong. In most cases, a hole 200x200 mm will be enough to bring the pipes to the street. The choice of plastic or metal should be made in accordance with the specific project and operating conditions of the ventilation system.

Bath of foam blocks must be ventilated and inside the walls. Layers of waterproofing and plating are separated by a ventilation gap, for external cladding it is 40-50 mm, and inside the bath is 30-40 mm.A typical design involves the use of crates, which already helps to keep the wall cladding. In addition to intra-wall ventilation, all rooms are equipped with an air intake at the bottom (most often behind stoves) and an outlet (right at the ceiling). The advantage of an active air freshening system is that it can be placed anywhere.

In most cases, baths from foam blocks are ventilated in a volley manner, that is, simultaneously opening the front door and the most distant window from it. Only professional calculation is guaranteed to determine whether artificial ventilation is necessary or if natural circulation of air masses is enough.

Components and materials

The fan heater for the bath should have a certain level of thermal protection (not lower than IP44), its case is always made of heat-resistant materials. Modern devices have very high power and work almost silently, the volume is no more than 35 dB.

In the role of ventilation holes in attics, you can use:

- special windows;

- aerators;

- spotlights.

Usually, natural air circulation is used in buildings made of CIP panels. But if in the houses it is still possible to come to terms with the constant leaving of heat to the outside, this is totally unacceptable for baths. Therefore, schemes with reverse heat input, or, in other words, heat utilization plants of the utilization type, are widely used. The use of metal pipes is contraindicated because they create a lot of noise and deteriorate the insulation inside the room. Natural air circulation can be used only for single-storey buildings, but if there are two floors or an area is very large, auxiliary devices are needed.

Mechanical valves placed during construction or finishing works should be made of plastic or asbestos-cement pipes. As for the lattice for bath ventilation, they must be clearly divided into external and installed inside. In the first case, it is allowed to use only aluminum constructions equipped with a grid (for preventing clogging) and means of heating.

The use of sewer pipes for exhaust only seems strange and unnatural. Among all the available options, it is recommended to pay attention primarily to solutions made of polypropylene, PVC and polyethylene.Easy installation (due to the rubber sealing of the sockets) and high resistance to destructive substances are undoubted advantages of such structures. Also, when purchasing components for ventilation, you need to pay attention to the properties of the plugs and the characteristics of the chimney.

Useful recommendations

In winter, it is better to refuse the use of supply fans, because they contribute to the inhaling of too cold air. If the outside air is very dirty, you need to use special filters. When calculating the required power of ventilation devices, it is necessary to focus on the requirement to update all the air in the bath in a maximum of 15 minutes. Into the steam room, supply and exhaust devices are ideally suited, but in the waiting room and the rest room, you can safely limit yourself to the natural circulation mode. When choosing the location of the products outside the building, you need to pay attention to the aesthetic qualities of the structure, the same requirement applies to the pipes being removed to the outside, to the fungi of aerators and valves.

If a pool is equipped in a bath, the air in this part should be 2-3 degrees warmer.than in other parts of the room, and its humidity should not exceed 55-60%.The use of flexible ducts is considered to be a better solution than the use of pipes of rigid construction. Taking into account all these recommendations, you can easily create a ventilation system with your own hands or control specialists.

How to make a ventilation in the bath with your own hands, see the following video.