How to choose concrete and independently prepare a mixture for the foundation?

Concrete is one of the main building materials used everywhere. One of the main directions in which it is used is the pouring of foundations or foundations. However, not every mixture is suitable for this.

Composition

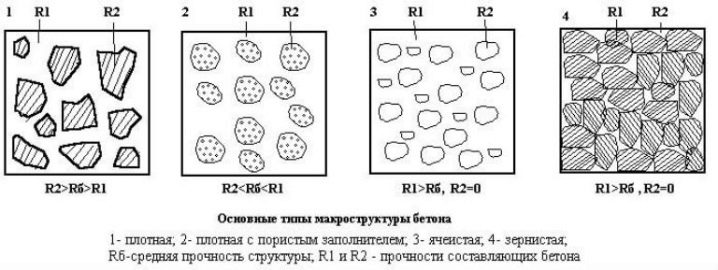

By itself, concrete is a stone of artificial origin. On the modern market there are many varieties of concrete, but the overall composition is always the same. So, the concrete mix consists of the knitting substance, fillers and water.

Cement is most often used as a binder. There are also non-cement concretes, but they are not used to fill the foundation, since their strength is significantly inferior to cement-containing analogues.

Sand, crushed stone or gravel can be used as a filler.Depending on what type of foundation is chosen, this or that option will do.

When combining the binder, aggregate and water in the required proportions, you get a quality solution. The hardening time also depends on the selected ingredients. They also determine the brand of concrete, its resistance to cold and water, as well as strength. In addition, depending on the composition, it is possible to work with cement only manually or there is a need to use special equipment (concrete mixers).

Brands and specifications

There are many nuances that you need to pay attention to when choosing a concrete mix.

Mark

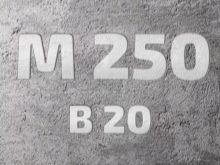

The underlying one is the concrete grade. A mark is a numerical mark on a package. From it you can immediately understand what indicators will have one or another composition. According to the norms of SNiP, not every concrete will be suitable for the foundation of a residential building. The brand must not be below M250.

The most common foundations for foundations are as follows:

- M250. This type is suitable only in cases when a small load is planned on the foundation. Also from the concrete of this brand are made of overlap, it covers the road.Thus, the area of use is extremely limited due to not very high strength characteristics. Will be suitable for the base under the frame house.

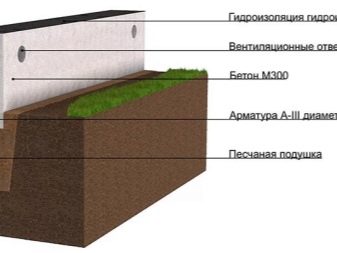

- M300. This more durable cement is suitable for more structures. For example, in addition to the foundation, they can fill the road, subject to high loads, perform staircases. Due to the greater strength, the possibility of pouring the foundation for single-story brick or wooden houses with an attic opens up.

- M350. This option is not much different from the previous one. As in the case of the M300, various structures can be constructed from M350 concrete. The strength will be only slightly higher, but if you are building a one-story house on a plot with heaving soil, it is better to pay attention to this particular brand.

- M400. This option is suitable for construction in cases where floor strength is more important than anything else. For example, the concrete of this brand can be poured as a foundation for a garage or a two-story house. In addition, this type is recommended for use in office space (workshops).

- M450. Concrete of this brand is one of the most durable, therefore it is more suitable for pouring foundations more than others.It is used in high-rise construction to fill not only the base, but also floors. If you build a house of heavy materials or in many floors, it is recommended to choose this brand.

- M500. The strongest of all brands suitable for the base. Concrete and floors are made of concrete M500 when it is not possible to use less durable mixtures. For example, it depends on the climatic conditions of the site: the presence of groundwater, strong winds, high acidity of the soil. If conditions allow, it is better to choose another type, for example, M450. The additives used in the composition increase the cost, and it is sometimes wiser to refuse to use this mixture.

So, once a brand is the main indicator that you need to focus on, then it must communicate some important information. The mark shows the maximum load a concrete block can withstand. All this is detected by practical consideration. For experiments, cubes of 15x15 cm are used. However, it should be borne in mind that the mark shows the average strength index, and the class shows the actual one.

Strength classes

In the conditions of domestic construction, accurate knowledge is often unnecessary, so you should not delve into it.All you need to know is how approximately the strength class is related to the brand. Understand this will help the following table. It is worth mentioning that the mark is denoted by the letter M, and the class - the letter B.

Compressive strength | Strength class | Mark |

261,9 | B20 | M250 |

294,4 | B22,5 | M300 |

327,4 | B25 | M350 |

392,9 | B30 | M400 |

392,9 | B30 | M400 |

Compressive strength is given in kg per square meter. cm.

Frost resistance

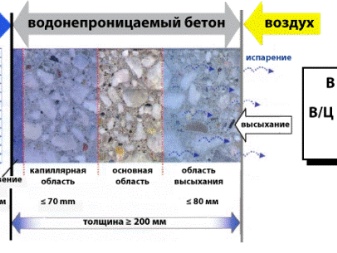

When it comes to frost resistance, they mean how many times it is possible to freeze and thaw concrete without consequences for its characteristics. Frost resistance is denoted by the letter F.

This quality is not equal to the number of years that can serve a concrete base. It would seem that the amount of frost and thawing is the number of winters, but in reality everything is not so simple. During one winter, temperatures can fluctuate greatly, with the result that several cycles of alternation occur in one season.

By and large, this indicator is important only in the case of moisture-containing concrete. If a dry mix was used, even a low index of frost resistance is not an obstacle to long service, while the expansion and contraction of water molecules in the so-called wet mixture can lead to severe damage to the concrete foundation after several cycles.

So, with high-quality waterproofing of the foundation, F150-F200 is the best indicator of frost resistance for it.

Water resistant

This indicator is characterized by the letter W. It is about how much water pressure a concrete block can withstand without passing water. If water is supplied without pressure, as a rule, all concrete structures are resistant to it.

By and large, when choosing a concrete for the foundation, this indicator is not so important. Where it is more important to pay attention to the brand of concrete that you choose. Indicator of water resistance inherent in a particular brand for the foundation, is enough.

But it is still best to show in the table how the indicators of strength are related to the water resistance and frost resistance of a particular brand.

Mark | Strength class | Water resistant | Frost resistance |

M250 | B20 | W4 | F100 |

M250 | B20 | W4 | F100 |

M350 | B25 | W8 | F200 |

M350 | B25 | W8 | F200 |

M350 | B25 | W8 | F200 |

From the table above you can find out everything you need. Please note that with the growth of the numerical index of the brand, other characteristics also improve.

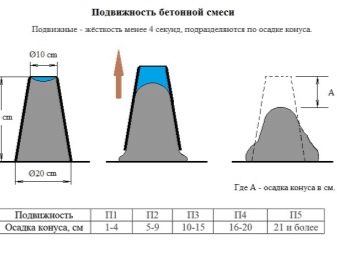

Workability

This indicator determines how comfortable it is to work with concrete, whether it can be used without mechanical means, manually poured.In the conditions of domestic construction, this parameter is more important than the others, since there is not always access to specialized equipment, and you have to be content with only a shovel and a drill with a special nozzle.

Workability determines the plasticity of concrete, its ability to quickly and evenly spread over the surface, as well as the setting time - hardening of the outer borders. It so happens that the concrete grasps very quickly, which is why there is no way to quickly fix irregularities or add a new mortar if the existing one is not enough. The plasticity index is characterized by the letter “P”.

Below are brief characteristics of each of the values.

Indicator | Characteristic |

P1 | Practically not used in private construction, since it is characterized by almost zero turnover. The texture resembles wet sand. |

P1 | Practically not used in private construction, since it is characterized by almost zero turnover. The texture resembles wet sand. |

P1 | Practically not used in private construction, since it is characterized by almost zero turnover. The texture resembles wet sand. |

P1 | Practically not used in private construction, since it is characterized by almost zero turnover. The texture resembles wet sand. |

A5 | It is not suitable for filling the foundation, as the solution turns out to be too liquid and mobile. |

Which one to choose?

First of all, you need to keep in mind that the brand of the chosen foundation must depend on three criteria: the type of the base, the material of the walls and the condition of the soil. Such a deliberate approach will help not only save on additives added to concrete, but also ensure the maximum service life of the base.

Keep in mind that in this case we are talking only about those concrete mixtures.which are ordered in finished form, since the preparation of your own solution is a difficult task, and it is not always possible to obtain the desired characteristics. On the contrary, in the case of the purchase version, all characteristics are guaranteed, and the overpayment is either minimal or not at all.

Among other things, it is recommended to pay close attention to the shelf life of the mixture and the conditions of its transportation and storage.

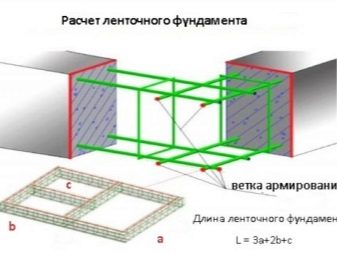

Base Type

In private construction most often used strip foundation.This is due to the simplicity of its construction and high performance in terms of reliability. Taking this into account, it makes sense to begin consideration of suitable options with this option.

For strip foundations, the spread of marks is large. The choice can vary from M200 to M450, depending on the flow of groundwater and the material from which the walls of the house will be made.

For the monolithic basement, most often selected for baths, sheds and other similar structures, concrete M350 and above will be needed.

For pile foundation, the indicator should be M200-M250. This is due to the fact that the design features of this type of foundation make it stronger than tape and monolithic.

Wall material and soil

So, if the groundwater occurs at a depth of more than 2 m, then the following brands will do:

Type of building | Brand of concrete |

light home | M200, M250 |

light home | M200, M250 |

two-story brick houses | M250, M300 |

two-story brick houses | M250, M300 |

It is necessary to make a reservation in advance that this is true only for strip foundations.

If the groundwater flows above 2 m, then the foundation brand should be no lower than M350. To summarize the data, the M350 is suitable for light buildings, the M400 is for single-story brick houses, the M450 is for two-and three-story brick private houses.Under the light houses are meant and wooden buildings.

Focusing on all the features inherent in your future home, you can easily determine which brand of cement for the base to use in your case.

Preparation of the solution

Before proceeding with the preparation of concrete mix, it is necessary to understand its components in more detail. The strength of the base, its resistance to stress, and its service life depend on the correct choice of its constituent components and their proportions. Since the foundation is literally the foundation of a house, any mistake can become fatal and lead to the fact that the house will not last for long.

First you need to make a reservation that all components must be of high quality. You should not replace any ingredient analogue, if you are not sure that it will not change the characteristics of the composition. For example, fine-grained fillers cannot be used in solutions intended for pouring in areas of shallow groundwater flow, since the permeability of such cement will be low.

Components

As mentioned above, the concrete for the foundation consists of three groups of components: binders, fillers and water.Non-cement concrete is not used to fill the foundations, so the only option for the binder in this case will be cement of different grades.

Cement

For adding to the concrete mix for the foundation is not suitable for any cement, but only a few types. This is due to the fact that some specific characteristics are needed.

It should also be borne in mind that concrete of concrete strength will require cement of a certain brand:

- for concrete, the compressive strength of which is in the framework of В3,5-В7,5, cement 300-400 is needed;

- if the compressive strength varies from B12.5 to B15, then cement brands 300, 400 or 500;

- for concrete of strength B20, cement brands 400, 500, 550 are needed;

- if the required strength of concrete is B22.5, then it is preferable to use cement grades 400, 500, 550 or 600;

- for concrete with strength of B25, 500, 550 and 600 brands of cement are suitable;

- if you need concrete strength of B30, then 500, 550 and 600 brands of cement will be required;

- for the strength of concrete B35, cement brands 500, 550 and 600 will be needed;

- For concrete strength B40, cement brands 550 or 600 are required.

Thus, the ratio of the grade of concrete to the grade of cement is determined.

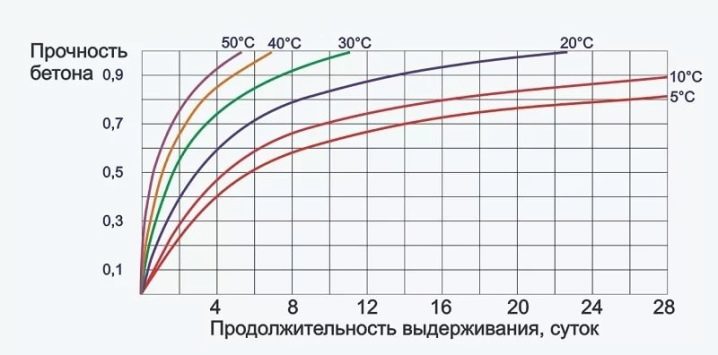

The second factor that needs attention is hardening time. It depends on the type of cement substance.

Portland cement - silicate based cement. It is characterized by a fast setting time, which, as a rule, does not exceed 3 hours after kneading. The end of the setting comes after 4-10 hours, depending on the selected species.

There are the following most common subtypes of portland cement:

- Quick hardening. Hardens 1-3 after kneading. Only suitable for mechanized pouring.

- Normally hardening. Setting time - 3-4 hours after kneading. Suitable for both manual fill and machine.

- Hydrophobic. It has increased resistance to moisture.

Depending on the needs and equipment available, one of the following options may be chosen. All of them are great for the foundation.

Slag Portland cement, in fact, in its characteristics is not much different from Portland cement. The only difference is in manufacturing technology. The setting time of slag Portland cement varies greatly depending on environmental conditions. After kneading, it can catch after 1 hour or after 6 hours. The warmer and drier the room, the sooner the solution will set.As a rule, such a cement is completely set after only 10-12 hours, so there is a time gap for eliminating flaws and flaws. Due to this, it is possible to use both a machine-based pouring method and manual. This type of cement is most preferred for use in conditions of high humidity. In addition, it can withstand temperatures up to 600 degrees.

Pozzolanic portland cement is suitable for use only in high-humidity conditions, since outdoors concrete based on pozzolanic portland cement will quickly dry out and lose its former strength. Also in the air such a concrete base will give a strong shrinkage. In cases when for some reason it is not possible to use cement of another type, it is recommended to constantly moisten the concrete foundation.

The advantage of pozzolanic portland cement is that it does not set as fast as other species, therefore, there is more time for leveling and deep vibrating. In addition, when using cement of this type, it is possible to carry out work on concreting even in the winter period.

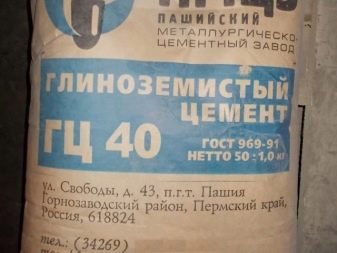

Alumina cement quickly hardens, so it is necessary when you need to quickly build a foundationwhile there is no time for its freezing. He grabs in an hour, while the maximum setting time under adverse conditions is 8 hours.

Remarkably, this type of cement seizes well with metal fittings. Due to this, high strength of the concrete foundation is achieved. In this case, the base is more dense than in all other cases. Foundations with the addition of high alumina cement can withstand strong water pressure.

Sand

Not every sand is suitable for filling concrete. For foundations, coarse and medium sand are most often used with sand grains of 3.5-2.4 mm and 2.5-1.9 mm, respectively. However, in some cases, small fractions with the size of sand grains 2.0-2.5 mm can be used. Grains are less used in the construction of foundations.

It is important that the sand is clean and does not contain any impurities. River sand is suitable for this. The amount of foreign substances should be no more than 5%, otherwise such raw materials can not be considered suitable for construction work.When self-extracting sand, take care to check it for the presence of impurities. If necessary, clean the mined sand.

Keep in mind that the easiest way is to purchase already cleaned sand. In this case, you will have no further problems: you minimize the risk that the concrete base will lose strength due to the particles of silt or clay contained in the sand.

To check the purity of the sand, you need to conduct the following experiment. Approximately 11 tablespoons of sand should be poured into a regular plastic half-liter bottle and filled with water. After that, after a minute and a half, the water must be drained, pour fresh water, shake the bottle, wait a minute and a half again and drain the water. This should be repeated until the water is clear. After this, it is necessary to estimate how much sand remains: if at least 10 tablespoons, then the contamination of the sand does not exceed 5%.

Rubble and gravel

Crushed stone can be of several fractions, ranging from small to large. To increase the strength of concrete, add several fractions of rubble. It is important that crushed stone or gravel is used no more than a third of the total concrete mix.

It is also necessary to pay attention to the large fraction rubble used for concrete under the foundation. It should be no more than the third part of the smallest size of the structure. In the case of a base, reinforcement rods are taken as the unit of comparison.

Keep in mind that the use of rubble or gravel affects only the ratio of water and dry mix. When working with gravel will require 5% more water than when using gravel.

With regard to water, then for the manufacture of concrete solution is suitable only one that is suitable for drinking. Moreover, even the water that can be drunk after boiling can be used. Do not use process water. Seawater can only be used with alumina cement or portland cement.

Proportions

To get concrete of a certain brand, you need to choose the right components in the right proportion. The table below illustrates the ratio of ingredients that are suitable for concrete mixes for the foundation.

Brand of concrete | Brand of cement | The ratio of ingredients in the dry mix (cement; sand; crushed stone) | Volumes of ingredients in dry mix (cement; sand; crushed stone) | The amount of concrete produced from 10 liters of cement |

250 | 400 | 1,0; 2,1; 3,9 | 10; 19; 34 | 43 |

500 | 1,0; 2,6; 4,5 | 10; 24; 39 | 50 | |

300 | 400 | 1,0; 1,9; 3.7 | 10; 17; 32 | 41 |

500 | 1,0; 2,4; 4,3 | 10; 22; 37 | 47 | |

400 | 400 | 1,0; 1,2; 2,7 | 10: 11; 24 | 31 |

500 | 1,0: 1,6: 3,2 | 10; 14; 28 | 36 |

So, you can get the same brand of concrete, using different brands of cement and changing the proportions of sand and rubble in the composition.

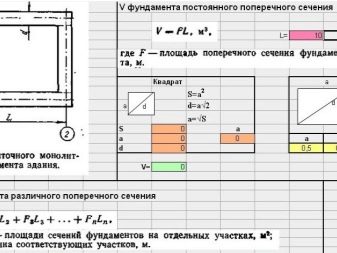

Consumption

The amount of concrete that may be required for the foundation depends primarily on the specifics of the house. For example, if we are talking about the popular tape foundation, then you need to take into account the depth and thickness of the tape. For the pile foundation, you need to think about the depth and diameter of the piles. Monolithic foundation requires consideration of the dimensions of the plate.

For example, calculate the amount of concrete for the strip foundation. Take the tape, the total length of which is 30 m, width - 0.4 m, and depth - 1.9 m. From the school course it is known that the volume is equal to the product of width, length and height (in our case, depth). Thus, 30x0.4x1.9 = 22.8 cu. m. Rounding up in a big way, we get 23 cu. m

Professional Tips

It is important to take into account several observations of professionals, which will help with the choice or preparation of concrete mix:

- At high temperatures, proper curing of the concrete may be at risk. It is necessary to sprinkle it with sawdust, which will need to be moistened from time to time.Then there will be no cracks in the foundation.

- Whenever possible the tape base should be filled in one run, but not in several. Then its maximum strength and uniformity will be guaranteed.

- Never neglect the waterproofing of the foundation. If this procedure is not carried out properly, the concrete may lose some of its strength characteristics.

To learn how to prepare concrete for pouring the foundation, see below.