What is cement made of?

The word cement is familiar to everyone. Even those who have never been involved in construction know that cement is needed for mortar for masonry, that it is the main component of reinforced concrete products. However, few people know what cement is made of.

Special features

Cement is ubiquitous. It is used not only in the construction of various buildings. Without it, it is impossible to do during the restoration and repair work. There is no substitute for cement yet. This justifies its demand.

The basis of the building material are knitting inorganic components. Cement is needed in the production of panel plates. From it do plaster and masonry solutions. In the composition of concrete cement is given one of the main places.

In essence, cement is a fine powder. The main feature of the powder mass is that, when interacting with water, it gradually begins to harden. The process of interaction between the two components (cement and water) is completed by the formation of a solid array, similar in hardness to natural stone.

Durable structure is formed with excessive moisture. There is a reaction both in the open air and in the water. Cement after hardening retains strength for a long time.

Properties

The physical characteristics of the cement depend on several factors.

The most significant are:

- types of additives;

- degree of grinding;

- composition.

Grinding cement affects the strength and time required for hardening. Fine grinding provides greater strength and faster hardening.

The smaller the particles of the powder, the stronger the concrete turns out, the faster it sets. The cost of the material also depends on the degree of grinding.

To determine the fineness of grinding using a special sieve with the smallest cells up to 80 microns. When preparing a mortar from too finely ground cement, more water is required.This disadvantage is eliminated by mixing particles of different sizes: large and small. Large particles of dust are 80 microns, and small - 40 microns.

Cement has the following properties:

- strength;

- corrosion resistance;

- frost resistance;

- water demand;

- setting time (freezing).

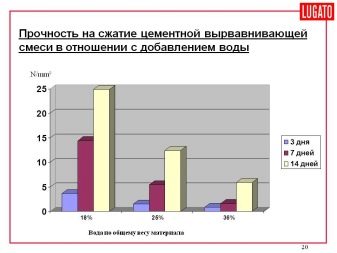

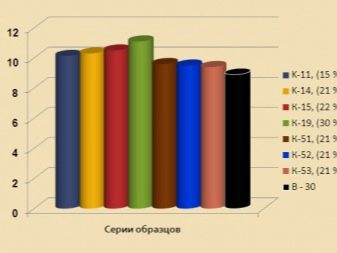

Strength

This indicator depends on the brand. Determine the strength properties by conducting compression tests. Experienced disc is kept under load for the lunar month - 28 days. After testing the sample cement is assigned the appropriate designation. Measured strength in MPa.

Cement grades 300 - 600 are suitable for domestic use. For products that require special strength, higher grades are used - 700 or even 1000.

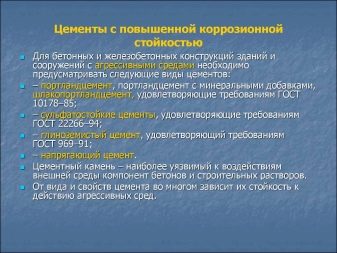

Corrosion resistance

Reinforced concrete products under the influence of water and other liquid media begin to corrode. Negative impact is eliminated in several ways. For example, you can change the composition, enter into the powder mixture hydroactive materials. The presence of specific substances prevents the occurrence of harmful chemical reactions.

Corrosion resistance increases with the use of polymer additives. As a result, microporosity decreases, product durability increases.

Pozzolan cement has the highest corrosion protection. Therefore, it is used for the construction of facilities operated in conditions of high humidity.

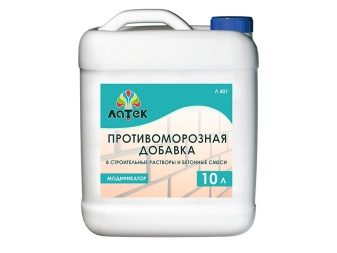

Frost resistance

One of the main indicators of quality cements is the ability to repeatedly freeze and thaw a concrete product.

In the cement stone there are micropores in which there is water. When freezing water may increase in volume by 8%.

Repeated freezing and subsequent defrosting over the years leads to the destruction of the stone structure, to the appearance of cracks.

In construction, cement without additives is not used. Components are added to different brands, giving cement the ability to resist temperature changes.

In the process of making concrete, airborne additives are included. The smallest air bubbles are distributed evenly inside the concrete body, thus solving the problem associated with the freezing of water and its expansion.

Water demand

This is a percentage of the amount of water that is required to obtain a cement mortar of optimum consistency.

In a solution of nominal water density as much as the cement can hold. For example, in Portland cement, this value is in the range of 22-28 percent.

From cement with a low water demand, concrete is obtained better, than from the fact that this indicator is high. In the first case, the products are resistant to temperature differences. In the second - concrete has a high porosity and is not suitable for construction at all. Such cement is used to produce reinforced concrete fences or drainage facilities.

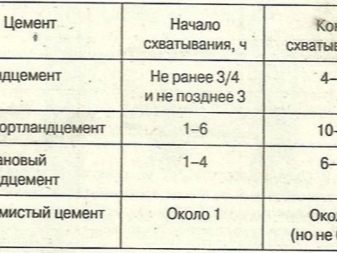

Setting time

This is the time period attributable to the change in the physical properties of the cement mortar from the state of plasticity to the formation of a stone.

The ideal solution is considered to solidify not too quickly, but not very slowly. The setting time is governed by the presence of a certain amount of gypsum in the composition of the material. A larger volume of gypsum provides high-speed setting. While the decrease in its content contributes to a longer solidification of the solution.

Not as dramatically as plaster, affect the setting and other factors.In particular, the volume of water in the solution and the ambient air temperature in the working area are important.

According to the standard in normal conditions, Portland cement begins to set after three quarters of an hour. The curing process should end in 10 hours.

Composition

Make cement at the specialized enterprises. Cement plants are built in close proximity to the sites for the extraction of raw materials.

Raw materials for its production are obtained from natural rocks:

- carbonate type fossil;

- clay materials.

Carbonates have an amorphous or crystalline structure, on which the efficiency of interaction of the material with other components in the firing process depends.

Carbonate rocks include:

- a piece of chalk;

- marl (marl limestone);

- limestone, including shell rock;

- Dolomite type rocks.

Clay materials are sedimentary rocks. Having a mineral base, they are endowed with plasticity, and with excessive moisture can increase in volume. Clay materials are used in the dry method of manufacture.

Clay rocks include:

- clay;

- loam;

- clay shale;

- loess.

In addition to raw materials, in the production of cement use corrective additives.

They are derived from minerals, which include:

- apatite;

- alumina;

- fluorspar;

- silica.

The additives introduced by a certain technology improve the quality of the described material.

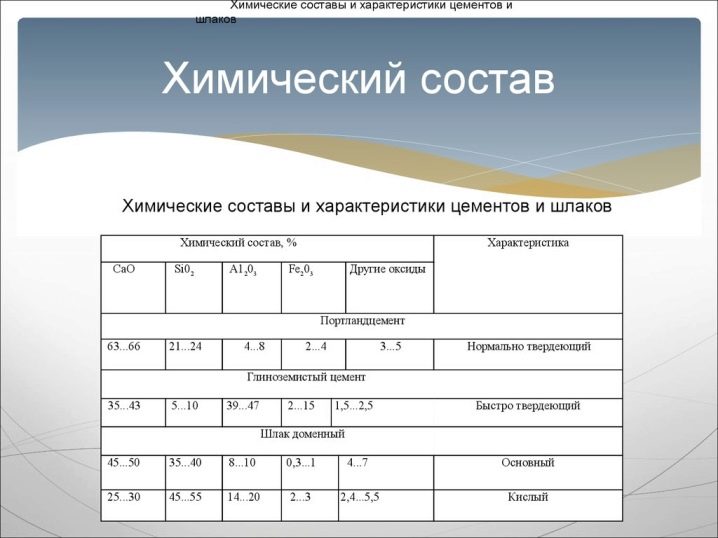

The composition of the cement depends on the required characteristics, which are determined by the grade assigned to the material.

The most popular portland cement consists of:

- 60% lime;

- 25% silicon dioxide;

- 10% iron and gypsum oxides;

- 5% aluminum (alumina).

In various grades, the percentage of raw materials is different, as is the composition. For example, slag Portland cement incorporates slag. Quantitative proportions may vary with the characteristics of the selected technology of manufacturing a building material.

For any brand of cement and for any method of its production, limestone and clay remain unchanged components. Moreover, limestone is always three times more clay. This ratio contributes to obtaining high-quality clinker, from which they make cement.

In industry for the production of cement use the following components:

- clinker;

- gypsum;

- special supplements.

Clinker is the most significant component of cement. It determines the strength properties of the final material. Clinker enters the production process in the form of granules. The diameter of the granules varies in the range of 10-60 mm. Heat treatment component is made at a temperature of about one and a half thousand degrees.

The amount of gypsum is determined by the established period of hardening. In the base case, gypsum in powder form is included in the cement in a volume of 6%.

Additives allow you to enhance specific characteristics. With their help, cement receives additional properties, which significantly expands its capabilities.

Production stages of cement manufacturing

First, limestone is mixed with clay at a ratio of 3/1. The mixture is then fired at high temperature. The result is a raw material for cement production. It is called clinker. Granulated clinker is sent for grinding in ball mills.

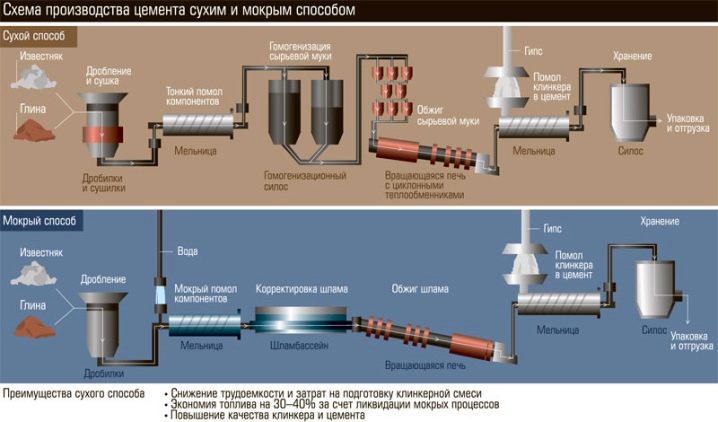

There are three ways to produce cement.

Depending on the manufacturing technology, it can be:

- wet;

- dry;

- combined.

The differences are in the methods of preparing the raw materials.

In accordance with wet technology, chalk is not used, but chalk. It is mixed with clay and other ingredients with the addition of water. The result is a mixture of humidity from 30 to 50 percent. The mixture is converted into clinker balls during firing.

According to the dry technology, the manufacturing process is shortened, since two operations (drying and grinding) are combined into one. The resulting mixture becomes powder.

Different enterprises use the combined method in different ways. In some cases, first get a dry mixture, and then moisturize it. In others, the wet and semi-dry method is used, with low humidity not exceeding 18%. Firing is performed in both cases.

Kinds

There are many different variations of cement. The most famous is Portland cement.

Other material options are quite popular:

- slag;

- pozzolanic;

- aluminous;

- expanding.

Portland cement is available in several grades: 400, 500, 550, 600. Construction mortars are made from M400 cement.

Higher brands are in demand in the manufacture of reinforced concrete structures, as well as in the creation of high-strength concrete products.

White Portland cement is characterized by fine grinding.The composition includes low-iron clinker, gypsum and dolomite additives. Differs in the high durability and resistance to an atmospheric precipitation. Products from white portland cement have an aesthetic appearance. Used in the manufacture of self-leveling floors, decorative elements, as well as in the construction of roads. It is the basis for colored cements.

Sulfate-resistant Portland cement is used in the manufacture of piles., supports for bridges, hydraulic structures, wherever there is repeated moistening and drying of structures, where structures are exposed to freezing and thawing.

The main purpose of slag cements - the creation of concrete products for structures located under the ground and under water.

Pozzolanic cements are needed in the construction of dams, river hydraulic structures, various underground utilities, as they are endowed with resistance to fresh water.

Alumina is not afraid of sea water, so they are part of reinforced concrete products in contact with saline water. Can be used for urgent tamping of wells, including oil; when concreting in winter; for fixing cracks in rocks.

The beauty of expanding cements is that they do not shrink during setting, but, on the contrary, expand in volume. The increase in volume - from 0.2 to 2 percent.

How to make yourself?

Cement can be prepared at home if it is possible to achieve a high firing temperature. Perhaps the most that can turn out to be an artisanal method is M-200 cement. It will require chalk and kaolin in a ratio of 3 to 1. About 5% of gypsum powder must be added to the calcined and crushed substance - and the cement is ready.

For home production will require appropriate knowledge, suitable raw materials, special equipment and the exact implementation of the process.

Even when everything is available, it is hardly worthwhile to engage in the production of cement on its own. Before you get started, answer the question about the feasibility of the process. It is unlikely that your work and the costs incurred will pay off. Most likely, it is more profitable just to buy a bag of ready-made cement.

Tips

Choosing cement for certain needs, remember that there are many varieties. The right choice at the initial stage of the work will give a guarantee of the durability of the building.You should not always give the choice to higher and more expensive brands. The strength of the product from this will not increase, and the costs will not be justified.

The process of obtaining cement, see the video below.