Cement-lime mortar: proportions and characteristics of brands

Over the past decades, the use in the construction and finishing of cement-lime mixtures has remained at the same level. But this is not due to the lack of new materials and technologies, but only because this composition meets all modern requirements for building materials. Cement-lime mortar remains relevant and in demand.

Main advantages

Cement-lime mortar is a durable and plastic material that is excellent as a binder in construction and for finishing works.

- It can be used as a masonry mortar or plaster material. In the form of masonry mix, it securely connects the blocks or bricks used in construction.As plaster it can be applied to internal and external finishing works.

- It is great for pouring monolithic floors, due to its characteristics. The lime which is a part of solution increases its term of hardening. Increasing the time of hardening and the viscosity of the composition help to avoid the formation of cracks and help to distribute the putty more evenly over the surface.

Penetrating power

Cement mortar with lime has a high degree of adhesion to the surface. It is able to easily fill small cracks and grooves, which increases the adhesion strength with any materials on which it is applied.

This solution is characterized by a high degree of adhesion, so it can be used even when working with wood. Plaster on shingles (wooden crate) is made with just such a solution.

Increased characteristics of strength, elasticity and moisture resistance make it possible to use the mixture for any finishing work. indoors even with high humidity, since dampness and precipitation do not destroy the finished coating.The solution can be used, for example, for finishing work in bathrooms, on facades or on the foundation, even in the part where it is directly adjacent to the blind area and, as a result, is exposed to moisture.

Specifications

The composition of such a solution necessarily includes cement, sand, slaked lime and water. It is worth paying attention to the fact that you need to add hydrated lime. Otherwise, the quenching reaction will begin in the solution itself when water is added, and the bubbles, already formed inside the solution, will lead to cracking of the plastered surface. This process of formation of bubbles will lead to a deterioration in the quality of the solution and to brittleness after it dries.

Due to the lime material that is part of it, pathogenic bacteria and fungi do not develop on it, besides, lime prevents the penetration of rodents and various pests into the dwelling.

Building mixtures, their composition and properties are governed by various state standards. It is necessary for standardization and regulation of norms in construction. GOST 28013-98 is the main regulatory legal act regulating the technical requirements for mortars and materials included in the composition.

This standard also includes the characteristics of quality indicators, the rules of acceptance and the conditions of transportation of finished solutions. It contains qualitative and quantitative characteristics of masonry mortars, materials for plastering and for interior work, used in various operating conditions.

Properties

The main properties of cement-lime mortars:

- mobility;

- the ability of the solution to retain water should be 90%;

- stratification of the prepared mixture should be up to 10%;

- application temperature up to 0 degrees;

- average density;

- humidity (this parameter applies only to dry mortar mixes).

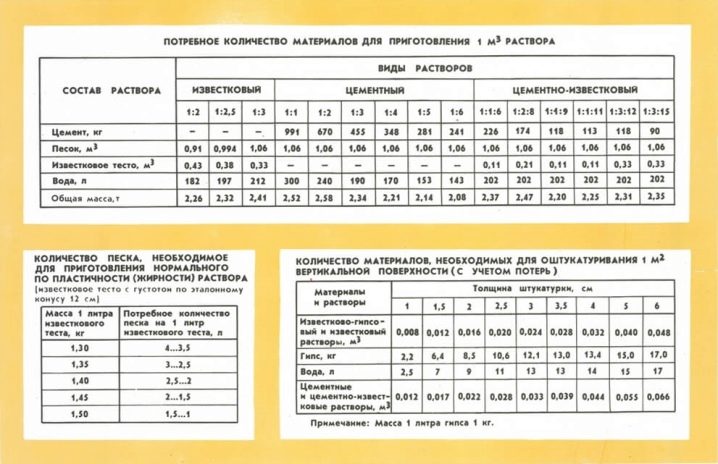

The composition of the mixture is selected depending on the type of material to which it will be applied, and on the conditions of further use of the finished coating.

There is such a thing as the fat content of the finished mixture. Fat content depends on the amount of binder that is included.

Cement-lime solutions are divided into three categories of fat.

- Normal - it is solutions with such plasticity, which is most universally suitable for use in various conditions.For solutions with such fat content, there is no shrinkage and, as a result, cracking of the finished coating.

- Skinny - These are solutions with minimal shrinkage. They are ideal for tiling.

- Fatty - It is a mixture with a high degree of plasticity, which is caused by a large number of binders that make up. Such material is best used for masonry work.

The category of fat content can be adjusted by adding components that can change the plasticity of the solution. For example, porous sand reduces fat content, and lime, on the contrary, can increase it.

Thus, it is possible to easily correct the plasticity of the finished solution and adjust its properties to specific operating conditions.

Density and marks

The components of the cement-lime mortar have a direct impact on its density. Also important is the ratio of these components.

As a result, the following types of solutions can be distinguished:

- low density or light - up to 1500 kg / m³;

- high density or heavy - from 1500 kg / m³.

Also solutions according to the ratio of components are divided into brands from M4 to M200 according to GOST 28013-98. For example, for laying the best fit solutions brands M100 and M75. They are characterized by high moisture resistance and strength. The components that make up these materials are more homogeneous, since, unlike concrete of similar grades, crushed stone is not included in them.

Ready-made solution of mark 100 or mark 75 is suitable for the construction of civil and industrial facilities. For the preparation of solutions of these grades it is necessary to mix cement, lime and sand in a certain proportion. So, for mortar M100 when using cement grade 500, the proportion will be 1: 0.5: 5.5. And for the M75 solution using the same cement grade, the proportions will already be different - 1: 0.8: 7.

For plastering, M50 and M25 solutions are very popular. They have such indisputable advantages as low cost and ease of preparation.

Solutions of mark 50 and mark 25 can be used at a humidity in the room above 75%. This allows you to use them in the construction of baths and other rooms where high humidity persists for a long time.Also, lime, which is part of the composition, prevents the formation of any type of fungus on the plastered surface, which, of course, is an advantage of such a coating.

Diversity

Plaster mixes can be divided into several types.

- Basic - used for the initial, rough alignment of the surface and seal large flaws and holes;

- Decorative - such variants may include decorative additives, such as pigment for coloring, crushed mica to create a flickering effect, plasticizing and hydrophobic additives;

- Special - used to improve the technical properties of the treated premises, they can serve for moisture-proof, sound-proof and heat-insulating tasks.

Dry mix or hand-made composition?

The undeniable advantage of this material is its cost. It is significantly cheaper than the similar application of cement-sand mortar. The benefit is caused by economical consumption when applied to different surfaces in comparison with the analogue. Sandy solution is less plastic due to the scattered fraction of sand and the absence of plasticizer.It has less adhesion and is less distributed over the surface.

Cement-lime mortar can be purchased as a dry mix. from various manufacturers, and you can make yourself. Now presents a wide range of manufacturers of ready-made mixtures with their own characteristics and applications.

Special attention should be paid to the labeling on the packaging in order to find the optimal mixture suitable for the type of work you need.

To use this mixture, add water in accordance with the instructions on the packaging, mix thoroughly to acquire a uniform texture. For these purposes, you can use the construction mixer or in the old-fashioned way to knead the composition with a trowel and shovel.

In that case, if you decide to make the mixture yourself, then it is quite easy to do. It is enough to purchase all the necessary ingredients (cement, lime, sand) and mix them in the proportion of the corresponding brand that you want to get.

In the manufacture of cement-lime mortar, you must add hydrated lime, but if you only have quicklime, you can independently extinguish it.

Method of slaking lime

This procedure should be carried out in compliance with safety regulations, wearing gloves, goggles and a mask.

- In the metal dish in which you plan to extinguish the lime, quick lime and water are placed in a ratio of 1: 1, in that order.

- After the end of boiling of the mixture, which is accompanied by a vigorous quenching reaction, it is necessary to add more water so that it completely covers the material.

- The contents of the container are mixed and covered with a lid.

- Capacity with lime should be left alone for 14 days. The process of cooking slaked lime is not so much time consuming as long.

Make a choice in favor of the purchase of the finished mixture or the preparation of the solution is up to you. But when making this or that decision, it is better to weigh the pros and cons of such an act in advance, because the manufacturers have done most of the work, and all you have to do is close the solution.

Subtleties of preparation of the solution, see the following video.