Features of the use of cement-sand mortars

Cement-sand mortar is rightly recognized as one of the most popular and sought-after formulations for construction and repair. They are very often used for different jobs, and this can be not only residential, but also industrial premises. Such solutions are considered easy to use, so they can be safely purchased even by inexperienced home craftsmen. Today we will consider in detail the features of the use of cement-sand mixtures.

Special features

High-quality cement-sand mixtures are unlikely to ever lose their popularity.Such compositions are distinguished by increased reliability and durability, which makes them relevant and relevant.

Cement-sand mixture is a special tool that has a special composition of the components combined in the correct ratio. Each element corresponds to certain parameters.

It is not so difficult to guess what these compositions are. It is enough to pay attention to their name. In the composition of such mixtures present fractional sand and cement. Often, these components are complemented by various additives that have different effects. The choice of a suitable solution depends on the purpose of its use.

Another feature of such solutions is that they can not be used independently. As a rule, they play the role of the main component in various mixtures. Using a qualitative composition, you can achieve the highest quality and aesthetic result of the work.

In addition, cement-sand mixtures are distinguished by the fact that they can be used for both internal and external works. They are also used in the manufacture of reliable reinforced concrete walls for different reservoirs and wastes.

Cement based mortars have their strengths and weaknesses. First of all, you should familiarize yourself with the advantages of such compositions:

- In the shops you can meet a lot of options for cement-sand mixtures, which include additional components. Such elements make the compositions more qualitative and reliable.

- A quality mixture with a suitable composition will not suffer from temperature fluctuations or frost.

- The choice of such mixtures is very large. Modern consumers can choose the most simple to use composition, for which you do not need to accurately calculate the number of all components. It is enough to fill in ready mixes with water and to mix well.

- Such mixtures are reliable and durable. That is why they are used in the decoration of facades of buildings.

- Cement-sand compositions are not afraid of high levels of humidity.

- Such materials can boast a long service life. Even being on the facade of a building, they can serve at least 15 years.

- Cement-sand mixtures have high adhesion with a variety of bases. They can be safely used in the design of concrete, brick, stone and block surfaces.

Ideal building and finishing materials do not exist. Cement-sand mortars are no exception. They have several minor flaws:

- Ready mixes are more expensive than the individual components that are in their composition.

- If you have prepared a solution, then it cannot be stored for a long time. It is necessary to part structure in that quantity what you will need for carrying out these or other works.

- Self-preparation of the mixture, of course, is cheaper, but more time-consuming. In addition, you will need to carefully consider the proportions of the necessary components in order for the solution to be of high quality and effective.

- In most cases, such compounds poorly adhere to wooden or painted bases.

- It is also not recommended to apply cement-sand mixture on gypsum. Too dense and heavy layer can damage the base or even tear it off.

- It is very difficult to work with heavier and viscous compositions. They are hard to level.

As you can see, there are no serious drawbacks in cement-sand mortars. To avoid many problemsIt is quite sufficient to competently treat the process of mixing the solution. Then it will turn out qualitative and it will be easy to work with it.

Specifications

Let us consider in detail what technical characteristics modern cement-sand mixtures have in accordance with GOST.

Density

The thermal conductivity and strength of the cement-sand layer largely depend on the level of its density. In pure form (without additional components), such solutions are rather heavy. They are distinguished by high density, which constitutes 1600-1800 kg / m 3 in solid state.

Cement-sand coatings are usually quite durable. Layers with high density are ideal not only for internal and external decoration, but also in the formation of sexual screed.

Heat conduction properties

Due to the high density thermal conductivity of such finishing materials is very high. In a room with such a design, a comfortable temperature and sufficient heat will always be maintained. A similar effect cannot be achieved with a lighter gypsum having a porous structure.

The coefficient of thermal conductivity of cement-sand mixtures is 0.3 watts. If we are talking about non-shrink plaster with a similar base, then its heat-conducting level is most often equal to 0.9 watts.

Vapor permeability

This characteristic is very important for any finishing material. Without it, condensation and excessive dampness will accumulate in the room. Over time, this will lead to the formation of mold and mildew.

In cement mortars, the vapor permeability parameter is 0.09 mg / mchPa.

Drying time

The drying time of the cement coating is directly dependent on the layer thickness. Thus, under conditions of temperature from +15 to -25, a layer of 2 cm will dry for 12-14 hours. The thicker the layer of the applied solution, the longer it will harden. Experts recommend not to touch the finished surface for another day after all the work. Of course, this rule is not categorical, but so you can avoid damage to the freshly applied layer of cement.

Species

There are several types of mixtures with a cement base. They are often found in specialized stores, but not every buyer knows how they differ from each other.

M100

This composition is used for the manufacture of plastering materials. In such a cement-sand mixture are present not only the main components, but also lime. Because of it, the proportion of cement decreases markedly.

The M1000 is relatively inexpensive. It is used not only in the preparation of high-quality plaster, but also for leveling certain surfaces and eliminating various defects. These can be cracks, noticeable drops, gouges or ugly cracks.

M150

Cement-sand mixture of this brand belongs to the universal. It is used for the preparation of plaster and masonry compositions.

The mixture marked M150 can be accessed in the case of the formation of a reliable screed. It is often used in various repair works.

Cement-sand mixture in everyday life can be replaced by almost any composition. The main thing is to determine in advance what properties the solution should possess. Often in a similar product add various components that make it stronger and more durable. It is also worth noting that the cement mixture M150 distinguishes democratic cost.

The main characteristics of such a cement-sand mortar include:

- recommended layer thickness from 5 to 50 mm;

- consumption per square meter - about 16.5 kg;

- the setting time of the composition is only 2 hours, and it will take 24 hours to fully cure.

The stores sell ready masonry mortars M150. If you plan to purchase such a mixture, then you need to pay attention to what additional components are present in its composition.

M2000

Such compositions with a cement base are often called assembly and masonry. They are available in different versions.

Each of the varieties of mixtures M200 is designed for a particular application:

- the manufacture of plaster;

- preparation of masonry mortar;

- manufacture of screed or foundation.

A layer of such a cement-sand mixture is sufficiently dense and reliable. The approximate consumption of such a composition is 7.5-8.5 kg per square meter. m (with a layer thickness of 5 mm).

M300

In everyday life such popular mixtures are called sand concrete or base compound. Such products are more expensive than all those listed, and the scope of their use is not as wide as, for example, the options with the marking M150.

Compounds M300 are used in cases where a mixture of increased strength is needed.Experts recommend to acquire such solutions when installing large installation structures or massive screeds. But as for the preparation of plasters, this mixture is absolutely not suitable.

Scope of application

Currently, cement mixes are very popular. Many repair and finishing works are not complete without them. For example, it can be plaster trim, brick cladding, cinder block or aerated concrete masonry, as well as a floor screed. The ratio of all the necessary components that are present in the content of the solution depends directly on the permitted scope of its use indicated on the original packaging, as well as the brand and strength properties of the material.

Most often, such compositions are used during interior decoration. In such mixtures there is a small amount of cement. In addition, in solutions for interior decoration there is lime. For such cement-sand compositions, very fine sand with a uniform structure is selected.

Universal compositions can be safely used for laying, and for interior and facade finishing works.In such mixtures there is an average content of such a component as cement. Often, universal solutions are supplemented with different plasticizers.

As for masonry mortars, they are used in the construction of mid-rise brick buildings, in preparing the floor screed and for facade finishing works. In these mixtures, as a rule, there is a high content of cement, as well as hydrophobic, frost-resistant and anti-shrinking substances.

Currently, there are more reliable mixture (M400, M500, M600)which are used in the construction of multi-storey buildings. In such solutions, high cement content, as well as reinforcing fiber and plasticizers.

Most formulations are often used for the construction of sexual screeds. More durable and reliable materials with high markings can be used to prepare a coating that does not require further finishing.

Cement-sand mixtures are ideal for optimal leveling of the floor or walls. With their help, you can eliminate many defects of such bases, which is especially important if you plan to lay tiles or glue paper wallpaper on them.

How to cook?

It is quite possible to make a cement-sand mixture on your own. To do this, you should adhere to the correct proportions and not waste time in vain, so that the composition does not begin to dry. Consider several options for the preparation of such a solution.

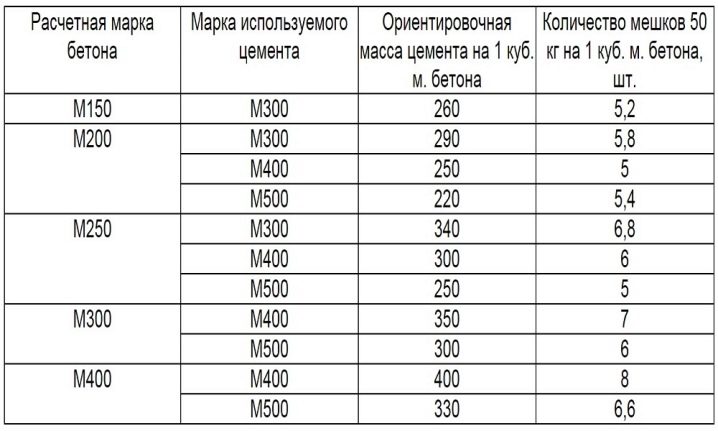

For screed

For such works, cement with marking M400 or M500 is most often used. If you choose brand 400, then you need to stick to the ratio of 1 to 2, and in the case of the M500 - 1 to 3.

To prevent cracks and other similar damages from appearing on the hardened coating, fiber should be added at the rate of 0.7-0.9 kg per m3.

For masonry

In this case, the quality of the finish determines the thickness of the seam. Much depends on how the sand was prepared. It must be carefully sieved and dried. As a rule, 3-5 parts of bulk material are taken for one part of the cement component.

Experts recommend to make masonry mixes in moderation. To begin with, you should check the quality of the resulting composition on a separate surface, after which it will be much easier to calculate the proportion of the binding components and the sand itself. At this point, it becomes clear and approximate consumption of cement-sand mixture for laying. Due to such actions, significant material waste can be avoided.

For plaster

The preparation of such formulations is quite simple. In this case, you need to knead all the components in a ratio of 1 to 3.

Preparation of a high-quality and durable solution depends not only on well-chosen components, but also on thorough mixing. Manual method of the desired effect is almost impossible to achieve, even if you apply the finished composition.

To accurately mix the mortar, you can use special nozzles for rotary hammers or electric drills. Such devices are found in many stores and are distinguished by affordable prices.

Supplements

In the cement mixtures are often added useful components that improve their performance.

The function of additional components is performed by the following elements:

- Slaked lime. Water is added to this component. Depending on its volume, the desired state of lime is formed. This may be a powder or lime water. Damping must be done a couple of weeks before direct repairs.

- PVA glue. This simple, but useful component is necessary to provide additional adhesion of the composition.Thanks to him, the cement-sand mortar will better adhere to one or another base. In addition, the glue will give the mixture additional plasticity, so it will be much easier to work with it. Such additives are especially relevant when it comes to plastering walls.

- Dishwashing liquid / liquid soap. These components can be used to make the finishing material of high plasticity. They need to be added immediately after the water in the amount of 50-100 g. If you overdo it with these components, the mixture will be foamed - soap bubbles provoke this effect.

- Graphite / carbon black. These components are used to impart color to the solution.

How to calculate the required amount?

It is recommended to proceed directly to construction and finishing works only after a competent calculation of the required amount of cement-sand material.

It is necessary to calculate the volume of cement mortar, and then multiply them by the cost values (by 1 meter in a cube) indicated in the description of the mixture purchased. Most often, these parameters are indicated in the form of "consumption per m2." In this case, a layer with a thickness of 1 cm is meant.To find out what the material costs per m3 will be, you just need to multiply the resulting value by 100.

The most common flow rates are:

- for compounds of high grade - up to 2200 kg per m3 (in this case it is meant a layer of material of 1 cm);

- for light plasters with lime in its composition - 1200-1600 kg per cubic meter.

As for the calculation of the consumption of the mixture for plastering or screed, there is nothing difficult. But the calculation of the mortar, in the first place, depends on the experience of the master. If you strictly adhere to the appropriate technology, then the consumption of cement-sand mixture will be about 25% of the total volume of the wall. However, there are cases when this figure is 35%, if you really try. This economical effect can be achieved if you make thick enough seams and avoid splashes.

Setting time

Typically, the setting time of cement-sand mixtures is about 1-1.5 hours. This indicator, first of all, depends on the water content in the solution. Based on the setting time, experts advise to prepare the composition in small portions.

Manufacturers

Currently, the range of quality and durable cement-based mortars is greater than ever. Of the large number of different manufacturers should be the most popular and sought after.

"Monolith"

This major manufacturer specializes in the production and sale of cement-sand mixtures in Kirov. The range of "Monolith" is represented by high-quality and reliable compositions of class M150, which are ideally suited for plastering various bases, sealing seams, as well as masonry work inside and outside buildings.

The manufacturer also offers durable formulations of class M300, which can be used in the manufacture of high-strength concrete structures.

Knauf

This well-known and large brand produces high-quality cement and plaster mixes, represented by the Grünband, Diamant, Zokelputs, Sievener, Unterputts, Adhesive lines.

This product boasts excellent thermal insulation properties. It can be used for both interior and exterior decorating. Most Knauf cement formulations contain additional components that enhance their positive qualities.

"Real"

This is another well-known manufacturer that produces high-quality cement mixtures of class M100 (200), M150 and M75. The range of the company "Real" allows consumers to choose the best option for a variety of repair and finishing works.

Dry mixes "Real" are complemented by components that provide frost resistance, so they can be used not only for interior but also for exterior decoration.

Dauer

The German company Dauer offers consumers a choice of high-quality and inexpensive cement-sand mixtures for the preparation of screeds, facade and interior decoration, as well as for the installation of bricks or blocks.

Dauer dry mixes are popular because of their low consumption. Together with the democratic price, this quality makes such finishing materials most profitable from an economic point of view.

BaltPiterStroy

This is another major Russian manufacturer that produces cement-sand mortars of all known brands. In addition, there are other popular products in the assortment of this company, for example, crushed stone, sand, gravel, rubble stone, bag cement, and even anti-icing agents.

"Stroyservice-Novablock"

The assortment of this popular manufacturer is represented by dry construction mixtures “Novanlock”, which were previously called “Plita Milks”, as well as cement-sand compositions. In addition, the company offers high-strength sand and gravel mix with marking M300.

The unsurpassed quality of Stroyservice-Novablock products is due to industrial scale production using modern factory equipment.

"Adamant SPB"

By LLC "Adamant SPB" is the plant with the memorable name "Young drummer". It offers the widest range of high-quality concrete, reinforced concrete structures, cement, sand and rubble.

As for the cement-sand mixtures of this manufacturer, they are represented by all possible brands, from simple and inexpensive M100 to high-strength M400.

Tips

Cement-sand mixtures for many years are the most common and popular materials used in the repair and finishing works.

When leveling walls with cement-sand composition, be sure to use beacons. Without them, the work will be more laborious, and the result may not suit you.

When purchasing cement mortar, pay attention to the time of its manufacture. Cement can be stored for 6 months in a dry place. If the humidity in the room was increased, then the quality of the building material will significantly suffer from this.

Do not forget that after preparing the cement mortar should be used within 2 hours. Otherwise, it will simply dry out and it will not be possible to use it. When adding water to the solution, it should be borne in mind that its volume should be equal to the volume of cement.

Wooden bases are not recommended to be finished with simple cement-sand compositions, however, for this purpose, clay solutions with a specific cement content can be used. Such mixtures can safely handle both internal and external bases.

Consider the impressive weight of cement-sand mortar. On the weak and unreliable basis they can hold out not for long.

The tools and containers that you use during work should be washed immediately upon completion. Otherwise, the solution will dry out and it will be almost impossible to remove it from the fixtures.

Many consumers are wondering which cement-sand mixtures will be the ideal solution for arranging the foundation. According to experts, high-quality and reliable composition of the M300 is perfect for such purposes. More simple and cheap mixtures (type M100) are not recommended.

If you want to extend the drying time of the composition, then in no case can you add additional portions of sand or cement. Water will not be able to sufficiently dissolve such dry formulations, and the material will turn out to be unusable.

To make a solution, it is recommended to use a metal or plastic container. Keep in mind that in the preparation of a mixture of ordinary river sand is not used. Instead, it is necessary to accumulate bulk material in the soil. Do not make the solution too liquid. Otherwise, it will be bad to lie on this or that basis, and will also slip from the spatula.

Do not save on the purchase of high-quality cement-sand mixture. Low-quality composition may be not only capricious in the work, but also very short-lived. Refer to products from well-known and popular suppliers.So you protect yourself from buying low-grade solution.

How to knead cement-sand mortar, see in the video below.