Portland cement brand 400: features and specifications

As is known, cement mixtures are the basis of any construction or repair work. Whether it is the installation of a foundation or the preparation of walls for covering with wallpaper or paint, cement is the basis of everything. Portland cement is one of the types of cement that has a fairly wide scope.

The product from the brand M400 - one of the most sought after in the domestic market due to its optimal composition, good technical characteristics and satisfactory price. The company has long been in the construction market and is well acquainted with the best technologies for the production of such raw materials, which guarantees even greater reliability.

Features and benefits

Portland cement is one of the subspecies of cement. It consists of gypsum, clinker powder and other additives, which we indicate below. It should be noted that the manufacture of the M400 mixture at each stage is under the strictest control, each additive is constantly being studied and improved.

Today, in addition to the above ingredients, the chemical composition of Portland cement includes the following components: calcium oxide, silicon dioxide, iron oxide, aluminum oxide.

When interacting with a water base, clinker contributes to the formation of new minerals, such as hydrated constituents, which form a cement stone. Classification of compositions occurs by purpose and additional components.

There are the following types:

- Portland cement (PC);

- fast-curing portland cement (BTC);

- hydrophobic product (GF);

- sulfate-resistant composition (SS);

- plasticized mixture (PL);

- white and color formulations (BC);

- slag portland cement (SHPC);

- pozzolanic product (PPV);

- expanding mixtures.

Portland cement M400 has a large number of advantages. The compositions have high strength, do not respond to changes in temperature and humidity, and are also resistant to adverse environmental conditions.This mixture is resistant to severe frosts, which contributes to a longer period of preservation of the walls of buildings.

Portland cement ensures the stability of reinforced concrete structures to the influence of even critically low or high temperatures. Buildings will have a long service life in all climatic zones, even if special ingredients are not added to the cement to counteract the frost.

Mixes made on the basis of M400, set very quickly due to the addition of gypsum in the ratio of 3-5% of the total. An important point that affects both the speed and the quality of setting is the type of grinding: the smaller it is, the faster the concrete base reaches optimum strength.

However, the density of the composition in the dry form may vary, as small particles begin to be stamped. Professional craftsmen recommend purchasing Portland cement with grains of 11-21 microns in size.

The proportion of cement under the brand M400 varies depending on the stage of its readiness. Freshly prepared portland cement weighs 1000-1200 m3, materials just delivered by a special machine have the same specific weight.If the composition is already stored for a long time on the shelf in the store, then its density reaches 1500-1700m3. This happens due to the convergence of particles and reducing the distance between them.

Despite the affordable price of M400 products, they are produced in rather large volumes: bags of 25 kg and 50 kg.

The parameters of the composition of the brand 400

Portland cement is considered one of the basic materials during construction and repair work. Universal mixture has optimal parameters and economical consumption. This material has an extract of about 400 kilograms per m2, respectively, the load can be very large, it is not a hindrance. M400 contains no more than 5% gypsum, which is also a great advantage of the compositions, while the number of active additives varies from 0 to 20%. Portland cement has a water requirement of 21–25%, and the mixture hardens in about eleven hours.

Marking and scope

The brand of portland cement is its main characteristic, since it is from it that the designation of the mixture and the level of compressive strength proceed. In the case of compositions M400, it is equal to 400 kg per cm2. This characteristic makes it possible to use the cement product for a wide range of cases: they can make a solid foundation or pour concrete to retaliate.According to the labeling of the goods, are there any plasticizing additives inside that contribute to an increase in the moisture resistance of the mixture and endow it with anti-corrosion characteristics. Due to such properties, the rate of drying of the composition in any environment, be it liquid or air, is regulated.

Also in the marking prescribe certain symbols that indicate the type and number of additional components. They, in turn, affect the use of Portland brand 400.

The label will show the following specifications:

- D0;

- D5;

- D20;

- D20B.

The number after the letter “D” indicates the presence of certain additives in percent.

Thus, the marking D0 tells the buyer that it is of Portland cement of pure origin, where there are no additional components that are added to ordinary compositions. This product is used to make most of the concrete parts used at high humidity levels or in direct contact with your favorite type of water.

Portland cement D5 is used for the production of bearing elements of increased density, such as tiled floors or blocks for assembled types of foundation.D5 provides maximum strength due to increased hydrophobicity, and prevents the occurrence of corrosion.

Cement mixture D20 has excellent technical characteristics, which allow to use it to produce separate blocks for assembled iron, concrete foundations or other parts of buildings. It is also suitable for many other coatings that are in frequent contact with unfavorable environments. For example, a tile on the sidewalk or a stone for a curb.

A distinctive feature of this product is a fairly rapid hardening, even at the very first stage of drying. Concrete prepared on the basis of the product D20, already seizes after 11 hours.

Portland cement D20B is a universal product that can be used everywhere. This is ensured by the presence of additional ingredients in the mixture. Of all the M400 products, this one is considered the highest quality and has the fastest freezing speed.

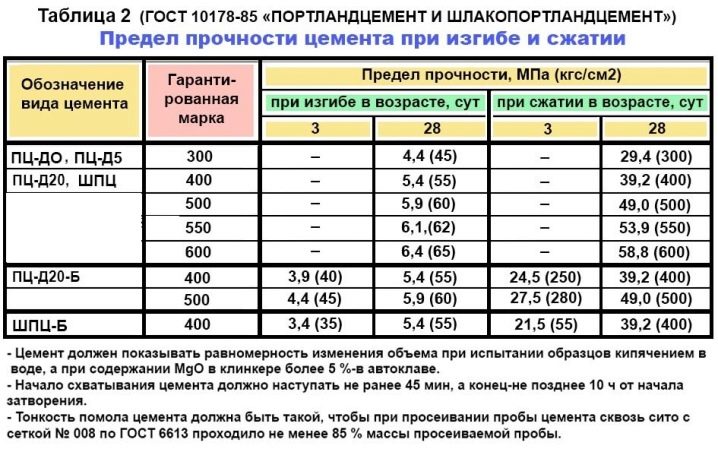

New labeling cement mixtures M400

As a rule, most of the Russian companies that manufacture Portland cement use the aforementioned labeling option.However, it is already slightly out of date, therefore, on the basis of GOST 31108-2003, a new, additional method of marking adopted in the European Union, which is becoming more common, was introduced.

- CEM. This label indicates that you see pure Portland cement without the presence of additional ingredients.

- CEMII - indicates the presence of slag in the composition of Portland cement. Depending on the level of content of this component, the compositions are divided into two subspecies: the first labeled "A" contains 6-20% of slag, and the second - "B" has 20-35% of this substance.

According to GOST 31108-2003, the Portland cement brand has ceased to be the main indicator, now it has become a level of strength. Thus, the composition of the M400 began to denote B30. The letter "B" is added to the marking of the fast-setting cement D20.

Watching the next video, you can learn how to choose the right cement for the solution.