We calculate the right cement consumption

Cement is widely used in construction and finishing works. Using it, they connect bricks, aerated concrete blocks, prepare plaster and floor screed. Each specific case forces you to carefully count the amount of materials needed. Having bought them too little, builders are forced to urgently purchase additional cement, sand. If too much raw material is bought, you will have to accept loss, organize storage, or look for someone to sell the surplus.

Special features

The consumption of cement per cube of brickwork is determined by the composition of the mixture. The standard cement mix for connecting building blocks implies the simultaneous use of sand and water. Varying the proportions of the components is extremely rare, mainly the achieved result depends on the brand of binder used.

Usually to get 1 cu. mthe solution uses 400 kg of dry cement, for 1 part of it you need to take 4 parts of sand.

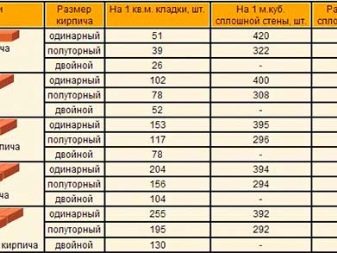

1 m3 of ordinary bricks can be laid using 0.25 - 0.3 cubic meters. m of the mixture, the number of consumable bricks is approximately 400 pieces. It is necessary to take into account the conditions of work. Ground laying in a high-humidity environment, mounting the wall below the groundwater layer is different, the proportions of the mixture vary slightly. Exterior walls are most often made of a mixture of M10, created on the basis of cement M400.

Cement consumption is also determined by the thickness of the walls under construction. If you need to lay a brick of 1⁄4 bricks, 1 m2 of it will require the use of 5 kg of cement (when preparing the M100 grade mortar), to prepare a mortar of the M50 type, you need half as much adhesive. In this solution, the proportions of sand are typical 4 parts to 1 part of the binder component.

This ratio is due to the fact that it allows to achieve the best balance between:

- fortress design;

- the mobility of the mixture;

- the rate of conversion of the solution into a solid material.

Other types of mixtures

When the kneading is carried out with the addition of additional substances (clay, calcareous rocks, marble, synthesized additives), it is assumed to take from 5 to 9 parts of sand to 1 part of the cement.Concrete is made by spending a maximum of 5 quintals of binder to produce 1 cu. m. ready mix. The relevant standards are prescribed by the state standard, however, builders can deviate from regulatory requirements, if you need to achieve a certain level of viscosity, make the solution more liquid, speed up or distance the solidification. When working, they use buckets and troughs (these are the most suitable containers), a perforator with mixing nozzles, and shovels for distributing portions.

The kneading is carried out initially on the basis of dry masses. Then, systematically and slowly add water. It is necessary to ensure that the masonry mortar becomes outwardly homogeneous throughout the entire thickness and does not spread too actively. The quality of the preparation of the mixture depends on the strength of the concrete and the service life of the brick walls.

For sand-cement mortar is characterized by high strength. However, if you deviate a little from the standard technology, cracks may appear. In the mixed version, slaked lime is added to the cement and sand (also called lime milk).

There is also a type with plasticizing additives, when in addition to cement and sand fraction of 0.2 cm polymers are used that make the solution more flexible.There is no need to take care of the preparation of such solutions: it is better to buy ready-made dry kits and dilute them with water as instructed.

Regardless of what kind of mixture is prepared, it is necessary to check that there is not a single lump in the dry mass.

The sand is passed through a sieve, the lime must be drained. If it is necessary to add lime, it is injected only after mixing powdered substances, pouring out in small portions. The temperature of the liquid should be about 20 degrees, the mixture is mixed, otherwise the composition will quickly set. Reduce the time of preparation of the solution to save power will help concrete mixer or perforator.

Binder costs

The standard consumption rate for 1 m3 or 1000 bricks can serve as a guideline for the purchase, but you must also take into account the professionalism of the craftsmen and the type of blocks used (if the products are empty or porous, more solution is needed). Smaller absorption is inherent in the mixture for the hyper pressed and facing bricks, rather than a simple ceramic material.

Mixture consumption per 1 cu. m. (based on the typical thickness of the seams) is 0.23 cubic meters. m. on average. If the thickness of the walls is half the bricks, 0,221 m3 of cement mix will be required for simply decorated surfaces made of ceramic material.

The consumption of the finished mixture per 1 m2 of a brick wall can vary, according to the quality of the resources used, the microclimate and weather conditions. Even on different floors, this number may vary slightly.

In a bucket designed for 10 liters, you can place 14 kg of cement; for sand, the same indicator (10 liters) will go 2 kg less. The ratio of sand and cement of the M400 brand is usually 3: 1, and if you take the M500 binder, then 4: 1. On a hot summer day, the solution should be made less thick, increasing plasticity is achieved by introducing small portions of laundry detergent or dishwashing. A cubic meter of ready-made cement slurry, made in a ratio of 1: 4, requires the use of 4.1 centners of cement grade M500 and 1.14 cubic meters. m. sand.

Since 1 m3 of wall thickness of one silicate brick with dimensions of 25x12x6.5 cm consumes 0.24 cubic meters. m, the consumption of cement mortar per m3 is calculated by multiplying the specific consumption by 410. In total, 98 kg of cement is obtained. If you use a binder M400, in a ratio of 1: 3, per 1 cu. m. the mixture will require 4.9 centners of cement. At 1 cu. mmasonry will need 117 kg of the original component.

Cement-lime mortars retain their qualities for no more than five hours. In summer, when the air is heated to +25, this period is reduced to 1 hour.

Lining consumption

At performance of facing works the approach changes. It is necessary to calculate the consumption of binding mixtures per 1m2 wall (not per cubic meter).

The real value is determined by:

- the tendency of building materials to absorb water;

- weather conditions;

- the number of internal cavities.

The norms prescribed in SNiP 82-02 in practice always turn out to be small, so when buying, it is necessary to take mortar or dry cement with a small reserve. The most economical material in this plan is a double brick (ceramic or silicate), which must necessarily have high strength. As a result, it is possible to save up to 1/5 of the whole mixture

Tips and tricks

In the overwhelming majority of cases, builders use mortars of the cement-sand mixture of category M75 to get it on the basis of Portland cement of the 300th series. It is required to part one part of the binder with three parts of sand.It is necessary to use compositions of M100 and stronger ones only for buildings with increased strength characteristics. When calculating the mass of cement going to perform partitions, you need to pay attention not only to the width of the seam, but also on how aligned a particular layer.

If a brick building is light and not too important (we are talking about household and ancillary facilities), it is acceptable to reduce the concentration of cement to 15-20% relative to the total mass of the mixture.

There is no need to take into account the geometry and volume of each individual block. Such calculations are very difficult for non-professionals, and the savings in mass will not justify the effort. It is enough to use the average figures obtained in the long-term construction practice, to make amendments on a specific situation.

See the video for the rules and secrets of mixing the solution.