Cement: types and features of production

Cement is indispensable for construction work. This is literally the basic element for many types of repairs. He is able to assume the function of other materials, while the cement itself is difficult to find a worthy alternative. This material is made universal by types and features of the production of cement mixtures that are well thought out by their component composition.

What it is?

Cement is a mixture of limestone rock that repeatedly passes through a crusher and firing at temperatures above 1500 degrees, with the addition of minerals and synthetic substances called plasticizers. They are needed to increase strength, and also slow down the process of moisture loss from a liquid solution.

A mixture of minerals is often confused with another building material - concrete.

Between them there is a fundamental difference in several points:

- Cement differs from concrete in that it can already be used for repairs when adding water. Concrete mixes consist of 4 components, one of which is cement.

- In the cementing mixtures, there are no components of a large fraction, and sand, crushed stone, gravel, and expanded clay are added to concrete.

- Due to the lack of coarse fillers, cement quickly sets and turns into a monolithic compound under any conditions.

- Various applications. Despite the fact that both materials are used in construction, they serve for different purposes. Foundations and elements of supporting structures are formed from concrete. Cement often acts as a masonry and leveling material.

- Technical characteristics and composition are regulated by different GOST.

Manufacturing and packaging

Production and packaging of cement is a long process requiring high-tech equipment and control. Its beginning lies in limestone quarries. Two types of limestone are used. The first is located close to the surface, at a depth of several tens of centimeters. This is the so-called "second-rate" limestone, but it already contains iron, aluminum oxide,silicon and other minerals. They give cement mixtures unique properties.

The second layer is located at a depth of several meters. It is cleaner, with almost no admixture of other minerals (except for calcium carbonate), and is considered top-notch.

In production they use both kinds, both pure and combined. in different proportions with each other and additional components. The ratio of first-class and second-grade substances, as well as the type and amount of additives determine the brand and cost of cement. Limestone in its natural state is a solid monolith. It is broken into small fragments with explosives, laying them in layers of limestone at a quarry, and then collected by loaders. The size of the fragments can be of different sizes, from small pebbles to the whole building block. In this form, they come to cement plants.

At the plant, the raw material first gets into the “primary crusher”. In it large fragments are crushed to the size of a tennis ball. In the process of grinding large fragments, water enters the crusher so that dust does not rise, and with it the mass of limestone is not lost.Ground stones are conveyed to a secondary crusher. There is a "grinding" of rock to fragments the size of rubble. The first and second grade are crushed separately.

Then a raw mix is formed for cement of different grades. After mixing, the finished “piles” are sent to the roller mill. In the process of grinding limestone in the course are additives: powdered magnesium, silicon and alumina, if they are contained in the limestone rock in insufficient quantities. Mill grinds rock to stone flour. Then this stone flour enters the preheater. In less than a minute, it heats up from 80 degrees Celsius to 800.

This procedure is necessary so that all components of the composition move and acquire the ability to harden to solid monolith when combined with water and contact with air.

Unnecessary components are separated in the heater.remains lime suitable for construction. She goes to the cylindrical firebox. The bottom of the firebox warms up to 1700 degrees. The mass inside the furnace is fused into small "glass" balls, which are called clinkers.When they exit the furnace, they are quickly cooled with a stream of cold air to 70-80 degrees. Quickly - the key point. If cooling is slow, the mixture is poor quality. This is the raw material for high-quality cement.

The cooled "glass balls" pass the last stage of processing - the final crushing. In fact, it is grinding of solid clinkers between steel balls of different diameters, which in one crusher are about one and a half tons. When grinding the clinkers, lumpy gypsum is added to the stone flour. It slows down the process of solidification of liquid cement. The powder mixture leaving the crusher is cement. Some manufacturers add plasticizers to increase strength.

The finished powder mixture undergoes the packaging procedure. To do this, use specialized machines with dispenser.

Cement bags rarely have a small volume of 10-15 kg. Usually the minimum weight - 25 kilograms, and the most popular - 50 kg. Bags of 50 kilograms are called slimbegs. Sometimes there are non-standard volumes of 30, 35, 42, 46 kg. The packing bag consists of several layers (from 2 to 5) of crafting paper.Also common packaging packaging for construction on an industrial scale - big bag. These are soft containers of high strength polypropylene or caprone with stiffeners and linings or without them. The weight of cement in big bags is from 300 to 3000 kg.

Big bags have several advantages over conventional packaging:

- bulk purchase of cement reduces the price of 1 kg of the mixture;

- on soft containers there are slings for loading;

- they are heavy duty, reusable and recyclable;

- polypropylene shell extends the shelf life, because it protects the cement from the negative influence of the external environment;

- containers can be equipped with liners for heat resistance, anti-static, waterproof, UV protection.

Species

The definition of “gray powdery substance” is not quite true for cement. It is also a different color. Color gives him a variety of additives that affect its technical characteristics, and colors. In addition to shades, the material varies according to other criteria. Classification is made by component composition, purpose, appearance of the powder and solution, the country of manufacture.

The composition and properties can be distinguished:

- Sulfate-resistant mixture. They are obtained by grinding clinkers, but without the addition of mineral components. Also, in the manufacture of such a cement, 90-92% of calcium aluminates are removed from the composition. They are added to concrete when a substance is needed that will be evenly distributed in the pores of the concrete without causing internal resistance.

- Portland cement. On the contrary, a large amount of powdered minerals is introduced into it. The result is a fast-hardening, durable layer. The strength of the layer is normalized not only for the “matured” substance on the fourth week, but also on the third day. This contributes to the fact that the cement during curing acquires greater strength and resistance to damage. It does not crack and withstands various mechanical shocks and loads. Such mixtures are added to the concrete in the manufacture of reinforced concrete structures. They are also used in home construction.

- With pad additives. These include synthetic substances and plasticizers, the number of which can reach three-tenths of the total mass. They are necessary for the absorption of cement sand, that is, envelop each cement grain with a film that does not allow the substance to adhere to each other.As a result, both the cement mortar itself and its connection with concrete acquire elasticity and are easier to stack, leveled off on the working surface.

- Hydrosulfoaluminate. Such quick-drying cement is often referred to as expanding due to its ability to grow in volume during the "setting" process. This happens due to the fact that calcium sulfate aluminates are added to the dry mixture, which, as a result of the reaction with water, increase in volume by one and a half or 2.5 times (relative to the initial solid substance). When dried, the mass increases by 2%. Despite this "yeast" effect, it has good density.

- Gypsum-alumina or straining cement. Same as self-expanding, only the component composition is changing. What it is, it is clear from the name of the material.

To work with such cement optimally in wet conditions. So it expands more effectively and gives the maximum effect. Expanding types of cement are used for leveling joints between elements of prefabricated reinforced concrete structures. It creates a good waterproofing, which is especially important in the construction of hydraulic facilities and pressure pipes.

- Aluminous. The name of this kind of cement is speaking. It is obtained from limestone, which is laid close to the clay deposits in the soil. In the process of burning and grinding, a large amount of limestone rock with a proportion of alumina is added to the mixture. It, in turn, contains aluminates, which turn cement into a quick-hardening viscous substance with hydraulic properties. This product is unique in its technical characteristics. It is used in rare cases when it is necessary to perform urgent repair work in conditions of high humidity, precipitation, and sub-zero temperatures. Aluminous cement is not capricious in this respect and is equally effective under different conditions. This leads to its high cost.

- Hydrophobic. It is produced by grinding the mineral clinkers with various additives. Suitable water repellents, such as asidol (extracted from the processing of kerosene, solar and oily waste oil with the addition of sulfuric acid). Common use of sodium soaps and mineral oils, oleic acid, fatty acids of synthetic origin.

The advantages of hydrophobic cement in its high frost resistance and water resistance, as well as its ability to be stored under any conditions without losing its properties. It is less durable than other types, therefore it is not suitable for supporting concrete structures. It produces light porous concrete blocks.

- Non-shrink It is a mixture of three components: gypsum, lime and aluminous limestone. Gypsum is used semi-aquatic, lime - slaked. In the process of drying does not expand and does not shrink. Used in the construction of foundations of buildings, tunnel ways.

- Magnesian. Get completely different from the production of conventional cement method. These are compounds of magnesium oxide and an aqueous solution of magnesium chloride. Such a mixture is heated only to 800 degrees Celsius, and then, when it solidifies into a whole mass of white, it is crushed. Such cement is similar in its properties to gypsum and is used rather for interior decoration, floor leveling and for architectural purposes.

- Pozzolanic For its production, active minerals (burnt clay, fuel ash) are added to stone flour from clinkers.These materials are easily accessible and cheap, and their share in the composition of cement is significant, so the cost of the total mass is lower than that of “pure” cement. In solid form, it is resistant to leaching and leaching with water. Scope - underwater and underground structures. Hardened cement must be in an aqueous medium or on the surface at all times, without alternating moisture.

- Silicate. Everyone who has dental fillings is closely acquainted with this material. A fine mixture with a large composition of sodium fluoride and calcium is used in dentistry. In its structure, it is very similar to tooth enamel. Water as a liquidation does not apply, for its cultivation special formulations are needed. It can be diluted with water for use in interior decorating as a material for decorative finishing. The cost of such cement is very high.

- Polycarboxylate. Substance with high adhesion to organic tissues. Like silicate cement, it has little to do with construction and is used for medical purposes. In particular, for filling milk teeth.

- Slag. Powder mix of cement, gypsum and blast furnace slag.Slag accounts for between 20 and 60% of the total composition. The more of it, the less active the cement. Its strength increases over time. It is steady against stable aggressive influence of the environment, but does not tolerate temperature drops and humidity levels.

- Lime and slag. In it, in addition to the components of slag cement, there is a proportion of lime. The strength of the material is not very high, so the solution is used for laying and manufacturing low-grade concrete. Can be added to plaster.

- Cementing. Its specific area of application is plugging of oil and gas wells. It consists of many components responsible for plasticity, hydrophobicity and high strength.

Manufacturers

A significant share of the cement market is occupied by Chinese manufacturers. Gosstandart in China and Russia for this material is different, so the Chinese products, which are offered on the market as cement of the 500 grade, are actually closer to 400. From the assortment - non-additive, portland cement and fast-hardening.

A serious competitor to Chinese manufacturers - turkish cement. It fully complies with European quality standards.With impeccable specifications, Turkish materials still benefit by several criteria. The price for them is not too high, since the dry process of processing raw materials prevails in the factories in Turkey. It is more economical and faster than the still popular wet method in Russia. Products are transported to the markets of other countries in big bags, having all possible ways of protection. It arrives in place safe and sound and can be stored in this form for a long time.

The range of Turkish cement - from 300 to 500 mark. It is recommended to get it in company packing. In the "nameless" bags, cement powder that has already been crushed and packaged after the expiration date may be sold, which may not have anything to do with Turkey. The Indian cement was unexpectedly of high quality for the Russian consumer. In the ranking of sales, he consistently takes his position in the first five lines. All raw materials meet the standards, and products cope with their tasks for all 100.

More from unexpected manufacturers in the list - Iran and Egypt. Good quality is different cement and domestic production.Among its advantages is a wide range, compliance with the state standard, the cost, which is lower than that of manufacturers from other countries. This is explained by the fact that the price does not include the cost of transportation across the border. Russian cement is mainly produced in the slim-run format in paper and polypropylene packaging without protective layers inside, which reduces its shelf life in some conditions.

In demand products manufactured in brazil. No experiments with the component composition (up to the recycling of ceramic materials) make it worse. In the product line you can find a suitable material for specific needs and conditions of use. Has established itself as an American-made product.

Competition to him are materials from the Asian region - Japan, Vietnam, South Korea. From European manufacturers are popular German goods.

Colour

The usual color of cement is dark or light gray. Some species may have a different shade (magnesia and silicate) during manufacture. They are white by nature. Part of the cement is painted in graphite, almost black.This affects the presence of additional components and dyes. Colored cement is less common. It is used mainly as a decorative and functional additive in concrete mortars and leveling compounds for the floor. The color leveling layer facilitates decorative finishing when using mixes for a bulk floor.

Paint the cement in two ways: directly during production (method more reliable and economical) and with the help of pigmented powder during solution dilution. Loose pigment makes it possible to dye the mixture in any color, be it red, blue or purple. But such a variety is required in exceptional cases, when the cement coating is immediately decorative. Combined grinding and burning of clinker with oxide of some metals gives a more effective staining, but the range of colors is limited to green, yellow and black colors of varying degrees of brightness.

Such mixtures are added to concrete to give it a color texture. Its color will not wear out and fade with time, in contrast to the dyed solution.

When using colored cement, it is important to consider that the addition of coloring pigments is insignificant,but still affects its technical characteristics. Basically, it affects the shrinkage of the solution. It is more pronounced than that of an unpainted substance.

Stamps: how to choose?

It is not easy for a non-professional in the field of repair and construction to understand what mysterious letters on cement packaging mean, how to choose the right material, relying on the marking in alphanumeric numbers, who installs them and how to find the right material to fill the foundation. Marking of cement is made in accordance with GOST. Since, a little more than 10 years ago, the generally accepted standard for Russia was changed to European, confusion may arise. Not all manufacturers switched to the new notation, and sometimes, under their outdated numbers, it is difficult to determine the required sulfate-resistant M500.

Old standards had only two designations: PC (Portland cement) and SCR (slag Portland cement). The quality was determined by the brand from 300 to 500, and the amount of additives - the letter D. For example, PC300D20 meant that in a bag there was portland cement with 20% of additives of various substances. The pan-European standard has made significant changes to this system.Now on the package the name of the cement is indicated (as in all European packaging with cement - CEM (from cement), strength class, type and quantity of additives, additional characteristics.

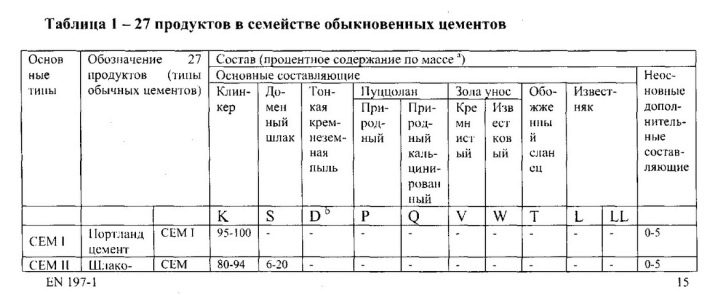

The classification by composition has expanded to five positions:

- CEM I is equal to Portland cement (HRC).

- CEM II - HRC with additives of mineral origin. This class has subclasses A and B demonstrating the amount of additives in the mixture. The numbers on the package are indicated without%, but the ratio is measured in them.

The exact name of the additive is indicated by a dash. W means slags, and - the content of lime, H - ash, MK - derivatives of silicon. Can be added burnt shale, silicate dust, pozzolana.

- CEM III - HRC with slag. It also has a subclass, but only one - A. It denotes the percentage of slag in the composition.

- CEM IV - pozzolanic.

- CEM V - compositional.

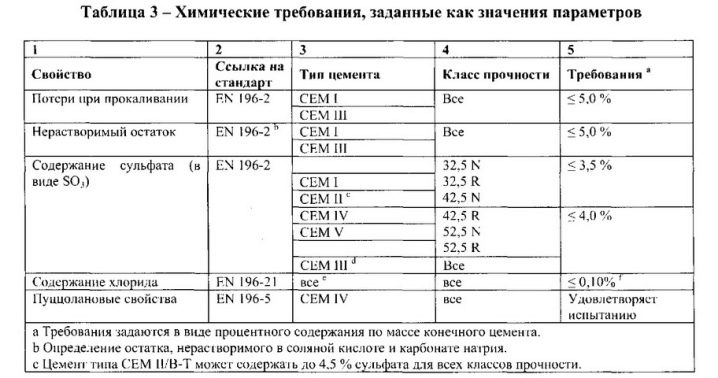

For detailing the composition of the class is strength. Measured in kilograms of weight per cubic centimeter. The accepted norms: 22,5–32,5, 42,5-52,5. Completes the information line determining the rate of hardening of the solution. H - normal, B - quick-hardening cement. For the second option, the layer strength for 2-3 days should be additionally indicated.

What should those who are accustomed to the old type of marking do, and how to choose the one that is best suited for specific purposes? To correlate the strength of the old standard with the strength of the new standard.

Cement M100 and M200 (strength - 12.5 kg per square centimeter) was used for various kinds of construction and repair work during private construction. The load on him was not as big as on a production scale, so he coped with a number of functions. Solution M100 or M200 was suitable for roughing the floor, masonry partitions inside the room, leveling the walls and seal complex defects, plastering. In the past few years, these brands have been discontinued due to poor quality.

Now the M300 is considered the minimum acceptable. (strength - 22.5 kg per square centimeter). It can be used for bricklaying of residential premises, stoves, fireplaces, for large-scale construction, repair work, pouring screed, foundation, for mixing with concrete components. He also participates in the production of reinforced concrete structures. The products have a permissible SNiP strength, suitable for use at different times of the year, resistant to moisture and sulphates, convenient to work in the form of a liquid solution. But to the ideal characteristics of the M300 does not reach.If possible, pay attention to higher brands.

M400 (32.5 kg / cm2) high strength, it is not subject to corrosion, is steady against moisture and low temperatures, wearproof. Considered affordable and versatile in quality. Depending on the additives can be used in private and large-scale construction. From pure cement 400 brands produce foundations, including prefabricated, as well as structures in contact with water. Hydrophobic additives make it suitable for the construction of wall panels of high-strength raw materials with additives to make curb blocks, floors, foundations.

M500 and M550, which are often put in the same line, have a strength index in the range of 42.5-52.5 kg / cm2. These types of cement are highly resistant to atmospheric influences, are not afraid of water, frost, temperature changes, sulphates, almost do not shrink, easy to work. Used for the manufacture of reinforced concrete precast structures of high class.

M600 cement (52.5-62.5 kg / cm2) mainly used under adverse conditions for recovery work in emergency situations. It has improved performance in relation to the M500.For private use there is no need to use this high strength and fast curing material. You can restrict M400-550. It will withstand everything, from building a foundation for a two-story cottage to laying a fireplace inside this cottage. Mark M700 - M1000 are purely professional materials.

Storage

There are several ways and options for storing dry cement:

- At home. It is not the most reliable way to keep the material suitable for construction and repair. A common mistake is to think that in a warm living room for cement is quite dry and it does not need additional protection. This is especially true for kraft packaging. Even in the house there may be too much air humidity, which is why cement loses some of its characteristics. And if water gets on it, then it begins to clump in the package. Also on its operational state affects the interaction with oxygen. It is a catalyst for many elements. Its effect on cement also reduces its quality characteristics.

- On the street. Here all the dangers are obvious: the impact of environmental factors can ruin the material in less than six months.Of course, it will not cease to become a viscous substance when water is added, unless the entire bag is filled, but poor storage conditions affect the main quality of the material - its activity. These are its actual binding properties and brand conformity. At best, the damaged cement will lose 10-15%, and instead of the M300, it will behave in the work as an unsuitable M200.

- Spring-summer. In the warm season, cement is threatened by increased humidity, exposure to UV from direct sunlight, the risk of a greenhouse effect under polyethylene.

- Winter-autumn there is a risk of precipitation, and for some mixtures severe frosts and temperature drops are harmful. Even before becoming a liquid mortar, cement already loses its useful qualities.

- In bags (paper or propylene). Both paper and polypropylene are capable of letting moisture in themselves, so any container needs additional protection.

- In bulk. The most problematic option for long storage. Bulk cement is a dry powder that is delivered to the buyer in sealed containers, and then simply poured into one heap without any storage containers.A special approach is needed to it, and it is better to order such cement at all just before the start of construction or repair.

The approximate shelf life of cement under favorable conditions is 1.5-2 years. So that it does not lose its important qualities with different methods of storage, it is important to follow the recommendations of professionals. It is advisable to purchase the cement immediately before use in the amount that will take several applications.

If for some reason construction work was interrupted, and the cement remained in a small volume, it can be stored at home. A suitable room should be dry, remote from rooms where water is constantly used (not a balcony or a loggia, not a basement), and ventilated. From time to time the bags need to be turned over so that the cement does not crumble. Fragile packaging can be protected with tight bags for construction waste (PVC film). It is not advisable to pour in, if the shelf life exceeds 6 months, as chemical reactions occur in the open air. The temperature in the room should not exceed 20-25 degrees, in order to avoid the greenhouse effect inside the package.Condensate can also ruin material.

A large supply of material is difficult to place in the living room, it will have to be taken out onto the street.

To protect it from dampness, you need:

- choose the most dry place;

- cover the base (soil, floor) with a PVC film in a single layer so that the substance does not absorb moisture from the soil;

- top to install wooden pallets. It is desirable to treat the pallets with a primer and varnish or paint, since the wood is also very absorbent. In the future, they will be useful again and again in the household;

- rewind each bag with food film;

- put in a particularly durable garbage bags 120 liters, sealed on top of the mounting tape;

- warm with old clothes, hay or sawdust;

- put under a shed or in an outbuilding. In this form, the cement will remain for several seasons without losing its properties.

Important nuance: the higher the activity of cement, the faster it is lost.

Bulk cement is stored in the so-called cement pits. Their organization will take a lot of time and effort. It is necessary to dig a deep hole, reinforce its walls so as not to crumble, take care of several layers of waterproofing and high-quality thermal insulation, and organize a shed.Mineral wool, foil sheets and PVC film for this purpose will cost no less than a new batch of cement, so loose material is not purchased in advance.

Application

With the help of cement many construction and repair tasks are solved. In some cases, it is effective on its own, and in some it forms a symbiotic substance with additional components or becomes part of the building mixture itself.

Common uses for cement:

- Filling of the base under the private house or garage. In its pure form, it is not used because of too much weight. To do this, it is introduced into the concrete composition, in which there is dry alluvial sand, stone or crushed stone, sand and gravel mix, water. Cement here plays the role of a binder and an elastic component.

- Fill floor screed. It is needed in almost any room. With a relatively flat surface of the rough floor without defects and large differences in height, you can do with a thin cement screed 30-40 mm. For more problematic areas it is used in two layers. Also, with the help of cement, you can make an inclined tie in rooms where you need to drain, or pour the contour of a water heated floor in order to avoid damage to the system from temperature differences inside the pipes.It is important to use acid-resistant cement and cement-sand mixtures for screeding.

- Production of reinforced concrete structures and precast foundations, floors and wall elements of the house. Straining (stressed) cement is needed here.

- Construction of structures in the water, road construction, construction of bridges, tunnels, residential buildings of high-rise buildings.

- Brickwork. In this case, liquid cement plays the role of mastic, interconnecting bricks, blocks, natural and decorative stone, and other laying materials. Masonry is used not only for the construction of partitions and walls in the room, but also for the construction of fireplaces and stoves. In the last two cases, the cement needs refractory, not lower than M400.

- Plastering and leveling ceilings and walls inside and outside the room. A solution of fine limestone with the addition of gypsum cements problem areas, making them suitable for decorative decoration. Since the process is long, PVA glue is added to the finished composition, which slows down the evaporation of moisture and improves adhesion to the working surface.

- Waterproofing. It is possible to “plant” a sheet of insulating material on the cement mortar so that it does not float when pouring the screed.

- Production of paving slabs and other decorative elements.It uses colored cement with high aesthetic qualities.

- The organization of garden paths using reinforcing mesh.

- For blind area. This design plays the role of removal of liquid precipitation and melt water from the building. In this case, 30-40% of the components of the faction fraction by the type of expanded clay, broken brick, slag are added to the cement mixture.

- "Iron". It works as a protective "shell" on a concrete surface. A liquid cement mixture is applied in a thin layer, and after hardening, it is rubbed to smoothness.

- Dressing. Cement perfectly replaces plaster to create sculptures, park and garden decor in the form of flower beds, pots and flowerpots.

How to make cement, see the following video.