Attic hatches: types and features of installation

In a country house can not do without the attic. A properly equipped attic can serve as an excellent storeroom for storing supplies and conservation, drying herbs and berries, or serving as a replacement for a hangar for storing household tools. And if you wisely approach the issue of warming the room, then this place can be turned into an additional full-fledged room for rest and relaxation.

Special features

In old projects of houses, the entrance to the attic was usually located outside the house, and it was possible to reach the door only with the help of a fixed staircase or step ladder. But in modern realities, this method is not very convenient, requires significant investments in the construction of reliable and safe stairs suitable for use in outdoor conditions, and in addition, can turn things stored in the attic into easy prey for thieves and vandals.

The best option would be to organize comfortable access to the attic from inside the building itself. Modern solutions offer the arrangement of the hatch with a special staircase for quick and aesthetic access to the attic of a country house. But the issue of installing the hatch must be approached with careful preparation and certain knowledge.

Errors in the installation of the hatch can lead to drafts and excessive cooling of adjacent rooms, and even damage to the incorrectly installed structure.

And the wrong design in combination with the lack of a vapor barrier will entail the accumulation of condensate and increased humidity, and in the end - the appearance of an unpleasant smell of mustiness.

During construction, it is necessary to take into account all requirements and standards.

Species

Lifting hatches for an attic differ in design features and in the type of material for production. The simplest designs are options with a single door. Complicated version is a combination of two covers, one of which is made according to the type of "sandwich". The hatch can be designed both secret and open.

It is possible to equip access to the attic with an added ladder or with a folding ladder. In addition, telescopic or retractable staircase models for attic hatches are becoming popular.

It is preferable to install the insulated construction, because it will avoid drafts. Fire extinguishing models on the market prevent the spread of fire and smoke in the event of a fire due to the thermal insulation properties and heat resistance of the materials used. The side parts of such structures are sheathed with metal sheets. In this case, the heat-resistant layer can be either on one side of the lid or double-sided.

The only obvious disadvantage of the operation of such a hatch is its serious weight, so for this design it is necessary to make a convenient handle for easy opening.

However, the presence of this design allows you to restrain the spread of flame lasting up to 40 minutes.

A relative novelty in the building materials market is a cover with a built-in ladder with dust-proof properties, which has enhanced thermal insulation. The special coating provides reduced accumulation of dust and will not allow to “drown” in a dusty cloud when a long-unused design is advanced.

According to the height of the hidden hatches, they differ depending on the dimensions of the ladder mounted with them. The kit may additionally contain a security fence that facilitates access to the attic. If it is absent, then in order to increase safety when climbing up it is necessary to buy such a fence or make it yourself.

The entire sliding hatch assembly with a lid and a ladder can be purchased in a ready color versionbut it is not always possible to find a suitable shade. To ensure the unique design of the premises, it is advisable to purchase an unpainted set of structures and perform the painting yourself, completely fitting the attic hatch and stairs into the whole project of a residential house.

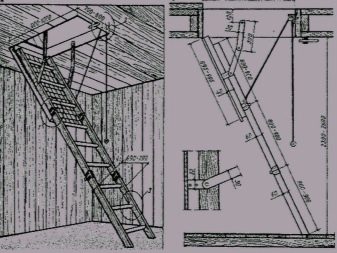

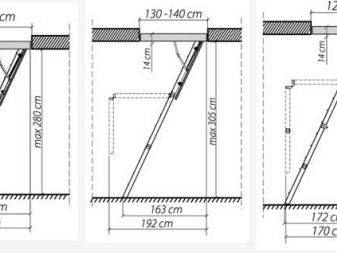

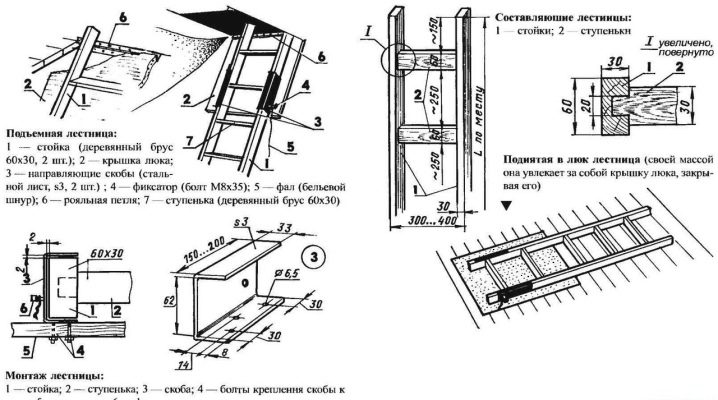

Drawings and diagrams

In the drawing below you can see the standard sizes of the popular ready-made versions of the hatch to the attic, equipped with a ladder

When planning the manufacture of the frame for installing the door, do not forget about the allowances: the opening must be made in such a way that it exceeds the frame dimensions by approximately 50 mm.

Do not forget about laying heat and vapor barrier layer on the future hatch cover according to the scheme below

The following figure shows the final product with insulation in the section

Materials

The most used materials for the manufacture of attic hatches are wood, metal and various plastics. There are also exotic variants of execution, for example, entirely from vacuum expanded polystyrene.

Metal hatches

Doors made of metal, reliable, strong and durable, but at the same time are quite heavy structures. Installation of such a hatch should include mounting using spring mechanisms and hydraulic cylinders to facilitate opening of the door.

To the metal hatch you also need a comfortable and long handle. If you do not take the necessary measures, then not every family member will be able to open such a lid. In addition, the risk of bruises and accidental injuries increases. It is necessary to take into account the strength of the ceilings themselves and their ability to withstand the installation of a bulky multi-kilogram structure.

Wood hatches

Wooden hatches are much less durable, but their weight is significantly less, they are easier to install together, and they do not require additional strengthening of the support on which they are installed.The wooden cover can be lifted effortlessly, and in the interior it looks beautiful and presentable. The most popular is the manufacture of larch caps, but also birch, aspen, and oak wood.

Sometimes for the cover they use the fragment of interfloor ceilings, obtained when cutting the attic opening. A box for mounting a wooden hatch is usually made of timber, which ensures the correct geometry of the structure and low residual moisture, and does not require much joinery experience and professional skills. Preferring wood, it is necessary to remember about the need to improve the fire-fighting properties of wood using specialized impregnation.

Plastic

Plastic hatches are less popular, but very convenient. As a rule, in such cases the same polyvinyl chloride is used as in the installation of plastic windows.

Related materials

As a heater, the best option is to use environmental mineral wool. Less commonly, polystyrene foam is used - a material consisting of styrene granules filled with natural or carbon dioxide.To provide vapor barrier, a good modern solution is a polyethylene vapor barrier, which is a polyethylene perforated thin film in the form of a membrane. The film is placed on both sides of the insulating layer with a rough side out.

How to set your own hands?

Below is the process of self-device attic hatch, starting with the cutting of the future opening.

First of all, you need to choose the location of the hole.

It should be borne in mind that the cover of the future attic hatch should be easy and free to open. Also, do not place the hatch under the rafters, so as not to interfere with the exit to the attic. You need to choose the area where there are no ceiling beams, so as not to reduce the strength of the ceiling, and if the floors are made of concrete, then it makes sense to mount the hatch at the junction of two plates.

The future staircase, if it is planned to be installed, should not block access to other rooms. Moreover, if it is a retractable design, it is necessary to reserve additional space for it.

The dimensions of the future opening are chosen according to the needs of the owner, but if you plan to purchase ready-made standard kits or purchase parts of structures, then you can rely on the standard parameters - 120x60 cm. If you do not plan to regularly move large-sized items to the attic, then these dimensions are usually sufficient for normal operation.

The initial stage depends on the material of the floors. If the overlap is concrete, you will need a hammer drill, "Bulgarian" and a sledgehammer.

You need to start with the designation of the place of the future opening with a pencil.

In the corners of the outlined rectangle it is necessary to place a perforator with a drill, guaranteed to exceed the thickness of the overlap with its length. Then you should drill 4 through holes in the corners, and then use a sander with a disc on the concrete to walk along all sides of the planned hatch, avoiding the tool hitting the floor reinforcement. It is necessary to examine the opening for the presence of voids and weak points, then you need to drill through them and knock out the remnants of concrete with a sledge hammer. At the end of the process it is necessary to remove the remnants of the reinforcement and smooth out the edges of the opening with a diamond-coated disk.

If the ceiling is wooden, the process will be much easier. The hole is sawn in wood using a jigsaw for rough work, and then completely processed with a circular saw. Even better, if you can get an oscillator cutter, then the preparation of the opening will take a minimum amount of time.

After that, a rectangular box with allowances for future sheathing of 4-5 cm on each side is made of pieces of wood about 30 mm in size.

The box can be sewn with plywood or fiberboard. The frame in the opening is fixed on special anchors. The lid is made of a piece of wood of the desired thickness, reinforcing it with a diagonal strut fixed by self-tapping screws.

On the basis of the lid itself put a vapor barrier, a layer of insulation and on top of another layer of polyethylene. Insulating materials are glued or fastened with wooden plank. The top layer is sewn up with plywood or special face plates and panels.

The ready hatch to the base is attached to the hinges from any side convenient for the owners, and along the perimeter it is laid with a compactor. The opening can be additionally sheathed with a casing, and the hatch itself can be equipped with a convenient handle and closers.

As can be seen, independent production of the hatch with certain skills and tools is not an overly complex task.

You can purchase and install a ready-made construction kit, which has a number of significant advantages:

- Ready kits are provided with detailed installation instructions.

- For the installation of a set of two people enough

- Finished stairs are available in various modifications that fit the different needs and sizes of the premises, and are distinguished by a high degree of reliability and safety guaranteed by the supplier. Popular options with steps that have anti-slip coating.

- Purchased hatches are aesthetic and ergonomic.

Useful tips and tricks

When selecting and installing the hatch should be aware of the following:

- if the floors are wooden, then make an opening to the attic and it can be insulated directly in the ceiling tree without using an additional frame;

- loops can be mounted from any convenient side, but the structure of the roofing system must be taken into account;

- the door, made on its own, must be reinforced with a wooden spreader to support the required weight;

- if the attic room is already insulated, it is not necessary to warm the door with a thick layer of mineral wool;

- mechanisms for opening and closing the hatch should choose the most simple and convenient - lessprobability of breakdown and, as a result, lack of prompt access to the premises;

- to fix the hatch in the opening, you can use the usual design of the door hinges;

- the modern market offers ready fireproof hatches, made not of metal, but of wood that has already been treated with antiseptic and heat-resistant impregnation (flame retardants);

- installation of closers and hydraulic cylinders will facilitate the opening and closing of the hatch door;

- if preference is given to a fireproof hatch, the opening of the door should be provided strictly and exclusively inside the attic space for reasons of proper operation and safety.

You can choose a folding attic hatch, which has an electric drive.

Such a homemade version should have a high-quality finish and reliable fittings. To lift will not need to make a lot of effort. Laz can be cold and warm.

Successful examples and options

You can pick up a design model of the attic hatch. Its price will accordingly be slightly higher, but it will fit into many interior styles and will harmoniously fit into them.

If you don’t have too much money for the purchase,Then you can choose a standard model from quality materials.

The folding attic hatch is very compact. This option is quite functional.

To learn how to properly install the attic, see the following video.