Device of garret overlappings: choice and installation of a heater

The attic is a dark or semi-dark space that serves to store unnecessary things and is visited only occasionally. But in order that this part of the house does not cause inconvenience, it is necessary to make garret floors as reliable as possible - they must be both mechanically strong and guaranteed to keep heat.

What it is?

Traditionally, the attic is considered a technical area that completes the structure, because above it is already located only the roof and the roof, which are external structures. In this part of the house there is extremely rarely living space, because it is usually used for life support systems and municipal infrastructure. But since the temperature in the residential and technical area of the building can not differ by more than 4 degrees, it is necessary to warm this space.

Special features

Attic, allowing you to expand the developed space at the expense of the attic, yet built quite a long and expensive. Construction requires a lot of effort, moreover, you need to thoroughly know the method of work and it is desirable to study at least one example of such arrangement. It is much easier just to warm the upper part of the dwelling - it will also save money.

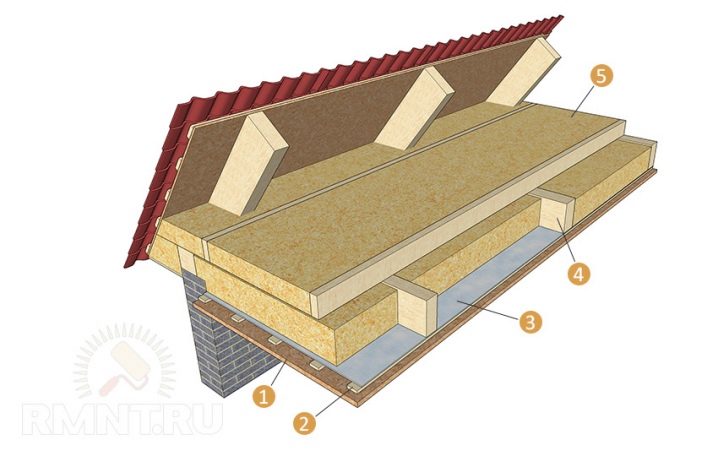

The overlap over the wooden beams is most often performed in the form of a pie, which includes:

- roll forward or boardwalk;

- layer stopping the spread of steam;

- ventilation clearance;

- insulating material;

- additional vapor barrier;

- floor, and sometimes flooring, if the attic is frequented.

Even for a cold attic, a dormer window is a useful element. Such designs can have a triangular configuration or be made in the form of an oval. Usually they are placed at a height of about a meter from the floor, equip with grilles and blinds. Installation of the ceiling, compensating for heat loss through this window, you need to do only after the installation of supporting structures.

Overlap options

In most cases, attic floors are made of wooden beams.

Characteristic features of this option are:

- Limited overlap length. The span from one leg to the other should be a maximum of 450 cm.

- The ease of construction, which provides a minimum load on the walls and, accordingly, on the foundation.

- Convenient installation.

- The availability of wooden structures compared to other materials.

- High speed of preparation, as well as the ability to perform all the work in one day, even without the use of lifting mechanisms.

- Compatibility with any sound insulation options.

It is necessary to immediately calculate the optimal cross-section of the beam, which should correspond to the load on it, and also take into account the climate and the thermal characteristics of the room.

Materials

Regardless of the chosen construction, it is preferable to use coniferous wood for the main unit, which is most resistant to high humidity, exposure to fungus and rotting. Beams with dimensions of 15x20 cm provide sufficient thermal insulation, but thinner ones (5x10 cm) are completely impractical. In between the rolls placed layers of waterproofing, vapor barrier and insulation.It is better not to fix the boards to the supports, but plywood with a thickness of 1.5-2 cm.

For fixing the lower flooring stuffed wooden bars 5x5 cm, the protrusion from which allows placing boards or sheets. The roll is attached to the bars with self-tapping screws. For the very insulation in a brick building can be used a variety of materials. When the beam is inserted into the wall, it is poured with cement mortar (if the thickness of the masonry is two bricks) or left free if the wall is lined with 2.5 bricks.

Private houses are mostly equipped with wooden beams. This is a fairly durable material, in addition, having a democratic price. However, the attic with wooden beams can be made only when the width and length of the house is no more than 10 meters, since longer lumber is not produced anywhere.

Metal beam (dvutavrovaya) stronger than wooden construction - it is capable of bearing a significant load without damage. The flip side of such advantages is the great weight of the structure, which does not allow its use in a wooden dwelling. Reinforced concrete beams obtained on the basis of reinforced concrete, which is carefully molded, are applicable only in apartment buildings.

What to insulate?

Aerated concrete house is quite warm - in terms of protection against freezing, it is three times as high as structures made of hollow ceramic bricks of comparable thickness. In this case, it is desirable to use an additional layer of waterproofing, since the likelihood of moisture and material damage by it is very high. It is possible to warm gas-concrete constructions only after 2-3 months from the moment of construction.

Most often, their thermal qualities are improved using:

- Styrofoam;

- extruded polystyrene foam;

- mineral wool;

- compacted mixtures for plastering.

For the attic floor can also use expanded clay, vermiculite, perlite, glass wool, polyurethane foam and peat slabs. But whatever material is chosen, one should strictly adhere to the standard technology.

Sequence of work

First of all, they conduct heat engineering calculations. Regardless of its result, you will need to create a heat-insulating layer with a thickness of 0.3 m. In those cases, when for some reason it will be less, you will have to accept insufficient thermal protection. Some of the insulation material is placed in the gaps between the beams, and about 1/3 of it is placed on top - this approach helps to avoid the appearance of cold bridges, which even beams themselves appear.

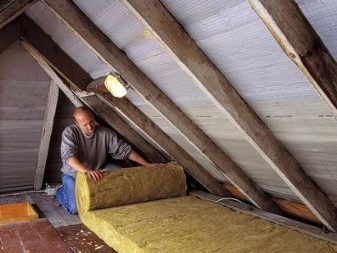

Suppose some kind of technical wool is chosen. The advantages of such a product do not cancel its deficiency: small suspension in contact with skin and mucous membranes, including inhalation, provokes irritation. It is better to place the plates on top of the wooden floor, which are placed in two layers in a checkerboard pattern.

Mineral wool should be cut with scissors or a knife, the docking edges should be tight to avoid heat leakage. Overalls must be worn beforehand: respirator, gloves, and goggles. Waterproofing a cold attic is required in the case when the roof system is not protected from moisture. But even if it is protected, such a measure is unlikely to be superfluous.

Installation of ceiling insulation

The device of the insulation layer on the wooden beams based on mineral wool begins with the installation of the vapor barrier. The film is placed in accordance with the technology, achieving an overlap of 10 cm. Each part protruding beyond the edge of the main unit should be rounded. The points of attachment of the film with the wall require that the material be lifted by at least 5 cm, and the thickness of the mineral wool is also taken into account.

At the second stage, the turn comes to the most insulated material. It is cut with construction knives, carefully making sure that the wool is not pressed through and does not have gaps, since both these factors will significantly worsen its quality. Do not raise cotton wool higher than beams. If you have to create a very thick layer, then the basic structures are built up with additional laths or a bar. Above the insulation is placed another layer of vapor barrier, and only then is a rough finish.

Floor insulation

Many people, in order to increase the living space in the house, make the attic the second floor. Warming its floor in this case has its own characteristics.

The sequence of layers in a wooden house is as follows:

- ceiling of the first floor;

- construction paper;

- the bearing beams from a good bar;

- mineral wool, it is placed in the cells formed by the beams themselves;

- another layer of paper;

- floor covering.

It is categorically unacceptable to deviate from this list or to interfere with the sequence of items in it, since this will greatly impair the protection against heat leakage and water penetration. A pair of plywood layers is added to the insulation in the “cake” - it helps to increase protection againstloud noises. And if instead of mineral wool to use expanded clay, then put a concrete screed in a dry way over it.

Warm the floor should be laying the material in the cellmolded by the truss system. Manufacturers took care of the transformation of simple technical wool into plates, which are much easier and more convenient to assemble. To be able to press the slab directly into the cells, its thickness should be at least 20 cm. Professionals love this method, but lovers should better give it up due to excessive material consumption. The best option is to place the plates under the rafters and in the intervals between them, if necessary, make the auxiliary frame parts.

Laying slab materials only under the rafters themselves will require the creation of additional crates, absorbing a part of the attic volume. Therefore, such a decision is allowed only in cases where no other measures help at all. If the ceiling of the second floor is located under the attic, and not under the roof itself, it is necessary to increase the thermal protection of the ceiling both from below and above.

To warm the floor of the second floor to give the best result, you need to work not only on it.Even the walls need to be prepared: close the slots with tow, impregnate with antiseptics. Only under this condition can we guarantee that with any changes in the environment in all parts of the house will be warm.

Then you will need:

- fix the horizontal slats for the ventilation system;

- mount a membrane that increases protection against steam;

- install vertical posts, which then allow to fix the plates;

- place insulation in the gaps of racks made of timber or aluminum profiles;

- fix the second vapor barrier layer;

- to finish the surface with clapboard, plasterboard sheets, chipboard or other coating.

Tips and tricks

To increase the protection of the upper part of the house against heat loss is possible not only due to thermal insulation materials. A very important factor is the arrangement of good ventilation. The total area of the holes for it should be equal to 0.5% of the total surface of the overlap. It is recommended to give preference to non-combustible insulation - this is especially important in wooden houses.

It is better to refuse foam plastic and polystyrene foam at all, as it easily lights up, attracts the attention of mice and insects, and the foam layer cannot be disassembled.

That is why even the excellent heat-shielding qualities of this material do not allow to consider it an acceptable solution.

Additionally, you should consider:

- there must be ladders to facilitate access to different places, they are created from boards;

- all wooden parts with which the heat-insulating material will come into contact need to be impregnated with fungicides and hydrophobic compounds;

- using foiled insulation, put it necessary to the shiny side down.

To learn how to properly perform attic overlap insulation, you can learn from the video below.