Warming attic in a house with a cold roof: the choice of material and stages of work

Salvation from the Russian harsh climate for many people is a warm home. Not always enough insulation basement, basement and walls: if the roof of the house is cold, you need to properly insulate the attic. This procedure has a number of features that need to be considered before starting work. Otherwise, all means and forces will be wasted, the result will not justify the effort.

Special features

Regardless of the type of construction and its number of floors, work with ceilings should be carried out according to strict rules.

- It is required to provide a safety margin covering its own weight and design load.

- Under the full design load should not occur deformation, deflection.

- It is necessary to ensure the level of sound insulation prescribed by regulations or special recommendations for building projects.

- It is assumed to maintain the limit of fire resistance established by regulatory documents.

When we insulate the attics, any of these requirements may be violated out of ignorance, due to carelessness or due to deviation from standard technology. The rest of the nuances relate to any one group of floors.

Types of floors

From the attic the main part of the house can be separated attic and interfloor floors. The difference is that in the first case, the upper part of the building is not heated, and in the second it is turned into a residential attic.

By design, the supporting segments of the floors are beamed and non-beam. The first ones are formed by beams and filling, the second ones are uniform, made in the form of plates or panels.

Beam ceilings in a private house are created in such a way that the main the elements were at the same distance. The main construction material is wood. Metal and reinforced concrete are practically not used..

Wooden blocks are quite light, but have a serious disadvantage - the limitation on the greatest length.In the inter-floor version, they can be used if the span is not longer than 5 m. For an unexploited attic, you can increase the permissible value by 1 m.

Sometimes you need to make the span more. Then you want to use metal structures. In the summer cottage such a solution, for obvious reasons, is not used. Most often, the flooring, which is placed on top of the beams, at the same time acts as a ceiling (for the lower floor), and as a floor (for the attic or a simple attic).

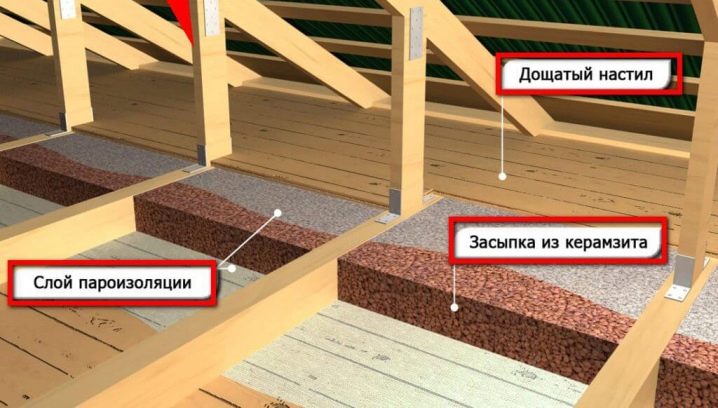

In addition to the beams and the flooring, they also install a reel and insulation layer..

Houses, resembling a rectangle in shape, overlap parallel to the shortest wall. Strictly determined distance and cross section of the structure help to avoid bending of beams in the loaded state.. These indicators are interrelated.

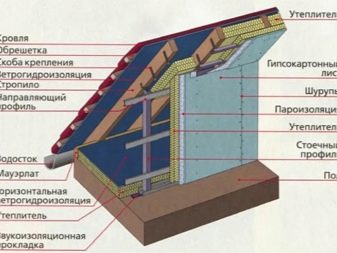

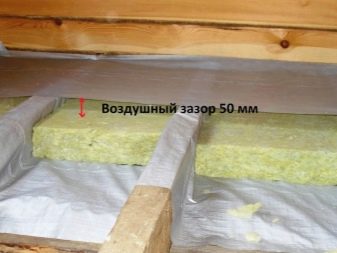

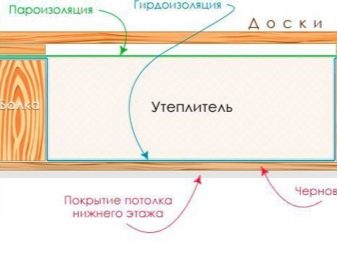

Under a cold roof, it is necessary to put beams with a gap larger than under the attic. (this is due to the difference in load). Regardless of the specific option, it is necessary to warm the ceiling in such a way as to guarantee protection of the rafters from water ingress. It is required to create a material impermeable to steam over the protective layer.

Materials

Proper insulation always begins with drying the attic by opening windows. It is important to take into account the nuance: they work with the attic floor, and not with the ceiling of living rooms.

The range of insulation is great, in any hardware store you can find a lot of varieties. They are divided into three main groups - bulk, roll and made in the form of plates. Each of the varieties is suitable for solving strictly defined tasks.

Bulk products optimally combined with wooden beams, helping them to "breathe." But to mount styrofoam is not too convenient.

Roll options differ in the increased environmental friendliness.

Plate, despite the severity, it is well combined with concrete floors (for example, foam concrete), which themselves are distinguished by density.

Warming from the inside of the room (from the ceiling) during a cold attic is rarely practiced, which is associated with several problems:

- lowering the level of the room;

- permanent violation of the already created finish and the need for its repair;

- different environmental and health safety of insulating materials.

Installation of thermal protection from inside the room can be done cheaply or with preservation of the proper level of comfort.We have to abandon the mineral wool, keep the gap from insulation to the exterior (it is necessary for ventilation). Internal warming is the best option for preserving heat when arranging a suspended ceiling.

If warming is carried out by extruded polyurethane foam or polystyrene foam, pre-assembly of the batten is required, on top of which drywall is fixed. The thickness of the timber is chosen by 0.2 - 0.3 cm more than that of the heat-insulating layer itself, the installation step is 0.1 - 0.2 cm narrower than the penoplex. Use of mineral wool is recommended only in the most extreme cases: it is highly toxic.

Far better than ecowool, derived from cellulose with the addition of substancesreducing the risk of inflammation. Such material is excellent in holding out other sounds. If you use a reed, you can not be afraid of fire.

It's time to figure out what features each of the groups of coatings has, and what other materials belong to them.

Bulked

To use the bulk type of insulation began in ancient times. The main options are:

- expanded clay;

- sawdust;

- flax fiber;

- reed stems.

Each species has its own differences and performance characteristics. Ease of obtaining, availability and almost zero price of sawdust have a downside (they have some serious drawbacks).

In the sawdust mass, mice easily settle. This can be prevented by adding hydrated lime and carbide. A layer of 10 to 20 mm is enough to keep it warm, but this impressive quality is crossed out by its high combustibility..

Expanded clay is compatible with wood and concrete floors: when it is filled, a full floor covering is created. The thickness of the layer varies from 20 to 25 mm, there should be a concrete screed about 5 mm below it..

In rolls

The undoubted advantages of any rolled insulation are the convenience of its use and the ease of careful installation of the blocks. This allows you to do the work yourself.

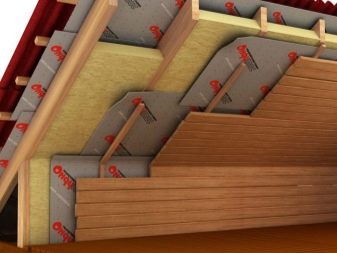

In most cases, despite all its shortcomings, mineral wool is used. Before laying the material, it is necessary to make a high-quality vapor barrier with glued seams for greater tightness.

Among the roll materials in the first place on environmental safety are algae. They are not prone to decay, but can become a container for microscopic organisms and parasitic animals. The probability of burning is very small, when processing with special solutions, it can be reduced to zero.

If the algae is safe, you can't say that. about glass wool. Resistance to water is depreciated by a serious inconvenience when working: it is necessary to defend against small, spiny and hazardous fibers. After some time, the material is compressed and largely loses its positive qualities..

In the form of mats and plates

Plate warming differs in reliable blocking of receipt of air. It should not be used in homes made of natural materials.. More often in the manufacture of plates using polystyrene foam, reeds, ecowool. seaweed.

The technology provides for installation strictly on flat surfaces with preliminary placement of vapor barrier films.. Even the smallest irregularities need to be fixed. Above the stove it is easy to make a full floor, which allows you to create residential attic even from the coldest initially attics.

Sprayed

The real technological breakthrough was the use of sprayed insulation.It is important to carefully approach their selection and take into account all the features, including the advantages and disadvantages of the coating being created.

The main positive aspects when using for insulation penoizol are:

- exceptionally high level of thermal protection;

- excellent absorption of extraneous sounds;

- solid vapor permeability (absence of condensate);

- the possibility of application in places that are not available or inaccessible for other insulation products;

- ease of installation on top of all existing building materials.

The last point does not mean that thorough preparation of the surface can be neglected.

Only thorough degreasing of the base ensures decent adhesion and stable performance of the material of its main function.

Regardless of the option chosen, the preparatory work is more or less the same.

Preparation for work

Before starting work in the attic of a wooden house you need to check the joints of the floors. It is important to consider: there should be no gaps or cracks on the base. Overlap any gap using lime mortar and tow. The frame elements are impregnated with antiseptic compounds and flame retardants.

If ventilation vents were not created before, the time has come to make them.

If you plan to make the insulation according to the roll pattern, you need to equip the floor slabs with lags (special bars). To fix them, you can use screws for concrete or dowel.

When it is planned to turn the attic into the attic, heating pipes must be warmed. The following types of technical wool are best for them:

- glass;

- mineral;

- slag;

- stone;

- basalt.

For your information: the cheapest options should be used in areas with mild winters. If the frost is tough enough, you will have to buy a more expensive and reliable insulation.

It is necessary to clean the surface of the smallest traces of dust and other contaminants. All parts of heating systems are covered with protective materials at least twice with overlap.

Features of the combination of heat and vapor barrier

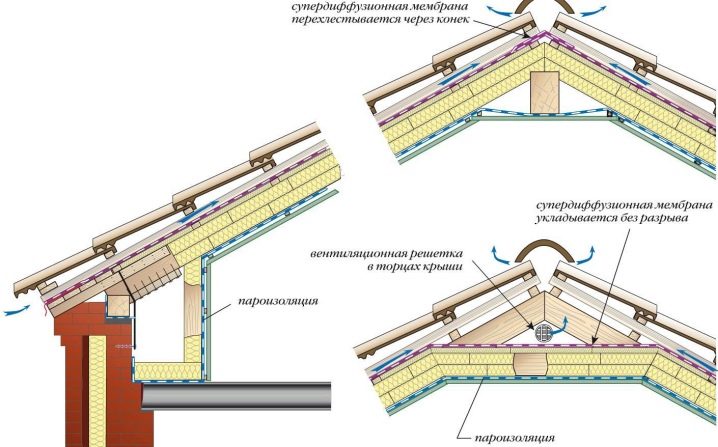

Vapor barrier in combination with thermal insulation is always done extremely tightly. Rolls overlap to 0.2 m, glue. A prerequisite - on the wall with the subsequent pressing plaster. Preference should be given to materials having a foil surface that effectively reflects infrared rays.

Floor cleaning

This moment can not be underestimated.It is worth a few months to use the house without visiting the cold attic, as there will accumulate an amazing amount of dust, dirt, cobwebs. It is necessary to remove all things, even the smallest and insignificant, to remove all the garbage before starting work.

Warming

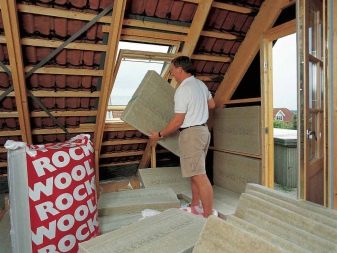

Disassemble the technology of laying all possible coatings will not work. It is necessary to stop on any one variant. For example, such as mineral mats.

First, you need to remove the board roll and attach a vapor barrier to the beams. For mounting membrane films should be used staples 14 - 16 mm, pushed into the base of the stapler. The gaps of the structures are filled with mats, which are fixed with the help of cross rails with a section of 20x50 mm. These slats will help keep additional vapor barrier.

Then you need to do with your own hands a wooden reel and arrange the ceiling. To protect the ventilation pipes from the cold, materials that form a kind of shell (for example, penofol) are better suited. It is better than polyethylene foam, does not so strongly absorb dust, which is inevitably present in any room.

If the ventilation pipe passes through the main wall, it must be placed in a heat-insulating sleeve.. When the ventilation channel goes through the room, you need to lay the material where it begins to feel freezing. Ventilation protection is done before covering the rest of the building.

A typical cake involves styling:

- solid board 25x100, 30x100 mm;

- double-layer windproof membrane;

- timber 5x5 cm across the overlapping beams (the distance between the blocks should be 59 cm);

- beams based on double beam 5x20 cm;

- New timber 5x5 cm;

- vapor barrier (best with aluminum foil);

- boards over the vapor barrier overlaps.

In attics one has to face the problem of a freezing wall or even several walls at the same time. Only simultaneous warming of the structure both outside and inside the building will help to eliminate this nuisance. The minimum thickness of the inner layer should be from 20 cm. This is the rare case when there is nothing better than plain mineral wool.

Using another old method of warming the main part of the attic (using flax), you should act in the same way as when working with sawdust. The difference is manifested only in the closure of the formed layer with kraft paper, which reduces the risk of damage to the material and its getting wet.

Overlaps

Interfloor hardwood floor can not be insulated, unless separate heating of rooms is planned in order to save. The vapor barrier in this case will have to be mounted above and below.

The sequence of work with concrete floors is as follows:

- cleaning;

- leveling the terrain;

- preparation on the basis of monolithic screed slopes for the outflow of moisture;

- placement of waterproofing (release on the edges is required);

- the formation of cement-sand screed thickness up to 50 mm;

- Roofing and sealing.

When the roof is already done, there is not much point in revealing and touching it. It is better to use penoplex or other material that does not need to be protected from contact with moisture. In one embodiment, the lags are mounted, closing them with insulation and blocking the gaps revealed by the foam. In another method, the plates are fixed on the floor using umbrella dowels.

Roofs

To guarantee a sufficient level of thermal protection, it is necessary to warm not only the overlap, but also the overhangs of the eaves, grouse, and the junction with the walls. Work strictly from lower points to highwhile keeping inviolable all biases. The overlap is at least 15 cm, the insulating layer itself must go back to back to back to back.

Cloths are placed from the ridge to the overhang with a slope of not more than 15% parallel to the skates, with a larger one - perpendicularly. Care must be taken to keep rolls free of dents., air bubbles and leakage.

Roofing treatment

If the truss legs are thinner than the intended layer of insulation, they should definitely be built up with wooden slats. Themselves reiki in advance soaked with protective solutions. Roof treatment to prevent fire and insect damage will also be required.

Professional Construction Tips

Any experienced builder in the insulation of various parts of the building is guided by SNiP II-3-79.

In addition to ready-made formulas for calculating the thickness and type of material required to pay attention to:

- climatic conditions of the area;

- wind load features;

- wall material;

- specifics of heating in the house.

This specialist or team proceeds to weatherization only after all the roofing work is completed.

How to insulate the attic with your own hands, see the next video.