The intricacies of the process of the inner lining of the house imitation timber

The materials from which the house is built, are not so important for its visual appeal. Comfort and beauty of the rooms gives interior decoration. Imitation timber is widely popular, because it allows you to realize a variety of design solutions, in addition, gives the rooms an original and unique look. Also, with the help of this material, it is possible to even out walls that need repair without any extra effort and expense.

Special features

Imitation of a bar is made of natural wood of various breeds. This means that the color and texture of materials are different.It should be noted that this material meets all the requirements of environmental friendliness. Due to the fact that in the design of the rooms there is maximum naturalness, being in such rooms is very comfortable.

Since the basis is wood, it is necessary to highlight the durability and strength of imitation timber, its excellent sound insulation and thermal insulation properties. The low thermal conductivity of products contributes to the creation of a comfortable indoor microclimate. In addition, when choosing a tree of individual species, its healing properties will manifest.

Also among the advantages should be noted ease of installation. All parts of the construction have connecting studs and grooves and practically do not give a load to the surface, thereby protecting it from deformation.

If the house is erected from a natural timber, the price can increase significantly, and also considerable time is lost while waiting for the shrinkage process.

However, like any natural wood, imitation has its downsides. First of all, the adverse microclimate and high humidity can significantly reduce the life of the products. The material is required to be regularly coated with antiseptic compounds, as well as varnished or painted.Also, it will not be superfluous to impregnate with fire-resistant mixtures to eliminate the risk of fire.

Boards of inadequate quality may not be strong enough, they are able to deform and crack over time, as well as be subject to rotting processes. This can be avoided only with the condition of buying quality goods from trusted manufacturers.

Design

Finishing for imitation timber can be of two types: monolithic and combined. It depends on the design idea.

- Monolithic finish It is a complete covering of a room with imitation of a bar. In this case, they can cover the walls, floor and ceiling. The panels fit together very tightly, forming a single composition.

- Combined the same finish includes various materials. The basis is the imitation of timber, and some parts of the room can be covered, for example, with tiles or wallpaper. The main thing - to ensure that the finish was made in the same style and a single color scheme. You can also implement original design solutions by combining different types of wood.

Regardless of the type of finish, along with the imitation of the timber you need to purchase additional decorative elements. It can be corners, moldings, giving personality and completeness.They can be made not only in the color of the tree, but also in any other shade: white, black, chrome and others. In the construction market, these details are presented in a wide range.

Installation

Before you start installing imitation timber, you need to make a clear plan of work. First of all, you should study the technology of installation of the panels and perform the preparatory work. The base must be leveled and the materials themselves soaked with an antiseptic solution. After that the obreshetka is mounted, the measurement is calculated and the material is selected.

Installation should be carried out strictly following instructions. After it, the panels are covered with protective equipment.

Training

You can sheat a room with your own hands, for this you need to know the general rules and precisely follow the technology. For a start - you can not carry out finishing work until the cottage, cottage or country house will not shrink. In case the house is frame, the finishing can be practiced immediately after construction.

- Before installation, a thorough cleaning of the surface and its alignment is required.

- With the help of mastic waterproofing is carried out.For vapor barrier film overlaps, how to be fixed and fixed with adhesive tape.

- After that, the frame is made. The crate, made of wood, must be treated with antiseptic.

- To create thermal insulation of the room, you can use special materials, for example, mineral wool or polystyrene foam. The layer is fixed, closed with polyethylene and processed with mounting tape.

It should be borne in mind that in the houses of natural timber insulation is not a necessity, and in buildings made of concrete, it is indispensable.

Material selection

Imitation of a bar is selected, first of all, depending on the type of wood, its class and size of panels.

There are several types of material. The highest quality varieties are considered "Extra" and "Premium", but they differ in the highest price. Cheaper at cost are grades A, B and C.

When choosing panels, one should take into account the uniformity of the wood texture and its color, the absence of defects on the material, the presence of knots on the surface, some of which are permissible on the budget level panels.

When buying, you need to consider not only the price category and the quality of the material,but also the needs of the consumer. For example, it is impractical to buy panels of class "Extra" for finishing bath or balcony. But in the rooms where it is planned to create a luxurious design, their use will be quite appropriate.

As for the size - the range of offers on the market is very wide. Experts give some tips on this. For example, the large size of the panels can visually reduce the height and size of the room. The best option can be elements with a width of 100-150 millimeters. Smaller ones will resemble cheap clapboard.

When choosing the length, it is necessary to consider the surface area and decor of the room.

Imitation of a bar can be from 3 to 6 meters in size. The thickness should not exceed 12 millimeters.

The walls, trimmed with panels of smaller length and thickness, will not only look more advantageous, but also require less cash. A well-considered and successful combination will allow you to create a unique and unique interior room.

When choosing the type of wood you need to study its quality and characteristics.

- It is possible to cite as an example the most popular materials, one of which is larch. This tree has a high fire resistance, it is very durable, and also has a very pleasant shade. Larch can be used for finishing both inside and outside the room; it endures even the unfavorable operating conditions, and also has healing properties. Finishing by imitation of a bar from this tree can be carried out even in rooms with the increased humidity and differences of temperatures, such as a bath and a sauna.

- Using panels from lime You can perform work on finishing the ceilings and walls. It has a smooth beautiful color, which tends to persist even with changes in temperature and humidity.

- As for oak - this tree is one of the most durable. It is resistant to rotting and insects, has a large number of shades, but is very difficult to process. In addition, oak materials have a higher price compared to others.

- Aspen on the contrary, it is easy to handle, resistant to high humidity. At the same time, it does not differ in special durability. If the wood is properly processed and dried, over time it will have good indicators of density and resistance to high temperatures.At the same time, the material has a huge disadvantage in that it can have rotten fibers inside. This nuance can not be detected in a timely manner, it will be revealed only during operation. The only way out is to replace a poor-quality element with a new one.

- Panels from cedar have a high price, but at the same time have excellent quality. They are durable and easily tolerate any adverse effects. An important point is the selection during the operation of medicinal natural resins. However, it must be said that cedar is forged quite often, and imitation of timber on its basis is made of low-quality wood, so you should purchase material from reliable suppliers and check the necessary certificates.

- Finally, a fairly popular material due to the very reasonable price is Pine. It can be used in any premises. The only caveat - the ability to allocate the resin with a sharp increase in temperature.

In the case of a complete home decoration imitation of timber can be considered a combination of wood, depending on preferences in price, quality, as well as starting from the properties and characteristics of the material.

Fastener

Imitation of timber is preferably fixed with the help of clamps. They are suitable for hidden fasteners and do not spoil the visual appearance of the surface with holes. In addition, this option is quite economical due to the small consumption of elements.

Also, the mount depends on the base material. For example, on wooden surfaces it is convenient to use screws or nail elements with nails. On concrete, brick or block bases it is worth using dowels and self-tapping screws.

It should be noted that the position of all fixed parts should be checked using the construction level: in this case, the surface will be smooth and even.

Finishing technology

Installation by imitation of a bar is quite simple and does not have significant differences in both the external and the internal decoration of the house. If we follow the technology, the installation will be quick, and the result will please with its quality.

Before finishing the indoor materials you need to bring inside, open the package and let them lie down for several days. During this time, the panel will get used to the new microclimate. The boards should be mounted exclusively in a horizontal position. From above or from below to begin installation - it does not matter. The main thing is to leave an indent from the desired edge of about 50 millimeters in size in order to circulate the air flow and to prevent the accumulation of moisture under the material.

The panels should be placed upwards with spikes - this will make it possible to eliminate the ingress of water into the grooves. The corners and openings under the doors and windows should be treated very carefully, observing the verticality and clarity of the cuts.

Also, the decorative coating should hide all installed communications. At the transitions you need to install the plinth - they will give the finish a complete and neat look.

Tips

- The room can be finished both independently and with the help of specialists.

- For greater consistency in the style of the room, you should carefully consider the selection of decorative elements. They are worth buying with a small margin. However, we must bear in mind that their excessive amount can create a repulsive effect.

- It is better not to save on materials. High-quality imitation timber will look great and will not create problems during operation for a long time, and will not require additional maintenance.

- Before installing the panels, the base must be treated with antiseptic and special impregnations.

Painting products can be carried out at any convenient time, regardless of the finishing work, taking into account the characteristics of the material. For example, in heated premises, this process is recommended to be postponed for a couple of months after installation.

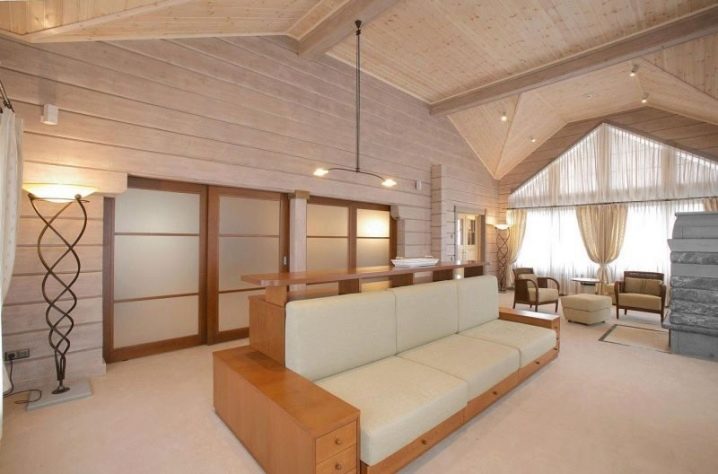

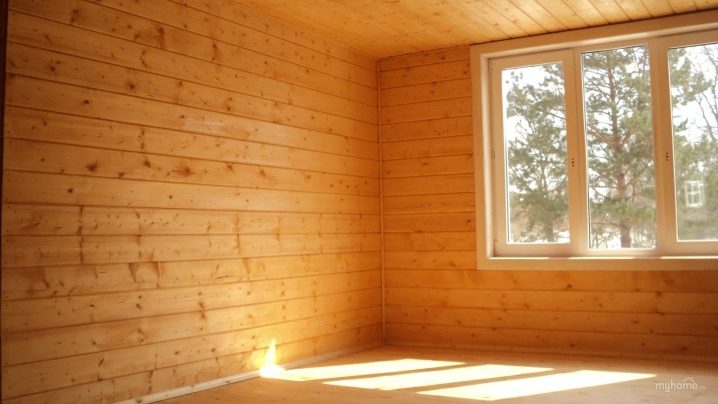

Beautiful examples

Consider some design solutions and examples of interiors.

For information on how to trim imitation timber inside the house, see the following video.