Aluminum facades: designs

Aluminum facades of buildings are the most popular way of modern design of external walls of buildings. Their demand is due to excellent decorative properties and versatility.

Features and benefits

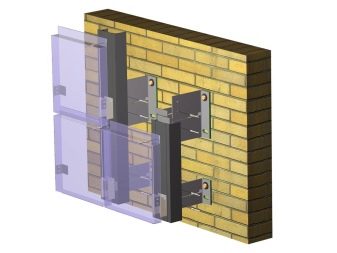

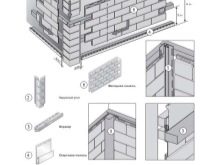

Aluminum facades are easy to install, which occurs by fixing the cladding material on a metal frame, pre-installed on the facade of the building. An insulation layer is laid between the cladding material and the frame, and a little empty space is left between the external and internal elements.The air gap allows to avoid the formation of condensate and mold under the cladding layer on the walls of the building and prolongs the service life of the structures.

Installation of products involves the use of special brackets and other components along with facing material. The quality and appearance of the latter depends on the design and practical properties of the building.

Aluminum facades are good for their versatility: they are equally well in tune with siding, professional sheet metal, ceramic granite, glass. Today glass cladding is particularly popular, giving style and airiness to any structure.

Like any other material, aluminum profile has its advantages, such as:

- the service life of facades reaches up to half a century, and the facades of such materials are extremely durable;

- installation can be carried out at any time, regardless of weather conditions and time of year;

- facades do not need special care and for many years retain their original properties;

- for the manufacture of facades using non-flammable or flame-retardant materials;

- different materials can be used as cladding;

- aluminum facades increase the level of sound and noise insulation of the building;

- with their help, you can hide engineering communications, irregularities and defects in the walls.

If we talk about the shortcomings of aluminum facades, then it is worth first of all to note the high cost. The material is characterized by an attractive sheen, which over time is lost.

Aluminum is easily prone to scratches, and it is worth being careful with sharp corners that can cause injury.

Kinds

There are two types of aluminum facades.

- Ventilated They are a structure in the form of an aluminum frame (subsystem), insulation and decorative facing material. Different materials can act as cladding: composite panels, fiber cement, siding.

- Translucent are designs for 90% consisting of glass. If desired, glass can be replaced with plastic, but aluminum support profiles are always used as a support. This type of lining is widely used in the design of facades of office buildings, hotels, shopping centers, sports complexes, swimming pools and residential buildings.

The listed structures are divided into several types of facades.

- Rack-mount facade. It is considered one of the most reliable and durable among all others. But at the same time there are few design options - the facade of the building will always resemble a glass cube, since the glass profile can only have a rectangular shape.

- Semi-structured facade. All bearing racks are located inside the building, and outside there is only a clamping mechanism that fixes the glass. Such facades have a higher price and variety of appearance.

- Structural facade. Unlike the previous type of glass is mounted with a sealant, and not fixed on a metal frame. But this does not affect its strength properties - such a facade is in no way inferior to the previous species, and even aesthetically benefits.

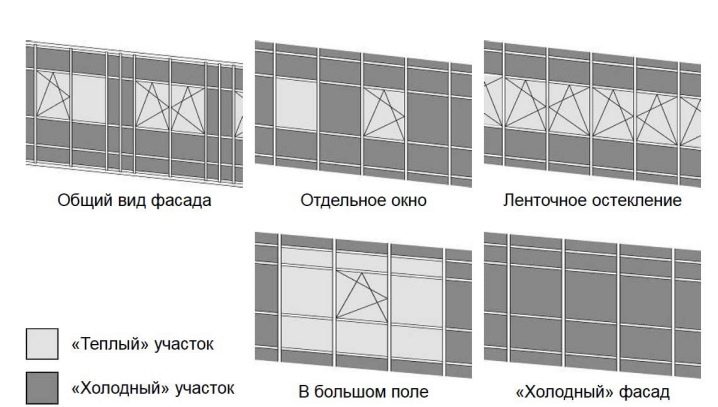

Facade aluminum systems are "warm" and "cold."

- "Warm" are mounted to the already finished wall of the building. For example, it can be a glazing of a balcony or loggia. Such structures are characterized by a high level of thermal insulation, for which they received such a name.

- Systems of the "cold" profile are fixed as separate supporting structures. Often, an aluminum frame equipped with tempered glass with a thickness of 1-2 cm.

Combined systems are considered to be equally popular. This is when the facade is equipped with either horizontal or vertical metal profiles. Mainly used structural or semi-structural curtain walls. There is a trapezoidal front profile, solid, hollow and an open-ended profile.

The choice of the form, as well as the design, and the quality of the material depends on the appearance of the future facade.

The modern building materials market offers many options for aluminum cladding.

- Porcelain tiles are quite expensive material, but they are distinguished by high strength, reliability, durability, and a wide palette of natural colors. The standard size of the panels is 600x600 mm. The larger the size of the plate, the more expensive its cost.

- Composite aluminum panels are made from sheets of aluminum, between which lay a layer of non-combustible material. On special equipment, metal is folded to the desired size and forms a cassette.Basically for the cladding of the facade using cassette size 1250x4000 mm.

- Block house - This is a great option for a luxurious and inexpensive lining. Material parameters can be any up to the creation of boards according to individual sizes. It is installed together with a wooden crate. The cost of material depends on the type of wood and manufacturer.

- Metal siding - This is one of the most popular options for trimming the profile frame. The popularity of the material is due to the availability of prices, functionality and practicality, a wide palette of colors. The dimensions of the panels reach 200-300 mm, some manufacturers can customize the size.

- Fiber cement and asbestos cement plates (Japanese facade) is a durable, reliable material, while incredibly flexible. Its advantage lies in resistance to corrosion, ultraviolet, moisture and shock. The only negative is the high price.

- Terracotta (ceramic) plates. Clay is used as the basis for the production of this raw material. Plates are used for cladding country cottages, government agencies, shopping centers, various private buildings.Buildings lined with this material look solid and elegant.

- A natural stone - This is an expensive material, the cost of which is fully justified by the strength and aesthetic properties. It belongs to the premium segment of materials for cladding, and also requires a professional approach to installation and appropriate framing in the exterior and interior.

- Glass. Glass arrays are strongly associated with modern construction. For plating used high-strength glass, which is well tolerated load, wind, precipitation. There is a special facade glass with the use of aluminum: laminated, armored, sheet, patterned, reinforced, polished, flame resistant, sunscreen, frosted, tempered, with a hard and soft coating.

Dimensions

Aluminum profiles for facades can be of any size. The most common options are products 45x45 and 50x25 mm. They are used to create the frame and the various partitions of the subsystem. The sizes of the angular aluminum profile are also quite diverse: 10x10, 12x12, 15x15, 25x25, 30x30, 40x20, 40x40, 40x80 mm.There are also more dimensional constructions of size 70x70, 100x50, 120x40 mm. Small aluminum profiles, such as 25x25 mm, are used for cladding the facade of standard office buildings.

But more dimensional systems are used in private construction, where the architecture of the building is more non-standard.

Company rating

Currently, more than a hundred companies are represented on the domestic market, offering design and manufacturing services for a facade profile.

It is worth getting acquainted with the list of brands whose products are time-tested.

- Company Tatprof - It is the leader in domestic production of facade metal structures. On the market for over 25 years and during this time product quality has reached the highest level. Products undergo 7 stages of testing, and the high strength and reliability of products is due to modern equipment of the company. Tatprof is engaged in the development of new projects in the field of energy saving, construction, engineering and production, which makes it possible to talk about the creation of new, improved products.

- Company "Alutech" ranks second in the top five leading manufacturers of aluminum facades.The corporation has five manufacturing enterprises and 25 sales companies. For the manufacture of products using modern equipment that meets European standards and provides the release of structures of excellent quality. The company has its own production facilities, which makes it possible to fully control the quality of products at all stages of production.

- Company "Realit" - is a domestic manufacturer of extrusion aluminum profile. This company is engaged in the design, manufacture and production of finished products of any complexity. In addition to facade systems, the company produces profiles for windows and doors. The holding is not inferior to the leaders of facade production. The company even opened its own engineering and exhibition and training center. The quality of products is controlled by the best specialists of the company’s laboratory

- Company "Plastal" offers certified products that have passed a series of tests confirming its quality. It has a huge dealer network, and profiles are considered to be among the best in the country.

- Company "Premium Window" enjoys wide popularity and offers aluminum profiles of German quality. All brand products comply with European quality certificates. The production uses environmentally friendly materials, so products can be used in buildings with high sanitary requirements.

Accessories

Installation of aluminum facade structures requires additional materials. To fix the system, you will need the following elements:

- L-shaped brackets;

- sliders for compaction;

- pipes;

- guides (lamellae);

- clamps;

- cant;

- stub.

The brackets are necessary for fixing the system to the facade wall. With the help of sliders, the material can take the necessary shape, change the configuration and volume under the influence of temperature and humidity.

Guides and clamps are used to align and secure sheet material.

Raw Material Tips

The advantage of using a ventilated facade is that, if desired, the installation can be carried out personally. The ease of installation of aluminum facades due to the ease of fixing the material.

But despite this, it is desirable to know the following nuances, then the quality of the arrangement of the facade will be at the level:

- it is necessary to strictly follow the installation instructions of the facade system, insulation boards and carefully monitor the quality of performance of all items;

- It is best if the layout of the facade design will be developed individually for the building and preferably before the materials are purchased. In addition, planning will provide an opportunity to think through all the stages of facing the facade;

- It is not recommended to save on materials, tools and other necessary technical elements. The strength, reliability and durability of the future facade depends on their quality;

- Care should be taken to select fasteners. It is best to give preference to proven manufacturers, the quality of which you can be completely sure.

You will learn more about aluminum facades from the following video.

Examples in the exterior

- The glass façade is an excellent example of the combination of exquisite architecture, modern design and building functionality.

- Connoisseurs of strict forms and concise design should look at the facades, lined with siding.

- Bright ventilated facade panels are a great way to design an office. The wide palette of materials allows to embody the most creative ideas.

- The most advantageous option is the use of combined materials. Such design options are referred to as premium cladding. They will never go out of style!

- Original lighting can dramatically change the design of the building.

- The advantage of ventilated facades is the ability to create any shape from a classic cube to a polygon.