How to sheathe the facade of the house with professional sheet with insulation?

Decking (he is a professional sheet) appeared on the construction market relatively recently, but in a short time it became one of the most sought-after materials. Such popularity contributes to the universality of this material, a relatively small number of flaws with a large number of positive qualities, as well as affordability. Such sheets are used in the decoration of commercial buildings, housing, cafes, garages and other public and industrial buildings.

Special features

The growing demand for metal siding finishes confirmsThis material is a quality construction product with universal characteristics and possibilities for transportation and operation. Durability and durability, rich color gamut and a wide choice of simulated materials force buyers to make a choice in favor of profiled sheeting. And the opportunity to refuse the installation of the services of specialists, availability at any time of the year, a small price and ease of maintenance of the facade make the material unique and almost indispensable.

Sheathing metal profile is ideal for people who want to insulate your home and improve its design. First you need to understand what a professional sheet is. Galvanized steel and polymer coating are in the composition of the profiled sheet. The creation of the material takes place in three stages: a corrosion-resistant coating is applied to the galvanized sheet, then a layer of polymer coating is applied, and a thin layer of primer and paint is applied to the production. As a result, the sheet acquires a thickness of about 4-16 mm.

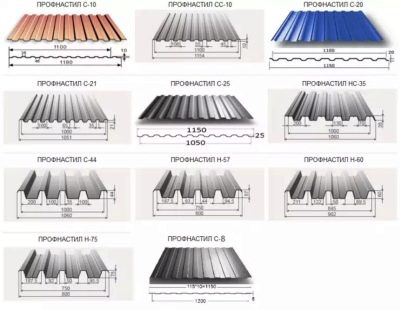

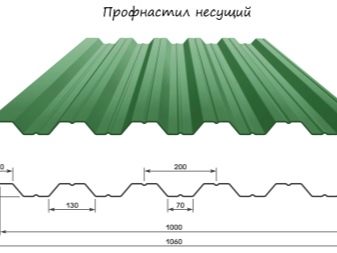

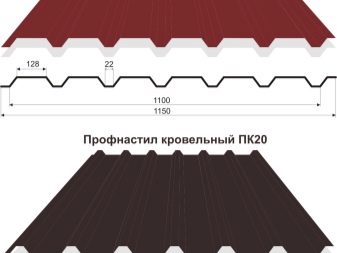

It is very important to choose the right material. There are different types of work, so profiled sheets are represented by several varieties, each of which has its own label.

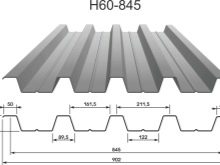

- Reliable metal roofing can be formed from specially designed products with the designation "H".

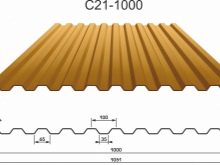

- Facade decking, labeled "C", is suitable not only for the facade, but also for facing the fence.

- Products marked "NS" have universal characteristics, but this option is not available to everyone because of the rather high prices.

To create a beautiful and reliable coverage, additional components are needed that perform various functions:

- corner lining allows you to hide the joints in the corners;

- moldings are suitable for doors and windows.

Advantages and disadvantages

A large number of advantages of this material explains the growing demand of users.

- Convex ribs provide uniform load distribution, which makes profiled flooring one of the most durable materials capable of withstanding even serious mechanical stress.

- For the exterior of the house does not require professional equipment or special skills, because the installation technology is very simple.

- At the moment there are a large number of professional sheets of colors, as well as options for coatings that mimic different natural materials.The shape and color is selected for individual customer requirements.

- Tightness, protection from external natural influences, such as rain, hail, snow.

- Fire resistance

- Resistance to sudden temperature fluctuations (from -50 ° C to + 120 ° C).

- Environmental Safety.

- Ability to trim without joints.

- Low cost compared to other building materials.

- The lifetime is approximately 50 years.

However, despite the large number of advantages, during use, there are also some weaknesses that can spoil the overall impression..

- Sheeting is able to withstand high loads, but minor damage may cause damage to the material. Scratch marks reduce visual appeal.

- During rain and hail, the material amplifies noise penetrating from the street.

- Professional sheets are very hot in the sun, which can cause burns when in contact with the material.

- Damage during transport may contribute to rust.

It is very important when choosing to devote enough time to study the quality of the material. The cheapest or very thin products will not last long.

Installation

With a responsible approach, sheathing a house with a professional sheet can be done independently. It is important to carefully study the installation technology, since even small violations in the process of insulation can lead to undesirable consequences. Wall cladding occurs in several stages of work performed in series or in parallel.

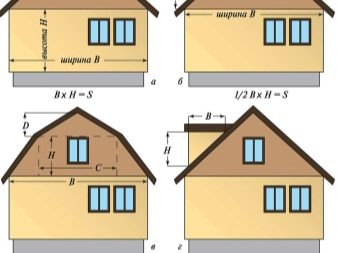

Stage 1. Calculation of the required amount of material

First, the area of the house or garage is determined. It is better to measure each surface, after summing up the data and subtracting the area of door and window openings from the result. It is necessary to purchase metal siding with a margin (at least 10% of the required quantity).

Stage 2 Training

It should be noted that the installation of metal siding with their own hands requires serious preparation. Additional materials and tools will allow you to make the design look complete.

- Wooden and metal elements are used as a guide profile.

- Suspensions will be required to install the steel profile.

- Self-tapping screws will allow to fix the frame and facing.

It is also necessary to prepare a drill, drills, hammer, saw and metal shears.It is better to refuse Bulgarian because the heating of the edges leads to the appearance of rust.

Then you need to go to the surface preparation. Decorative material will hide defects, but will not eliminate them, and ignoring this action will only aggravate existing problems.

It is worth considering that black spots on the walls may indicate a fungus.

Such surface areas require more thorough processing.

- Remnants of the previous coating are removed, the base is cleaned of dirt and dust.

- All cracks are cleared and carefully plastered.

- The walls are treated with antiseptics.

- The foundation is hydroprotected.

Stage 3 Frame installation

The frame must be strong and reliable. It must withstand various influences, so the metal profile is most often used. The process of installing the frame is quite simple.

- The location of the sheet is set: the horizontal ensures a higher protection against moisture penetration, the vertical will strengthen the surface.

- Alignment takes place, taking into account the step guides, which is determined by the size of the selected insulation.

- Suspensions are placed on the marking, on which guides are sequentially fixed, for reinforcement of which bridges are additionally mounted.

4 stage. Installation

This stage is the last and most crucial.

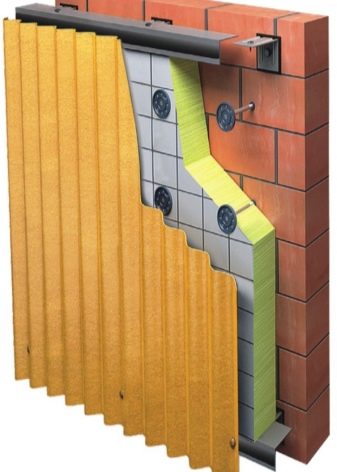

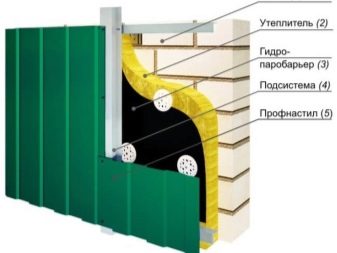

- A layer of insulation is installed and covered with a protective membrane.

- Low tide is adjusted, a high base is faced separately.

- All parts are fixed and checked.

- On all elements docking modules are mounted.

- At the end are fixed corner and window plates.

It is important to leave a ventilated space between the wall and the insulation layer, otherwise the house will not be protected from condensation. In total, the facade of the metal profile should consist of five layers:

- vapor barrier layer;

- wind barrier;

- the heat-insulating layer, the dimensions of which must completely coincide with the size of the metal siding;

- frame made of bars (the thickness must be at least 40 mm) or profiled sheets;

- facing.

Tips and tricks

- Profiled sheets are not universal, they are divided into roofing, bearing and wall. Each species has its own characteristics, and therefore its value.

- The thickness of the metal from which the profiled sheet is made is the most important feature of this material, it directly affects the service life and cost. Metal is selected by the customer in accordance with his needs.

- It is better to choose sheets with zinc, alyumotsinkovy or polyester coating. Professional sheets, covered with such a composition, longer retain the original color. They are also more resistant to aggressive substances, frost and heat, corrosion and most mechanical damage.

- During assembly, it is customary to stack profiled sheets with an overlap, with a length of overlapping of one sheet on another from 1 cm.

- To fix the material to be stronger and more reliable, direct attachment to the crate is made only in the lower part of the profile.

- At installation of a roof from a professional flooring it is necessary to plan free movement of air. This will allow installation of thermal insulation and vapor barrier layer.

- Budgeting is a mandatory stage of any construction. Pre-cost calculations will allow you to plan the project budget and adjust it. Any estimate includes the calculation of the cost of the material (this part is preferably"Split" into several separate subsections) and the calculation of construction work.

Beautiful examples

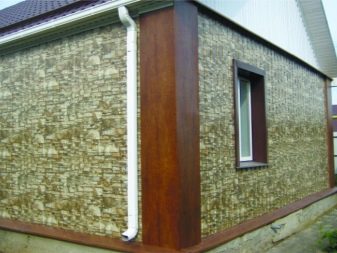

Houses finished with profiled flooring are more common today.

Thanks to the production according to certain requirements and standards, this facade cladding gives a beautiful appearance to any, even the most modest building.

- Metal siding “under the log” can be one of the options for transforming a house. Voluminous professional sheets imitating a log according to texture and color are an advantageous, practical and universal solution. From a distance, the house looks like a classic wooden building, without having to look for ways to solve problems such as mold and insects.

- As a facade cladding, you can choose another option. Imitation bricks or simply color design can give the building a solid and "expensive" look.

How to sheathe the house as a professional sheet, see the video below.