Facing stone for the facade: types and features of installation

The facade of the house is the business card of the owners. And if you decide to distinguish your house from others, then you should pay attention to facing it with stone, since even a modest house with a stone facade attracts much more enthusiastic views than a three-story cottage. The stone decor gives the house a more presentable and luxurious look, which speaks of the taste, lifestyle and style of the owner. Therefore, it can be stated with complete confidence that stone facing is unmatched.

Special features

Stone is used in the construction of houses for hundreds of years. And today, facing stone is a leader among the methods of finishing the facade of the house, second only to the popular plaster.Apart from the fact that the stone facade has an attractive and original appearance, it also gives additional strength and extends the life of the walls.

The stone facade has been at its peak of popularity for many years and there are many reasons for this:

- A variety of materials - today builders and designers offer natural and artificial finishing materials.

- A large variety of shapes and colors - modern finishing materials are available in various shapes: rectangular or square tiles, stripes, solid plates.

- Eco-friendly material - natural and artificial stone is absolutely safe for humans.

- The original appearance - the stone facade is able to give the building grandeur and elegance. The beauty of natural design turns the facade into a unique work of art.

- The ability to revet the house in whole or in part - in any case, the facade will look more advantageous against the background of neighboring buildings.

- Increases fire safety - the stone does not support the process of burning and does not spread fire.

- Practicality and reliability - the front stone is resistant to high humidity, temperature extremes and mechanical stress.In addition, an additional layer of stone extends the life of the external walls and the building itself.

- Additional sound insulation.

- Increases heat insulation - natural stone also serves as an additional heat insulation layer. In the summer in such a house is cool, and in the winter - warm.

- Simplicity in leaving - the stone facade does not need to be polished and painted.

- Durability - it will serve for many years.

Types of materials

All materials are divided into two groups: natural and artificial. Natural materials are cut into small plates and natural stone is processed and calibrated.

The front of the left relief, and the seamy side is made flat to simplify the installation process.

Among the most popular natural stones for facade cladding include:

Marble

It has a rich color range and is one of the most expensive finishing materials. For cladding the facade is most often used medium density marble, the last polished. Under direct sunlight, this gives the surface a deeper and more saturated color.

Granite

Also applies to the elite material segment. When finishing the facade is used as a polished (glossy) and unpolished (matte) stone. Manufacturers offer granite of various sizes.The most popular are large slabs and paving of medium size.

There are three types of granite:

- plagiogranite - has a predominantly light gray tint;

- Alaskit - has a pink tint;

- porphyritic granite - is something medium between other species and has a pink tint with small light gray patches.

Granite is not affected by any climatic factors.

But besides a large number of advantages, it also has disadvantages - it is a big cost of material and an impressive weight.

Limestone

It can be of any shape - from classical rectangular and square to polygonal. The material can have a relief punched surface or be ground and have a matte smooth side. Most often, the stone has a white and yellow color.

Limestone can be called plastic and pliable material, it can be given any shape during processing. Only limestone with a calcite content of up to 98% is used as a cladding material, which indicates high strength and reliability of the stone. Not for nothing the Egyptians used it to build the pyramids.But limestone is not suitable for a sharply continental climate. When changing seasons, high humidity and temperature drops, the stone may break.

Labradorite

A beautiful stone with a blue, red or yellow pattern. It is a durable and reliable finishing material, which is not afraid of climate change.

Sandstone

An inexperienced person may be confused with limestone. Both stones are similar in color and size. To the touch, the stone is slightly rough and may have a beige, yellow or brown tint. Sandstone is considered a more durable and reliable material.

There are 4 types of stone:

- oolitic;

- pyzolitic;

- shell rock;

- lithographic.

But only the first two types are suitable for cladding the facade: oolitic and pisolitic sandstone. A shell rock and lithographic are used for the construction of buildings. Slate - has a smooth and flat surface.

Compared to other natural materials, it has less weight, which allows it to be used also for interior work.

Slate

It has a smooth and flat surface. Compared to other natural materials, it has less weight, which allows it to be used also for interior work.

Modern manufacturers have allowed to bring the facade facing to a new level. Artificial stones can look completely different from natural materials and are not inferior to them in durability and strength. And at the same time they have significantly less weight, which allows not to carry out additional work to strengthen the facade. And besides, it is easier and faster to work with facing panels.

Strong and reliable analogues filled the entire construction market. And manufacturers do not give to doubt the durability of artificial stones - some types of alternative materials are guaranteed up to 100 years.

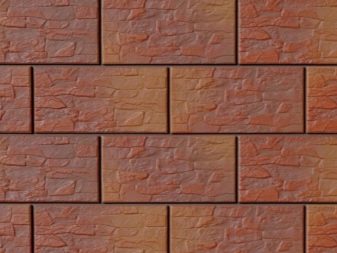

The clinker brick or tile can imitate both brick and crushed stone.

The basis of the material is clay. After the formation of the mold, the stone undergoes high-temperature processing and is burned in a furnace at a temperature of 1200 ° C, which allows achieving high strength and reliability of the material. In addition, the clinker tile has high frost resistance, durability and resistance to UV rays.

In the production of stone from concrete, high-strength brand cement is poured into the mold and compacted on a vibrating table. Artificial concrete stone can be given any color even at home. Experts also recommend to cover the stone with reinforcing primer for three years. Thus he will serve about 30 years.

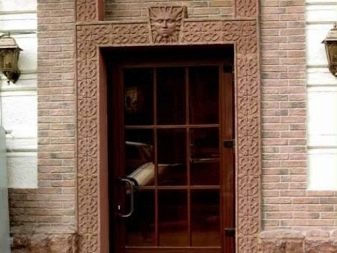

The process of producing architectural stone is no different from concrete. Only in this case high-strength white cement is used. An architectural stone can have any shape, repeating openwork details and curved lines. Most often, the architectural stone is used for partial decoration of the facade and is located near the doors, window openings, as well as under the roof.

Polymer sand panels are based on polymers and sand.

In this case, sand is used more to give shade and economy than for strength.

Synthetic resin panels perfectly mimic natural stone. Synthetic resins are used as a bonding material, and the base of the panel includes dust and a crumb of natural stone, which allow you to create an amazingly beautiful natural pattern.

Flexible stone - a modern coating with excellent imitation of stone in color, pattern and texture. Facing a flexible coating is made by hand and career sandstone is best suited for this.The composition of a flexible stone includes a natural stone cut, due to which, at first glance, the fixed coating does not differ from a natural stone. A small layer of natural material with a thickness of no more than 3 mm is applied on the outer side of the fabric surface. The finished coating combines the advantages of natural and decorative material. The unique structure of the flexible stone has a small weight, has excellent moisture resistance and fire resistance.

Colors and design

Stone decor perfectly complement many architectural styles and trends. "Wild" stone with a unique pattern allows you to create an excellent composition on the facade. This is possible thanks to the labor-intensive work on the extraction and preparation of the material for lining. To do this, large stone slabs split into a large number of smaller parts.

The composition and structure of the stone is influenced by all natural factors: rain, snow, wind, sun.

Depending on the specific climatic zone, organic and inorganic substances are formed. Therefore, all stones are unique in their own way - they have different sizes and shapes, torn edges and a rough surface.Harmoniously combining colors and texture, you can create the most unusual combinations and variations of the lining.

As you know, the color palette creates a mood and has an impact on perception. Natural stones have a beautiful pure color and many different shades. Natural and artificial lighting in different ways affects the perception of the stone.

Therefore, when choosing the color of the lining is to follow a few rules:

- The architectural style of the house affects the color of the building. Evaluate the appearance of the building and try to find the right palette. So, for example, in the classical style it is unacceptable to use bright and catchy colors that will perfectly complement the style of modern solutions. Complex architecture will look much more spectacular in a neutral and calm palette.

- In most cases, it is wiser to choose light shades: white, soft beige and other milky tones. They blend harmoniously with the natural landscape all year round.

- Yellow, green, blue and other colors related to nature look cozy and bright on the facade.

- Gray belongs to the category of neutral tones and goes well with other colors.Gray color is not always associated with melancholy and gloom, it is great for the facade of a house in the style of a medieval castle or fortress.

- But it is worth thinking carefully before using the dark palette. It is best suited for homes of simple form. The main feature of dark colors is that they attract the sun's rays, so on a hot day, the lining will quickly heat up, causing the artificial surface to fade and lose its rich color.

- And although bright and saturated colors visually increase the area and highlight the house from the rest of the buildings, they will also quickly change color under direct sunlight.

- When you design the facade, you can combine several shades. Well combined shades of a single palette, for example, from dark brown to beige.

- Perhaps, one of the most popular options is considered to be a combination of rich red and brown in suburban construction. The color of the brick is perfectly combined with white window frames and a dark roof. These colors are great for buildings of simple architecture.

- And to give a finished look to the site, you can decorate with a stone a porch, stairs, walkways and areas. For this perfect stone veneer. It represents sheets with a relief surface.Veneer has a rich color range and texture, so it can be suitable for combination with any facing material.

- You can also use stone decor in the interior. For use in the room is ideally “ragged” stone, which undergoes additional processing in production. On the front side, the stone retains the relief surface and natural pattern, and on the reverse side it has a smooth surface to facilitate installation work.

How to choose?

Facing stone allows you to embody any bold design decisions and ideas in the design of the facade. All facing materials differ in strength, appearance and resistance to various factors. And in this case it is impossible to isolate the best stone.

For cladding private homes mainly used limestone, sandstone, slate and artificial stones.

And for the decoration of the basement and the first floors of administrative buildings, granite or marble is most often used. When choosing a facing material, you must first focus on your wishes and needs, which may be associated with the appearance of the stone, its value or other factors.

When finishing the facade facing material should also pay attention to the other elements:

- a socle;

- window frames;

- doorways;

- garage doors;

- the stairs.

Also facing stone can be used not only for exterior decoration, but also for interior decoration. But like any finishing material, the stone undergoes industrial processing, after which the material receives the necessary structure:

- "Rock" - as much as possible saves natural natural texture. This stone is in harmony with metal wrought iron elements.

- Lordly - on the surface of the stone are formed traces of punctures.

- Ground - as the name implies, the surface of the stone has a smooth and smooth texture.

- Polished - outwardly similar to polished, but has a matte surface.

- Polished - has a brilliant glossy, almost mirror-like surface.

- Sawn - has a rough surface. This decor is great for a log house.

Of course, natural stone is not cheap, in addition, half of the total cost of the material is processing and calibration.Of course, the money spent will pay off over time, since natural stone can last about 100 years. But you can also use the artificial stone for facing without embarrassment.

The price of decorative materials is much lower and it is easier to work with them than with natural ones. But if you still decide to choose a natural stone for the facade, listen to the reviews, entrust the lining work to experienced specialists.

Types of laying

It is necessary to choose a suitable finishing option taking into account the style of the house and the site. From the chosen type of masonry depends on the appearance of the facade of the house.

Facing a die allows you to get a natural natural pattern and is considered the most affordable way of laying.

The most commonly used natural raw materials are sandstone, slate, limestone and some types of dolomite. The cost of this masonry is almost the same as facing artificial materials.

Before laying, no additional processing of the material is required, which allows you to create a picture that is closer to the natural style.

- Laying complexity die is to choose different materials in size in such a way that there are no gaps between the elements.

- Cust translated from English means "castle".With this clutch, the facing should be as close as possible to the medieval castle. Sandstone, slate, limestone, marble, granite are excellent for this type of masonry. And you can also use more affordable artificial materials. For such masonry, rectangular stones measuring 5x10 cm with uneven and prickly sides are best suited. The sizes of the stones can be different, but the obligatory condition is that the form should be rectangular.

- Plateau - figured way of laying, which has nothing to do with the natural natural pattern. The stone can have a rectangular or square shape, and for the convenience of masonry its edges are processed. The side of the stone must be a multiple of 5. But the laying process is complicated by the fact that it is necessary to adjust and distribute stones of different shapes so that the revetted facade looks complete and stylish. Often, the plateau type of masonry is used when finishing the basement, windows and corners of the building.

- When laying Shahriar all elements have a rectangular shape, which greatly facilitates the process of laying. The edges of each element have a border, which is a distinctive feature of this masonry.The surface of the stone can be embossed prick, polished or smooth. But after polishing a stone looks more like a brick, therefore stones with a natural, unprocessed surface are very popular. Even a novice will cope with this method of laying, the only difficulty is to lay the first layer evenly, after which the work process will be much easier.

- Gonna - for such masonry thin elongated rectangular plates are used. They can be made of both natural and artificial stone. Most often shale and sandstone are used as the base. Facing the wall with masonry Assol creates the illusion of a massive massive facade. But the installation work takes a lot of time and effort, since each stone has its own thickness, it’s not so easy to create a harmonious composition with an equal number of rows.

- Rondo - an unusual type of laying in a nautical style. For cladding, pebbles or other river stones of round shape of different sizes are used. The material does not undergo additional processing and is used in its original form.Finishing of the entire wall with rondo masonry is rare, the most often used facing of small areas on the facade: doorways, windows, porch and basement. The process of laying rondo is much easier than other options. First of all, large stones are attached to the facade, and then smaller elements are fixed in small openings and slots.

Quantity calculation

To make an estimate and calculate the approximate cost of the work, it is necessary to determine the surface area for lining. For this, the height of the wall is multiplied by the width. But it does not need to take into account the area of windows, doors and other areas that can not be finished. Then the total area of the facade of the entire building is calculated. The resulting figure is divided into the area of a single stone. This method of counting is suitable if all finishing units are the same size.

Some manufacturers to facilitate the work offer an additional corner stones.

To calculate their volume, it is necessary to add the length of all the corners of the building and divide by the height of one stone.

It is necessary to buy material with a reserve for unforeseen expenses and force majeure circumstances. Therefore, the total amount must be added 10%. This amount is enough for both fitting the material and cutting during the deformation of the stone.

Installation

Natural and artificial stones are mounted on the same principle. It is important to follow all the strict rules and recommendations. Any installation work with a stone should be carried out at a temperature from + 6 ° С to + 25 ° С. When finishing the facade does not necessarily cover all the walls with stone. In some cases, a more advantageous option is considered a partial cladding of the building. This task can even be performed by a beginner with his own hands.

Before starting work, we recommend drawing the future facade of the house in order to clearly understand the sequence in which to use various materials.

A general picture of a stone must be selected in advance in small sections on a horizontal surface not far from the wall. So it will be easier to transfer the picture to the facade.

It is also necessary to prepare the surface of the walls for future work.

The key point in this case is the humidity of the facade. For cement walls, an indicator of 4.5% is optimal, and for wood or drywall - not more than 0.5%.

The facade removes old paint, lining and insulation. This is necessary in order to reduce the load on the walls. The surface should also be perfectly smooth and even without sharply noticeable drops. To do this, all irregularities are eliminated, cleaned and primed. The surface is cleaned from dust and debris. The facade of the building must be covered with deep penetration soil to strengthen the structure.

The facing stone can fasten to a facade on self-tapping screws or on glue. In this case, we consider the option of mounting on a special building glue. Therefore, the next step will be fixing the metal mesh to the wall for future plaster.

At the level of the lower layer of stone laying is set a metal corner or a wooden bar.

It is necessary in order to ensure smooth laying. After this, it is necessary to dissolve the trowel construction glue and apply a composition approximately 2 cm thick to the reinforced wall. Also, the adhesive must be applied to the stones from the wrong side. All elements are pressed against the wall. You can tap on the surface with a slightly rubber hammer.Speaking from all sides of the stone, the solution is carefully removed with a spatula.

After completion of the installation work and partial drying of the wall, it is necessary to seal the joints between the stones. The simplest analogue of the construction device is considered to be a plastic bag. To do this, it is filled with a stitching material and a small corner of polyethylene is cut off. Thus, a kind of "pastry bag" is obtained, with which you can gradually fill all the seams with a solution.

The finishing touch is the treatment of a new facade with a water-repellent protective agent that will additionally protect the facade of the house from natural phenomena.

Finish examples

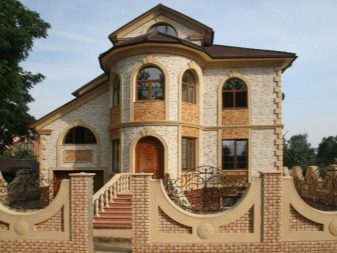

- With the help of facing stone, you can focus on the house and make it unique, as well as emphasize the merits and hide the disadvantages of the surface

- The original method of finishing the facade is facing with stone vertical and horizontal zones of the house. The remaining areas can be covered with plaster of light shades. This combination will create a beautiful contrast of neutral tones with the cool color of the stone.

- Stone decor outside gives the house presentable and history.

- Architectural artificial stone can decorate the entrance group or window openings.

- Other buildings, trimmed with stone, a gazebo, a fence and paths on the site will give the site a finished look.

- And also from some types of stones it is possible to create a handrail, arches and even columns. But such structures will have an impressive weight, so in some cases it is easier to revet the finished forms with natural or artificial stone.

Recommendations for the installation of cladding stone for the facade, see the video below.