Finishing the basement of a private house: the rules for choosing materials

The plinth lining has an important function - to protect the base of the house. In addition, being part of the facade, it has a decorative meaning. How to arrange the base and what materials to use for this?

Special features

The basement of the building, that is, the protruding part of the foundation in contact with the facade, provides protection and increase the thermal efficiency of the building. At the same time, it is exposed to increased mechanical loads, more than others it is exposed to moisture, chemical reagents. In winter, the base freezes, so that may break down.

All this necessitates the protection of the base, for which special heat and waterproofing materials are used, more reliable finish.

We must not forget that this part of the house is a continuation of the facade, so it is important to take care of the aesthetic appeal of finishing materials for the basement.

Among the main technical requirements for basement materials, there are:

- High moisture resistance - it is important that the moisture from the outer surface of the cap does not penetrate through the thickness of the finish. Otherwise, it will lose its attractive appearance and lose its operational characteristics. Will get wet insulation (if any), the surfaces of the basement. As a result, there is a decrease in the thermal efficiency of the structure, an increase in the humidity of the air, the appearance of an unpleasant, musty smell, mold inside and outside the building, the destruction of not only the basement, but also the facade and the floor covering.

- Depends on indicators of moisture resistance cold resistance of tiles. It should be at least 150 freezing cycles.

- Mechanical strength - the basement of more than other parts of the facade is experiencing stress, including mechanical damage. The durability and preservation of the surfaces of the base depends on how strong the tile is. The load of wall panels is transmitted not only to the base, but also its finishing materials. It is clear that with insufficient strength of the latter they will not be able to evenly distribute the load on the foundation and protect it from excessive pressure.

- Resistance to temperature changes - unacceptable cracking of the material during temperature fluctuations. Even the smallest crack on the surface causes a decrease in water resistance of the cladding product, and, as a result, frost resistance. Water molecules that have fallen into cracks under the influence of negative temperatures turn into ice, which literally tears the material from the inside.

Some types of tiles tend to expand slightly due to temperature fluctuations. This is considered normal (for example, for clinker tiles). To avoid deformation of the tiles and their cracking allows preservation of the inter-tile gap during installation.

As for the aesthetics criterion, it is individual for each customer. Naturally, the material for the base should be attractive, combined with the other elements of the facade and exterior.

What is needed?

Finishing the basement of the building allows you to solve several problems:

- Base and base protection from the negative effects of moisture, high and low temperatures and other negative natural factors that reduce the strength, and hence reduce the durability of the surface.

- Pollution protectionwhich represent not only an aesthetic problem, as it may seem at first glance. The composition of the mud contains aggressive components, for example, road reagents. With prolonged exposure, they can damage even such a reliable material as concrete, causing erosion on the surface.

- Improving the biostability of the foundation - modern facade materials prevent damage to the basement by rodents, prevent the appearance of fungus or mold on the surface.

- Basement insulation, which contributes to improving the thermal efficiency of the building, as well as helps to preserve the integrity of the materialIt is known that with a significant decrease in temperature, erosion forms on the concrete surface.

- Finally, the basement finish has a decorative meaning. With the help of this or that material, it is possible to transform a house, to achieve its maximum compliance with a certain style.

The use of tiles, as well as brick or stone surfaces allows you to give the structure a cost-effective look, add refinement.

Types of basement designs

In relation to the surface of the facade base can be:

- speakers (i.e. a little outstanding in comparison with the wall);

- crying relative to the facade (in this case, the facade is already being pulled forward);

- performed flush with front part.

Most often you can find a protruding base. It is usually arranged in buildings with thin walls, equipped with a warm basement. The base in this case plays an important insulating role.

If in a similar building to make a basement flush with the facade, then you can not avoid high humidity in the basement, which means dampness inside the building. When performing insulation such a basement will have to face the difficulties of choosing and installing insulation.

Plinth type socles are usually organized in buildings that do not have a basement. They are best protected from the negative impact of the environment. The support function will perform the facing of the base. With this system, the easiest way to perform high-quality multi-layer hydro-and thermal insulation.

The features of the basement depend on the type of foundation.

So, the base on the strip foundation performs the carrier function, and for the pile-screw - protective. For the plinth on piles, a flush-type plinth is usually organized. It is suitable for both wooden and brick houses, not having a warm underground.

Materials

For clearance base there are many types of materials. The most common are the following:

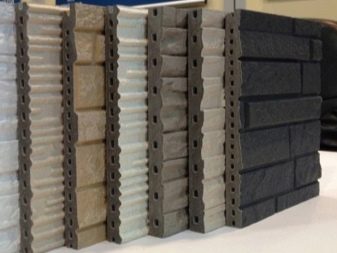

Clinker tiles

It is an eco-friendly clay-based material undergoing molding or extrusion and high-temperature calcination. The result is a reliable, heat-resistant water-resistant material (moisture absorption coefficient is only 2-3%).

It differs in durability (minimum service life of 50 years), chemical inertness, wear resistance. The front side imitates brickwork (from smooth, corrugated or aged brick) or various stone surfaces (wild and treated stone).

The material does not have a low thermal conductivity, so it is recommended to use it with insulation or use clinker clinker panels.

The latter are a standard tile with a polyurethane or mineral wool insulation fixed on the wrong side of the material. The thickness of the last layer is 30-100 mm.

The disadvantage is a fairly large weight and high cost (although this finishing option will be more cost-effective compared to the design of clinker bricks). Despite great strengths (which is on average M 400, and a maximum M 800), loose tiles are extremely fragile. This should be considered during transportation and installation.

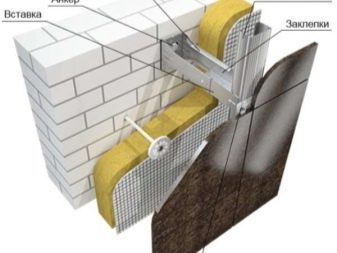

Mounted clinker wet (that is, on a wall or solid crate with glue) or dry (assumes fastening to the metal frame with bolts or screws). When mounted with the second method (it is also called the hinged facade system), a ventilated facade is usually arranged. Mineral wool insulation is laid between the wall and the cladding.

If thermopanels are used, there is no need for a warming layer.

Brick

When finishing brick it is possible to achieve reliability and high-quality moisture protection of surfaces. The advantage is the versatility of the finish. It is suitable for any type of base, and also has a wide selection of facing bricks (ceramic, hollow, slotted and hyper-pressed its variations).

If the base itself is made of red baked bricks, then it performs two functions at once - protective and aesthetic, that is, it does not need lining.

Due to the relatively large weight brick facing masonry requires the organization of the foundation for it.

The organization of masonry requires certain professional skills, and the type of finish is one of the most expensive. Such plating is more expensive than using clinker tiles.

A natural stone

The finishing of the socle with natural stone will ensure its durability, resistance to mechanical damage and impact, and water resistance. All this guarantees the duration of the material.

Granite, gravel, dolomite versions of stone are usually used for decoration. They will provide the maximum strength of the considered part of the facade.

Marble trimming will provide the most durable, but very expensive surface.

From the point of view of convenience, preference should be given cladding flagstone. The latter combines different types of materials, characterized by a flat, tile-like form and a small (up to 5 cm) thickness.

The large weight of natural stone complicates the process of its transportation and installation and requires mandatory additional reinforcement of the base. The complexity of the finish and high cost cause high prices for the material.

The stone is fastened on a pre-primed surface, the material is fixed with the help of frost-resistant cement mortar. After hardening, all seams are treated with a hydrophobic grout.

Fake diamond

These drawbacks of natural stone prompted technologists to create a material that has the advantages of natural stone, but is lighter, easier to install and maintain, and affordable material. It has become an artificial stone, the basis of which consists of small-fraction granite or other high-strength stone and polymers.

Due to the peculiarities of the composition and technological process, natural stone is distinguished by its durability, increased moisture resistance, weather resistance. Its surfaces do not emit radiation, bio-resistant, easy to clean (many have self-cleaning surface).

The release form is monolithic slabs, the front side of which imitates natural stone.

Fastening is carried out on a flat primed surface with a special glue or on the sheathing.

Panels

The panels are sheets based on plastic, metal or fiber cement (the most common variants are indicated), the surfaces of which can be given any shade or imitation of wood, stone, brickwork.

All panels are characterized by resistance to moisture and UV rays, heat resistance, but have different strength indicators.

Plastic models are considered the least durable. With a sufficiently strong impact, they can be covered with a network of cracks, so they are rarely used for finishing the basement (although manufacturers also include collections of basement PVC panels).

Metal siding is a more reliable option.

Low weight, anti-corrosion protection, ease of installation - all this makes the panel popular, especially for those foundations that do not have additional reinforcement.

Fiber cement panels basically have a concrete solution. Dried pulp is added to enhance the technical properties and ease the mass. The result is a durable material, which, however, can only be used on solid foundations.

The surface of the fibrous cement-based panels can be painted in a specific color, simulate the finish with natural materials, or be characterized by the presence of a powdery stone crumb. To protect the front side of the material from burning, ceramic spraying is applied to it.

All panels, regardless of the type are mounted on the frame. Fixation is carried out by means of brackets and screws, the reliability of adhesion of the panels to each other, as well as their wind resistance are achieved due to the presence of the locking system.

Plaster

Installation is carried out in a wet manner, and this type of finish requires flawlessly flat surfaces of the basement.To protect plastered surfaces from exposure to moisture and sunlight as a topcoat used waterproofing compositions on an acrylic basis.

If necessary, to obtain a colored surface, you can paint the dried layer of plaster or use a mixture containing pigment.

Popularly referred to as "mosaic" plaster. In its composition there is the smallest stone chips of different colors. After application and drying, it creates a mosaic effect, shimmering and changing shade depending on the angle of light and visibility.

Available in the form of a dry mix, which is mixed with water before use.

Polymer sand tile

Differs in durability, moisture impermeability and heat resistance. Due to the sandy basis it is lightweight.

The polymer component provides the plasticity of the tile, which eliminates its cracking and the absence of chipping on the surface. Externally, this tile is similar to the clinker, but it is much cheaper.

A significant drawback is the lack of additional elements, which complicates the installation process, especially when finishing complex configuration of buildings.

The tile can be mounted on glue, but another method of installation has spread, on a batten. In this case, using polymer-sand tiles, it is possible to create a warmed ventilated system.

Porcelain stoneware

When finishing with granite, the building acquires a respectable and aristocratic appearance. That's because the material imitates granite surfaces. Initially, this material was used for cladding of administrative buildings, but due to its exquisite appearance, impressive service life (on average half a century), strength and moisture resistance, it is increasingly used for cladding facades of private houses.

Professional sheet

Sheeting with a professional sheet is an affordable and easy way to protect the base. True, the special decorative qualities can not speak.

Dressing

The decoration of the basement can be performed not only through the use of facade materials. One of the easiest and most affordable options is to paint the base with suitable formulations. (Required for outdoor work, frost-resistant, weather-resistant).

Choosing a color, you can select the base or, on the contrary, give it a shade,close to the colors of the facade. Using special materials and 2 close in tone type of paint, you can achieve imitation stone. To do this, on a lighter layer of paint after it dries, smears are applied with darker paint, which is then rubbed.

Slightly more difficult is decorating the plaster base. The plastered surface may have a flat surface or be characterized by the presence of decorative reliefs, which also allow to achieve an imitation of a stone base.

In the presence of columns, their lower part is also revetted with the material used for the decoration of the basement. This will allow to achieve the stylistic unity of the building elements.

Preparatory work

The quality of the preparatory work depends on the indicators of hydro and thermal insulation of the basement, and hence the entire building.

Waterproofing basement involves its external protection, as well as isolation from groundwater. To do this, around the perimeter of the basement, a trench rumbles near it, the depth of which is 60-80 cm with a width of 1 m. With a strong crumbling of the soil, the reinforcement of the trench with a metal grid is shown. The lower part of it is covered with gravel - this is how drainage is provided.

The surface of the cap is cleaned, treated with water-repellent impregnation, insulated.

Preparation of the visible part of the cap for lining involves leveling the surface and treating it with a primer for better adhesion with finishing materials.

If a hinged system is used, it is possible not to waste time and effort on correcting minor defects. Of course, the preparatory work in this case also implies the cleaning and leveling of surfaces, the installation of a cladding frame.

Preparatory work should be carried out at temperatures above 0 degrees, in dry weather. After applying the primer should be allowed to dry.

Device ebb

Ebb tides are designed to protect the basement from moisture flowing down the facade, especially in the rain. The base of one of its part is fixed to the bottom of the facade at a small (10-15 degrees) angle, which contributes to the collection of moisture. Since this element hangs over the base 2-3 cm, the moisture collected drains to the ground, and not to the surface of the base. Visually, the ebb as if separates the facade and basement.

As an ebb, slats with a width of 40-50 cm from waterproof materials are used. They can be sold in finished form or made by hand from a suitable strip.The design and color of the design is selected taking into account the appearance of the finish.

Depending on the material used are distinguished:

- metal (universal) ebb;

- plastic (usually combined with siding);

- concrete and clinker (applicable for stone and brick facades) analogues.

Plastic models, despite the high moisture resistance, are rarely used, which is due to their low strength and low frost resistance.

Metallic Options (aluminum, copper or steel) demonstrate the optimum ratio of moisture resistance, strength characteristics and low weight. They have a corrosion-resistant coating, so self-cutting of ebb is unacceptable. Such strips are mounted overlap.

Concrete models are molded from durable (brand no less than M450) cement with the addition of river sand, plasticizers. Raw materials are poured into silicone molds. After solidification, a strong frost-resistant element is obtained, which is fixed on a special solution on the border of the facade and the socle.

The most expensive are clinkers, which have not only high strength (comparable to ceramic granite), but also low moisture absorption, as well as an exquisite design.

Installation ebb depends on its type, as well as the structural features of the building and wall material.

For example, clinker and concrete ebbs will not be suitable for wooden walls, since they are mounted on glue. Lacking sufficient adhesion indicators, wood simply cannot withstand the ebb. Available are metal options with fixation on the screws.

Concrete and ceramic elements are usually mounted at the stage of facing the facade and basement. Fastening them starts from the corner, glue is used to fix the element for outdoor work on stone and brick. After gluing the outflow, sealing of the joints of its fit to the wall surface is performed using silicone sealant. After it dries, the installation of the ebb is considered complete, you can start facing work.

If it became necessary to fix the ebb on the lined surfaces, it remains to use only metal or plastic structures. Their installation also begins with corners, for which special corner parts are purchased.

The next step will be the finishing of all the protruding architectural elements, and slats are being installed between them on a flat surface. Fastening is carried out on the screws (to the wall) and nail dowels (fixed to the protruding part of the base). The resulting joints are filled with silicone sealant or putty.

The installation of the ebb is preceded by a thorough sealing of the joints of the wall and the base. Moisture-resistant sealants are well suited for this purpose.

The next step is to mark the wall and determine the highest point of the basement. A horizontal line is drawn from it, along which the ebb will be set.

Subtleties of installation

Facing the base with your own hands is an easy process. But to obtain a quality result, you should comply with the technology of plating:

- The surfaces to be treated should be smooth and clean. It is necessary to beat off all the protruding parts, pour self-leveling mortar into small depressions. Large cracks and gaps to close the cement mortar, pre-reinforced surface.

- Be sure to use priming compositions. They will improve the adhesion of materials, as well as prevent the material from absorbing moisture from the adhesive.

- Some materials need preliminary preparation before using outside the house.So, it is recommended to protect the artificial stone additionally with a water-repellent compound, and soak the clinker tile in warm water for 10-15 minutes.

- Beautifully revet the corners allows the use of special corner elements. In most cases, installation begins with their installation.

- All metal surfaces must be made of stainless steel or have a corrosion-resistant coating.

- If you decide to sheathe the basement with clinker, remember that the material itself has a high thermal conductivity. To prevent the appearance of cold bridges allows the use of special pads, stacked in the joints of the inner insulating material.

- To decorate the facade basement material, if the strength of the foundation allows, is permissible. However, to do the opposite, using facade tiles or siding for facing the basement, it is impossible.

Waterproofing

One of the mandatory stages of facing the basement is its waterproofing, which is carried out by horizontal and vertical methods. The first is aimed at protecting walls from moisture, the second provides waterproofing of the space between the foundation and the basement.Vertical isolation, in turn, is subdivided into internal and external.

For external protection against moisture, roll coating and injection materials and compositions are used. Coating insulation is performed using semi-liquid compositions based on bitumen, polymer, special cement coatings applied to the substrate.

The advantage of the compositions is the low price and the possibility of applying to all types of surfaces. However, such a waterproofing layer is unstable to mechanical stress and requires frequent updating.

Roll materials can stick to the surface (due to bitumen mastics) or build-up (a burner is used, under the influence of which one of the layers of the roll is melted and fixed with the base).

Roll materials have an affordable price, they are easy to assemble, the process does not take much time. However, with regard to the mechanical strength of the roll waterproofing, there are more reliable options, for example, innovative injection technology.

It involves the treatment of a moist base with special impregnations of deep penetration.Under the influence of water, the components of the composition are transformed into crystals that penetrate the pores of concrete to a depth of 15-25 cm and make it waterproof.

Today, the injection method of waterproofing is the most effective, but at the same time expensive, time-consuming.

The choice of waterproofing material and the type of its installation for exterior surfaces is determined by the lining material used.

Heater

Laying insulation on the outer part of the cap goes to 60-80 cm under the ground, that is, the insulating material is superimposed on the walls of the foundation, located underground. For this, a trench of the specified length is excavated along the entire facade with a width of 100 cm.

The bottom of the trench is equipped with a drainage system to eliminate the risk of getting wet insulating material under the action of groundwater.

In the case of wet facade finishing, a layer of mastic on a bitumen base or a more modern liquid waterproofing layer is applied on the reinforced insulation. After drying this layer, you can fix the cladding elements.

When organizing a hinged system, the heat-insulating material in the sheets is hung on the waterproofed surface of the base.A windproof membrane is applied over the insulation, after which both materials are screwed to the wall at 2-3 points. Disc bolts are used as fasteners. The hinged system does not involve trenching.

The choice of insulation and its thickness are determined by climatic conditions, the type of building and lining used. The available option is extruded polystyrene foam. It shows high rates of thermal insulation, moisture resistance, has a small weight. Due to the flammability of insulation, its use requires the use of non-combustible basement finish.

For the organization of ventilated systems use mineral wool (needs powerful hydro- and vapor barrier) or polystyrene foam.

When using thermopanels with a clinker surface, they usually do without additional insulation. And under the tile is attached polystyrene, polyurethane or mineral wool insulation.

Facing

The peculiarities of the decoration of the basement depend on the chosen material. The simplest option is to apply plaster.

An important point - regardless of the type of material, all work is carried out only on prepared, clean and dry bases!

Dry plaster mixture is diluted with water, thoroughly mixed and applied evenly to the surface, leveling with a spatula. If you have artistic skills, you can give the surface relief or make the characteristic bulges and grooves, imitating the stone coating. To achieve a similar effect allows the use of a special mold. It is applied to a fresh layer of plaster, clinging to the surface. By removing the form, you get a foundation for stonework.

However, even without these delights, the plastered and painted basement is reliably protected and attractive enough.

It is possible to paint a layer of plaster after it is completely dry. (after about 2-3 days). The surface is pre-sanded. To do this, use acrylic paint. It is suitable for outdoor work, allows surfaces to "breathe." Acceptable is the use of dye compositions based on silicone, polyurethane. It is better to refuse enamel analogs, they are not vapor-permeable and environmentally dangerous.

More reliable is the concrete trim base. In the future, surfaces can be painted with paints on concrete or decorated with vinyl panels, tiles, and brickwork.

This process is quite simple.First, a reinforcing mesh is fixed on the base (usually it is fixed with dowels), then the formwork is installed and the concrete solution is poured. After solidification, it is necessary to remove the formwork and proceed to further finishing.

Facing natural stone because of its large mass, it requires strengthening the base. To do this, a reinforcing mesh is stretched on its surface, and plaster is being applied over it. After drying, the concrete surface is primed with a deep penetration compound.

Now stones are planted on a special glue. It is important to immediately remove excess glue. The use of beacons is optional, because the material still has different geometries. After waiting for the glue to fully set, they start to grout the joints.

Installation of artificial stone is generally similar to that described above.

The only difference is that the stages of additional reinforcement of the basement are skipped. It is not necessary to strengthen it, since the artificial stone has a much smaller weight than the natural one.

Clinker tiles it is also glued to an absolutely flat surface of the base or solid crate.However, to maintain the same inter-tile space, the mounting beacons are used. In their absence, you can install a rod with a circular cross section, the diameter of which is 6-8 mm. Laying begins with a corner, is from left to right, bottom to top.

For the organization of external corners, you can dock tiles or use special corner elements. They can be extruded (solid right angles) or extruded (plastic analogues, the bending angle of which is specified by the user).

After curing the glue, you can begin to fill the joints between the tiles. The work is done with a spatula or with a special tool (similar to those in which sealants are produced).

Siding base plates mounted only on the crate. It represents metal profiles or wooden bars. There are also combined options. In any case, all elements of the framework must have moisture-proof characteristics.

The brackets are installed first. In the space between them fit sheet insulating material. A hydroprotection film is pre-laid under it, a wind-proof material is laid over it. Then all 3 layers (heat, hydro and windproof materials) are fixed to the wall with dowels.

At a distance of 25-35 cm from the heater is installed crate design. After that siding panels are fastened with screws. Additional strength connections provide locking elements. That is, the panels are additionally snapped together. Corners and other complex elements of the basement are made using additional elements.

Porcelain tiles also require the installation of a metal subsystem. The fixing of the tiles is carried out with special fixings, the compatible halves of which are located on the profiles and the tiles themselves.

Despite the strength of ceramic granite, its outer layer is very fragile. This should be taken into account during installation - a slight damage will not only reduce the attractiveness of the coating, but also the technical properties of the material, primarily the degree of resistance to moisture.

Flat slate is fixed on a wooden subsystem with the help of screws. The installation starts from the corner, and upon completion of the cladding, the corners of the basement are covered with special iron, zinc-coated corners. Immediately after that, you can begin to paint the surface.

When cutting slate, it is important to protect the respiratory organs, because at this moment asbestos dust harmful to health hovers at the workplace. Before installing the material is recommended to cover with a layer of antiseptic.

Tips

- Choosing the option of finishing the base, it is better to give preference to thick-layer, wear-resistant materials. In the first place - it is a natural and artificial stone, clinker and porcelain tiles.

- In addition, the material must be moisture-resistant and durable. As for its thickness, in most cases the maximum should be chosen (as far as the foundation and the surface of the basement allows). For regions with harsh climatic conditions, as well as buildings in places of high humidity (a house near a river, for example), this recommendation is particularly relevant.

- If we talk about affordability, then plaster and cladding will be cheaper than other options. However, plastered surfaces have a shorter lifetime.

- If you do not have a sufficient level of skill or have never performed facing with stone or tile, it is better to entrust the work to a professional. From the first time it is hardly possible to flawlessly trim.And the high cost of materials does not imply such “training” on it.

- When choosing any material for lining, give preference to well-known manufacturers. In some cases, you can save money and buy tiles or panels of domestic production. Definitely, you can do this by purchasing plaster mixes. They have enough quality Russian manufacturers. The brick tile is better to buy German (more expensive) or Polish (more affordable option) brands. Domestic usually does not meet the high requirements for the reliability of tiles.

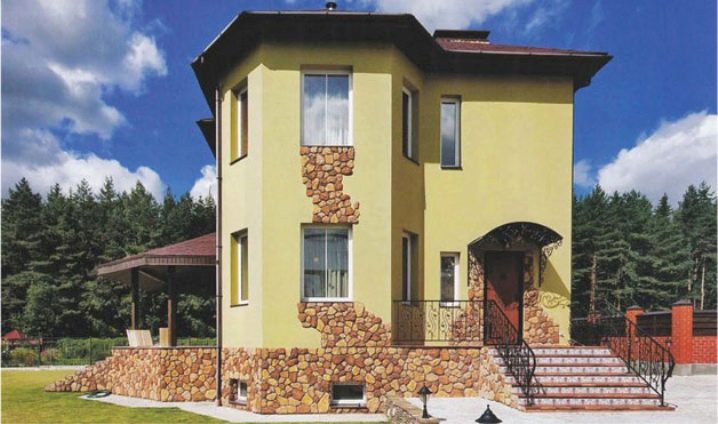

Beautiful examples

The use of stone and brick in the decoration of the base gives the buildings a monumentality, good quality, makes them respectable.

Staining and plastering of surfaces is usually used for small plinths of small height (up to 40 cm). The shade of paint is usually darker than the color of the facade.

One of the latest trends in finishing was the trend to "continue" the base, using the same material for finishing the bottom of the facade.

Select the basement of the building using the color can, using siding panels. The decision can be gentle or contrast.

As a rule, the shade or texture of the basement is repeated in the decoration of the facade elements or the use of the same color in the design of the roof.

How to independently carry out the finishing of the basement plinth with facade panels, you will learn from the following video.