Fiber concrete panels: types and application in construction

Fiber concrete panels are a new generation of finishing materials. As an alternative to plaster finishes, they have all the advantages of a predecessor, but without the characteristic drawbacks. This building material allows high quality and in a short time to finish the house, which will please with high strength and long service life, as well as decorate the facade of the building with an excellent texture, imitating various finishing materials, such as stone and brick masonry, wood and so on.

What it is?

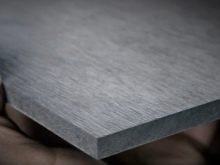

Fiber concrete - a synonym for fiber cement panels - is a type of finishing material produced in the form of slabs and siding panels. The main part of the composition - from 85 to 90% - is cement, about 10-15% more - various minerals and fiber (cellulose or synthetic fiber).

The latter performs the function of a reinforcing component, reinforcing fiber-reinforced concrete panels, giving them elasticity and, as a consequence, increasing bending strength.

The front part of the panels is a weatherproof and simulating brick or masonry coating. In addition, the composition of fiber-reinforced concrete panels contains hydrophobic additives that increase the moisture resistance of the material by reducing the porosity, but contribute to the vapor permeability of the panels, the property responsible for the normal ventilation of the wall.

Specifications

Exemplary characteristics showing the possible values of parameters for various types of fiber-reinforced concrete panels. These include:

- density - from 1.5 g / cu. cm;

- panel weight - 16-26 kg / sq. m;

- bending strength - from 20 MPa;

- impact strength - from 2 kJ / sq. m;

- moisture absorption - 7-20%;

- panel thickness - 6-35 mm;

- the length of the panel is 1.2, 1.5, 1.8, 2.4, 3.0, 3.6 meters;

- the panel width is 190, 455, 910, 1200, 1500 mm.

Species

Fiber concrete panels are made with a variety of external performance, simulating various finishing materials.

We can distinguish the following types:

- products with imitation masonry, vary in size and shape, imitating different types of stone in color, texture, degree of detail and other parameters;

- imitating brickwork, most species imitate red and yellow bricks, although the choice is quite diverse and unlimited in two ways;

- wood panels, a wide range of breeds with their inherent color and texture;

- fiber reinforced concrete slabs with a texture imitating stone chips, a wide range of colors, there are not monochromatic types with the addition of other shades, and the panels also vary in size of the crumb;

- monotone panels imitating plastered walls;

- monotone plates with a smooth surface They are mainly used for finishing large shopping centers, office buildings and similar structures, the surface lends itself well to painting and other decorative finishing.

A certain percentage of panels is realized with an unpainted surface. This feature allows you to choose the color and shade yourself, if among the range of the manufacturer there is no suitable option.

On the one hand, this feature expands the variety of external execution of panels, on the other hand, additional painting work is necessary, which requires time and money. The cost of unstained fiber-reinforced concrete panels is 10-20% lower than similar painted models.

Purpose and scope

The use of fiber-reinforced concrete in construction works allows to achieve a number of positive effects, including:

- reduction of the total mass of the structure;

- preventing the formation and spread of cracks on the wall surface;

- increase the strength of the wall;

- thinning of wall structures;

- the use of new, more advanced construction technologies;

- obtaining the appearance inherent in the decoration of wood and stone, but with more optimal performance and simpler installation process;

- finishing facades with curvilinear geometry;

- reconstruction and restoration of old buildings, the ease of building materials is particularly relevant in this matter;

- elimination of uneven portions of the facade;

- getting a strong and smooth surface for further decorative finishing work.

With the use of fiber-reinforced concrete, finishing of objects with various features is carried out, namely:

- facing multi-family and private houses and cottages;

- design of shopping centers, hotels, sports complexes, airports, supermarkets, government and public facilities;

- finishing of ventilated facades;

- interior decoration;

- facing balconies.

Technical characteristics of fiber cement are quite high. Today, increasingly, glass fiber-reinforced concrete and foam glass are used at the construction site. Such thermopanels reliably protect any construction.

Advantages and disadvantages

Modern equipment and new production technologies using high pressure and steam processing allow producing material with excellent operational and aesthetic qualities. Fibroconcrete panels consumers choose due to their positive qualities.

- Long service life. Duration of use of panels varies in the range of 25-50 years.

- Low weight products. Slabs and siding panels are relatively easy to lift, assemble, transport and store.And the load on the wall is also reduced, and less powerful tools are needed for fixing.

- Simple and convenient installation. The technology of installation of plates is much simpler and less expensive than plaster. The large dimensions of the panels reduce the scope of work and the mounting means necessary for fastening. In addition, it is easier to detect and eliminate irregularities when installing panels. Installation work can be carried out with a minimum set of tools and a small baggage of knowledge about the method of installation. Moreover, work can be carried out in conditions of negative temperatures.

- Versatility. The panels are presented in various format-size variants, which allows you to choose products for surface finishing with various features.

- High strength. Fiber cement panels tolerate shock, vibration, friction, and bending pressure well.

- Good thermal insulation performance. Provided by the use of cellulose filler, reduce the power of the necessary insulating materials in the finish, for example, the thickness of the layer of mineral wool.

- Frost resistance. Products retain structural integrity and appearance throughout many freeze / thaw cycles.This fact makes them an excellent facing material for regions with a harsh and continental climate, in which a hot summer gives way to a cold winter, which corresponds to almost the entire territory of the Russian Federation.

- High waterproofing performance. Thanks to special additives, the panels are not afraid of moisture and can be washed using water from both the front and back sides.

- Resistance to temperature extremes.

- Do not corrode, do not rot, do not shrink.

- Fully eco-friendly composition. The production uses natural raw materials and non-toxic additives, microparticles of the material do not provoke allergic reactions and do not contribute to negative processes in the body. No asbestos and no harmful tar.

- Resistance to sunlight. The color of fiber-reinforced concrete does not deteriorate under the influence of infrared radiation throughout its entire service life. Ultraviolet does not destroy the structure of the coating - does not lead to cracking, as in some finishing materials.

- Good noise isolation. Reduce the level of incoming and outgoing sound.

- Wide selection. The ability to choose applies not only to the color and its shades, but also to the shape and texture of the cover panel.

- Easy cleaning. The material itself is cleaned under pouring rain, in addition, you can wash the surface with a garden hose.

- Absolute fire safety. The material is 100% non-flammable and non-smoldering, and also does not melt under the influence of direct fire.

In addition to the positive qualities, fibrobeton panels have several drawbacks.

- Vulnerability to prolonged exposure to moisture. Despite the high waterproofing qualities, with prolonged exposure to water, the cement in the composition of the products still begins to absorb water. Saturation can increase up to 10-20% and lead to a slight deformation of the panels - up to 2%, which does not affect the appearance or structural integrity, the flexibility of the panels fully compensates for this phenomenon.

- Specific installation work. With all the positive aspects in this matter, there is one nuance - large panels require installation by at least two people, which can cause some difficulties.

About what fiber concrete, see the following video.