Facade panels for stone: types and characteristics

Exterior walls in buildings should be protected from atmospheric damage, additionally insulated and taken care of acceptable appearance. To finish the facades of houses used natural and artificial materials. The original decorative effect creates a natural stone. Modern and practical solution for the arrangement of the exterior are front panels with imitation stone.

Features and benefits

Front panels perform decorative and protective function of external walls. The natural stone design helps create a beautiful and elegant background for everything.houses.

Stone panels have many advantages:

- a variety of textures and colors;

- high level of imitation of stone structure;

- quick installation;

- cheaper than natural analogues;

- moisture resistance;

- the size and weight of the panel is adapted for self-assembly;

- do not fade;

- frost resistance to -40 degrees;

- resistance to heat up to +50 degrees;

- can serve up to 30 years;

- easy care;

- environmental friendliness;

- maintainability;

- does not give a large load on the supporting structures.

When covering the facade of a new house, you can achieve a unique design by combining different textures and colors. Installation of panels on houses with a long-term year of construction will hide the destroyed and unpresentable exterior of the building. To do this, do not need repair and reconstruction of the walls themselves. Installation requires only the construction of the framework of crates. Under the panel, you can install a heat insulation layer. Mineral basalt wool, glass wool, polystyrene foam, foam plastic are used as insulation.

In addition to facing the facade and foundation, panels under the stone can be used to finish fences. It is not necessary to sheathe the whole house,it is possible to partially finish the desired structural element, the upper or lower floor.

Description

Stone panels were originally used for foundation plating. Finishing siding showed high performance and was used to cover the entire facade. With the expansion of the range of products of different textures can be made aesthetically attractive and durable lining of the house.

The production of cladding panels is based on copying various masonry from natural materials. For exterior walls, they imitate various types of natural stone: they are slate, granite, sandstone, rubble stone, limestone, dolomite, and many others.

To give realism, the plates are painted in natural shades of a particular type of stone and give the appropriate relief and shape.

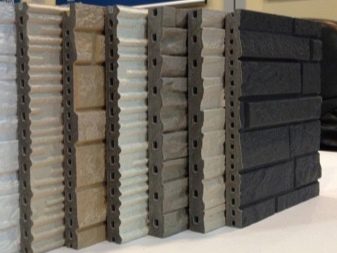

Depending on the structure, there are two types of panels for exterior decoration of the house.

- Composite. The design assumes the presence of several layers. The outer protective layer on the surface acts as a decorative finish. The inner heat-insulating layer contains an artificial insulation of polystyrene foam.

- Homogeneous. The plate consists of one external covering. When installing the flexible panels are not deformed, they are easily interconnected in a monolithic lining. Differ in the small price and small weight.

Composition

For the production of plates, similar to natural stone, using artificial and natural raw materials.

In accordance with the material of manufacture facade cladding panels are of two types:

- fiber cement;

- polymeric.

Fiber cement products consist of quartz sand and cement with the addition of cellulose fibers. They are characterized by fire safety, frost resistance up to -60 degrees, sound-absorbing qualities. The negative side is the ability of the material to absorb water, making the structure heavier. The low level of impact resistance shows a tendency to damage. Fibropanels do not have a pronounced deep texture of the stone, as they are made by casting.

The composition of the polymer panels include polyvinyl chloride, resin, foam, stone dust. If a composite panel is made, then a layer of polyurethane foam is added. PVC panels are able to clearly highlight the stone texture, emphasize quarrystone and wild stone.Plastic does not react to moisture, has antiseptic properties. The panels are resistant to impact and damage.

Dimensions and weight

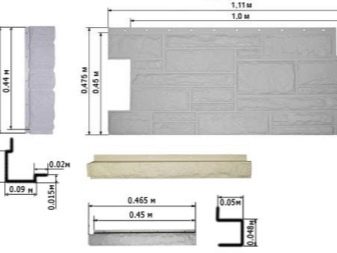

The weight of the front panel depends on its size and material of manufacture. The size is determined by the ease of installation and transportation. Lightweight plastic plates weigh approximately 1.8-2.2 kg. The size of the panels is developed by the manufacturer. Depending on the type of stones being simulated, the length and width parameters vary. The length can vary from 80 cm to 130 cm. The width varies from 45 to 60 cm. On average, the area of one panel takes up half a square meter. The thickness is small - only 1-2 mm.

Fiber cement boards for the facade differ in large size and large weights. Length is from 1.5 to 3 m, width is from 45 to 120 cm. The smallest panel thickness is 6 mm, and the maximum is 2 cm. The weight of heavy cement products may vary depending on the thickness of 13-20 kg per square meter. On average, fiber cement boards weigh 22-40 kg. One large thick panel can reach a weight of more than 100 kg.

Design

The variety of shapes and sizes of facade panels makes it possible to sheathe the design of any configuration. The decorative properties of the material depend on the texture of the front side.Manufacturers produce a wide range of artificial stone with a large color gamut.

The texture of the panel is similar to the natural laying of different breeds. For facade decoration, you can pick up rocky or rubble stone, “wild” sandstone, hewn masonry. The color varies depending on the type of natural stone - beige, brown, gray, sand, chestnut.

Slabs with stone chips for original and exclusive design are produced. Between themselves, fractions are sealed with epoxy resin. The granular stone structure is painted in any bright colors - malachite, terracotta, turquoise, white. The disadvantage of such an invoice - over time, wiped, poorly washed.

Manufacturers Overview

The market of finishing panels for the facade is shared by foreign and Russian manufacturers. Among foreign manufacturers are distinguished companies Döcke, Novik, Nailaite, KMEW. Positive reviews are received by domestic manufacturers - “Alta-profile”, “Dolomit”, “Tekhosnastka”.

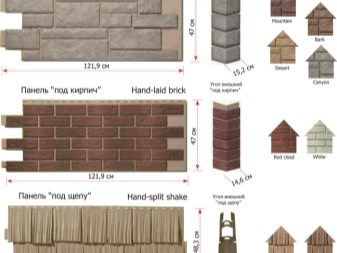

- Canadian company Novik produces front panels with texture under field stone, hewn masonry, river stone, wild and hewn limestone.Characterized by high quality, increased thickness of more than 2 mm.

- German mark Döcke produces high-quality facade panels 6 collections imitating rocks, sandstone, wild stone.

- American company Nailaite supplies facing siding of several series - quarrystone, natural and ashlar.

- Japanese fiber cement facade panels are distinguished by a large assortment. KMEW. The size of the plates is 3030x455 mm with a protective coating.

- Leading production takes domestic company Alta Profile. In assortment 44 options of a siding under a stone laying. There is an imitation of granite, wild stone, rubble stone, the collection "Canyon" and "Fagot." The products have all the certificates of conformity and a developed sales system in many cities of the country.

- Company "Dolomite" engaged in the production of PVC coatings for exterior home decoration. The assortment includes a basement siding with a rocky reef texture, sandstone, slate, dolomite, alpine stone. The profile is 22 cm wide and 3 m long. The panels are stained with three variants - completely uniformly painted over, with stained seams, inhomogeneous multilayer coloring. The declared lifetime is 50 years.

- Company "European Building Technologies" manufactures Hardplast facade panels imitating the structure of slate. Available in three colors - gray, brown and red. They are characterized by a small size: 22 cm wide, 44 cm long, 16 mm thick, which is convenient for self-assembly. The production material is polymer mixture.

- Belarusian concern "Yu-layer" lets out a vinyl siding with the invoice of a natural stone of the Stone House series. Panels with dimensions of 3035 mm long and 23 cm wide in four colors. The service period is at least 30 years.

- Moscow Plant "Technician" manufactures facade panels from polymeric materials. Covering a wild stone, imitating rocky texture and granite, will allow you to mount a fire-resistant, durable, eco-friendly facade. The domestic company Fineber produces panels of slate, rock, stone texture of polypropylene 110x50 cm in size.

- Domestic manufacturer of fiber cement boards is a factory "Profist". In the product line, there are panels under the stone "Profist-Stone" with a coating of natural stone chips.More than 30 color shades with a granular structure will allow to realize any design of the facade. Standard dimensions are 120 cm wide, 157 cm long and 8 mm thick.

Recommendations for use

Finishing the house with facade panels can be carried out independently or by a special construction team. Pre-count the number of panels needed for plating. The number depends on the size of the plate itself and the area of the lining. Determine the area of the walls without windows and doors. External and internal corners, starting guides, platbands and slats are purchased.

With self-installation, you need to take care of the availability of working tools. You will need a level, a drill, a saw, a sharp knife, a tape measure. It is better to fasten structural elements with zinc-coated screws.

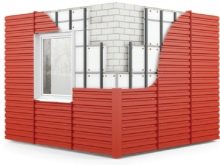

If the facade finish is combined with the wall insulation outside, then first install the vapor barrier membrane.

On the wall is placed vertical crate. As a guide used a timber of small section or a metal profile. Thermal insulation is installed in the frame of the batten. The material is placed close to no bridges of cold.A layer of insulation is protected by a waterproofing film.

Then a ventilated facade with a gap of a few centimeters is erected. To do this, mount the counter lattice of the rails or metal guides. To avoid distortions and bumps in the finished facade, all parts of the frame are placed in one plane.

You must follow certain rules for installation of facade cladding:

- you need to arrange and fix all the strips in their places;

- installation start from the bottom corner;

- installation is carried out in horizontal rows;

- between the panels and the ground level there should be a gap of up to 5 cm;

- each subsequent detail enters the groove with a small indent;

- fix the panel to the crate is not close;

- screws are placed in the middle of the holes provided;

- when mounting the screws do not bury the cap, leave room for thermal expansion;

- Do not mount the panels close to the roof, leave a compensation slot.

The corners are fixed to the finished finish.

Facing plates do not need special care. In case of persistent pollution, it is enough to treat with a soap solution and wash the stains with clean water. You should not clean the facade with alkali or acid.

Spectacular examples in the exterior

Stone wall facade panels determine the style and attractiveness of the entire building. To highlight the necessary parts of a private house, you can use the color zoning of space. Another color can be highlighted corners, slopes of windows and doors, the foundation in various variations.

The façade trimmed under a white stone with contrasting anthracite elements will look elegant and unusual. Bright and juicy bright terracotta finish. It is necessary to take into account the surrounding landscape in order to harmoniously fit the exterior of the house into the local landscape.

How to install base panels, see the following video.