Ventilated facades of houses: device and installation

Exterior decoration of the house or building each year goes to a new and higher quality level. Today, the owners of private houses and buildings have increasingly begun to use ventilated facades for cladding their homes. This is a beautiful and practical way to decorate your home, which almost anyone can handle.

Features and purpose

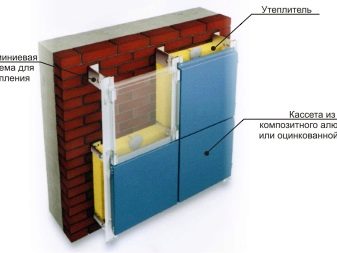

If we turn to the definition of a ventilated facade, then it is characterized as a whole system consisting of several components.

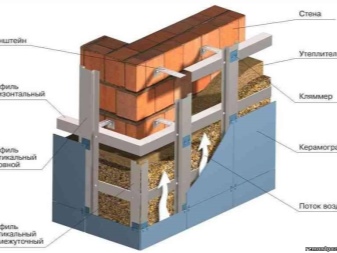

- Metal carcass. It is attached directly to the bearing walls in such a way that an air pocket remains between the facing plates and the layer of insulation. For this reason, this type of construction is called ventilated.

- Insulation layer. As a rule, mineral wool is used.Masters are advised not to use polystyrene or polystyrene foam as insulation, since they have a low level of noise absorption and vapor barrier.

- Cladding plates or blocks. They may be of porcelain stoneware, fiber cement and other materials.

Ventilated facades are widely used in Russia due to a number of distinctive and unique properties. This technology was borrowed from Western colleagues and is widely used in our country with success. They are installed both on ordinary private houses, and as exterior cladding of buildings, for example, supermarkets, shopping centers. Their merits are difficult to embellish.

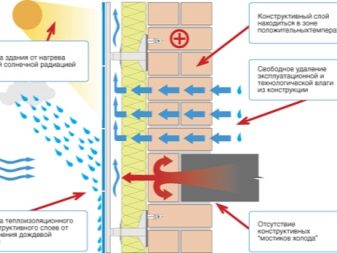

It should highlight its protective properties. As a rule, ventfasad is made of durable hydrophobic materials that perfectly protect the walls and the building itself from moisture and temperature fluctuations. If any part of the water vapor has leaked between the cracks, then it is absorbed by a thick layer of drainage. Cladding lining is at least 25-30 years. Duration of service life depends on the selected material. If porcelain stoneware is used, then the guaranteed lifetime is at least 50 years.

This system has a number of distinctive features and in its insulating qualities. Such a facade does not allow the walls to heat up, and as a result, the interior does not overheat. The room is always comfortable: moderately warm and cool. Thanks to its ease of installation, it is possible to make external cosmetic repairs very quickly. A large variety of material gives an unlimited number of options to create a unique design of the building.

Not to mention its soundproofing properties. Because of the air gap such a facade is able to contain quite a high level of noise. In combination with a triple or double glazed window such walls will give an optimum level of silence in a noisy city. Materials that are included in the system of ventilated facades are fire resistant and do not allow to spread to the fire.

Design: pros and cons

Over the past few years, the number of projects of residential buildings, public organizations, educational institutions with the installation of a ventilated facade has increased tenfold. Like other cladding structures, ventfasad has a number of advantages and disadvantages that must be taken into account during its installation and further operation.

This façade has few disadvantages, but they do occur. First of all, experts note that the system of frame metal assemblies for fastening can degrade the uniformity of the thermal air barrier. Metal does not keep heat, so it is necessary to lay a thicker layer of insulation. This is especially important for the northern regions of the country.

With an illiterate calculation of the thermal coefficient of materials, thermal insulation will be poor. For this reason, there may be a number of problems that require another cash infusion. If we talk about insulation, then there are also a number of nuances. During prolonged use, it undergoes a series of changes: shrinkage and thinning.

In order for this structure to perform its functions well, the masters advise laying the insulation material as a “cake”. The first layer consists of a softer and more friable insulation, and the next one is more rigid and dense.

The ventilated facade device implies a small air gap and narrow slots. During rain or active spring thaw, moisture easily enters the air pockets.This leads to swelling and weighting of mineral wool, as well as the appearance of mold in the house or apartment. To prevent such consequences, it is necessary to lay a special waterproofing film for vapor barrier. The financial side of the issue is also important. Installing a ventilated facade is a bit more expensive than fixing ordinary siding panels. This price is due to the large number of calculations and the material used.

If we talk about the pros, then you should start with the versatility of ventilated facades. Due to its ease of installation, it can be used on buildings and structures of any type. This design is installed much faster than conventional lining, as it does not require initial preparation of the walls for installation.

If some kind of facing plate is deformed (it has been chipped or broken off), then it changes easily and simply. No need to remove all panels from the row.

Ventfasad is an excellent protective shield for the building from atmospheric phenomena. Due to the unique ventilation system, the air flow prevents accumulation of water vapor, “blows out” the excess heat on a hot day, and also preserves the internal heat of the building due to the air pocket. This facade can be recouped in 10–15 years of use, provided high-quality installation according to all the rules and regulations. The owner of the building will spend a lot less money to keep the room warm.

In the conditions of a private house, where there is its own heating, it will take much less gas or other fuel to maintain a comfortable temperature in the rooms. Additional funds for the care of the lining is not required. If we compare the number of positive and negative sides of the ventilation façade, then we can confidently say that it is excellent for the climatic conditions of Russia and will serve its entire guaranteed operational life.

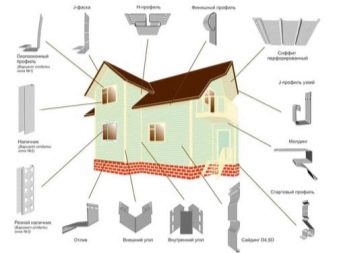

Main elements: types and properties

The ventilated facade has a clear structure, which consists of a number of elements. It is very important that the installer is able to work with all the species diversity of materials and know their physical properties. Otherwise, an inexperienced worker can make a large number of blunders that can significantly affect the final result. The first and most basic element is the support wall. Its technical parameters determine the choice of design, which will be installed in the future.

- The deviation of the walls vertically and horizontally from a straight axis. It is often necessary to work with a building where the foundation is twisted or the walls have an uneven structure. In this regard, it is necessary to select a special system of fasteners, which will not increase the load on the structure.

- Material used for the construction of the object. Today, houses and buildings are built from various building materials: brick, wood, foam blocks and others. They have a different composition and certain technical parameters that must be taken into account when installing a ventilated facade.

- Degree of wear load-bearing walls and structures.

If you want to improve the facade of a building that is built of old and crumbling bricks, then you need to use lightweight and at the same time durable materials. They will “hold” the walls and prevent them from collapsing further.

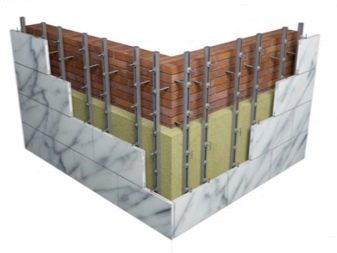

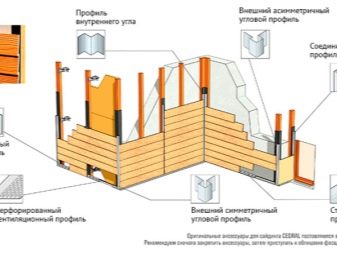

The second element of the ventilation façade is a substructure or a subsystem. These include the following elements:

- brackets;

- carrier profile;

- auxiliary materials (fixing angles, anchors, dowels, screws and others).

With the help of these elements, a solid grille is created, on which the insulation and facing material is subsequently attached. Thanks to her, the most necessary air space or ventilation pockets are created. And also the glue solution is not required to fix the front plates, and this is a significant cost savings. Today there is a production of both wooden and metal slats. The choice of material depends on the building, insulation and cladding plates.

The next layer is thermal insulation. It includes a layer of insulation, which performs the following functions:

- protects the walls from freezing, the formation of ice crust, frost;

- does not allow moisture to destroy the structure of the house from the inside;

- retains heat inside the building;

- provides additional sound insulation in the room.

It is best to take the mineral wool as a heater - it is non-combustible material. It does not absorb moisture, is easy to use and performs its functions perfectly. In colder regions, very often, a paronitic gasket is installed in front of a layer of insulation material, which performs a thermal breaking function.Additional insulation helps to avoid the appearance of so-called cold bridges.

The fourth element in the system of the ventilated facade is a windproof membrane. It is necessary in order to hold back moisture and not allow it to penetrate into further layers.

In the market, you can find insulation that already has a layer of this film, but it is better to buy it separately (the intervals between the plates should also be “covered”).

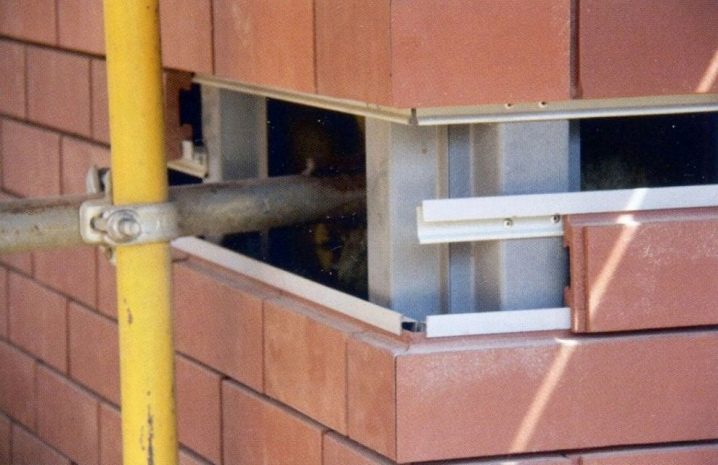

The next link in this design is the air gap. Here he plays a key role, because thanks to him a traction effect is created. Air flows evenly circulate under the facing material and do not allow moisture to settle on the surface of the insulation and the protective film. He also participates in heat exchange between the environment and the building itself. Due to the gap heat loss in winter is much lower.

The final element of the system is facing plates. They can be made of various materials: sandstone, porcelain stoneware, marble and others. Facade panels are selected for the type of building, the condition of its walls (degree of decay) and other aesthetic preferences (color, shape, structure). Facing performs the following functions:

- protects the building from external influences: temperature drops, rain, snow and others;

- Hides under a heater and other communications in the presence;

- improves the appearance of the building, and also gives it a modern and beautiful look.

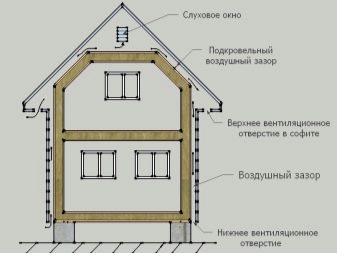

Air gap

One of the important aspects of the ventilated facade is the air gap. First of all, it is necessary to understand its main functions, such as:

- it helps to equalize the pressure exerted on the facade of a building during severe hurricanes or sudden gusts of wind;

- an air pocket helps keep heat inside the building;

- ventzazor does not allow rain to penetrate inside. The walls are always dry;

- thanks to its “capillary” system, the facade is blown. In this regard, water vapor is not retained inside, as a result of which the risk of mold and fungus is reduced;

- the air gap helps to hide all the roughness and unevenness of the wall surface. Such a facade is particularly relevant for old buildings.

There are a number of regulations that indicate the minimum value of the ventilation gap.The air gap between the insulation and cladding panels should be at least 2–2.5 cm. The distance may decrease or increase depending on the flatness of the wall or the climatic characteristics of the region. The main thing is that it is enough for the normal functioning of the drainage layer. There are also very long distances - 10–13 cm.

Masters advise that the gap does not exceed 15 cm, since it will not perform its main function - thermal insulation.

The calculation is based on parameters such as:

- the area of a single sheet or slab of a facade covering;

- its thickness.

If there are open seams on each side of the panel, then the gap should be 5 cm, provided that the facing material is 0.2–1 cm wide and the surface area of the individual slab is 0.3–0.4 square meters. m, and with a smaller area - 3 cm. In the case of only horizontal or vertical open seams, the distance of the air gap should be 4 cm, when the width is also 0.2–1 cm and the surface area of one panel is 0.3–0.4 sq. m. With a smaller area ventilation gap should be 2 cm.

An important point when calculating the distance between the lining and insulation is fire safety.From the school course in physics, everyone remembers that fire burns only where there is oxygen. Since there is an air flow between the front plates, which can create a traction effect like in a Russian stove, it can create a situation that promotes the spread of fire around the building. Therefore, the larger the width of the air pocket, the greater the risk of a building during a fire. In this regard, the installation of a special barrier is required, which will restrain air currents and prevent the flame from spreading. If the gap is small (2-3 cm), then it is not required.

Varieties of systems

Today the market is filled with a variety of materials for the installation of a ventilated facade. They vary in price and quality. In this regard, conventionally there are three groups that differ in price policy. This is just a basic list of systems used on ventilated facades. Every year there are more and more perfect and universal facing plates or panels, which can please with their appearance, excellent physical properties and a pleasant price.

- A budget option. It uses inexpensive materials.The metal frame is made of aluminum or zinc profile. Glass wool or slag wool is used as insulation. Facing is also simple. It can be a tile from an artificial stone, wooden panels, a vinyl or aluminum siding.

- Medium price option. As a rule, goods with an average price are selected here, or some materials are more expensive, and some are cheaper. For example, the frame can be made of galvanized steel, the insulation is selected with an average price, and as the lining - professional sheet or metal profile. Or, on the contrary, they save on a frame with insulation and acquire a higher quality facade tile made of composite materials.

- Dear option. Here high-quality materials are selected to maximize the life of the ventilation facade. If, for example, this is a private cottage and the owner wants to make external cosmetic repairs as rarely as possible, then preference will be given to a steel frame with anti-corrosion coating, high-quality insulation - mineral wool, foam panels, and composite tiles (they are particularly resistant to aggressive external environment).

It should be understood and the fact that the choice of components must be based on the material from which the walls are built. If it is aerated concrete, then all selected materials should be lightweight. For a monolithic or brick house fit almost any design.

Masters classify ventilated facades according to the type of facade plates used.

- Cladding of fiber cement panels. This is one of the frequently used types of cladding. It consists of cement, fiberglass, cellulose and plastics. The plates have a long service life and are an excellent additional heat insulator due to its dense structure. They have a beautiful texture, as well as a large color palette. They are an environmentally friendly product, do not emit toxic substances into the atmosphere when heated. One more positive quality of such facing is adjustable weight. Manufacturers can make lighter and thinner slabs for dilapidated buildings to reduce the load on the bearing walls and the foundation. There are few significant drawbacks - the ability to absorb moisture, and as a result, increase the weight by 4-6% of the total mass.

- Facing under the imitation of natural stone or brick. This option is practical and always in fashion. This front material will last a long time. It is made from a mixture of cement, gypsum and stone chips. It does not absorb moisture, is lightweight and is available in various color options.

- Aluminum composite panels. Immediately it should be noted that this is a multilayer facing material, which consists of several layers of aluminum, cellulose or plastic. Negative qualities include a high price and the ability to scratch a layer of paint. The advantages of such facade plates are many, namely:

- have excellent sound and thermal insulation properties;

- do not corrode;

- not subject to ultraviolet rays, food acids and alkaline solutions;

- excellent balance of weight and strength, the plates are very strong and rigid in structure;

- do not absorb moisture;

- not amenable to burning.

- Algomerate plates. It is one of the most durable facing materials. It consists of only natural ingredients: granite and marble chips. By its structure, it is a very durable and reliable material, so the tile is not susceptible to the effects of weather in the form of rain, hail, snow, strong wind.If we talk about the texture, it is rough and smooth. The color palette is very diverse and will delight the buyer with a large selection.

Such a lining has a considerable weight, so the masters recommend mounting such plates only on a steel frame.

- Glass front panels. This type is most often found on large business centers or shopping complexes. They give a special charm and beauty, making the building ultramodern, fashionable and airy. This type of lining has both positive and negative sides. The advantages include spectacular facade, reliability and durability and low weight. To the cons of glass facade panels belong, such as:

- during the cold period condensate forms;

- need for monthly cleaning, otherwise there will be stains from raindrops or other precipitations on the surface;

- if the plates are loose or the building collapses, they can break and form glass chips, which are very traumatic

- Natural wood panels. Wood veneering has been on the market for a long time and is valued for its unique qualities. First of all, it is an environmentally friendly material that does not harm people. These panels "breathe" and have excellent thermal insulation properties.Wooden panels make the building or house more comfortable and pleasant to look at.

The only disadvantage of such a facade is that it must often be treated from pests, covered with a protective solution against mold and mildew.

Manufacturers and Innovations

The ventilated facade is a relatively recently borrowed technology for facing a building. She has already managed to recommend herself in the market and get positive feedback from consumers. Today in Russia there are more than 150 companies that are engaged in the production of the necessary component materials (fasteners, tiles, insulation and others), its calculation for buildings, followed by installation.

If we talk about individual firms, one of the most famous is the White Hills. This company is engaged in the production of cladding panels made of stone using vibratory casting technology. They have established themselves as a supplier and manufacturer of quality products that will help to implement any design idea. And also they have a unique system of fastening of front plates. Thanks to her, the moisture does not stay in the air pockets, and the air is constantly circulating.

White Hills ensures that its products last at least 40 years. White Hills ventilated facades are valued abroad.

Not inferior in quality and firm from Switzerland Alucobond. Their product is metal multicomponent sandwich panels, which are also called alucobond. It is a durable building material that can last at least 40–50 years without repair or any other interventions. Due to its plastic properties, such panels are easy to cut and “fit” to the shape of the wall. They are very durable, do not corrode, do not react to food acids and alkaline solutions.

The design of this facing material has a lot of options. The panels have a wide choice of colors, and can also imitate various surfaces (marble, wood, chrome, and others). Consumers say that they are easily and quickly fastened and do not create an additional load on the foundation and load-bearing walls. The disadvantages of alucobond include the following:

- the material emits toxic substances during combustion;

- in case of replacement it is necessary to remove a number of additional panels.

Nord Fox products are highly valued. It produces all the necessary components for the installation of a ventilated facade, as well as high-quality cladding panels.They are installed both on private buildings and on multi-storey business centers. Beauty and aesthetics of facade tiles are distinguished by the production of “Facade-system”. It is appreciated for a large selection of textures and textures of the material, as well as a reasonable price.

Pleases products of Scanroc. It provides a large selection of material at a nice price. Japan is one of the most technically advanced countries. In the manufacture of facade panels, Japanese companies also distinguished themselves. Japanese facing plates are solar panels that accumulate solar energy and convert it into electricity.

This type of facade is very expensive, but it pays off after about 5–6 years of use.

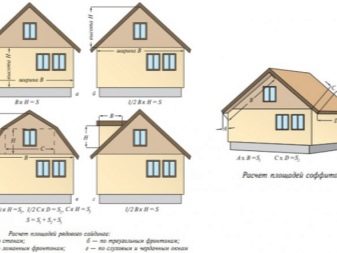

Rules for calculating materials

According to the rules and regulations of construction and finishing works, all calculations of component materials are carried out at the design stage of a private building or house. But in practice it turns out a little differently. It so happens that the owner wants to improve the external and internal condition of the building by installing a ventilated facade, where a preliminary calculation of the necessary elements will also be needed.

You can make as an independent calculation, and contact the experts, if there is little experience in this matter. The second option is simpler and better, since the person will receive accurate data: the number of fasteners, thickness and density of insulation (it all depends on the humidity of the region and the thermal parameters of the building), as well as the amount of facing material. In the case when you want to save money, almost anyone will cope with this task.

First you need to make a construction scheme, where parameters such as height, width and length will be indicated. In order not to measure yourself, you can use the technical map of the building, where all values are indicated. Further, by simple mathematical operations is the area of the walls. Since windows and doors are not covered by a ventilated facade, their square is subtracted from the total surface area of the walls.

If the structure has an unusual or complex shape, then for simplicity of calculations it is divided into simple shapes (square, rectangle).

Knowing the necessary parameters, you can proceed to the calculation of the material. It is worth starting with vapor barrier. Its quantity equals the surface area of the walls.Plus, it is necessary to add 20–30 cm from each edge to the overlap in the corners in order to achieve a uniform coating. The amount of insulation exactly coincides with the area. No need to leave allowances.

The main parameter in his choice will be the density coefficient and the thickness of one plate. Each region of Russia has its own climatic features, so these values are very important. Where the humid continental climate dominates, masters advise to use a denser and thicker layer, but the ventilation gap should be small in order to get less moisture. This is due to the fact that the mineral wool absorbs moisture and increases its weight, and consequently the pressure increases by 1 m ² of the wall surface.

Do not forget about building fungi for fixing insulation. Their number is taken at the rate of 5–6 pieces per 1 sheet.

Facing material is equal to the area of the walls, but it is worth adding a few slabs in case of marriage or trimming. The larger the structure, the greater should be the stock (approximately 5-7% of the total). A little difficult will be the calculation of the metal frame. This is due to the fact that the frequency of intersections depends on the type and weight of facade plates or panels.

Masters recommend taking a frame with a margin: the stronger the material holds, the longer it will last.

Mounting methods

Technology installation ventfasada quite complicated. To do everything right with your own hands, you need to do all the work step by step and without haste. As the masters say, only during the year after installation will all the flaws and inaccuracies be revealed: the facade tile may fall off, a piece of insulation may fall out if it is poorly attached. All work is divided into several stages.

- Preparatory work. The first thing to do is to isolate the territory with warning signs for the safety of others. This rule mainly applies to large buildings that are located in the busy places of the city. Next, an inspection of the walls is done. All flaws and the condition of the supporting structures are identified. It is necessary to dismantle all mounted fasteners that will interfere with further work. Garbage is removed, old plaster is scraped off. The surface is prepared for installation of the substructure (metal or wood frame).

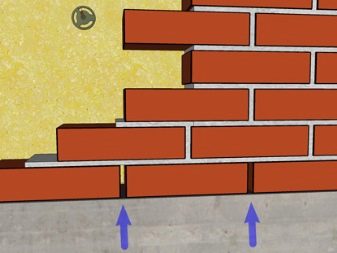

- The walls are lined. At this stage, you will need a tape measure, laser and string.They will help to make a line without curvature and deviations. The first step is the lower horizontal line, which will be a guideline for installing the lowest level of facing material. Further, with the help of a rope, vertical and horizontal axes are made at a right angle with the same distance from each other.

In the places of their intersection, so-called lighthouses are fastened - these are the future attachment points for wooden beams, dowels and brackets.

- Installation of brackets that will hold the metal frame. For this purpose, holes are made at the designated points using a perforator. It should be noted that the punch is not suitable for all walls. If they are made of aerated concrete blocks or porous bricks, then you need to use a drill with a special drill. Next, drive a dowel.

- Installation of a metal frame. It is fixed with screws. Here is the production of the so-called grid, in which, as in a puzzle, the mineral wrap will be laid. At the same stage, the fire cut-offs, which are necessary for blocking the free running of the air flow, are mounted.They do not allow the spread of fire around the outer perimeter of the building. It should be noted that the length of the hole should be a few millimeters more. Then with the help of anchors are fixed brackets.

- Laying insulation. Before insulating the walls, they must be pre-treated with a special solution that prevents the appearance of mold and fungus. Sheets of insulation are placed in the finished "grid" wall frame. They are fixed with dowels with a specific cap on the end, so that the material does not slide off or sags. A waterproofing film is laid on top.

It is very important that its edges find each other at least 15 cm, otherwise the desired effect will not be achieved. Masters advise to start laying insulation sheets from bottom to top in the horizontal direction. So, there will be less gaps and inconsistencies between the material.

- Installation of facing plates. First, load-bearing guides are installed. On top of them are mounted profiles, which will be hung front plates or panels. The profile should be selected under the type of facade material, since each of them has its own specific parameters: weight, thickness, and others.Facing material is fixed with special rivets or screws. It is necessary to maintain the same distance between the joints of the plates. For structural strength, the square of the tiles inside is fixed with an additional metal lock.

- Installation of slopes. After mounting the facade, you can proceed to the window slopes and slopes on the loggia or balcony.

Beautiful examples

There are many possible options for the design of the ventilated facade. The main thing is that beauty is combined with functionality without damage to the building. This image shows a bright combination of colors that refreshes the building and makes it more attractive.

A private house can also be unusual and modern. Here there is a combination of two types of facing plates: from metal and porcelain tile. In the northern regions of the country, a ventilated facade with double-layer insulation that blocks the appearance of “cold bridges” is often made.

The presence of two layers does not affect the appearance of the building.

Front plates can have absolutely different form and invoice. This example shows a successful combination of hexagonal shape and glass surface.The structure looks very impressive and unusual. Special attention is required to non-standard design of the roof. The tile was not laid clearly along the contour of the house, and made a little higher. Because of this, the whole structure seems more airy and light.

Such a building will forever be remembered by the residents of this city. It shows a successful combination of shapes, colors and textures. Round windows and a rounded ornament on the ventfasade create a futuristic look that you always want to look at.

On the features of installation and marking of ventilated facades, see the following video.