Tingard cellar: characteristics and subtleties of installation

The constant way to preserve canned vegetables, create your own collection of wines, in the hot summer to cool drinks without the use of a refrigerator is the use of the cellar, which provides a constant temperature for storing food throughout the year. Achievements of scientific and technical progress made it possible to make changes in the long and rather complicated process of building a cellar, significantly reducing the amount of time and physical costs of this work. Currently, technical solutions have emerged that are ideally suited for use in difficult operating conditions, including when flooding a cellar room.

Features and characteristics of the cellar Tingard

The Tingard cellar is a plastic container made by the method of rotational formation of polyethylene, intended for the storage of food products.A device equipped with an upper entrance is completely buried in the ground. It can be installed both in the middle of the land plot and in the basement of the future house.

The huge advantage of the container is that it has no seams at all. This fact fully protects the products in the container from flooding the soil and groundwater, which the owners of many sites are trying to fight. Also, access to the container is closed to rodents and insects. Cheaper models are made by welding from several parts, and they do not have such advantages.

High-quality materials from which the cellar is made, do not emit odors, are not subject to corrosion. It is a finished product that does not need to be assembled and welded.

Unlike metal options, the plastic cellar does not need to be painted regularly, it is not subject to corrosion.

Additionally, at the request of the customer, the package, in addition to the installation kit for installation, includes:

- Ventilation system consisting of inlet and chimney. It provides a continuous flow of air inside, not allowing it to stagnate, and removes excess moisture.

- Lighting. They are necessary, as inside does not get external lighting and sunlight.

- Shelves of wood, which are designed for convenient placement of products and canned stocks inside the cellar.

- A wooden floor that separates and protects the bottom of the container.

- The staircase, without which you do not descend inside and do not go upstairs.

- Weather station. It provides control of temperature and humidity in the cellar.

- The neck with a sealed cover that protects against precipitation.

To provide the cellar with the necessary strength, the case is equipped with metal stiffening ribs that allow it to withstand the pressure of the soil on the walls and top of the structure.

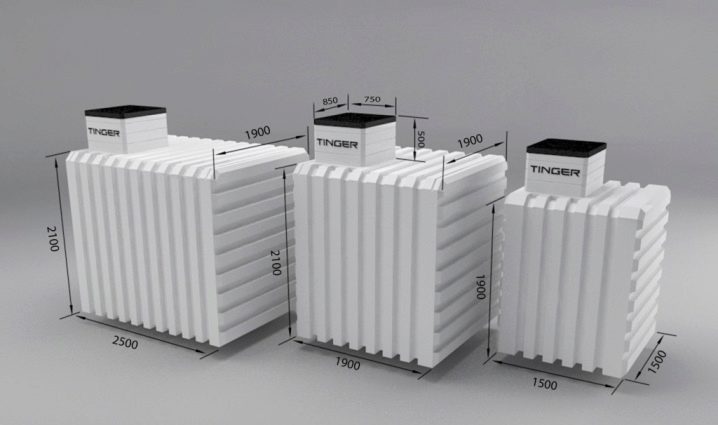

Cellars have a wall thickness of up to 1.5 cm, the total weight of the structure is 360 - 655 kg, depending on the size and configuration, the size of the neck is 800x700x500 mm. The external parameters of the container are 1500 x 1500 x 2500, 1900x1900x2600, 2400x1900x2600 mm. The warranty service life of the cellars is more than 100 years at acceptable temperatures from -50 to + 60 degrees.

A limited number of Tingard cellar sizes is a disadvantage of this product, compared to cellars made of brick or concrete, which can be laid out of almost any shape and size.However, this feature is compensated by the advantages that are inherent only in seamless plastic structures.

Cellar mounting technology

Before the start of work, the area where the cellar is planned to be located must be cleared of debris. Also markings are made along the edge of the pit for the hull. Top fertile soil layer is removed and retracted to the side. After that, you can start digging a pit with a depth of 2.5 meters.

The edges of the pit should be vertical, so that the container freely entered into it and not stuck. A concrete slab 50 cm larger than the bottom of the cellar is placed on the bottom in order to prevent its deformation due to soil subsidence. Instead of a concrete slab, you can make a screed. It should be noted that the surface of the foundation must be flat, otherwise the container may be damaged in places of projections.

Next, two cables are laid on the concrete base at a distance of 40-50 cm from the edge. Devices for tensioning the cables should be placed taking into account the possibility of their use after the cellar is lowered into place.

Between the installed cellar and the edges of the excavation there should be a distance of at least 25 cm on all sides. After installation, the cables are tensioned and placed in special slots for them. Waterproofing materials with an opening for a mouth are stacked on the upper part of the container.

After this, the cellar is covered with soil from all sides. It is necessary to take into account the subsidence of the soil. So, when using sand as a filler, the drawdown will be minimal. If you use the earth, then after a while it is necessary to fill it up on the sagging places. This should be done before the termination of the subsidence of the soil.

Before filling the top, it is necessary to mount the ventilation elements and lay the lighting wires. In order not to let insects fly in, a special mesh is installed on the ventilation holes.

If passive ventilation is not enough, you can always add active elements to it - fans that provide the necessary air flow rate. In this case, prior to the installation of active ventilation, one should take into account the additional power consumption and assess the real need for this.

On top of the cellar it is necessary to lay thermal insulation to create a thermal barrier between the upper soils.which can get very hot in the sun, and the surface of the container itself. Sheets of foam plastic, which is an excellent thermal insulation material and is not subject to corrosion, are quite suitable for this purpose.

Seamless production technology allows the use of the cellar in places with high groundwater levels, where seasonal flooding is possible.

When installing the structure in such places, it is necessary to take into account the need for its weighting, so that the cellar does not push it upward by the force of groundwater, like a float. In such cases, put extra heavy plates on the bottom.

When planning the installation of the cellar, you need to assess the possibility of approaching the place of special equipment, such as cranes, which may be needed to install concrete slabs and the container itself weighing about 600 kg. At the same time, there are no requirements for the location, except for technical possibilities to carry out the installation. Thus, it can be placed both on an open land plot, and in the form of a basement of a house under construction.

After installation of the structure, the remaining elements and lighting wiring, shelves for product placement are installed. The number of shelves and their location can be changed within certain limits.

By choosing a Tingard cellar, the owner will provide himself with a safe place for all-season food storage. High-quality materials will ensure the absence of extraneous odors, tightness and durability of the product. The undoubted guarantee of the reliability of Tingard cellars are numerous positive customer reviews.

Installation Tinger cellar - in the next video.