Armopoyas in the house of aerated concrete: the purpose and rules of installation

Today aerated concrete is a very popular building material. From it often build houses of various configurations. Today we will take a closer look at why armored belts are needed for aerated concrete houses and how to make them properly.

What is armopoyas

Before considering the features and nuances of the construction of a reinforced belt for a gas concrete house, it is necessary to answer the important question of what it is. Armopoyas is also called seismic belt or monolithic belt.

This component of the dwelling is a special construction, which is aimed at solving two important tasks:

- load distribution from the structures on top to the lower part of the building;

- the binding of the entire plane on which the reinforcement is in a single whole.

Load can distribute monolithic, concrete, as well as brick reinforced belt. Such structures evenly cope with impressive loads, for example, from heavy wall ceilings.

If you are building an armopoyas for a bunch of walls into one, then the concrete option would be the ideal solution.

Why is aromopoyas necessary?

Many owners of private houses neglect the arrangement of the reinforced belt. However, such structures are very important for any erections, including aerated concrete. Let us consider in detail why such a building detail is necessary. We can not ignore the fact that the blocks are building materials that are susceptible to cracking. Their fragility necessitates high-quality reinforcement in accordance with all the State Standards and SNiP. Similar fastenings of structures are equipped at different sites depending on the specific project of construction.

In this case, the seismic resistance of the region in which the construction is carried out plays a significant role.

A reliable belt-shaped reinforcement cage is installed in accordance with the level of overlap in order to evenly distribute the vertical loads while working in tension. In the course of the laying of aerated concrete wall ceilings, 2 special longitudinally positioned grooves are made along the diameter of the bar of metal. It is in this part that the armature is installed (in two rows). This method of strengthening is usually applied to all rows. Seismic belt is also designed to protect fragile aerated concrete blocks from possible cracking.

In addition, such structures give the building materials integrity.

In addition, the reinforced belt is needed to give additional stability to the aerated concrete housing under the following conditions:

- strong winds;

- uneven shrinkage of the structure;

- temperature jumps, which can not be avoided during the change of seasons (this also applies to those changes that occur during the day);

- ground subsidence under the foundation.

It is necessary to take into account the fact that in the construction of the roof truss structure a point-like excessive stress of the blocks may occur, which often leads to the formation of cracks and chips.Similar destruction can end the process of attaching anchors / studs on the mauerlat (beam) to the bearing floors. Armopoyas allows you to avoid such problems, so its organization is required when constructing houses from a gas block. Reinforced belt is also very important when using systems of hanging rafters. In this case, the reinforcement acts as a reliable expansion, which distributes the load from the roof structure to the entire block house.

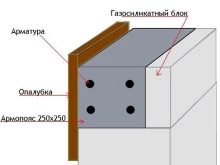

Dimensions

Reinforcement monolithic type is poured around the perimeter of the house. Its dimensional parameters directly depend on the width of the external and internal wall ceilings. The recommended height of such a structure is from 200 mm to 300 mm. As a rule, the width of the reinforced belt is slightly thinner than the wall. This parameter is necessary so that when building a house there is a small gap for the installation of a warming layer.

According to experienced craftsmen, extruded polystyrene foam is best suited for this, since it copes with the task of home insulation.

Options

Currently, there are several variations of the reinforced belt.A classic construction with the use of reinforcement is used, although other materials are used in the construction of similar structures.

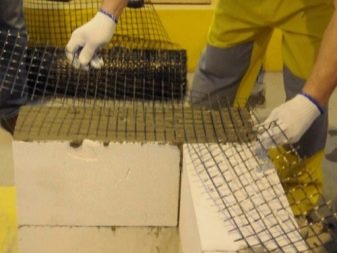

With galvanized metal mesh

Such an erection is assembled from welded steel rods in the same perpendicular position. Metal meshes are considered to be the most reliable. However, such parts have one serious drawback that needs to be taken into account: the special adhesive composition for fastening wall blocks provokes the formation of metal corrosion, which leads to the loss of most of the advantages of this type of reinforcement. In addition, the transverse rods in the winter season play the role of "bridges" for the cold.

Because of these shortcomings, experts rarely advise installing an armor plating with a galvanized metal mesh.

With basalt mesh

Similar structures are assembled from basalt fiber rods. They are arranged in parallel with respect to each other. In the nodules at the joints, the rods are fixed with wire, clamps or a special adhesive substance. Similar options for bonding are responsible for the correct and even shape of individual cells.The main advantages of the basalt mesh is that it is not subject to the detrimental effect of corrosion, and also does not suffer in conditions of constant and sudden temperature changes. Such elements have a minimum thermal conductivity, and therefore do not create cold “bridges” that occur in the case of steel meshes. The basalt net can also boast that it is able to withstand the significant impact of breaking loads (approximately 50 kN / m).

However, it has a very modest weight, which facilitates the construction of such a variant of reinforcement.

With mounting perforated metal tape

This tape is a galvanized steel strip with holes located along the entire length. For the construction of such a belt, it is enough to purchase a tape with dimensions of 16x1 mm. Reinforcement of masonry in this situation can be done without making concrete blocks by fastening them to self-tapping screws. As for the remaining works, they are similar to simple reinforcement options. To give the structure additional strength characteristics, it is possible to turn to the fastening of metal ribbons in pairs using steel wire.Of course, this option can not boast bending strength, as in the case of profiled reinforcement.

The advantages of such instances include:

- substantial savings in transportation issues, since the tape has a very modest size;

- There is no need to make the road marks (in this way, you can save on glue and the work itself as a whole).

With fiberglass reinforcement

In this case fiberglass is the main raw material of the reinforcement. A thread is coiled on it to ensure better and stronger adhesion to concrete.

Structures with the use of fiberglass reinforcement distinguish the following features:

- small weight in comparison with other options;

- minimum thermal conductivity parameter due to which the grid does not create cold “bridges”;

- ease of installation due to the minimum number of joints.

Consider that when using a fiberglass option you will not manage to build a rigid framework. For this reason, such reinforcement is not recommended to be built in seismic zones.

Also, reinforced belts differ in their types. Let's get to know them better.

Grillage

Such a belt is usually underground. It acts as a support for the tape-type foundation walls. This type of belt can be directed to a bunch of individual components of the foundation. Due to this, such reinforcement can be considered a basement. Rostverk - a belt that is responsible for strengthening the entire block of the house. The highest requirements of durability are imposed on it. Rostverk must be present under all the bearing bases of the building. This feature is the main difference of this structure from other types.

Ground unloading

Such a seismic belt is constructed after mounting on a grillage of walls from tape-type foundation blocks. Its arrangement does not relate to the height of the foundation structure above the ground. When constructing such a component, it is necessary to take into account a number of important nuances. Only install such a belt around the perimeter of the external partitions if you are using reinforced concrete slabs. The width of the reinforcement will depend on the subsequent stage of warming the block house.

In the first case, this perimeter should correspond to the width of the wall,and in the second - it is necessary to take into account the dimensional parameters of the insulation or place strips of expanded polystyrene under the formwork before embarking on it. The frame for such a structure is not required. There is enough mesh of 12-millimeter reinforcement. Reinforced belt waterproofing gaskets do not replace the foundation waterproofing work. However, these elements must be present.

To damp and moisture did not pass through the concrete, it is necessary to lay the roofing material (waterproofing) in 2 layers.

Interfloor unloading

This design is designed to strengthen the fencing elements, align the plane of the crown, as well as evenly distribute the load from the floor slabs to the box of the block house. Moreover, the effect of axial loads on the walls of a dwelling leads to a “divergence” of floors — the interfloor belt is also aimed at solving this problem.

Under roof

This structure performs the following functions:

- distributes the loads that come from the roof, onto the truss structure and enclosing elements;

- allows you to secure the power plate as securely as possible;

- aligns the horizontal box built.

If there are inclined elements in the truss system, then it is better not to neglect the installation of the reinforcement under the roof on the bearing wall ceiling, since it is this foundation that acts as a support.

How to do?

Do not think that the construction of reinforcement - the prerogative of the highly skilled and experienced craftsmen. In fact, to cope with the manufacture of such a design is possible without special knowledge and rich experience. It is only important to adhere to the manual and not to neglect any of the specified stages of work to strengthen the aerated concrete masonry. Consider in brief the technology of the manufacture of armored belt.

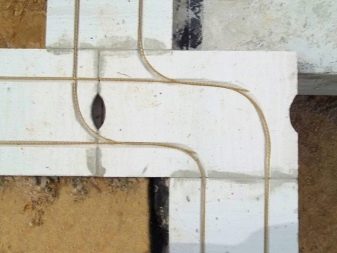

In the course of the device reinforcement aerated concrete floors on the block need to do 2 strokes. From the extreme sections they should be at a distance of 60 mm. Gates can be made by a wall chaser. Before you install metal bars in the cavities, you need to remove any debris from them. This can be done with a special hair dryer or brush. After this, construction glue is poured into the grooves, a frame is installed. The adhesive solution will protect the rods from corrosion, as well as provide better adhesion of these parts to the blocks.If there are thin seams on the walls, then a special metal frame can be used.

For its installation does not need stroking, as it is fixed with glue.

As for the reinforcement of window and door lintels, here the majority of builders use a U-shaped block. It should be noted that the blocks that will become supports for the lintel must also be strengthened by 900 mm from both sides of the openings. In advance, you should make structures of wood in the openings. It is on them that U-blocks will be based. They must be installed in such a way that the thicker side is outside. It is recommended to warm the groove with a polystyrene foam plate, close the outer part of the blocks, and then install the frame. After that, you can proceed to pouring cement lintel.

If you plan to reinforce a lightweight roof, it is usually sufficient to make only in-line processing using two tapes. At the same time, the distance between the rafters is reduced for better load distribution. Working with a roof trimmed with a rather heavy tile, several U-like blocks will come in handy. They are placed on pre-sawn and reinforced aerocrete.

The groove is recommended to fill with a thick concrete solution.

Recommendations of specialists

Bearing wall ceilings of aerated concrete can be built with a height of not more than 20 m, which corresponds to five floors. For self-supporting bases, a height of 30 m is allowed, which corresponds to 9 floors.

Armature at the corners should go continuously - straight rod. Such a detail should be rounded in accordance with the strobes. If the reinforcement bar is in the corner, then it must be cut off.

If you use reinforcement for reinforcement of structures, it is recommended to use steel rods having a diameter of 8 mm and marking A3.

To make the strokes even, you can nail the board to the outer row of blocks. It will be used during the cutting of the necessary cavity.

Consider that the most expensive of all the options is the basalt mesh. However, its strength characteristics justify the high cost.

If we talk about mounting the perforated tape, then you need to consider that in most hardware stores there is a product that has a thickness of 0.5-0.6 mm. Similar elements for reinforcement cannot be used. We need to find the tape, which has a thickness of 1 mm.As a rule, these products are found in specialized outlets or online stores. Unfortunately, in the construction market we are accustomed to, such details are extremely rare.

Experts recommend for a one-story building to make a belt in the middle of the wall, as well as at the top - under the roof. As for the two-storey block houses, here the belt is built under the overlap between the floors and the roof.

Do not forget that fiberglass reinforcement is not the most durable and reliable. It does not withstand the stress on fracture, despite the fact that it is one of the main tasks of reinforcing concrete blocks.

Seismopoyas are made only of ribbed rods. Concrete clings to their relief edges, and this has a positive effect on the increase in the bearing characteristics of the structure. This type of belt is able to work in tension.

If you need to strengthen the basement-type armored belt, it is recommended to use thicker reinforcement or mount fewer cores. There is another solution - laying the grid in two layers.

In the absence of a grillage, the base belt does not make sense. Inexperienced craftsmen who want to save on the construction of the grillage, are engaged in strengthening only the base belt, using reinforcement with a large diameter. Some people believe that this allegedly increases the carrying capacity of the home. In fact, these actions are unreasonable.

Reinforcement of openings should be done one row before the window. For example, if you are going to open it at the level of 1 m, then you need to subtract 25 cm. The result will be a reinforcement zone.

For pouring it is not necessary to add too much water to concrete. This can lead to the fact that the composition is not very durable.

Many users are wondering if vertical reinforcement is necessary for wall ceilings.

Yes, they turn to him, but rarely and only in such cases:

- if there are heavy loads on the wall (side);

- if aerated concrete with a low density is used (blocks are not of the highest quality);

- in places of reliance on the walls of elements with high weight;

- in the case of a corner joint of the joints of adjacent overlaps;

- when reinforcing small walls, as well as door / window openings;

- during the construction of columns.

To learn how to make an armopoyas in the house of aerated concrete, see the video below.