How to build a house of cinder block?

Many of those who want to build a durable and reliable house, choose a cinder block as the main material of the walls. Such raw materials are famous for their strength characteristics and flexibility in work. Today we will learn about the features, advantages and disadvantages of houses built from cinder block.

Special features

It's no secret that the current range of building materials is replete with its diversity. For the construction of a residential building it is possible to use not only wood or brick, but also practical block elements. They are manufactured using different technologies and have different performance characteristics. From a number of such products should be allocated cinder blocks.

This material is a special building stone.

Its production is made in special forms.The binding component of cinder blocks is concrete. Various components are used for filling - it can be environmentally friendly expanded clay, slag, bricks and other similar elements.

Houses made of cinder blocks are characterized by a long service life. Such buildings can easily stand for many years. At the same time, such a dwelling will not have to be regularly maintained, such as, for example, buildings made of natural wood.

Slagblock houses are often built by the owners themselves, without the involvement of experienced craftsmen. Experts say that even an inexperienced user who has not previously encountered similar processes can cope with such work. Of course, if a person doubts his power or is afraid to make serious mistakes, it is better for him to call professionals.

Some people make cinder blocks at home. This is usually done using inexpensive and affordable raw materials. In order to produce high-quality and strong materials as a result of manufacturing, it is very important to adhere to all the required proportions. Consider that it is impossible to build a house from fragile and low-grade blocks, as this will affect the durability and quality of the entire building as a whole.

This material is very versatile. It is often turned to for the manufacture of various components of the site, such as a gazebo, a small extension, flower bed or fence. Also from the cinder block make various outbuildings for household purposes. Such designs are made easily and quickly, so to cope with the conduct of such work is not difficult.

Advantages and disadvantages

Slagblock houses are found with an enviable frequency. They are difficult to confuse with any other buildings, because they are distinguished by their sturdy appearance, which speaks of their durability and reliability. However, if you decide to build a house of cinder blocks, you need to familiarize yourself with its advantages and disadvantages.

Nowadays, many users stop their choice on the slag blocks, as they are recognized as fireproof, which is very important for any private house. Slag blocks not only do not provoke the appearance of a flame, but also do not support the combustion that has already occurred.

Buildings of cinder blocks can boast a long service life. They do not suffer from strong winds or hurricanes.Of course, such useful characteristics should be supported by high-quality reinforcement materials.

Usually in this case they turn to steel rods, which are capable of making the structure more wear-resistant.

Slag-block houses are being repaired without any problems, as evidenced by feedback from the owners of such structures. For example, you can easily repair unexpectedly formed cracks. To carry out such work will not have to spend a lot of effort, time and money.

Houses from cinder blocks are built very quickly. This results from the fact that such building materials differ in the impressive sizes. As mentioned above, even an inexperienced master, who does not have special education, can build a house from such blocks. The main thing is to follow the instructions and not to neglect any of the steps of work.

You should not think that it will be possible to build from the cinder block only the same type and stereotyped structures that do not have any zest. In fact, you can build a very original structure of a non-standard configuration. To do this, you just need to show a little imagination and turn to people experienced in these matters.

Carrying out construction work with the use of cinder blocks will not cost the owners expensive. This fact is noted by many consumers who have significantly saved by choosing this material as the basis. Few people know that slag stones are made not only with the use of slags. Today, there are products that have different components. Due to this, it will be possible to choose suitable raw materials for any conditions.

Masters claim that during the construction of a cinder block house, quite a bit of cement is removed, which also reduces the cost of the process.

Despite its size, the cinder block, as a rule, has a very small weight. This is explained by the fact that such material is inferior to brick in terms of density. Thanks to this property, blocks can be used if you are building a house on a lightweight foundation.

A slag unit is a product that does not attract rodents or insects. Such structures do not need to be treated with protective and antiseptic solutions, since they are not susceptible to the formation of mold or fungus. Such residential buildings are not afraid of low temperature values, which indicates frost resistance of slag stones.

It is possible to transport blocks not only with the use of pallets. These materials can be easily stored in a truck / trailer.

The houses of them boast good noise insulation characteristics. They usually do not hear annoying sounds from the street.

Slag blocks are heat-absorbing materials.

Unfortunately, buildings from cinder blocks have some drawbacks. For example, some types of cinder blocks are heavy. Today sold and heavyweight options that are difficult to handle. In many cases, with similar materials work, resorting to the use of special equipment.

Before you start building a house, it is important to remember that the unfinished block buildings do not look very attractive. If you have not acquired a special decorative material, then you will have to trim the dwelling to make it look more aesthetically pleasing.

If you chose a cinder block for building a house, then you need to be prepared for the fact that the installation of pipes and cables will not be the easiest. For this reason, craftsmen often have to use special devices during construction to facilitate this task.

If you use a hollow cinder block during construction, then you will have to fill it with slag.to ensure high thermal insulation performance. Such work is considered difficult. In addition, over time, such backfill may settle, and voids will again appear in the materials.

From such material it will not be possible to build a high-rise housing. This is due to the fact that too heavy structures can reduce the density and strength of materials.

It is not necessary to decorate the cinder block walls with simple plaster. Appeal to such a design can lead to the fact that the material simply loses the density of the upper layer, and it will fall off.

As well as foam blocks, cinder blocks have not the most correct geometry. Because of this, during construction, they have to file and grind to form smooth surfaces.

The minuses of the cinder block houses are still less than the advantages. Many problems can be avoided by adhering to the appropriate technology, as well as using quality (and appropriate) materials / tools.

Types of material

As mentioned earlier, a material such as a cinder block has several varieties, each of which has its own characteristics and application rules.Let's get acquainted closer with such products.

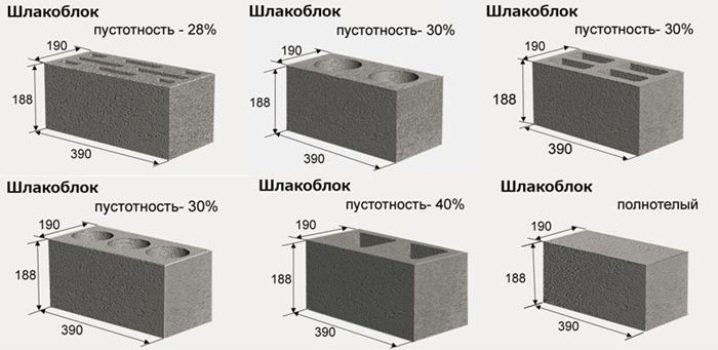

Hollow and corpulent

Both of these options blocks are in great demand. For example, common full-bodied varieties are most often used in the construction of foundation structures, columns of various modifications and bearing foundations. Moreover, hollow blocks are great for forming basements.

The above materials are characterized by remarkable strength characteristics and can withstand more severe loads than hollow versions.

As for hollow blocks, they are usually purchased for the construction of partitions and walls. They have a modest weight, so they do not weigh down the common basis of the dwelling at all.

Decorative

Such lining materials have occupied their niche in the market quite recently. They are complemented by a special decorative coating, which can be located both on one side and on both sides of the block. This additional layer can repeat all sorts of textures (for example, stone or plaster). In addition, in this way, it will be possible to protect the blocks themselves from such negative factors as moisture and dampness.If you have chosen for the construction of decorative materials, then from the exterior of the building can be abandoned.

Partitioning

If you have moved to the construction of partition walls in a block house, then you need to apply the specified types of materials. Such specimens are distinguished by the fact that even and neat walls can be constructed from them, while saving on the solution. It should also be noted that the partitioning slag stones are lightweight, and their installation is quick and easy.

Foundation

Base type blocks are differently called building stone. These materials have high strength and durability. Over time, such blocks do not cause serious shrinkage, and also do not collapse, which indicates their increased reliability. If you are laying breeze blocks on a fairly strong and stable base, then you should remember about the need to use reinforced concrete tape. Its layer must be at least 1.5 cm.

Experts advise to pay attention to the fact that the walls of the cinder block foundation structures must necessarily be heat- and steam-insulated with special materials.

Chipped and ragged

Not so long ago, the market of building materials was replenished with original slag blocks, which have a decorative surface with imitation of torn / crushed bricks. These options are most often used when finishing various buildings and fences.

Color

There is a color version of cinder block on the market. From similar material most often construct fences, pediments or columns. The required shade of this material is achieved at the stage of its manufacture.

Usually, red brick chips or chalk of different colors are mixed in for this purpose.

Slag blocks differ from each other and their main components.

Based on slag

The properties and characteristics of such blocks, first of all, depend on the properties of the feedstock. This mainly relates to the environmental safety of materials (meaning the presence of toxic substances in their composition). This parameter should be taken into account when choosing slag units.

These materials are distinguished by high thermal insulation qualities. As for the service life, it is the same as that of the brick. But here it is necessary to build on the filler present in the material.Slag-based blocks will last a very long time and will not cause problems if they are properly laid and finished.

Arbolitovye

Arbolit-based blocks are in great demand today. Such materials are in great demand because they have remarkable thermal insulation characteristics. However, such products have one serious drawback - they cannot boast of a sufficiently long service life. Of course, in the process of manufacturing arbolite blocks can be made more durable, but their environmental friendliness usually suffers from this. Such negative changes are due to the fact that special substances are added to the normal composition, which cannot boast of natural origin.

Haydite

The most secure and environmentally friendly units are recognized as being based on expanded clay. Such products are famous for their excellent thermal insulation qualities and durability.

It is necessary to take into account that the popularity of such blocks is explained not only by their ecologically clean foundation. These varieties are lightweight, and there are multiple voids in their structure.Most experts recommend using such types of cinder blocks for the construction of the house. Currently, more than 50% of dwellings in Europe are made of similar elements.

Design

It is not a secret for anybody that competent drawing up a project at home is a very important stage, which cannot be excluded. To do this, it is recommended to contact specialists. If you are limited in the budget, you can try to do this work yourself.

The project should necessarily reflect:

- dimensional parameters of the future home;

- the number and dimensions of windows / doors and other similar components.

Unfortunately, the presence of such a project will not allow you to make changes regarding the planning, which are often addressed by the owners of the future dwelling.

But it will be easier and more convenient for you to calculate the volume and specific type of materials, as well as calculate how much the construction of a cinder block house will take.

Payment

It is impossible to proceed to building a house without calculating the required amount of materials.

To determine how much you need them, you need to adhere to the following algorithm:

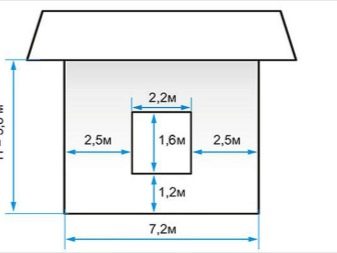

- you need to take the dimensional parameters of the height and length of the wall and multiply them;

- subtract from the resulting value the area of window and door openings;

- identical calculations are performed for the remaining walls of the cinder block dwelling.

Next you need to correctly determine the thickness of the walls. This value will be determined by the specific method of laying blocks and the climate in the region where the work will be carried out. In areas where winters are fairly harsh, walls should not be less than 60 cm thick. And in those regions where moderate temperatures prevail, it is acceptable to build walls that are less thick.

After that, you need to proceed to the calculation of the area of the used cinder block (implies the outer edge of the elements).

The building material produced at the plant has the following dimensions (standard):

- width - 190 mm;

- length - 390 mm;

- height - 188 mm.

If you are going to lay cinder blocks with a wider half outwards, then the area of individual elements will be 0.0741 square meters. m (you need to multiply 190 by 390). If the materials are planned to be placed by the narrow side, then the required value should be calculated differently - multiply 190 by 188.The result is the required area of building stone - 0.03572 square meters. m

Next, you should determine how many blocks will be needed to install 1 m2 of the wall. For this it is necessary to divide the area of the site by the previously calculated block area. As a result, we get the value we need. The final calculations will be easy, because you will know absolutely all the values of the structure and the number of cinder blocks for building walls.

Building

Slag-block house can be built by hand. For this, it is not necessary to be an experienced master. The main thing is to follow the step by step instructions. Consider in stages how to build such a home.

Before proceeding to the construction work, you will need to stock up a number of necessary tools:

- trowel;

- level;

- a plumb line;

- a tub

- shovel;

- pickaxe;

- a bucket;

- special stretchers;

- protective equipment (respirator, gloves, etc.).

If you have purchased all the necessary accessories, you can safely proceed to the construction of a cinder block house.

Main steps:

- The first will be earthworks. You will need to level the area on which the planned construction of the house.

- It will take a foundation. In most cases, people construct the ribbon version, since it is made easily, but it turns out to be strong and reliable.

- After pouring, you need to give the concrete a fix. It usually takes about 4 weeks. After this period, you can continue construction work.

- When the foundation has reached the required strength level, you can lay slag blocks on it. Begin laying should be from the corners - the only way to get smooth walls.

- Lay the blocks in the corners and level them using a plumb line and level.

- Next, pull the string between the corners, which should be located on the outer corner of the blocks.

- Putting new parts, you should pay attention to the fact that they do not move the string, otherwise the walls will not be smooth.

- In order to bond separate slag blocks with each other, it is necessary to use cement mortar. When laying, its thickness should be from 1.5 to 2 cm. If you put thicker layers, the walls will be cold, since cold “bridges” will form in them.

- When laying the blocks, you should use a mallet or a rubber mallet.With the help of such devices you can easily and seamlessly trim the already laid elements.

- When you get to the window and door openings, you will need to use special reinforced concrete lintels. They are characterized by high strength and work well for bending, so the walls with them are quite strong.

- Having completed the erection of wall structures, you need to cover them with a special water-repellent agent to protect against dampness and moisture. After that, you can proceed to the design of the roof.

Recommendations

For cinder blocks are usually used the same fasteners as for concrete. However, most experienced craftsmen recommend using a special chemical anchor. It is more expensive than the usual dowel, however, will provide a more reliable fastening of materials.

Making the installation of cinder blocks, it is important to ensure that the joints between them are not too wide, because through them the heat will subsequently leave the house outside.

The external surfaces of the walls of the cinder block must be covered with moisture-proof and heat-insulating materials.

Do not neglect these works.

Consider that home-made cinder blocks, although they are cheaper, can later "behave" completely unpredictable, so it is better to purchase materials manufactured at the factory.

Laying cinder blocks, special attention should be paid to the first row. The quality and evenness of the subsequent rows will depend on it.

Many users are interested in what materials can be used to finish the external walls of cinder-block houses. It is permissible to mount siding panels, brick, decorative stone or wood on such a base.

Successful examples

From the cinder block you can build a chic two- or three-story cottage with a high angular roof, which has several slopes. It is permissible to decorate such a structure with a combination of red and white bricks, and to use dark gray shingles as the roof.

From such blocks you will get a spectacular one-storey, L-shaped house with a wood paneling or brick finish. On the roof, you can lay a soft contrasting roof, and the lower part of the house is decorated with white panels.

Unfinished cinder block house with two floors will look stylish if you cover it with a high cone-shaped roof of a dark shade,put large windows with black frames, and on the lawn before the construction put street lamps in the Gothic style.

How to make a cinder block at home, see the following video.