Features of insulation and sound insulation of interfloor overlapping on wooden beams

When building a house, an important task is insulation and sound insulation. Unlike the walls, the insulation of interfloor overlapping has a number of features. Consider the main ones.

Description

The fastest and simplest method of interfloor insulation, is flooring on wooden beams. Installation of timber through a certain distance does not require much effort. After that, it will only be necessary to fill the voids formed with heat and sound-proofing material and to close all the floors and attic floors. Wood is a good conductor of sound. Consequently, if you just sheathe the beams between the floors with wood, heat and sound insulation will leave much to be desired.

The correct choice of thermal insulation material, it is necessary to carry out starting from where the overlap is. So, for the overlap between floors, sound insulation is of great importance. The overlap between the floor and the attic should have more insulating qualities. In a house that has heating on all floors, consider the transfer of heat to the upper floors. In this case, the choice in favor of the insulating characteristics of the material will provide an opportunity to maintain the microclimate of each room. Great attention should be paid to the protection of heat and sound insulating material from moisture. For this purpose, steam and water insulators are used.

Standards and requirements

The overlap between the floors is constantly under mechanical and acoustic effects that cause noise (walking in shoes, falling objects, slamming doors, working TVs, speakers, talking people and so on). In this regard, strict requirements for insulation. Soundproofing ability is indicated by two indices. The airborne sound insulation index is Rw, dB and the reduced impact noise level index Lnw, dB. Requirements and standards are regulated in SNiP 23-01-2003 "Protection against noise".In order to meet the requirements for interfloor overlaps, the airborne sound insulation index should be higher and the reduced impact noise index should be less than the standard value.

The requirements set forth in SNiP 23-02-2003 “Thermal Protection of Buildings” are also imposed on the insulation of floors in the Russian Federation. Requirements for insulation, determined by the location of the floor. When choosing insulation for floors between floors, more guided by what will be the design. For example, if insulation is placed between lags or beams, preference is given to low density basalt heaters or fiberglass.

If the insulation suit under the screed, the density should be high. In addition to thermal insulation properties, insulation must meet the requirements of environmental safety.

Classification

To classify noise insulation, it is possible to divide all methods of dealing with noise penetration into two parts.

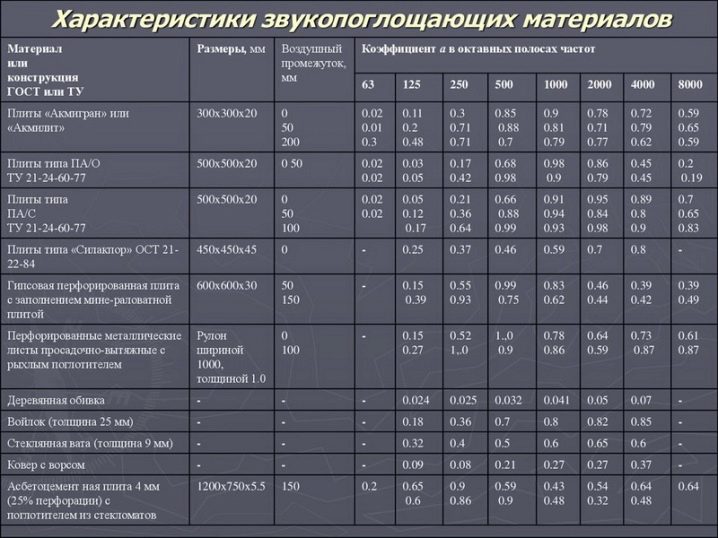

- Soundproofing - reflects the sound from the wall or ceiling, which significantly impede the penetration of noise behind the structure.Such properties have dense materials (concrete, brick, drywall and other reflective, sound, materials) The ability to reflect sound is determined primarily by the thickness of the material. In construction, the design takes into account the reflection index of the building material. On average, it ranges from 52 to 60 dB.

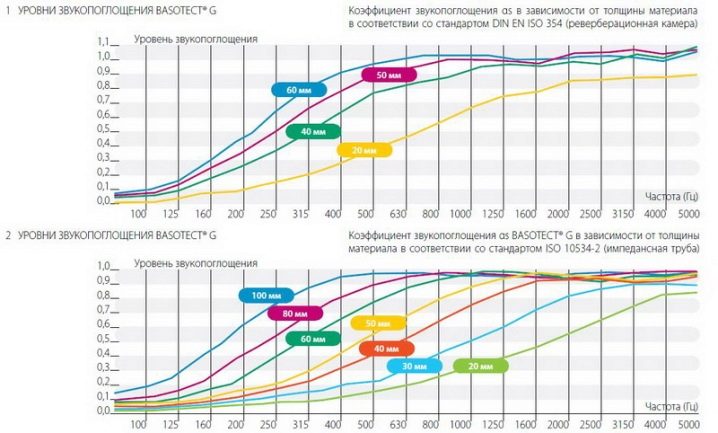

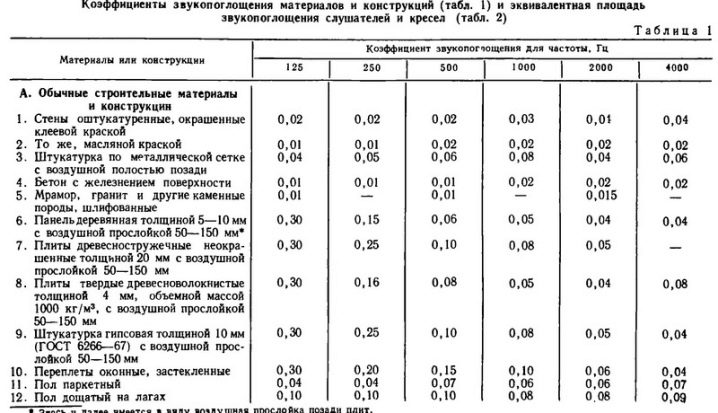

- Sound absorption - absorbs noise, preventing it from reflecting back into the room. Sound absorption materials have, as a rule, a cellular, granular or fibrous structure. How well the material absorbs sound is estimated by the sound absorption coefficient. It changes from 0 to 1. At unity, the sound is completely absorbed, and at zero it is fully reflected. It should be noted here that in practice materials with a coefficient of 0 or 1 does not exist.

It is considered to be suitable for insulation materials that have a sound absorption coefficient of more than 0.4.

Such raw materials are divided into three types: soft, solid, semi-rigid.

- Solid materials are mainly made from mineral wool. For greater sound absorption, fillers such as perlite, pumice, vermiculite are added to cotton wool. These materials have an average sound absorption coefficient of 0.5.Density is about 300-400 kg / m3.

- Soft materials are made on the basis of fiberglass, mineral wool, cotton wool, felt, and so on. The coefficient of such materials ranges from 0.7 to 0.95. Specific weight is up to 70 kg / m3.

- Glass fiber plates, mineral wool plates, materials with a cellular structure (polyurethane, foam plastic, etc.) can be attributed to semi-rigid materials. Such materials are called materials with a sound absorption coefficient from 0.5 to 0.75.

Material selection

Noise isolation and sound insulation in houses with wooden floors can be carried out with different materials.

The list of the most common ones below.

- Fibrous sound-absorbing materials - are rolled or sheet insulation (mineral and basalt wool, ecowool and others). This is the best way to deal with noise. Located between the plane of the ceiling and the floor of the ceiling.

- Felt - stacked on top of the lag, as well as at the junction of walls, seams and other areas where it is necessary to prevent penetration through the looseness of the structure.

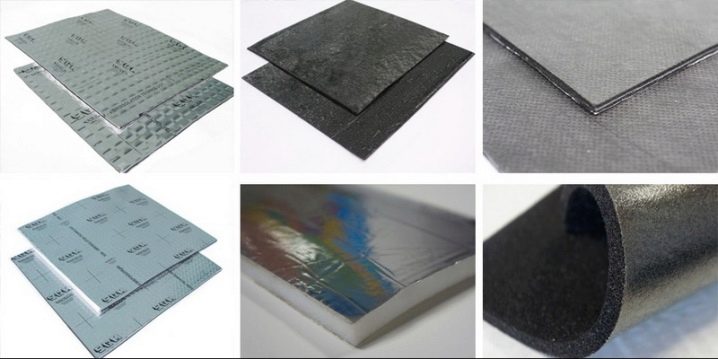

- Cork, foil, rubber, polystyrene backing - a thin material for laying on top of the floor covering or beams. Isolates the room from shock noise and vibration.

- Sand is laid on a polyethylene backing, at the bottom of the entire sound insulation. This makes it possible to almost completely solve the problem of sound insulation, in combination with other materials.

- Expanded clay - laying and the principle of operation as in sand, but at the expense of lumpy structure and a smaller specific gravity is more convenient. Eliminates spillage at rupture of the substrate.

- Draft floor - mounted from sheets of particleboard and OSB on the principle of a floating floor, does not have a rigid connection with the overlap, due to this it dampens sounds.

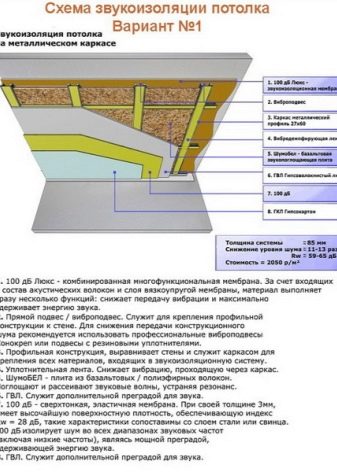

To achieve the required level of noise isolation, a “pie” is assembled from a combination of different materials. A good result, for example, gives the following order of materials: ceiling coating, lathing, vapor barrier material, mineral wool with a rubber cork backing, OSB or DSP plate, finishing materials. To choose insulation materials, you need a little study the most common of them in more detail and select the most appropriate ones by description.

- Glass wool - material is made of fiberglass. It has high strength, high vibration resistance and elasticity. Due to the presence of empty spaces between the fibers, it absorbs sounds well.The advantages of this material made it one of the most common in heat insulation and sound insulation. These include low weight, chemical passivity (no corrosion of contacting metals), non-hygroscopicity, elasticity. Glass wool is produced in the form of mats or rolls. Depending on the design of the floor, you can choose the most suitable option.

- Mineral wool - material made from rock melts, metallurgical slags or mixtures thereof. The advantages are fire safety and chemical passivity. Due to the chaotic arrangement of the fibers in a vertical and horizontal position at different angles, a large absorption is achieved. In comparison with the glass wool lack of this material more weight.

- Multi-layered panel - At present, soundproofing systems are convenient to use, since they are one of the leading means of soundproofing partitions (a wall of brick or concrete, etc.). These systems are made of drywall and sandwich panels. The sandwich panel itself is a combination of dense and light gypsum fiber layers and mineral or glass wool of various thickness.From the model of the sandwich panel depends on what material is used in it and how the layers of materials vary in thickness. Not flammable, but not recommended for use for insulation of floors, as in this situation the installation and the cost of material is complicated, which will lead to unnecessary construction costs. It can be used for ceilings in certain specific situations if this simplifies the installation of sound insulation. The big drawback of the panels is their heavy weight, which must be taken into account when building.

- Pressed from natural cork crumb sheet - one of the effective materials for isolation from shock noise. The material is resistant to rodents, mold, parasites and decay. Inert to chemicals. In addition, the advantage is durability (serves 40 years or more).

- PE foam - most suitable as a substrate for laminate, parquet and other floor coverings. Effective from shock noise. It has several varieties, which is a plus to achieve the corresponding requirements of sound insulation and minimal costs. Resistant to oils, gasoline and many solvents.It has a number of drawbacks such as fire hazard, instability to ultraviolet radiation, it loses up to 76% of its thickness during long-term loads. Cases of moisture creates conditions for the formation of mold and fungi. One of the inexpensive materials.

- Probkorezinovy substrate - made in the form of a mixture of synthetic rubber and granular cork. Designed to reduce shock Noises. Convenient for use under elastic and textile coatings (linoleum, carpet and others). With no less efficiency is used under hard flooring. The disadvantage of this material can be called the fact that in the presence of moisture it can serve as a favorable environment for mold, therefore additional moisture insulation is necessary. Polyethylene film is suitable for this.

- Bitumen backing - made of kraft paper impregnated with bitumen and sprinkled with cork chips. Cork filling is located below, this helps to remove moisture from under the laminate. Waterproofing is not necessary. The disadvantages of this material is that cork crumbs can fly away from the canvas, with excessive moisture, it rots and stains during installation.

- Composite material - consists of two layers of plastic film and a layer of expanded polystyrene granules between them. Polyethylene films have a different structure. The top layer protects against moisture, while the bottom layer allows moisture to penetrate into the middle layer, which removes it around the perimeter.

- Extruded polystyrene foam - has low water absorption, high strength. The ease of installation of this material is determined by the ease of cutting, simple and quick installation, the minimum amount of waste. Easy installation determines the low cost of work. Durable, retains properties for 50 years.

- Fiberglass - applicable to the isolation of structural noise. The porous fiber structure provides this capability. It is used with sandwich panels, frame sound insulation cladding and partitions, wooden floors and ceilings. Depending on the material with which it is applied, the installation technology is also selected. When installing wooden floors or floors laid in places of support on the walls and under the beams. Moreover, if the ends of the beams are supported on the walls, to avoid hard contact with other building structures, the fiberglass must be insulated with a gasket.

- Vibroacoustic Sealant - serves to provide vibration isolation. To reduce structural noise is located between the structures. Easy to use to fill words in constitutions. Good adhesion with plaster, brick, glass, metal, plastic and many other building materials. After hardening, there is no smell, it is not dangerous in circulation. During work, the premises must be ventilated. Do not get in eyes while working.

Based on the properties outlined above, you can choose the most appropriate material for the constructed overlap.

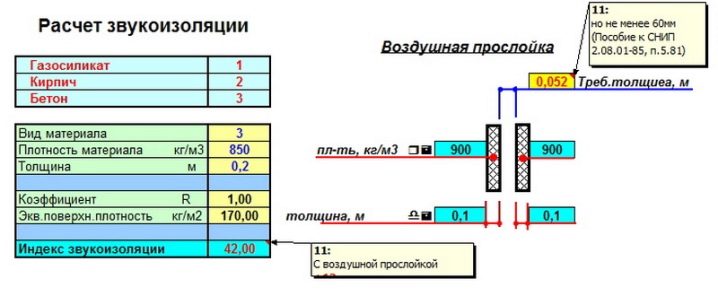

Payment

Characteristic errors in the calculation of sound insulation is a comparison of two materials, which indicate the characteristics of sound insulation and sound absorption. These are two different indicators that cannot be compared. The sound insulation index is determined at frequencies in the range from 100 to 3000 Hz. A mistake is also the common opinion that foam plastic is a good soundproof material. In this case, a layer of 5 mm of good soundproof material exceeds the 5-centimeter layer of foam. Polyfoam refers to hard materials, and prevent impact noise.The greatest effect of noise insulation is achieved in the case when combined hard and soft insulating materials.

Each insulating material is characterized by resistance to heat transfer. The greater this characteristic, the better the material resists heat transfer. To provide the necessary level of thermal insulation, vary the thickness of the material. Currently, there are many online calculators for calculating insulation and sound insulation. It is enough to enter data about the material and get the result. Comparing with the tables of requirements of SNiP, find out how the proposed option satisfies the necessary standards.

Laying technology

In a private wooden house, the installation of noise and sound insulation is best done during construction or at the stage of rough finishing. This will eliminate the finishing materials from pollution (wallpaper, paint, ceiling, and so on). Technologically, the process of laying noise and sound insulation is not complicated, and you can do it yourself.

An example is the following order of installation steps.

- First of all, the entire timber must be covered with an antiseptic.This will protect the tree from the appearance of parasites, mold, fungi and decay.

- At the next stage, the rough flooring is packed below the beams. For this board suitable thickness of 25-30 mm.

- Then the vapor barrier is installed over the formed structure. The joints of the vapor barrier must be glued together with building tape. This will prevent the shedding of insulation. The edges should come on the walls to a height of 10-15 cm, which will protect the insulating material on the sides from moisture penetration from the walls.

- After the vapor barrier is hermetically sealed to the rough flooring, insulation is placed on it. In this case, the insulation material is mounted not only between the beams, but also on top of them. This is done to avoid cracks through which sound and heat can flow. In general, this approach will provide the highest level of sound and sound insulation.

- At the final stage, the entire insulation is covered with a vapor barrier. As in the initial stages, this will serve as protection of the insulation from moisture and steam. It is also necessary to glue the joints of the vapor barrier together with tape. After these stages, heat and sound insulation are ready. It remains to mount the subfloor.For this you can use boards with a width of 30 mm. But the best option would be mounting chipboard, in two layers. In this case, the edges of the chipboard should lie on the lags, and the second layer should be mounted so as to overlap the joints of the first layer.

- As a result of the operations performed on the subfloor, there will be a coating that does not have connections with beams, a technology called a floating floor. In this case, the coating is held at the expense of its own weight, and the absence of fastening with the beam structure prevents the passage of impact noise. This method is an additional sound insulation. When purchasing chipboard and OSB slabs, insulation materials, it is imperative to know their manufacturer and, if possible, the type of material. Building materials may emit toxic gases, therefore better materials are recommended.

In monolithic houses, two-story or having more floors, on concrete floors, heat and sound insulation are arranged under a screed.

Useful recommendations

When choosing noise insulation and thermal insulation, it is necessary to take into account all the characteristics of materials for the resistance to heat and noise transmission.Find out how they meet the standards or personal requirements to pay attention to cost reduction. Since the desired effect can be achieved only with alternative materials or a different procedure for laying insulation. An important role is also played by the extent to which the raw materials used are harmless to health.

An additional role in increasing the noise and sound insulation can play a change in the design of the ceiling. For example, different types of wood have different thermal conductivity and sound conductivity. Large voids between the lags also contribute to increased sound insulation. You can use different types of gaskets for fixing lag, subfloor, finishing cover. If the insulation and sound insulation is mounted independently, then it is advisable not to neglect the advice and recommendations of specialists. Special attention should be paid to the fact that the violation of the technology of laying insulation materials can lead to a decrease in the desired result, an increase in costs, and in the worst case, to the loss of material and the fragility of work.

For information on how to soundproof interfloor overlap on wooden beams, see the following video.