Warming of the frame house: where to start and what material to choose?

Frame houses are built very, very actively. But even such reliable and high-quality structures in the Russian climate cannot do without insulation. And this means that a quiet life in the house depends on the choice of the correct variant of it and on the literacy of work.

Why do you need?

Shield buildings are very popular among summer residents: they are attracted by the opportunity, starting work in the late autumn, by the beginning of the season to have a full-fledged house. At the same time such facilities:

- ecologically safe;

- are inexpensive;

- serve many decades.

But all these advantages are realized only if the insulation of the frame house is done properly.

Otherwise, it will be quite difficult to call it comfortable. It should immediately distinguish between two types of buildings.

- Buildings for permanent use by default should have solid thermal protection.

- If you plan to go there only from the end of spring to the end of autumn, the insulation should be minimal - strictly to maintain the stability of the structure itself.

In the "skeleton", intended for the summer period, the wall thickness is not more than 70 mm. In the cold season, the required figure is at least twice as high. If we confine ourselves to a thinner layer of material, the heat leakage will be disproportionately large, and we will either have to freeze or lose huge money on heating.

Important: for winter living, it is necessary to insulate not the entire volume of the frame, but only its individual parts, first of all:

- stingrays;

- cellars;

- garret planes;

- basement structures.

Doing only one warm floor, even if its power is excessive, will not work.Through the basements, external walls and other parts of the construction of the panel house, the heat will continue to leak all the same cheerfully. Given the variety of conditions where insulation will be placed, it is impossible to give a universal answer about the best option. Basement walls are equipped with some types of thermal protection, load-bearing walls - with others, the overlapping of a cold attic - with third ones. But in any case, the choice of suitable insulation formats always comes first.

Types of thermal insulation

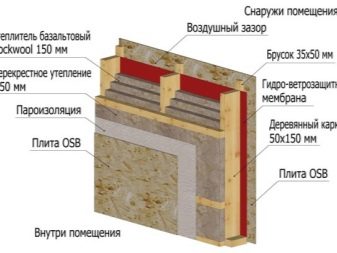

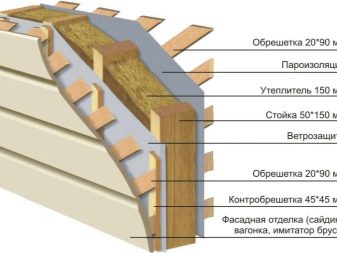

Cross (additional) insulation of frame structures is carried out, as its name implies, by adding an auxiliary volume of insulation to one layer. This solution allows you to securely close the existing cold bridges. Most builders prefer the external location of insulation - because it does not take away precious internal space, which is always lacking in country houses and in rural dwellings. In addition to thermal protection of the plane of the facade, special attention should be paid to the prevention of heat loss through the corners.

They are the most problem points in any dwelling; Now you can find out which solutions to all these tasks should be preferred.

What is worth warming?

Insulation for a frame house can not be bulk; standard technology involves the use of tiles or rolls only. The difference is not only that “one thing is laid, the other is unwound.” Technologists are aware of the differences in nominal thickness. Usually increasing the thickness of the layer increases the energy efficiency of the material.

But it is worth remembering that even immaculate material in itself can be applied incorrectly, and this immediately devalues all merits. Therefore, it is better to either turn to professionals, or to study the slightest subtleties and nuances of each coating.

The overwhelming majority of amateur builders and official firms use the “brilliant four”:

- mineral wool;

- polystyrene foam;

- mineral plates;

- isolon

There are many other options, the main division of which is carried out by chemical nature (organic or inorganic substances in the base) or by structure - solid blocks and loose substances. You can even choose the clay, metallurgical slag and other bulk reagents. But the problem with this solution is the gradual shrinkage of the layer of thermal protection.It is necessary to thoroughly tamp the stacked layer, and not just fill the entire volume of the wall, floor and so on with the selected composition. Plate materials do not deliver such problems - but they also have their own “pitfalls”.

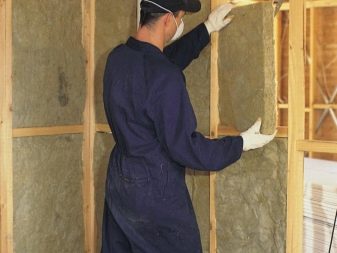

So, to use mineral wool in its pure form for external wall insulation is meaningless: it will keep badly, and will retain thermal qualities only until the first rain or snow. A prerequisite for success is the attachment to a special construction of bars, filled vertically. Each beam is placed only where the boundary between the slabs of mineral wool will pass. You should also take care of external protection from getting wet.

It is important to wear respiratory protection when working, wear special glasses and do not take off gloves.

Polyfoam - the substance of organic nature. Its undoubted advantages are:

- low specific gravity;

- protection of walls from strong winds;

- elimination of rotting.

But these advantages have a downside: high fire risks. Therefore, it is impossible to finish the walls with foam plastic that has not undergone special treatment.

Mineral wool is absolutely not prone to ignition.A similar advantage can be obtained when using basalt wool, but it still has a significant plus - ease of processing and perfect safety for builders.

The use of penoisol is often called the ideal solution.

But he also has weak points - in a few years, areas are formed where the material will fit loosely. Therefore, the loss of heat will increase dramatically. The liquid coating variant is distinguished by more powerful adhesion and lasts 50–60 years (a guarantee is given for such a period). The disadvantage is also, however, obvious - without special equipment, success will not work. But Penoizol is in any case acceptable for preserving heat in the floor, roof and walls.

Internal insulation of the walls of frame buildings with roll materials is impossible. More precisely, it will work to attach them to the walls, but then the walls themselves will shrink, and the insulation will inevitably be damaged. Regardless of the option chosen, and whether the work is being done inside or outside the house, it should be done very carefully. Remembering this is useful whenever the idea arises to save money by working independently.If among all materials the choice fell on penoizol, its installation is preceded by the installation of profiles.

With claydite, frame constructions are insulated extremely rarely, and such a choice does not even justify its low cost. Yes, the material is very dense and poorly absorbs water. But if he has already absorbed the liquid, its return will be very slow. Expanded clay is very heavy, and even with a minimum density in a dry form, it presses on the walls, the foundation is very strong. This circumstance will have to be taken into account in the external decoration, choosing the most durable solutions for it.

But the main thing is not even in this, but in the fact that expanded clay is three times worse in thermal properties than mineral wool and foam plastic. Be sure to therefore have to use layers of waterproofing and vapor barrier. A solid competition with this material is also made of stone wool. It is a pleasure to work with its plates, there is no need for complex tools. Cutting on the necessary fragments is made by a knife or a saw with small teeth.

For information: blocks of stone wool cannot be squeezed, rammed and squeezed. This will necessarily lead to negative consequences.It is also necessary to use ecowool wisely. So, in its pure form, ecological wool is very easily ignited, but if you mix it with borax and boric acid, the level of fire danger will sharply decrease. In addition, this treatment will avoid the interest of microscopic organisms and certain species of animals.

Near the surface, ecowool can contain up to 20% water (by weight) and retain the main insulating properties.

When the material dries, it fully restores performance. Such advantages as an optimal microclimate, extinction of extraneous sounds, lack of seams and sanitary safety will also be attractive to people. As for possible problems, they are:

- will have to limit vertical backfilling to ensure heat protection;

- you will definitely need specialized equipment;

- if fastener control was poor, the material may settle;

- Ecowool is not very appropriate where high humidity may be present.

Warming of frame houses with sawdust is another traditional, even centuries-old technology. But there is no reason to consider it exclusively primitive, as modern people often do. Careful consideration of the features of the material makes it possible to embody its positive features favorably and weaken the negative ones. The undoubted advantage of sawdust is natural origin, reasonable price and decent heat retention. It is only necessary to deal with the risk of ignition and with the settlement of rodents in the material.

Antiseptic ingredients, lime, clay, gypsum or cement help solve such problems.

Important: choosing an additive for sawdust, it is worth paying attention to how hygroscopic it is.

In many places, high humidity can lead to very unpleasant consequences. Sawdust coarse fraction is usually taken on the draft insulating layer, and the retention of heat is mainly provided by smaller substance. When buying or self-procurement should pay attention to the dryness of the material, it depends on the quality of thermal protection.

Adherents of modern materials and the latest technology can warm frame houses extruded polystyrene foam. It is quite widely used when working on floors, including:

- over unheated basements and technical undergrounds;

- under overlapping attics;

- to enhance the acoustic protection of structures separating the floors of the house.

Typically, polystyrene foam is placed on the floors of frame houses in the intervals of lags, at the request of the owners or craftsmen, it can be mounted under a reinforced screed cement and sand. The disadvantage of the material (easily fixed, however, with a neat approach) is the need to strictly observe the specified gaps between the plates. Expanding during heating, polystyrene foam can be damaged - to prevent such a development of events, gaps are needed. It is important to remember about the flammability of this synthetic substance, it should be used with caution.

It is unacceptable to glue it on mixtures containing any highly flammable or simply caustic component.

In addition to insulation it is worth remembering that in a frame house must be provided with reliable, well-designed ventilation.

Entering fresh air is always organized from the utility rooms, and the flow is carried out under the doors that divide the rooms. If you do not take care of the presence of a gap under them, then not only freshness,but the uniform distribution of heat in the home will not succeed. When it is impossible to form a similar gap, they come to the rescue:

- special channels for the flow;

- lattices through the wall;

- separate channels for the passage of air into a particular room.

Specifications

The monolithic layer of insulation, the more stable it usually keeps heat. because on the density of the structure should pay paramount attentionIt is much more important than a big name or a number of certificates. The only particularly lightweight material that deserves attention is foam polystyrene (including such a modification as foam plastic). Even mineral wool is already just a light category, although its specific gravity can vary widely. This circumstance allows you to choose the optimal solution for a variety of conditions and situations.

If you need the strongest blockage of cold (in living rooms and on the floor), you need to use the most dense version. For non-residential loft, the bar requirements below. At a density of 75 kg per 1 cu. m. wadded insulation is suitable only on surfaces that carry a relatively weak load, as well as for thermal protection of pipes.

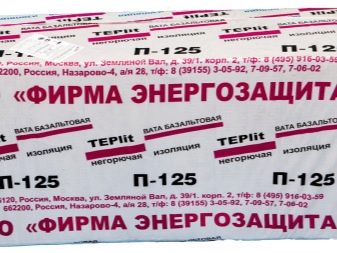

Mark P-125 is already more decent, it can be used in different procedures:

- ceiling and floor paneling;

- wall insulation;

- heat shielding of partitions;

- suppression of external noise.

Cotton wool of the PZh-175 category has increased rigidity and is not used in frame housesit is mostly used in stone and concrete buildings. If you plan to cover the walls with siding, you can use basalt wool with a density of from 40 to 90 kg per 1 cu. m. And the most dense material is recommended to be used in the upper parts of the walls. Under the plaster, experts advise taking cotton wool with a specific gravity of 140–160 kg per 1 cu. The requirements for heaters used in the interior of a frame house are less high.

When a dwelling is covered with a pitched roof, the optimal parameters are 30–45 kg per 1 cu. m, and if you plan to warm the attic, the lower bar is already 35 kg.

Five times the minimum figure for mineral wool under a flat roof, and for expanded polystyrene it is much more sparing, only 40 kg per 1 cu. m maximum. In floors, loose insulation is allowed to be used only when laying in the intervals of lags. Otherwise, the thermal protection will be a mechanically loaded element, which will adversely affect its characteristics.

Residents of frame houses naturally strive to ensure that their habitats are not only warm, but also environmentally friendly; errors in the selection of insulation can prevent the achievement of this goal. Only recently, an environmentally friendly method of thermal protection could only be found in elite areas, but now such schemes have become much more accessible. Fibers of natural raw materials are predictably in the first place:

- woody;

- flaxseed;

- hemp and some others.

The advantage of such substances is the zero degree of allergic and toxicological risk. The softness of the structure makes it difficult for individual components to penetrate the external space. In an ecologically clean house there is absolutely no place for mineral and glass wool. Fragments of glass and stone fibers, insignificant in size, cannot be seen without a magnifying glass. But they can do harm to health quite scale.

Important: no matter how great was the desire for cleanliness and health protection, this is not a reason to refuse antiseptic treatment of a number of materials - where it is really needed.

Flame retardants are most often made from borax, a natural mineral that is completely safe. The overwhelming majority of the components of thermal protection, however, do not pose a danger only in strictly specified conditions. One of them is always the preservation of the integrity of the insulating “cake”, from which one or another substance cannot normally escape. Linen insulation is relatively cheap and at the same time quite normal, based on data obtained from medical research in different countries.

Peat blocks are now becoming increasingly popular in frame construction. 1 cu. m of such material costs about 3 thousand rubles, and it will serve from 75 years, all this time being a sharply unfavorable place for microbes. What is important in our turbulent era, such a heater is able to reduce the flow of penetrating radiation into the house by 80%. The only problem is that the operating experience is still small, and it is unclear how the blocks of peat will behave in different conditions after many years.

Cork structures are easily placed under the wallpaper, on the interior walls and under the floor; but because of the very high price it is unlikely that in the foreseeable future many people will be able to evaluate their quality.

Manufacturers Overview

Reviews allow us to appreciate not only the various types of insulation materials, but also the professionalism and integrity of individual firms.

Attention: it is necessary to take into account that the discussion will deal only with the really best of the best companies, which have shown all of their capabilities during the years of competition.

Firm "Rokvol" supplies to the market fireproof insulation of stone wool. It places emphasis on ensuring the highest environmental and sanitary indicators of its products. It is possible to use such mineral wool as a part of thermal protection:

- pipes;

- facade walls;

- room dividers;

- roof structures;

- sites experiencing intense stress.

It takes 100 mm of such a plate to replace almost 2 m of brickwork.

French corporation "Izover" sells glass wool to its customers in a roll, plate or matt configuration. Of course, environmental safety is somewhat less, but the cost of products is noticeably less and optimal fire protection properties are guaranteed. The level of thermal conductivity also meets the necessary requirements.In the company's lineup there are extruded materials that are easy to put even without using fasteners.

Glass wool is supplied under the brand name. URSA, which by production uses much smaller amount of phenol, and in some cases got rid of it at all. The product range includes:

- slabs of moderate hardness;

- products adapted for medical and children's organizations;

- hydrophobic structures of high density;

- products resistant to deforming loads.

Calculations

Regardless of what particular substance is used, it is necessary to carefully calculate the thickness of the insulation. If you miscalculate with this indicator, you get either insufficient effect or excessively large costs for the purchase of thermal protection and for working with it. When the work is entrusted to a professional team, you still need to monitor the measurements and calculations made by it. As practice shows, installers who are left without supervision, having made sure that no one checks them, will sooner or later “err” in their favor.

The main role in the calculations play indicators such as thermal conductivity and thermal resistance.

Glass wool has a very high resistance to heat removal - but its shortcomings prevent the widespread use of this material. When calculating it is necessary to focus on the climatic properties of a particular area. So, in Moscow and its environs, the recommended layer of most good insulation does not exceed 0.2 m. If you use so many of them in the High North, the result will be deplorable for residents.

The standard formula of the form δout = (R - 0.16 - δ1 / λ1 - δ2 / λ2 - δi / λi) × λute has the following components (consecutively):

- heat resistance of structures in a particular area;

- total thickness of all layers;

- coefficient of thermal conductivity;

- the ability of a heater to transmit heat.

Raw materials and tools

When the type of insulation is selected, the calculations are made, it's time to get ready for work as it should. Be sure to select the necessary tools as carefully as possible, given the slightest nuances.

- In the case of a dry variant of warming with a “raw material”, it is possible to consider, along with the selected thermal protection, bar or metal structures of the frame being created. It is also useful to choose decorative materials that are consistent with the material, waterproofing films, membranes, and vapor barriers.

- The “wet” scheme is realized with the help of water-based adhesives.

Typical tools for wall and roof insulation include:

- screwdriver;

- guns for applying foam;

- hammers;

- jigsaws for precise cutting of wood and metal;

- perforator;

- spatulas;

- hydraulic levels;

- roulettes;

- scissors for metal;

- containers for the preparation of solutions and so on.

The exact set cannot be predicted in advance, because it strongly depends on the chosen technology, on the nuances of the frame house and the amount of work. In any case, you should try to buy high-quality tools and consumables. All devices purchased specifically or already on hand should be carefully checked before starting work. Otherwise, it will not be possible to guarantee the quality and safety of manipulations during insulation. In almost all cases, a square is beneficial for the masters: it can both mark exact right angles and measure the actual angles formed by the sides of the part.

Of all the hammers, the locksmith is best suited.

It is suitable for processing any surfaces. On the one hand, such a tool is smooth and allows you to strike,and on the other, pointed, like a chisel. If you have to dismantle building elements and structures, you need a nail puller. It is possible to divide polystyrene and other insulating parts into parts, decorative elements using saws with a fine tooth. Teeth should be specially diluted and honed in a special way.

For the preparation of building mixtures, only mixers with a spiral-shaped working part made of strong steel grades are quite suitable. With rollers it is easy to apply primers and a variety of paints, even if the surface is very rough or rough. To apply the glue solution for the subsequent implementation of the reinforcing mesh, it is recommended to use Swiss ironing tools with teeth. The optimal size of the tooth is 8 x 8 or 10 x 10 mm, it is determined by the manufacturer of facade systems.

Self cover

Step by step instructions in any case requires to mount a layer that protects from moisture. The only exception is made for those situations where such protection is already outside (or inside). The reason is simple - double-sided locking of the water prevents its exit.Liquid will accumulate inside the walls and gradually destroy them.

The first step is usually the measurement of external surfaces and the cutting of waterproofing material in accordance with their size.

It is recommended to fasten material with your own hands with a stapler on racks, ensuring that the frame is sheathed completely. Optimum waterproofing installation - with an overlap, when the top layer overlaps the bottom by 10 cm approximately.

Further work with vapor barrier follows. It will not be possible to bypass this moment in the case when hydrophobic or neutral substances that transfer contact with water are used for insulation. Indeed, besides them, the “pie” includes other details that are much more sensitive to getting wet. When insulating inside and outside, it will be correct to use a special film or foamed polyethylene to contain water vapor. Such materials are attached to the racks of the frames, providing the most dense pressure to the insulation.

Important: wrapping blocks of thermal protection in a film is a violation of the standard scheme - until all the components of the framework are covered from water, the work cannot be considered completed.

Only when all this is completed, begin to work with the filler itself.

At the same time, safety requirements are strictly followed, especially relevant when choosing mineral or glass wool.

The final step is sewing the walls from the inside. Outside the competition in the amount of their qualities there will be drywall and oriented chipboard. GKL recommended to put, if the frame is perfectly smooth, then the outer surface will be smooth. But OSB due to its rigidity to cope with the flaws as effectively as possible. But in any case, this is only preparation for a real finishing.

Master classes from professionals

Master classes organized by professionals provide the most up-to-date and adequate information on all problems of insulation and related topics. As a result of the consultation, it will become clear what the width of the frame board should be in a specific case, and how to calculate the thickness of a fundamentally new material.

Experienced craftsmen understand security measures and storage mode, transporting each insulation coating is better than ordinary amateur builders.Many mistakes are made when fixing structures, drawing up diagrams and determining the sequence of layers in the “pie”. But communicating with knowledgeable people helps to correct this situation.

When mineral wool is used, try to prevent the ingress of condensate from warm rooms. But waterproofing and vapor barrier, too, are fraught with many "pitfalls". The choice of material for plating is often dictated by tradition, personal tastes or stereotypes - and meanwhile, thoughtful design is much nicer. Professionals will tell you when you can use natural insulation, and when it is better to use artificial ones. It is very important to understand the compatibility of the materials with each other: here again, master classes help.

On what kind of insulation keeps heat better, see the following video.