Use of Rockwool mineral wool

Any residential or industrial building needs high-quality thermal insulation. The world market of insulation has long been seized by the company Rockwool. So the best producer does not cause questions. But in the presence of a huge variety of products offered, it is important to understand the material and decide on which one to choose during construction. In this article we will tell you in detail about the mineral wool and all areas in which it is used.

What it is?

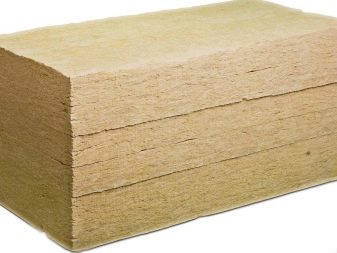

First of all, you should understand what mineral wool is as a heater. The material is also called basalt or stone wool. This is the same insulation, which consists of a heat-insulating substance.

There are different technologies for its production.Rockwool mineral wool is made with the addition of special components that perfectly protect the material from moisture. You can also identify such distinctive features as lightness and high elasticity.

The technology itself is always more or less the same and the main element is basalt stone. It is melted at very high temperatures, after which special resins are added. And the fibers that make up the stone wool are formed.

Rockwool has long been the world's leading manufacturer of non-combustible insulation material, based on stone wool. Over the long years of existence in the market, the company has developed unique production technologies, some of which are kept secret.

The divisions of the companies Rockwool are engaged in the manufacture of suspended ceilings, artificial soil, decorative facades, panels, insulating road noise, and even consult clients on the energy efficiency of buildings. Now they own 27 factories in Asia, America and Europe.

In Russia, the company became known around the 70s. And the first Russian factory Rockwool earned in 1999.Since then, the manufacturer has become a leader in the insulation market, year by year improving the technology of the process of insulation. New products help ease installation, ensure safety, and save money for both the customer and the customer.

Special features

Mineral wool is safe for residential buildings, and its fire resistance will protect in case of a sudden fire. Stone wool is also able to "breathe", thereby preventing the occurrence of mold and dampness.

Rockwool stone wool is used in four main areas: sound insulation, heat insulation, noise insulation and fire protection. Suitable for residential and industrial premises.

The material can be of different density and thickness in the form of plates, mats, cylinders and lamellae. Such a variety allows the use of stone wool in shipbuilding, industry and in the construction of complex buildings. Technical characteristics provide almost unlimited service life.

Installation is quite simple: you just need to avoid cracks between the plates during installation and ensure the material is dry.

Basalt foil wool is well suited for the construction of premises with high humidity (baths, saunas, underground buildings).An additional aluminum layer provides the necessary vapor barrier.

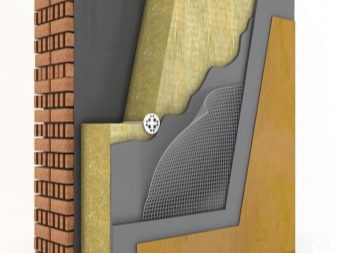

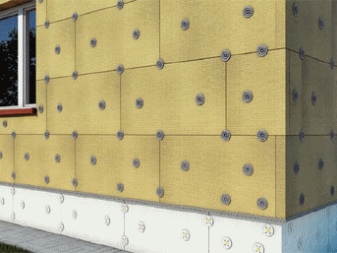

For the decoration of the walls of buildings, a special line “Facade Butts” was invented, in which they produce insulation in the form of slabs. They are mounted on construction glue and dowels and can be the last layer before the final decorative finish.

The dimensions of such plates may vary depending on the application. Thickness varies from 2.5 cm to 18 cm. The latter are often used for acoustic insulation.

Specifications

Understanding the technical characteristics, it is worth remembering that there are a lot of insulation and each model has distinctive features. Therefore, we will try to clarify by giving examples of averages.

Density

The average density is 50–80 kg / m3. But it is necessary to determine the density of the material on the basis of its specific purpose. For example, stone wool for a pitched roof will be almost weightless with the lowest density possible.

For the equipment of a flat roof, on the contrary, cotton with high density is needed.

Thermal conductivity

This is one of the most important indicators for any insulation.The average figure for mineral wool is about 0.038–0.043 W / m. This indicator speaks of good thermal insulation, which not all materials have for insulation.

Fire resistance

Absolutely all types of stone wool are not burning in the fire. She is also not able to draw water. The percentage of water absorption is from 0.5 to 2% of the total mass.

Vapor permeability

This important indicator makes it possible to use insulation in the arrangement of breathing walls, roofing or any other structures with natural regulation of the microclimate.

Compression ratio

This characteristic is directly related to the density: the lower the density, the higher this coefficient. Mineral wool sandwich panels used for pitched roofs have a density of about 30–40 kg / m3. This means that their strain rate is high and can reach up to 50%. This plate can be compressed and reduced in size by almost half, while not violating the integrity of the structure. Working with such material, you can not spend a lot of time fitting the plates to the size of the frame.

Sometimes the compression ratio is only a couple of percent, that is, the material is practically not compressed.Such plates have a high density and are designed for strong physical effects.

Working temperature

There is no large variation in this category. Any stone wool can withstand from -50 to +100 degrees Celsius. The material can not ignite, so the maximum rate may vary in the direction of increasing with short-term loads.

The main characteristics of Rockwool mineral wool:

- Low thermal conductivity. Due to the structure consisting of very fine fibers, the material conducts heat poorly.

- Soundproofing. Thanks to the same structure, wool can absorb sounds and reduce the force of vibrations.

- Fire resistance Even the highest temperature is not capable of making the material melt or emit smoke. Completely non-flammable material.

- Durability. With proper installation of stone wool insulation will last for decades.

- Environmental friendliness. Cotton wool is made of natural material, does not harm human health and does not have a negative impact on the environment.

Species

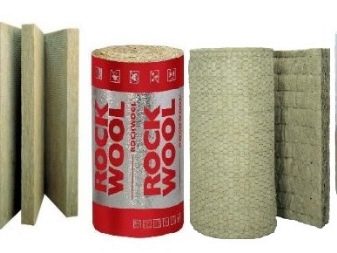

Speaking about the varieties of mineral wool, you can immediately select its main forms:

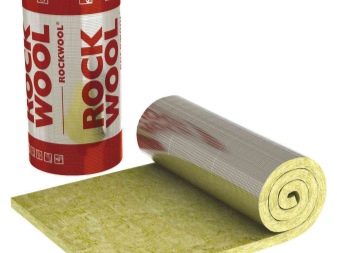

- Rolls. Not the most common form and is used for warming the floor or attic space.

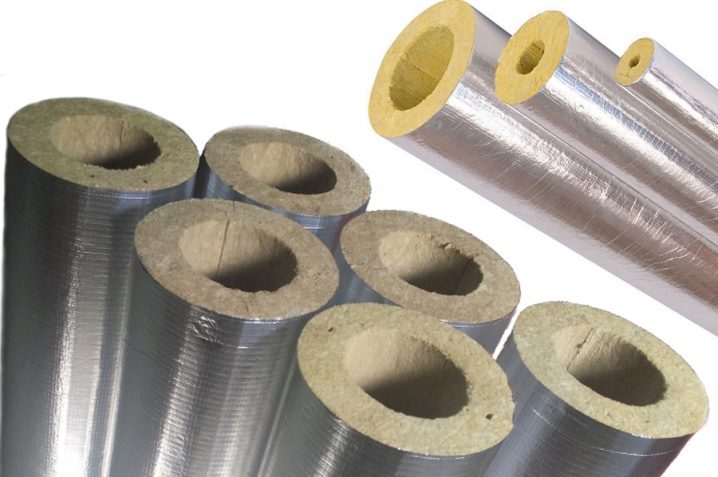

- Cylinders. Used to protect against condensate in pipes with low temperature, central heating, hot water pipes. They are made by cutting out elements of stone wool and are then covered with a glass wool or foil layer. Great for thermal insulation of pipelines.

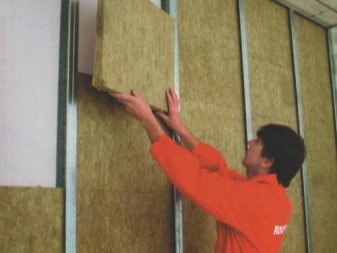

- Plates. Used for interior and exterior wall cladding. The most popular form. Against the background of rolls and cylinders, it is easier to install: even under the ceiling, you can lay the plates yourself.

Now we will analyze the individual material models for different types of finishes and thermal insulation. For stoves, fireplaces and other heating surfaces, Fire batts 30 Dm 110 wool with a foil layer is well suited. The material is able to withstand heating up to +750 degrees, which noticeably distinguishes it against the background of conventional thermal insulation, which, even at +250 degrees, can lose its protective characteristics.

An additional aluminum layer will help to warm up the room in a shorter time and save fuel.

For the technical insulation of air ducts or tanks, Rockwool developed the Lamella Mat. This is stone wool in the form of strips that are glued to a layer of reinforced foil.Such an elastic form allows the material not to be deformed in the corners and folds. Lamella Mat can be used with any building materials due to its chemical inertness. When installing usually use wire or adhesive bandage tape.

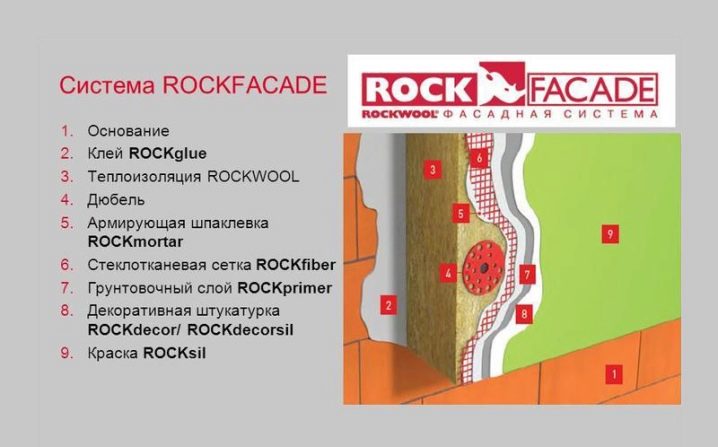

To work with the facades created a whole set of compatible components - Rockfacade. The set includes heat-insulating plates, fasteners and materials for finishing decoration of the facade, which are tinted at the factory.

The advantages of the system:

- All layers have a breathable ability, which ensures high vapor permeability.

- Almost zero fire hazard.

- High thermal performance.

- Many decorative variations, and hence the architectural possibilities.

- Durability.

- Environmental friendliness. All system components are made from natural materials.

- Convenience of installation is provided by manufacturability of materials.

- All components are selected specifically and you can not think about the color combination when finishing.

The Rockfacade system is used in buildings of any complexity and height. Features of installation allow to use for buildings with broken architecture and uneven surfaces.Due to the large color and decorative diversity, it is also used for the reconstruction of old buildings with the possibility of recreating all the architectural elements.

For external facing of walls and finishing of facades, elements of balconies and loggias use a separate invention of the company Rockwell - Rockpanel. These are flat sheets, pressed from stone wool and painted with paint. These panels combine the advantages of wood and stone. A wide range of assortment allows you to not be limited when choosing a design.

Rockpanel perfectly protects the building from rain and can be used in the restoration of historic buildings and in the construction of new ones.

Advantages of the Rockpanel system:

- Durability and flexibility. Installation on surfaces with a complex shape is not difficult. This opens up great design and architectural possibilities. The material serves as a stone for a long time and is easy to process as wood.

- Fireproof. The facade system can be used in rooms with any indicator of fire hazard. Mineral wool fibers do not change their structure at temperatures up to +1500 degrees, do not support combustion, and are able to prevent the spread of flame.

- Vapor permeability. The fibers of the material are intertwined chaotically and many small gaps remain between them.It is through them that water vapor passes.

- Stability of geometric dimensions. Stone wool slabs are able to withstand the influence of any weather conditions without being deformed. They do not rot and stratify over time. Observing the manufacturer's recommendations, the plates can be laid end-to-end without seams.

- Ease. The low density of cotton wool, standard thickness (6–10 mm) and excellent strength characteristics ensured a small weight per square meter of material.

- Stable color. Rockpanel front panels are UV resistant. They are painted with paints and covered on top with a transparent layer of ProtectPlus, thanks to which the front surface becomes as flat as possible.

- Non-repeating pattern. On the panels there is no pattern that would need to be observed when mounting. The appearance of the plates will be the same regardless of the direction and angle of their installation. This greatly simplifies the installation process and increases its efficiency.

For sound and heat insulation of the surface inside the ventilation ducts used Industrial Batts 80. It is also used in the manufacture of sound-absorbing screens and chamber silencers.Plates are manufactured with fiberglass coating on one side.

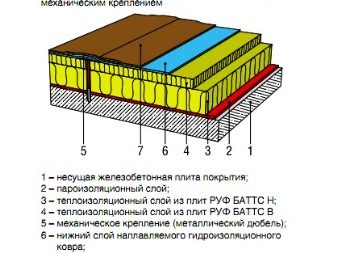

For the fire protection of slabs of reinforced concrete and floors of various buildings, special druh hollow mineral slabs FT Barrier are used. They have two layers - durable top (3 cm thick) and soft bottom (5–17 cm thick).

Advantages of FT Barrier plates:

- The combination of the material insulating and flame retardant characteristics.

- Installation can be performed at any time of the year: the plates are mounted without the use of glue.

- The possibility of repair.

- Can be used as a decorative coating.

Rockwool has developed a large selection of coatings for SeaRox thermal insulation:

- Reinforced foil. This type of coating is often used for vapor barrier. The maximum temperature that the surface can withstand is 80 degrees.

- Fiberglass white. The coating provides a shock-resistant surface with an aesthetic appearance. The maximum operating temperature is the same 80 degrees.

- Laminated fiberglass. Used as a final layer, which does not need additional plating metal. The foil layer provides condensation protection and vapor barrier.The maximum temperature is 80 degrees.

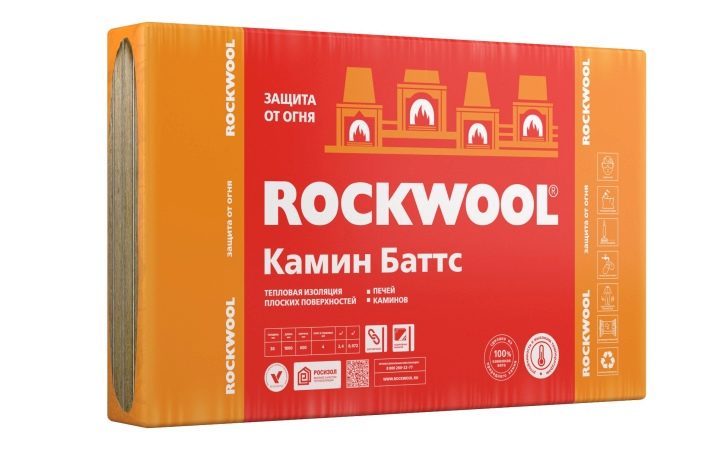

There is also a product that is specifically designed to protect buildings near the hot surfaces of the fireplace (firebox) or equipment operating at high temperatures - the “Fireplace Butts” stove. They have a dense structure and one-sided coating of aluminum foil. The material is made on a natural basis and has high rates of fire safety.

The product is mounted in the inner frame of the fireplace at a distance of not less than 4 cm from the firebox inside.

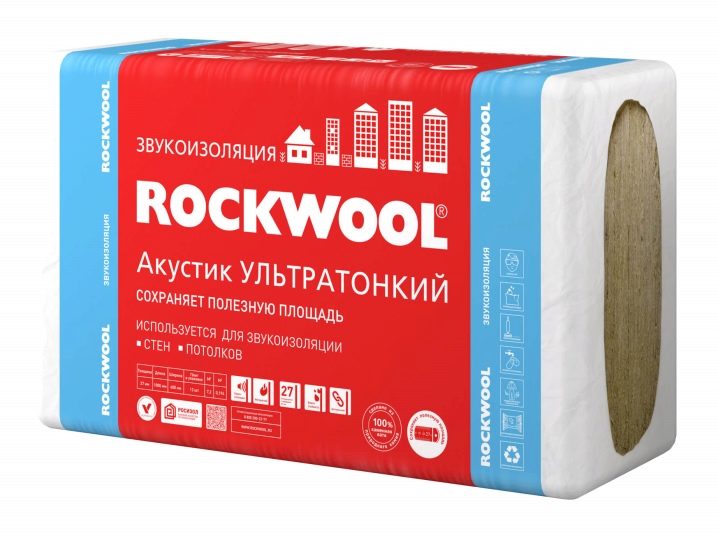

The ideal sound-absorbing material is Rockwool Acoustic Ultrathin mineral wool. Its thickness is only 27 mm, it is used for sound insulation of already finished walls and ceilings. Due to its fineness it is very convenient for use in compact rooms. The product is capable of absorbing high and medium frequencies of sound.

Considering all the characteristics, the material can be compared with a standard sound-absorbing structure 5 cm thick.

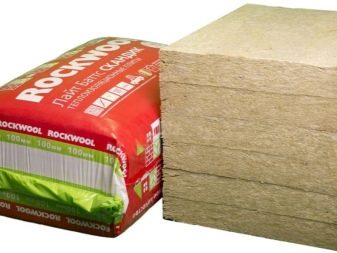

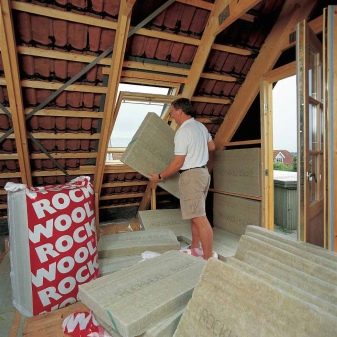

The most common product for warming a dwelling house is Light Butts Extra. For more convenience, it is available in two forms: standard (80 x 60 cm) and XL (12 x 60 cm).It is used for the equipment of pitched roofs of attic rooms, interfloor ceilings, frame walls, partitions, balconies.

If the building does not imply important nuances that should be taken into account, then you can choose the material for cladding from the categories Standard or Economy.

Rockwool has designed products for buildings with completely different features and characteristics.

How to choose?

Choosing mineral wool, you need to familiarize yourself with all the specified areas of construction, in which it can be used for thermal conductivity indicators. If the material is intended for insulation of the facade, then it will not work for work with the roof, ceiling or floor. It is worth paying attention to the service life, it is desirable that it be at least 10 years.

If all heaters are divided into groups according to directions, then the following can be distinguished:

- For the facade.

- For roofing.

- For the floor.

- For internal and external walls.

- For soundproofing equipment.

- For the pipeline.

Facade

Here the most popular and frequently used product line is “Venti Butts”, which is used for arranging facades with ventilation.This material is not capable of absorbing moisture and is not subject to the effects of atmospheric and domestic phenomena. In addition, the plate is a line made specifically for finishing frame houses.

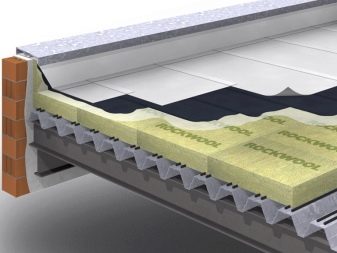

Roof

Especially for the equipment of the roof, Roof and Light Butts slabs were developed. The latter have a low density and a large compression ratio. Thanks to this feature, they can be mounted literally everywhere you want and need. You can call it a universal insulation.

For other purposes, Ruff Butts is suitable and has directly opposite indicators of density and compression ratio. These plates are very dense and able to withstand very large loads.

Both of the options described above are easy to install, durable and waterproof.

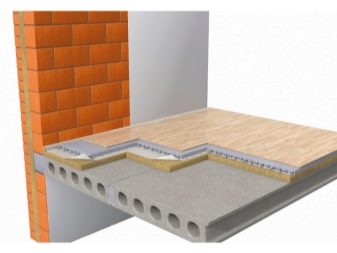

Floor

For installation under the lags, Rockwell Light Butts are also great. Only the lags should first be firmly fixed and sheathed with a board. "Rokvul Flor" get under the screed. These are durable plates with a low compression ratio, which are able to withstand huge loads without deformation.

Internal and external walls

For this type of work, the Light Batts Scandic product is ideal.To work with insulation partitions often use the model Acoustics. Plates for such works can extinguish various noises. With the help of such partitions it is possible to divide the space into smaller zones. Sauna Butts waterproofing slabs are designed specifically for warming sauna rooms and saunas.

So, having clearly defined the course of construction and the vision of the final result, you can choose a suitable heater made of stone wool and be sure that it will not fail.

Pipeline

For insulating pipes, a specially designed product of the cylindrical form ROCKWOOL 100. The cylinders have two longitudinal cuts for easy installation. The material is intended for thermal insulation of heating pipes, ventilation systems, air conditioning and other things.

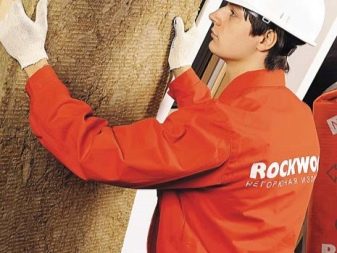

How to warm?

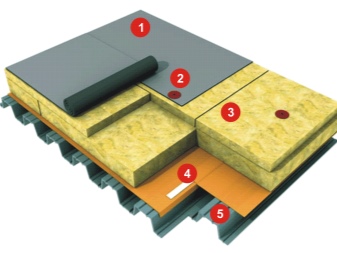

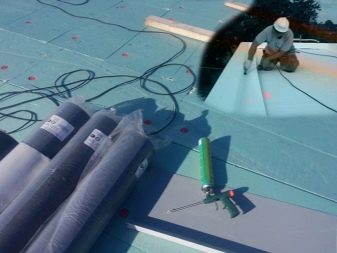

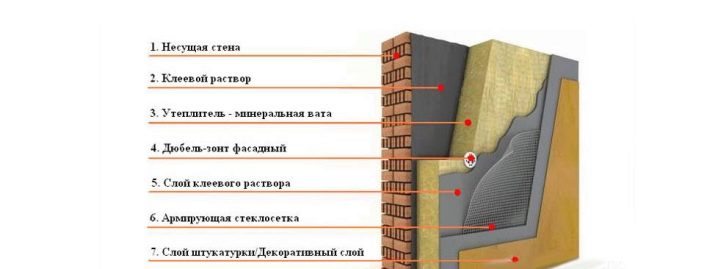

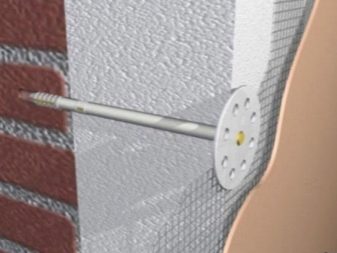

Briefly, the thermal insulation process can be described as follows: mineral wool plates are glued to the cleaned surface and fixed with the help of dowels. Then the plates are covered with glue, and a reinforced mesh is placed on top. After another layer of glue, you can plaster the walls. Users have long noted that Rockwull stone wool is well suited for insulation of pitched roofs.Often the roof has a frame system, inside it have insulation. Schematically, the order of laying layers is shown in the figure below.

If you follow the rules of installation and do not neglect the nuances of work, you can cope with the insulation of a small room in just a day.

There are many reasons why the majority makes a choice in favor of outdoor insulation of walls, rather than internal. First of all, it will save living space. Also in the process of installing insulation outside you can reconstruct the facade and carry out the necessary repairs.

Wall preparation

If the walls have a decorative coating, then it must be removed to the ground (brick, wood or concrete). Overfalls of the primer level more than 2 cm must be combed or patched. For these purposes, it is better to choose a deep penetration mortar, after removing all dirt and dust from the wall.

To create a control grid, on which it will be possible to navigate during further work, it is necessary to fasten a strong thread with plumb lines on the screws.

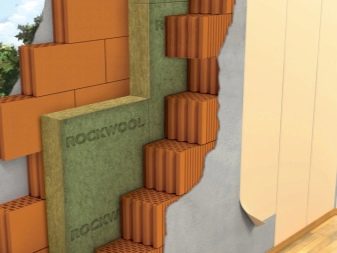

It is recommended to use two types of mineral wool for wall insulation outside, which differ in density.Softer mats are mounted to the wall, for example, the material will well fill the irregularities of the brick wall. More dense and rigid fit on top because. they can be used to form a more or less flat surface, which will later facilitate the decoration.

The thickness of the two layers of stone wool should not exceed 100 mm. The most qualitative will be the variant of warming, in which the wool is placed under the future brickwork. In this case, the insulation will be inside the wall between the layers, which will significantly improve the insulation.

We present a universal step-by-step instruction for the process of wall insulation:

- If the work is carried out with wooden walls, before starting work they need to be soaked in an antiseptic. The areas with dampness or fungus must be thoroughly cleaned and also impregnated with a solution. The walls of brick or concrete just enough to clean the paint. Wet walls need to be dried, remove the slopes of windows and doors for a while (as well as all decorative elements that can interfere with construction).

- A vapor-permeable membrane is placed under the layer of mineral wool in such a way that the side that permits steam is located against the wall, and the other - to the insulation.This membrane is needed to ensure that water vapor is drained from the walls.

- On top of the membrane are mounted wooden slats with screws. The distance between the slats should exceed the thickness of the insulation material by about 1–2 cm. At this stage it is important to use a level or special hangers.

- The space between the slats is completely filled with thermal insulation. Laying should start from the bottom, gradually moving upwards if the mineral wool has the shape of rectangular mats. The roll should be laid, starting from the top, gradually fixing it on the wall with dowels.

- A windscreen layer is laid on top of the insulation. The film is attached to the rails by the construction stapler, after which the entire layer of insulation is additionally fixed. To provide even greater waterproofing of the place of attachment of layers, you can glue with special metallized adhesive tape.

- One of the most important stages is the arrangement of a ventilated facade. The gap through which the wall will breathe should be about 5–7 cm. To do this, you need to attach additional slats or profiles.

Beginning the warming of the external walls of the house, you need to remember that their thickness will increase markedly and you will need to make new window slopes, trim, and other decorative elements.But this method at least does not hide the space inside the room, so replacing some parts should not be a big problem.

Laying the layers for insulation of external walls is shown in the figure below.

Insulation process

Work needs to be started from the bottom and used for fixing not just building glue, but special glue for stone slabs. Often it is sold in packs of 25 kg. The width of the joints should be minimal.

Be sure to perform reinforcement coating. This can be done with plastic dowels. This will increase the strength of the entire insulation coating and prevent the formation of cracks in the walls.

The order of the layers is shown in the diagram below.

Then you can begin to decorate the walls. For this fit plaster or water-based paint.

There are several ways to apply decorative plaster:

- Bouffant. To do this, use a brush made of metal with a pile of wire. The surface with a layer of plaster is literally combed, and the resulting drawing is left for a day for drying. When the surface dries slightly, you can gently wipe the wall so that small and poorly fixed particles crumble.

- Stamping. Performs roller, which is attached to the nozzle with any pattern.It's all very simple: you do not even need to repeat the passage of the roller in the same place. Decorating will take on the strength of a few hours.

- Facing It is made using a rubber or ordinary sponge, which is soaked in soapy water. On a fresh layer of paint is applied drawing that can imitate the texture of a stone or any other.

There is a method of finishing the walls, which provides a ventilated facade. Such a system allows free air to evaporate. Mineral plates have a very good resistance to moisture, but they still pass a small percentage through the fibers. Therefore, the ventilation system will not be superfluous.

The installation procedure for a ventilated facade is simple: first, a vapor barrier is installed, then a small layer of air is left using anchors. On top of the insulation, you can install a wooden lattice or impose a windproof membrane in the form of a film. At the end of the work should be decorative trim.

Analogs

Despite the big name and demand all over the world, Rockwool products have several drawbacks:

- When compared with counterparts, Rockwool insulation is quite expensive.

- When mounting or cutting the material, protective clothing and glasses should be used. This may bring some inconvenience, but this is hardly a problem for an experienced builder.

- The water-repellent characteristics of the material are achieved by treatment with special solutions, which are not 100 percent waterproof.

Therefore, it is useful to install an additional membrane to protect against moisture.

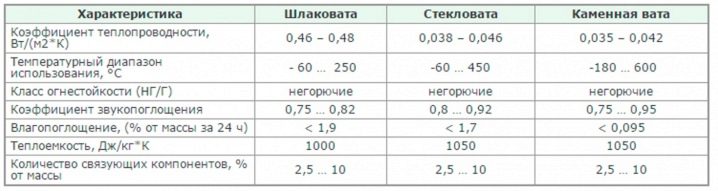

In the Russian market there are fairly high-quality, but cheaper, analogues of almost all varieties of mineral wool. These are manufacturers such as Isover, TechnoNICOL, Knauf, Paroc, Isoroc. On specialized sites you can compare manufacturers for any characteristics using special tables.

Many could hear about such material as slag wool. This insulation, made of blast furnace slag. It was widely popular in the Soviet era, and was manufactured at metallurgical plants.

Having high indices of hydroscopicity, the insulation was not very effective. Of the conspicuous minuses can also be distinguished quite a high level of acidity and low vibration resistance.Not the best set of characteristics, but at the time it was the only insulating material of its kind. Naturally, over time, new manufacturers have driven slag stone from the market, but many buildings that have been insulated with this material are still standing today.

Do not forget about such material as glass wool. He, too, was quite popular before. By the way, it is used for insulation and now, but rather with the aim of saving on material and, accordingly, on quality.

Broken glass and quartz are taken as the basis for its manufacture. There is a common misconception that glass wool does not apply to mineral raw materials. This is not true. It belongs to the same category with stone wool - mineral wool. Some characteristics of them are distinguished, having familiarized with them, one can understand the nature of such a delusion.

Like mineral wool, the material is heated in a furnace at high temperatures, and then drawn into very thin fibers, which are later connected to each other.

The material cannot be called absolutely safe, since formaldehyde resins serve as a binding element for fibers.

At the cost of glass wool is much more affordable stone.

This can be explained by the cheapness of the raw materials used. Shipping costs are also smaller, because when packed the material takes up very little space. After unpacking glass wool takes the same form.

It does not burn, does not cause corrosion, coming into contact with metals, and has a low density. And the sound insulation performance is even higher than that of stone wool. Along with these obvious advantages, there is a rather tangible minus: glass wool over time shrinks as a result of the crystallization process of the fibers of the substance.

Working with material is quite difficult. It irritates the skin, eyes and respiratory tract. Therefore, to neglect the protective clothing can not in any case.

If the process of laying insulation does not use gloves, the smallest particles of glass will penetrate into the skin and get rid of them then it will be quite problematic. The impact of small particles on the mucous membrane of each will be individual, but it is better to buy ordinary safety glasses in advance and not bring the situation to the doctor.

Useful recommendations

Reviews of regular customers speak for themselves: Rockwool products have long been better in the world. But in order for the heater to serve for a long time and meet all its characteristics, you need to follow some rules:

- It is important to pay particular attention to transporting the material. Mineral wool is able to absorb moisture from the air, so it must be transported in closed machines, and then stored in a dry room.

And in order to reduce the footprint, mats are recommended to be transported in a compressed form.

- Stacks with plates for transportation should not be less than two meters, and rolls and mats should be laid in an upright position. This will facilitate subsequent unloading.

- It is undesirable to walk on stone wool without packaging, because it can damage it.

- In order to fit the mineral slabs to the required dimensions, they are usually cut with a long hacksaw, leaving 1–2 cm of allowances at the edges. They are necessary for the material to completely fill the space, slightly compressing, the cotton wool will go into the frame more closely. The plates are cut individually, and the rolls can be cut without unwrapping.

- When cutting products it is recommended to wear construction gloves and protective clothing made of thick fabric, eyes should be protected with special glasses, and the face - with a mask.

- There are some universal tips that will help when using any kind of mineral wool: warming a flat roof, it is better to put insulation in two layers, granulated stone wool is perfect for sound insulation, it is often considered to be the strongest plates with ventilation grooves, for insulation of attics they are also often used two layers of cotton wool.

- To give the roof a slope for the runoff of water suitable use of mineral mats with variable cross-section.

- When building one-story buildings with walls of three layers, it is not necessary to leave a ventilation gap.

- To perform the insulation work with the maximum quality, you need to take a material with a width of 1.5–2 cm longer than the distance between the frame supports.

- Do not forget that the layer of vapor barrier and waterproofing can provide good ventilation layer of insulation.

- For wall insulation, it is most convenient to use mineral wool in rectangular plates. They clearly fit together and help to reduce the gaps between the plates or to prevent them altogether.

- Prior to the start of installation work, all cracks and cracks in the surface should be properly repaired.For this fit foam or felt.

- Professionals do not recommend laying the insulating layer on the cables and wires. Wiring should always be left on top to reduce the chance of fire.

- When pipe insulation is laid in several layers, it is necessary to provide that the joints between the plates on different layers do not coincide with each other and do not overlap each other.

When buying a sealing material it is necessary to pay attention to its edges: they should not be torn or uneven. This will help to prevent gaps between the plates during installation and other damage that may result from this.

Watch the live hacking on Rockwool mineral wool in the video below.