Styrofoam insulation: use options and laying technology

Expanded polystyrene is a popular insulation that is used in private housing. The material has a lot of advantages. Let us examine the use cases and technologies of styrofoam styling.

What it is?

For the production of polystyrene polymeric mass is used, which is subjected to steam treatment under high pressure. The result of processing is an increase in mass in volume.

The foam has numerous air bubbles that have thin shells. In fact, polystyrene foam is a foam with sufficient strength and hardness that allows you to retain heat. In everyday life polystyrene foam is called foam. The technology of obtaining material implies filling styrene granules with gas dissolved in a polymer base. This is a common basis for the production technology for the two materials, but the materials have distinctive characteristics.

In conventional foam, ordinary natural gas is used to fill the pellets. Fire resistant options are filled with carbon dioxide. There are still variants of vacuum foam in which there is no gas component at all.

For example, externally at the foam plastic it is possible to distinguish granular components, whereas expanded polystyrene is a more homogeneous material. If you break the foam in half, many granules are formed. At expanded polystyrene there is no such quality. Polyfoam is cheaper, which is a significant help in the external insulation of buildings. Styrofoam has the best mechanical strength.

The material is successfully used as insulation of the walls outside and inside the foundation of the house.It weighs little, can be used as insulation of concrete, brick, foam concrete and wooden walls.

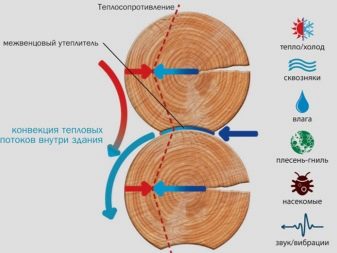

Insulation with polystyrene wooden walls has a limitation due to the fact that the foam has a greater tightness than front wood. Styrofoam itself does not rot. Since the material is completely synthetic, it is biologically neutral to the appearance of mold and fungi.

To date, polystyrene is characterized by convenience and affordability. The main advantage of the material - undisputed thermal insulation properties. Polyfoam differs in durability and convenience in work. It is an ideal choice for brick and concrete walls. When working with the material it is important not to forget about the features of wood.

Styrofoam has two main varieties:

- Extruded. It is a non-pressed material that is manufactured using equipment such as an extruder. Some manufacturers call this kind of extrusion.

- Extrusion The material is a slightly different polymer mass with a more uniform structure.Usually, disposable food packaging and disposable tableware are made from it.

- Still exists pressed expanded polystyrene, which has a high strength.

- Autoclave Styrofoam is an extrusion variety, but is rarely mentioned by manufacturers.

- Pressless expanded polystyrene is a popular variety that is relatively fragile, but buyers are attracted by the final cost of the material.

In general, polystyrene foam is a material with ambiguous characteristics. The advantages and disadvantages of the material are vigorously discussed by both amateurs and professionals in the construction industry. Let us examine them in more detail.

Specifications

The main characteristics of polystyrene foam are:

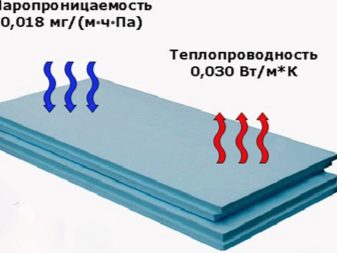

- Thermal conductivity. The level of eee can be compared with indicators of mineral wool. Polystyrene foam is of different density, and mineral wool has standard values. Choosing a dense polystyrene, it is possible to significantly increase the thermal conductivity of the material.

- Vapor permeability Conventional foam is characterized by zero vapor permeability. Polystyrene shells do not have the ability to transmit moisture.Some extruded polystyrene options have excellent vapor permeability characteristics. Cutting is used to form it, so steam can get into the material through cuts.

- Moisture absorption. The situation with this characteristic develops in such a way that the usual polystyrene foam placed in water absorbs ten times more water than the extruded version. Therefore, extruded foam is recommended for facades. And this foam should be provided with high-quality protection, otherwise wetted material will not properly retain heat.

- Strength. If you compare the usual polystyrene with extruded material, the latter has a higher strength characteristics. This option has a greater density, which means stronger ties between the smallest granules. Indicators of the bending strength of the first variant range from 0.4 to 1 kg / cm. sq. Normal polystyrene shows values from 0.02 to 0.2.

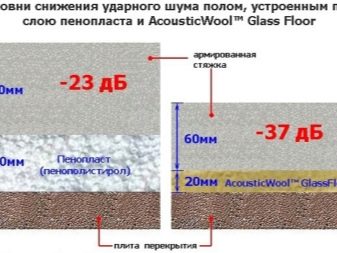

- Soundproofing. Many people think that foam is good protection against cold. and from the noise. However, due to the air structure, the material only slightly muffles the impact noise.For soundproofing from impact noise, the material must be laid in several layers, observing construction technologies. Greater discomfort usually bring air noise. Even when the thickness of the foam is sufficient, it is not a barrier to airborne noise.

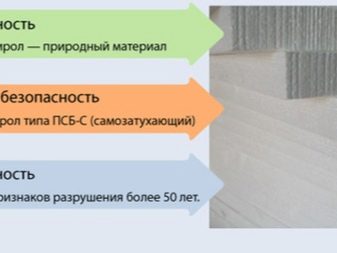

- Environmental friendliness. Some nonprofessionals believe that insulation of the foam from the inside of the house will have a detrimental effect on human health. But the environmental safety of expanded polystyrene is proven by appropriate tests. Insulation is not in vain recommended to cover the insulation and surface finish. If material is left in the open air, especially not extruded, it will release harmful components into the atmosphere. However, their concentration is not so high as to cause any harm to humans or the environment.

- Flammability This is also a controversial characteristic, as many consider polystyrene foam safer than wood. To catch fire, the tree really needs small temperature readings. To ignite polystyrene need high temperatures. But before the appearance of open fire, the material melts and emits toxic smoke.At the same time, expanded polystyrene is incapable of independent attenuation, although some manufacturers claim the opposite. According to national regulations, all expanded polystyrene are among the most dangerous materials for combustibility.

European standards are different from domestic ones, therefore the values of the characteristics of combustibility are different.

No modern supplements will improve this quality, as any materials are aging. Quality indicators, including flammability, decrease with time, polystyrene foam becomes susceptible to burning. The use of polystyrene foam is often limited to these qualities.

Application area

Styrofoam proved to be an excellent basement insulation. The layout of the material requires a pre-prepared site. At the same time both single-layer and two-layer laying is allowed. After installation, the polystyrene foam is poured with concrete. Further construction is built in the usual manner. The method allows you to apply a concrete screed at the same time for the base of the floor without the construction of the basement space.

If expanded polystyrene is applied to the basement, it is possible to achieve high-quality insulation of the foundations. This is true for the northern regions. At the same time both horizontal and vertical installation will save from freezing. Creating protection for exterior walls involves making a trench of about a meter width. Depth is determined by the depth of soil freezing. The plates are laid along the basement and filled with soil. This variant of insulation is suitable for a wooden house. It is better to warm the walls in the apartment from inside the room.

Expanded polystyrene well proved to be a heat insulator for engineering communications. It is already well known that through poorly insulated communications there is a heat leakage of up to 30 percent. Polystyrene foam began to be used for pipelines, ventilation, cables and other lines. The use of expanded polystyrene contributes to the fact that the lines can be laid at a shallower depth, which reduces labor costs.

The material showed itself well as an insulator of refrigeration rooms, freezers, refrigerated display cases. For industrial installations, moisture absorption and thermal conductivity is important.Traditional heat insulators have indicators more modest.

Styrofoam does not have any restrictions. The material is successfully used to isolate the floor, walls and partitions. Slabs 5 cm thick play the role of a heat insulator and sound insulator, as they reduce the level of impact noise. The technology of laying the material involves a complete sealing of the seams, as well as the mandatory coating of plates, which can be chipboard or concrete bases.

Styrofoam is also suitable for roof insulation. For this purpose, slabs with a thickness of about 7 cm are used. At the same time, it is customary to lay bitumen waterproofing on top of the material.

The technology of work involves the installation of polystyrene foam on the back side of the surface. The formation of condensate will regulate the ventilated cavity, which should be provided for.

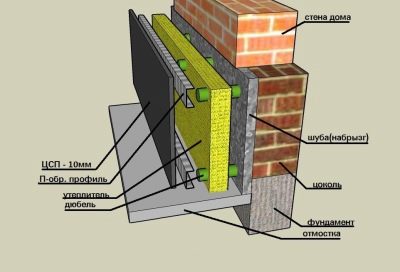

The foundation is also insulated with polystyrene foam. Since this is the basis of the building, the durability of the whole structure depends on it. The issue of thermal insulation of the foundation is of prime importance, especially in regions with a harsh climate. Expanded polystyrene is often used as a formwork.This option significantly reduces the consumption of more expensive building materials. Let us consider in more detail the technology of external wall insulation that can be done by hand.

Subtleties of implementation

Attach the styrofoam taken outside the house. The technology involves the transfer of "dew point". In addition, if you glue the material outside, the useful area will remain inside. Exterior insulation polystyrene will increase the heat in the building by half. Installation of plates can be carried out under siding or under plaster. But before you glue them, the work surface must be properly prepared.

The surfaces need to be cleaned from dirt, paint, plaster. If necessary, the verticals are aligned. With his own hands, heat insulation plates are easy to stick on the walls. In addition to glue, polystyrene foam can be fixed with plastic dowels with a wide cap.

To ensure the quality of thermal insulation at a decent level, it is important to fasten the plates tightly to each other. For convenience, the technology involves the mounting plates from the bottom up. This is important because the upper plates can move down due to the slowly hardening adhesive mixture.

For better fixation of the plates, experts recommend installing the frame. If the plates are glued directly onto the wall, a reinforcing mesh can be installed on top. It must be anti-corrosion, suitable for exterior decoration. The reinforcing mesh will contribute to better rigidity of the insulation, so it will be less susceptible to damage. In addition, if the insulation is glued on top of the plaster facing layer, reinforcing mesh is also needed. She better keep this layer.

After the adhesive mixture is completely hardened, the insulation is coated with a leveling primer. On top of the primer is mounted any finish. It is worth considering that outdoor insulation should be carried out in dry and calm weather. The ambient temperature must be at least 5 degrees.

In addition, each subsequent facing layer is applied only after complete drying of the previous one. Only in this case it is possible to talk about the observance of technology and the long service life of the mounted insulation.

Expanded polystyrene is actively used in private construction for brick and wooden walls. Technologies of warming of these types of the bases differ.

If we talk about extruded polystyrene foam, which is used for outdoor insulation, it is worth considering that the material does not allow air. Therefore, in case of incorrect work carried out, moisture will accumulate between the wall and the layer of insulation. To avoid this, a small gap should be left between the facade and the styrofoam. Circulating air will dry the walls, and excess moisture will be removed.

When carrying out work, it is necessary to take into account the tendency of wood to rot. At the first stages of warming it is important to eliminate possible cold bridges. Through these sites, the formation of moldy formations can be triggered. Expanded polystyrene for wooden walls can be applied only by the method of the hinged facade. It is also worth considering that the wooden houses themselves have good thermal insulation qualities.

Warming a wooden house may be necessary if:

- after prolonged use, the walls of the house began to pass air;

- there is a violation of the surface layer;

- from the joints, the walls are clearly blown out;

- the log walls began to crack.

The whole process of work can be divided into stages:

- preparatory stage;

- installation of vapor barrier;

- installation of polystyrene;

- installation finishes.

The stage of preparation of a wooden surface can be divided into the following works:

- removing old paint;

- drying;

- checking the base material for the density of the joints;

- if necessary - sealing joints;

- processing and impregnation of wood.

The last point is of great importance, so at this stage it is important to choose quality tools.

Installation of vapor barrier produced at the point of contact of wood and insulation. Vapor barrier is a membrane film, which consists of three layers. The basis of the film is reinforced polypropylene. Polyethylene fiber is applied on both sides. Such a vapor barrier perfectly protects the inner surface from steam and condensate, which will come from the insulating material.

Parobaryer may be a four-layer. A reflective aluminum foil layer has been added to its inner surface. This additional insulation, as well as protection from steam. Vapor barriers vary in density. This value affects the quality properties, as well as the price tag.

The technology of laying a vapor barrier involves mounting the film both along and across the insulation boards. It is of great importance which side to lay the film. This point should be carefully studied in the installation instructions, as the process depends on the manufacturer.

Recommendations

Feedback on expanded polystyrene is mostly positive. Users write that for private construction this material is recommended by professionals. Professional builders mark the convenience in work and the excellent quality of the material. Inside apartments, polystyrene often insulate balconies.

Most users have noted easy installation of the material. It is possible to warm the house in order to reduce heating costs, especially if the area of housing is decent.

Expanded polystyrene is not suitable for finishing slopes, it is also not a good choice for roof insulation. The material is not very safe in terms of flammability. Relatively small fires in the premises, finished with polymeric materials, lead to poisoning by poisonous volatile products.

In addition, polystyrene, according to users, still eat up insects, as well as rodents.Although other users have successfully used the material for roof insulation.

Experts recommend:

- Securely cover polystyrene foam from the sun, rain and snow. The material can be completely destroyed even by a small sunbeam.

- Do not use polystyrene foam for insulation inside buildings. It should take into account the high flammability of this material. The products of combustion of polystyrene foam will bring great harm to people's health. In addition, the insulation of the walls from the inside leads to a rapid accumulation of moisture, resulting in fungi. Because of them there are various diseases.

- It is necessary to study in more detail the properties of polystyrene, if the choice fell on this heater. Expanded polystyrene is poorly studied precisely as a building material. The thermal insulation qualities of the material are good, but it appeared on the market not so long ago, so it is not known how the material will behave during long-term operation.

To learn how to warm the base of the base with polystyrene foam, see the video below.