Technical characteristics and description of foam glass

Professionals consider foam glass a material, behind which lies a serious resource of reducing the cost of housing being built and improving energy conservation. Relatively recently, this material was used in mass construction, but you can’t call it “young” - foam glass was invented back in the 30s of the last century, and they began to be used in practice in Canada several years later.

However, only half a century later he took his place among the popular materials - it was then that the technology was thoroughly tested, and the cost of its production was reduced.

Special features

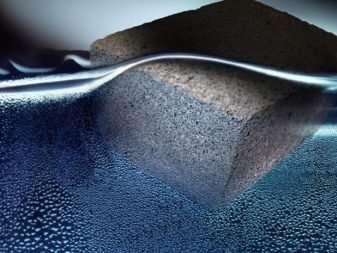

When two different substances are combined in one material, this can have a very interesting effect. This was exactly the case with foam glass - here classical silicate glass, which in previous years stood in most windows, and foam, merged into one wholeconsisting of small bubbles interconnected by thin layers of liquid.

The material is obtained by heating a silicate substance into which a substance that forms a gas is introduced. Under the influence of elevated temperatures, it begins to melt, in parallel the gasifier decomposes, releasing small bubbles, they are “caught” by hot melt and firmly fixed in it.

Foam glass has unique consumer properties:

- small weight:

- strength;

- water tightness;

- combustible and heat resistant;

- inertness with respect to chemical reactions.

The foamglass receives a part of its characteristics from silicate raw materials, and a part from gas. For example, the material loses the transparency of the glass, but acquires high noise-absorbing and heat-insulating properties.

Separately, it is necessary to dwell on the physico-technical parameters of the composition

The foam glass has a fairly low density, which is 100-250 kg / m3. For comparison, the density of wood varies from 550 to 700 kg / m3. By the way, that is why foam glass was repeatedly tried to be used as a floating building material.

The volumetric weight is approximately 70-170 kg / m3, and the sound insulation of a 10 cm thick block is 52 dB.

The material is resistant to burning: fire class A1 (non-combustible). It does not decompose under the influence of adverse atmospheric factors, and also does not emit harmful and toxic substances.

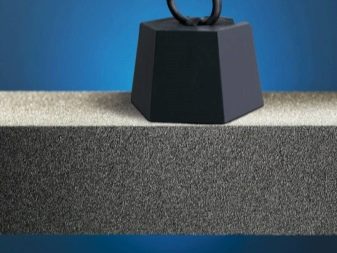

Compressive strength of foam glass is quite high - the material easily withstands pressures up to 100 tons per 1m2, the other characteristics also inspire optimism for craftsmen who intend to use foam glass for construction work.

Thermal conductivity at a standard temperature is 0.04 W / ms, which is higher than that of wood (its index is only 0.09 W / ms), while the ability to absorb sound waves is comparable only with mineral wool and is 45-56 dB.

Water absorption coefficient does not exceed 2%. This means that the foamed glass practically does not absorb moisture, and the vapor permeability is almost zero - 0.005 mg / (m h. Pa). This material can be called the perfect vapor barrier.

The blocks withstand elevated temperatures, retaining their properties even at 300 ° C, and if special additives are present in the composition, then the threshold of thermal stability can even reach 1 thousand C.At the same time, the material is not afraid of low temperatures and easily transfers contact with liquid nitrogen (-200 C) without any signs of destruction.

Chemical inertness is a fairly valuable quality along with high environmental friendliness. Perhaps there are not so many modern heaters, which would be equally harmless.

Another plus is durability.. For comparison, polymers quickly grow old, losing their performance characteristics, and begin to emit toxic substances into the environment. Foam glass of such minuses is deprived - its use is more justified than the use of PVC plastics or expanded polystyrene. The service life of foam glass blocks reaches 100 years.

Advantages and disadvantages

Exceptional physical properties “awarded” the material with a large number of advantages:

- simplicity in processing - material easily fastens; installation work can be carried out with your own hands, even without a lot of experience in construction and decoration;

- corrosion resistance - foam glass does not form rust;

- biostability - the material is resistant to the products of vital activity of representatives of flora and fauna, as well as to microorganisms of all types;

- chemical inertness - foam glass does not react with acid-base solutions;

- the constancy of the size of the blocks - throughout the entire period of use, the blocks do not shrink, do not stretch and do not contract, their dimensions are unchanged in any conditions;

- resistance to mold and fungus - foamed glass is not an environment in which mold and other dangerous microorganisms reproduce, so you can always be sure that the fungi will not penetrate the room and do not harm the health of the household;

- high degree of resistance to fire - the material does not ignite spontaneously and does not sustain combustion, protecting walls from damage in the event of a fire;

- hygroscopicity - the product does not absorb moisture;

- vapor tightness;

- environmental friendliness;

- sound absorption.

The material is recommended for use in rooms with high sanitary and hygienic requirements.

Throughout the long term of use, the blocks do not change their forms, seasonal temperature drops and precipitation do not have a destructive effect on them, the material reliably protects the structure from the appearance of any cold bridges due to compression or sagging of the insulation coating.

If we talk about the shortcomings, the most important of them can be called a high cost.This is due to the fact that the technology of glass production is associated with high energy costs. In addition, the firing itself is quite time-consuming and technological process. All this significantly affects the final price of the product.

The second minus is the low strength for mechanical damage. However, this figure can not be considered critical, since insulation is rarely subjected to shock.

The foam glass is characterized by low elasticity, therefore, during installation work, it requires reliable fixation. In addition, it is very important to observe the exact technology of laying, otherwise the blocks will begin to crack.

Kinds

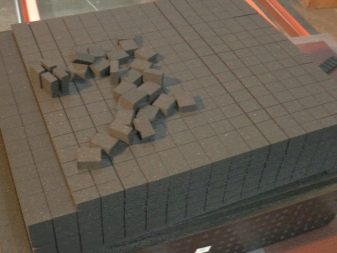

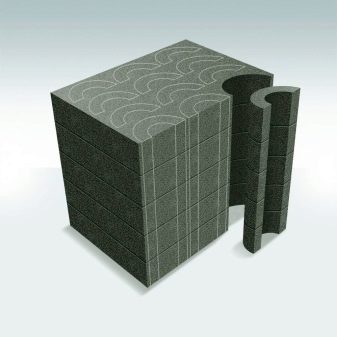

Foam glass in the construction market is available in two versions - these are foam glass granules and blocks. They have a different production technology.

As is known, foam glass is obtained from waste simple glass, which is crushed to a powdery state and then heated with the addition of gas-forming components to 850 C.

The granular material is made in metal tunnel kilns and, after processing, is sawn into blocks of the desired size. It is a bit like expanded clay.

The technical properties of foam glass made in the form of granules can be considered unique - it is a light material that is absolutely not susceptible to corrosion, it does not take root mold with fungi and does not form damage. It has a very long “life span”.

Granular foam glass is most often isolated frame houses - it is added to the glue and kneaded. The result is a composition with high thermal insulation properties.

Blocks are most often used to insulate the ceiling. These are tough, but at the same time quite light materials, which by their properties resemble polystyrene foam plates or products made of mineral wool.

Scope of application

The scope of foamed glass due to its physico-technical properties. The material is widely used in almost all spheres of life.

- In residential construction. The material is used as insulation utilities, roof and floor. They are covered with basements and foundations, basement and attic floors, and are often used to insulate facades from the outside and inside.

- In the construction of sports facilities - granulated foam glass is suitable for arranging sports arenas, as well as swimming pools and sports fields.

- In industrial facilities. Built-in glass can significantly reduce the cost of using objects due to their increased thermal resistance. Its use is justified not only in ground structures, but also in underground objects, for example, in buried reservoirs.

- In the national economy. On marshy soils, crushed stone made of foam glass is often used - that is why the material is optimal for building farms that are intended for breeding cattle and birds.

- In works on improvement. Bulk foam glass is often used in the construction of greenhouses and greenhouses, as well as in the formation of garden paths. The material has found its application in the construction of the drainage system.

Manufacturers and reviews

In Russia, several enterprises are engaged in the production of foam glass. Below are some of them.

- "Saitaks" (Moscow region) - The production of block and granulated foam glass is adjusted here.

- "Neoporm" (Vladimir) - material is produced in the form of tiled material and shaped products (shell,knees).

- Penostek (Moscow region) - mastered the manufacture of granulated insulation.

- "Izostek" (Krasnoyarsk) - produces foam glass in the form of plates.

- "United Industrial Initiative" (Kaluga region) - is engaged in release of foam glass rubble.

- "Thesis" (Sverdlovsk region) - realizes a foamglass crumb. Unclean material - contains binding agents, due to which vapor permeability increases.

- "Termoizol" (Yaroslavl region) - granulated glass.

- "Porositel" (Perm) - produced slab and block coating.

Manufacturers Integra, Etiz and Neftezol are also known to the Russian consumer.

It may seem that in Russia there are a large number of enterprises that have established a serious production of foam glass that meets all the quality requirements. This is not entirely true. Production facilities in our country are available, however, production volumes are negligible, and the quality is seriously inferior to imported counterparts.

Slightly better is the situation with the production of glass in other countries, for example, in the CIS. Fame throughout the world received the products of the Ukrainian company from Zaporozhye and Shostka.Consumer parameters of their products are very close to world requirements, but the volume of output is small, so products are usually fully sold in Ukraine.

Slightly lower performance of the Belarusian "Gomelsteklo". However, the volume of its production is sufficient to provide its country and neighboring Russia with foamed glass - we have this brand is considered the absolute leader in sales. By the way, this company is one of the first to start producing foam glass in the middle of the last century.

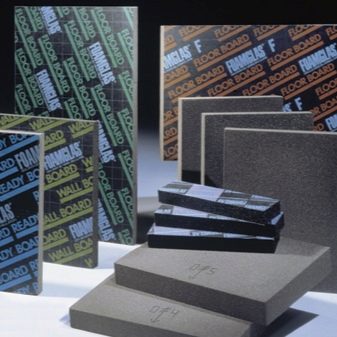

The products of the Chinese company NeoTim, as well as Pittsburgh Corning, whose capacities are located in the USA, the Czech Republic, Germany and Belgium, are very popular.

As they say consumer reviews, it is the products of this concern, manufactured under the brand name Foamglas, most closely matches all the declared parameters of the foamed glass.

Tips and tricks

Below are a few tips on how to increase the effectiveness of foamed glass.

When purchasing this material should be taken into account the insulating parameters of the product.For example, for walls built of brick or concrete, plates with a thickness of 12 cm are used, and for structures made of wood there is enough material of 8-10 cm.

For interior work, it is worthwhile to stop at 6 cm. Plates. They are fastened with glue and are reinforced with steel brackets and thin dowels.

If foam glass is used to create a floor heating system, then it is necessary to give preference to granular material, which effectively fills all voids and creates the necessary degree of thermal insulation.

To date, foam glass meets all the requirements that apply to building materials in terms of their reliability and safety.

On how to warm the floor with foam glass, see the following video.