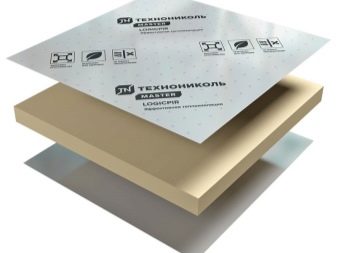

Technical characteristics of PIR plates "TechnoNIKOL"

An important stage of construction is the insulation of the premises. Modern construction market is filled with a huge amount of insulating materials. PIR plates are such a raw material, distinguished by many positive qualities, which are useful to learn in more detail.

What it is?

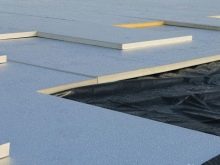

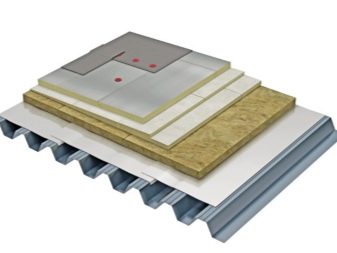

PIR plates are a heat-insulating construction material in the form of block panels (sandwich panels), consisting of polyisocyanurate (polymeric material), having a solid porous structure resistant to deformation and heat, and an external preserving layer, which can be used such materials like foil, polymer films, sheet steel or kraft paper.

Benefits

Polyisocyanurate is a close relative of polyurethane foam and has a number of valuable qualities that allow it to be a popular and relevant building material for thermal insulation.

- Low thermal conductivity. High quality insulation in ~ 0.022 W / m * K is provided by many closed gas pores ~ 97%, while the rest of the frame fits only 3% of the total volume and weight of the unit.

- Incombustible. With direct exposure to fire on the surface of the material, it is charred and thus creates a protective refractory layer, which does not burn or sustain combustion.

- Protection against moisture and moisture. Special chemical treatments, as well as a protective outer layer, keep the material from rotting, dampness and prolonged exposure to liquids, which allows it to be used to isolate not only warm rooms, but also cold ones: condensation does not form on it.

- Protection against damage when used. Covering the panel allows you to keep the polymer plate intact during transportation, eliminating the need for specialized equipment and protecting it from minor damage, as well as directly in the process of mounting and further use.

- Protection against rodents. Chemical impregnation repels rodents and other pests, eliminating the appearance of unwanted moves, holes and holes.

- Long service life. The high quality characteristics of PIR plates create ideal conditions for preserving its original qualities after many years of use. Research data shows that the plates have high performance even after 25 years of service. It is worth noting that this building material appeared in the world recently, research is physically limited in time since the creation and commissioning of the first such plates. The minimum service life of the material is more than 25 years.

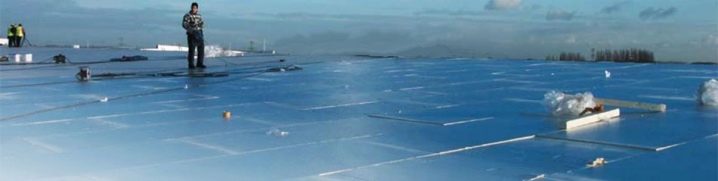

- Ease. In the process of manufacturing in the block, closed hollow cells are formed, filled with a special inert gas, which prevents the heat from passing through best. A huge number of such tiny pores in the final material makes polyisocyanurate very easy, which greatly simplifies working with it. When using, neither heavy machinery, nor a large number of workers, nor brute physical strength is required. All this saves resources.

- Simple processing. PIR blocks are easily affected by tools and do not require serious power.For all its strength, the plates are conveniently cut with a stationery knife, they retain their shape when screws are screwed into them, when nailing and when using dowels. They converge well and do not change size over their entire service life (they do not contract and do not expand under the influence of external factors).

- The ability to quickly dismantle. Blocks are easy to remove and remove from the installed state, do not require special tools or security features, do not leave behind dirt and debris.

What is needed and where are they applied?

This material is actively used in construction and renovations for thermal insulation of houses, heating or cooling objects and premises that require constant temperature preservation with minimal energy consumption.

Due to its physical and chemical properties, PIR plates are environmentally friendly and safe for health, and also will not cause any additional difficulties in emergency situations.

Manufacturer

Until 2015, Russian companies purchased insulation materials outside of the Russian Federation, as Russian insulation manufacturing enterprises noticeably lost in the quality of their products to their foreign competitors andThey did not have any material of similar quality produced, nor any established production in the country.

Imports of foreign materials had its drawbacks and difficulties associated with the timing, waste, quantity and quality of imported products. This problem was solved by the production company TehnoNIKOL.

The TekhnoNIKOL company began its activities in Russia in 1993 with the creation of roofing materials, after which it immediately began to be perceived as a leader in its manufacturing niche. In September 2015, she began the production of PIR-type thermal insulation panels in Russia.

The company has a reputation as an honest and conscientious company, responsible for its products and seeking to develop in its industry based on the feedback and needs of its customers.

Reviews

Customers using panels respond to them as a quality product that satisfies many requirements. Thanks to special grooves for bonding with the material, a person can work without professional skills, and the installation of this material is simple, fast and without garbage.And also highly valued are such properties as genuine incombustibility of the material and low thermal conductivity, which allows the use of products with a minimum thickness (20 mm), while not losing as thermal insulation.

Where can one buy?

You can purchase PIR blocks at any hardware store, since the material is very popular and relevant today. But there is also the possibility of both an online order and a direct wholesale order from the manufacturer TehnoNIKOL.

Specifications

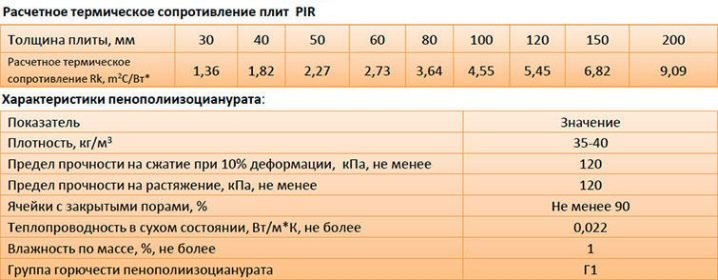

The main physical characteristics of PIR panels:

Property | Values * |

Thickness | 20 - 250 mm |

Length | 1200 - 2400 mm |

Width | 600 - 120 mm |

Density | 30 - 35 kg / m3 |

Thermal conductivity | 0.021 - 0.024 W / m * K |

Water absorption | ~ 2% of the volume |

Compressive strength at 10% deformation | 120 kPa |

Flammability group | G1 - G3 ** |

* exact values can be found when ordering

** depends on the type of protective coating of the plate

Cost of

The price of insulation depends on the size of the panel (thickness * length * width), on the retaining coating and on the point of sale.

Shops are able to charge for goods, but on average the cost per slab is 1 square meter. m with a thickness of 30 mm will be as follows:

Type of preserving coating (from two sides) | Cost in rubles |

Paper | 290 |

Film | 320 |

Foil | 375 |

Fiberglass | 440 |

Bituminous paper | 300 |

Foil paper | 400 |

Precautionary measures

Before purchasing a product, always try to check its capabilities as stated by the manufacturer. This will help not only to ascertain the quality of the purchased goods, but also to avoid the dire consequences in the future. Be careful.

For more on the use of PIR plates, see the following video.