What is the density of insulation when choosing a material?

One of the parameters that pay attention to when choosing insulation, is the density. What this or that indicator means and what characteristics of a heat-insulating material is influenced by its density - this and many other things will be discussed below.

Special features

By material density is meant the weight of a given substance, in one cubic meter of material. The unit is kg / m3 (kilogram per cubic meter). Another name for the density parameter is the specific gravity of the material.

Density indicators are due to the quality of the bond between the material molecules.The stronger the elements of insulation are connected, the higher its strength.

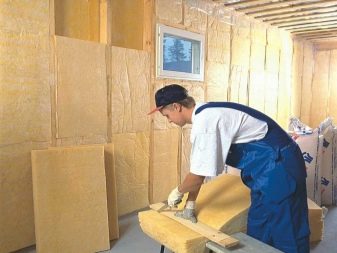

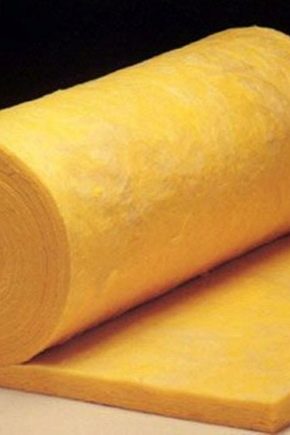

The easiest way to understand what density is when you consider a mineral wool insulation. It can be loose and noticeably soft, fiber-disassembling (a material with a low density, the molecules of which have weak bonds). You experience completely different sensations when touching mineral wool mats - their fibers are harder, but most importantly, they are as if pressed together (higher insulation density).

Classification

Depending on what criterion is the basis of the classification, insulators are divided into different groups. In this article, we are interested in density differentiation. In this case, the following types of thermal insulation materials are distinguished:

- Lungs. They have low weight and low thermal conductivity. Mineral wool materials primarily belong to this group.

- Average. An example of such a heater can make foam glass. Such heat-insulating materials are usually produced in the form of plates and blocks with high thermal and acoustic insulation.

- Hard. This is a dense insulation, usually obtained by pressing, for example, mineral wool mats.In addition to low thermal conductivity, they are characterized by moisture resistance and ability to withstand heavy loads.

Kinds

As already mentioned, all thermal insulation materials are divided into several types, depending on the specific weight indicators. From the latter depends on the scope of its application.

The table clearly illustrates this:

Density class | Density indicators | Scope of application |

Lungs | 11–35 kg / m3 | Lightweight and elastic materials that are used to insulate the roof and roof. |

35–75 kg / m3 | Wall insulation - insulation of walls, partitions, frame structures. | |

75–100 kg / m3 | Wrapping pipe oil pipelines, heating mains. | |

Average | 100–125 kg / m3 | External insulation for ventilated facade |

125–150 kg / m3 | Warming of concrete and brick walls, interfloor overlappings | |

Tough | 150–175 kg / m3 | Sheathing bearing structures |

175–225 kg / m3 | Stacked under the screed primer before finishing, are durable and fire resistant. |

It is important that certain types of insulation have their own classification, depending on their specific weight. For example, according to GOST, polystyrene is divided into brands PSB 15 (density is less than 15 kg / m3), PSB 25 (indicators 15–25 kg / m3), PSB 35 (specific weight from 25 to 35 kg / m3) and PSB 50 ( 50 kg / m3 and more).

The classification of hard wool by hardness is as follows:

- P-75 (density of the material, respectively, 75 kg / m3) is suitable for lightly loaded and horizontal surfaces;

- P-125 (the share of this wool is 125 kg / m3, but the insulation with a density of 110, 120 and 130 kg / m3 is also referred to this type) wall insulation;

- PZH-175 (density indicators are clear from the name) - material of increased density for exterior plating;

- PZH-200 (specific weight is 200 kg / m3 and higher) - it is used for outdoor work, it has a high fire resistance.

It should be noted that there are less dense cotton wool than the P-75. Their specific weight is 60–70 kg / m3.

Comparison of parameters

Different types of insulation have different average density.

- Mmineral wool insulation have a density of from 30 to 200 kg / m3, which ensures their versatility - you can choose the material for any part of the house.

- Maximum polyethylene foam density it is 25 kg / m3, while the material is rather thin - 8–10 mm. Increasing the density to 55 kg / m3 is achieved through the use of foil layer on one side. Interestingly, its appearance only slightly increases the density of the product, significantly increasing the heat-efficiency of the material.This is ensured by the ability of the foil coating to reflect up to 97% of thermal energy.

- Popular material for insulation Styrofoam has a specific weight of 80–160 kg / m3, and extruded polystyrene foam - 28 to 35 kg / m3. It is no coincidence that the latter is one of the lightest material for thermal insulation, having, moreover, low thermal conductivity.

- Due to the peculiarities of the composition and application technology (sprayed with a semi-liquid mass on the surface, after which it solidifies), penoizol also has a low density of 10 kg / m3. However, like most of similar materials, requires additional protection at a minimum - a layer of plaster.

- A wide range of specific weight indicators are characteristic and for foam glass - foam or cellular glass. Interestingly, the standard indicators are 200-400 kg / m3, and the light version has a density of 100-200 kg / m3. In combination with high thermal efficiency, because the coefficient of thermal conductivity is equal to the same values of mineral wool, the material allows to use for the insulation of facade structures a lightweight version, that is, having less weight and cost.

Impact on properties

Most characteristics of insulation are interrelated. Thus, the density indicator affects thermal conductivity.

As you know, air is the best heat insulator. A large number of air bubbles are located between the randomly directed fibers of mineral wool insulation, for example, stone wool. but if the specific gravity of the material is increased (in fact, the fibers are compressed more strongly), the volume of air bubbles will decrease, which will increase the thermal conductivity.

However, the relationship between density and thermal conductivity due to the structure of the material. For example, when the density of polystyrene foam changes, the volume of air contained in its capsules remains unchanged. This means that the thermal conductivity does not change when changing the density of the insulation.

But the sound insulation change in the proportion always affects. This is due to the fact that with a decrease in the air permeability of a heat insulator, its noise-absorbing performance increases.

In other words, the denser the material, the better sound insulation it is characterized. However, as density increases, so does the weight, the thickness of the material. Working with him becomes uncomfortable.

The way out of this situation will be the use of special insulation panels with improved sound insulation properties. It can be light glass wool or basalt insulation with twisted thin and long fibers. The density of the material may not exceed 50 kg / m3.

The connection between the parameter under consideration and the thickness of the insulation is undoubted. The greater its density, the thinner the layer is required to achieve the desired thermal effect.

Indicators of strength are also associated with the ability of a material to withstand heavy loads, and the connection here is directly proportional. In this regard, more dense materials should be used on the loadable areas. This is the only way to avoid deformation of the insulation.

Finally, the method of its installation depends on the specific weight of the insulation. So, between the lags and elements of the batten one can use light heat insulators, of small density. If the same option is mounted on the walls, it will simply slide, so the choice is made in favor of more durable mats and sheets.

Besides, dense insulation does not require additional mechanical protection, they are strong enough to withstand mechanical loads. Looser materials - foam, polystyrene foam, mineral wool - always need extra protection.

How to choose and where to apply?

Choose the density of the material should be primarily taking into account its scope. When it comes to wall cladding, you should consider the type of cladding material. So, for facades lined with siding, you can use lightweight insulation (40–90 kg / m3). If plastering is planned, the specific weight of the insulation should be increased to 140–160 kg / m3.

For pitched roofs, a heater with a density of up to 45 kg / m3 is sufficient, while a flat roof, exposed to increased loads, requires a more “serious” heat insulator. For mineral wool heaters, this figure will be equal to at least 150 kg / m3, for polystyrene foam - at least 40 kg / m3. Under the draft floor you need the most dense insulation, not less than 180 kg / m3, and between the lags you can put a light, loose insulation, because they take the whole load on themselves.

When choosing insulation depending on its density, you should consider criteria such as:

- types of work (external or internal insulation);

- material installation method;

- load, which is subjected to insulation;

- average temperatures in the winter season;

- the need for sound insulation.

When choosing insulation it is important to rely not only on its technical indicators, but also on the authority and fame of the manufacturer. Preference should be given to long-lived companies whose products have been on the construction market for a long time and receive positive customer reviews.

The products of some companies have a small selection of materials depending on the density. So, in the lines Ursa insulation practically does not occur, the density of which is above 35 kg / m3.

Most famous trademarks (Isover, Rockwool) produce both light and rigid insulation - a special kind for each type of work, including under the loadable ventilation façade.

Tips and tricks

Paying attention to specific products, you should carefully study the instructions for the material, paying attention not only to the density indicators, but also to the scope of application. So, in the Isover range there are plates of average density (50-80 kg m3), which, however, are suitable for insulation of facade systems.

Of interest are the plates that combine two textures - their outer side is more dense, stiff, the inner one is loose, soft. The use of such materials provides high-quality insulation, reduces the load on the building, as well as put plaster directly on top of the insulation.

Some manufacturers, for example, TekhnoNIKOL, produce materials of different rigidity in different lines, while the rulers of other brands include several at once in terms of the density of the types of material. For example, Knauf is a ruler, including both a material with a density of 35 kg / m3 and 150 kg / m3.

As for foam plates, manufacturers usually provide a clear differentiation of the material according to its purpose, which is inextricably linked with density. For example, the density of the plates "TechnoNICOL" CARBON SAND - 28 kg / m3. Low density, which means low weight, allow them to be used as part of sandwich panels. And the products of CARBON PROF of the same brand have a density of 30–35 kg / m3, which changes its purpose - now it serves as an independent insulation in residential buildings.

In other words, one of the main tips when buying insulation is to pay attention to the density and purpose of each manufacturer.

It is important to remember that not only different construction objects, but also different parts of the same building need insulators of different density and thermal conductivity.

For example, there is enough light insulation for walls, which has a low thermal conductivity and will not overload the structure with its weight. Suitable material with indicators of 50-200 kg / m3.

Even lighter insulators with a density of 28–55 kg / m3 should be used for internal insulation. But the foundation and basement parts require the use of rigid insulation of high density, at least 150 kg / m3.

Finally, we must not forget that heaters, whose density is less than 250 kg / m3, necessarily need an additional protective layer. Especially, if we are talking about outdoor insulation.

See if the density of insulating materials is important in the next video.