Door closers: device, types, installation and operation

Contrary to popular belief, door closers are a rather old invention - they were invented at the end of the 19th century. The authors of prototypes of modern devices can be considered immediately three mechanical engineers: Francis Richards, Lewis Norton and Eugene Blount. Scientists worked on the creation of devices independently of each other, and in 1873 Richards presented the world the first model of a spring closer. Seven years later, Norton invented a pneumatic model, and nine years later, through Blount’s efforts, a mechanical-hydraulic device was born.

Specifications and operation

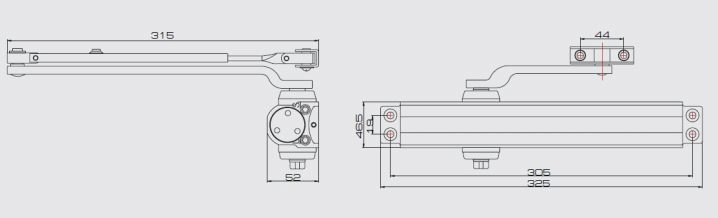

Classic spring door closers consist of lever arm and body with a mechanism. This mechanism is responsible for the slow closing of the door leaf and consists of a cylindrical capsule with a system of thin hydraulic channels, a spring block and a piston. During the opening of the door, the force, due to the lever, is transmitted to the piston, which, in turn, begins to move along the cylinder and compress the spring. As soon as the impact on the door ceases, the piston ceases to exert pressure on the spring and it begins to gradually open. From the speed with which the spring returns to its original position, depends on the speed of closing the canvas.

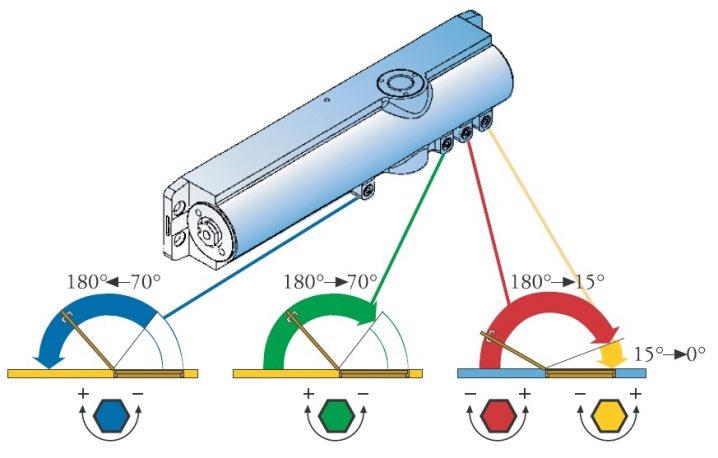

To increase or decrease this indicator, it is enough to change the size of the cross section of the hydraulic channels through which the oil moves. This can be achieved with the help of adjustment screws located at the end of the body and allowing to adjust the stroke of the canvas depending on external temperatures and personal preferences. The most technologically advanced models of closers are equipped with a special valve that allows to keep the movement of the web, starting at an angle of 70 degrees and up to its complete closure.Moreover, starting from 15 degrees, a sufficiently perceptible pressing is carried out, which ends, albeit with a soft, but at the same time, powerful latching. This allows the door leaf to overcome the air resistance, as well as the force of the seal and the latch.

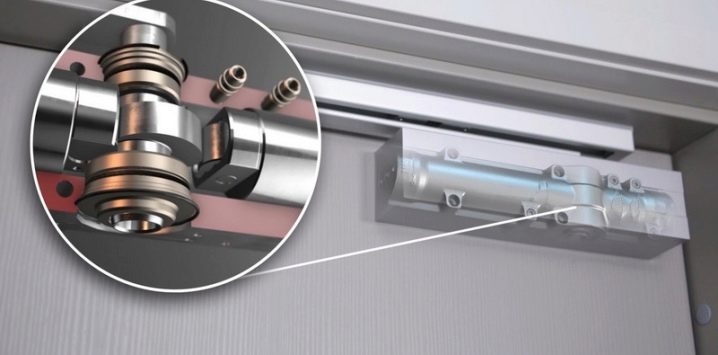

In modern devices, instead of the outdated spring technology, the gear-rail mechanism or the cam system is more often used. The basis of the first design is the hydraulic circuit, and the moment is transmitted by means of a mechanical rack and pinion. Such devices are capable of ensuring a smooth running of the web in a large range and possess a stronger hold-down and a powerful overcoming of the resistance of the seal and the latch. The cam technology also provides a tighter closing of the door and has a high efficiency compared to other mechanisms.

Kinds

In the modern market of door fittings, door closers are represented in a large assortment. Classification of models occurs according to a number of criteria, the determining of which is the method of transmitting torque. On this basis, there are two types of devices.

Lever models

In such devices the folding lever is engaged in the transmission of torque. This is the most common and budget type of mechanisms that provides reliable and durable articulated traction. The only drawback of knee devices is a low level of protection against vandals and a not very aesthetic appearance, and if you can still accept the last moment, then the probability of deliberately damaging the device is an acute problem and sometimes makes you refuse to use these simple and proven mechanisms in favor of more protected models. .

With a sliding channel

This type of device is less susceptible to vandal attacks, which allows it to be used more frequently in public places and various institutions. The transfer of force in such devices is carried out by means of a sliding rod, the lever of which moves along the channel. Due to the absence of angular designs, the models are more aesthetic and, unlike the previous type, do not have vulnerable protruding elements. In addition, the channel can be easily equipped with an elastic stop that controls the opening of the door leaf.

Not less important sign on which closers are subdivided is the place of their installation. According to this criterion, there are four categories of closers.

Upper

Devices with this method of placement belong to the largest group and are widely used in residential buildings, public buildings and production shops. Installation of the working body is made on the door itself or above it and depends on the design of the door system and the model of the device. Devices can have both gear, and cam execution, and work both on sliding, and on lever lever. The advantages of overhead closers are wide consumer availability and easy installation. The disadvantages include the need to pierce the door or wall, the visual blocking of the door leaf and the risk of spoiling the design of the room.

Outdoor

Such models are completely invisible, due to the absence of levers forcing the axis to move. In fact, the door leaf is located directly on the axis itself, which, in turn, imposes certain restrictions on the scope of their use: such door closers can be installed on doors whose weight does not exceed 300 kg.The devices are widely used in plastic and wooden interior doors installed in cinemas and shopping centers.

Hidden

These devices are intended for installation on door systems where the visual presence of the device should be as small as possible. Hidden models, in turn, are divided into two types: models with sliding rods and loop closers. The first in their design are not much different from the overlaid analogues, however, they have miniature dimensions and are located in a door niche or in the doorframe mounting plate. The advantages of the built-in devices include high strength of the mechanism and long service life. Among the shortcomings they note the need to violate the integrity of the door and box during installation, as well as the impossibility of operating in too heavy and overall door systems.

Loop closers are made in the form of a miniature device, the whole mechanism of which is housed inside the body of the door hinge. The main advantage of the devices is the absence of the need to chisel and drill through the door, which makes it possible to widely use models on glass paintings.The closer is mounted according to the principle of a conventional door hinge and is completely invisible by visual inspection. The disadvantages include the inability to use on heavy overall systems, as well as the demands on compliance with the rules of installation.

The door must be hinged using the building level, otherwise the closer will be difficult to manage the skewed construction. Hinge closers are widely used on room doors and have proven to be a very convenient device in homes where there are small children. In addition, door hinges are well suited for doors equipped with magnetic and electric locks, due to the lack of need to overcome the resistance of the latch and seal.

Specialized devices

This category of closers includes models for sliding and sliding interior systems, as well as compartment doors. By their construction, the devices resemble bar-type furniture closers, however, they differ from them in size and the initial force created. The installation of devices can be performed both in the box and in the canvas, and consists in forming holes of the required diameter at the ends of the box or door and then placing the device in them.

Criterias of choice

When choosing door closers, special attention should be paid to the power of the device. This criterion depends entirely on the size and weight of the door leaf, as well as on the traffic intensity. In some cases, with a large weight of the door structure and high traffic, it is more expedient to install two closers. This will distribute the load between the devices and significantly extend the life of each of them. The efforts developed by the closers are clearly regulated by the strict European standard EN1154.

In accordance with the norms of this document, seven classes of instrument power are allocated.where products of the first class have the lowest rates and are able to control the canvas with a width of not more than 75 cm and weighing up to 20 kg. Models of the second class will cope with the door of 85 cm, weighing up to 40 kg. The third class is limited to 95 cm by 60 kg, and products of the fourth class must be chosen if the web width does not exceed 110 cm and weighs no more than 80 kg. The following three classes - EN5, EN6 and EN7, include especially powerful models for overall and heavy doors, the maximum permissible parameters of which are 125, 140 and 160 cm wide, and 100, 120 and 160 kg of weight.

It should be noted that in addition to focusing on the maximum parameters of the door, it is necessary to take into account external factors. For example, when choosing a door closer for an outdoor door that has a width of more than 125 cm and is exposed to side winds for a long time, you should not choose the fifth, as required by the standard, class, but purchase a model of the sixth or even seventh grade. You should also act in a situation if the width of the canvas corresponds to one class and weight to another: in such cases it is necessary to provide a margin of safety and choose the higher one of these two classes.

No less significant factor in the choice of devices on the input group is their frost resistance. The modern market offers a huge selection of models that can withstand low and high temperatures in the range from -45 to +70 degrees. And the last sign that is worth paying attention to is the appearance and color of the model. When buying lever designs, it is better to choose models of the same color with the door, thus leveling the bulkiness and clumsiness of the device. For example, a black closer on a brown canvas looks extremely inharmonious, while on a black door it looks discreet and quite aesthetically pleasing.

Manufacturers and reviews

The rating of manufacturers of door closers is as follows: the German companies Dorma and Boda are deservedly located in the first and second places. Enterprises specialize in the production of models with sliding braces, which are very popular and are much better bought than knee models. Following the German firms are Italian Cisa and Cobra, offering consumers traditional lever and hidden floor devices. This is followed by the Korean KDC, which uses German components and produces anti-corrosion models for outdoor installation, and closes the six strongest Finnish Abloy.

Products of this company are equipped with independent valves that are responsible for the smoothness of the course and provide tight closure. In addition, models from Finland are equipped with a very precise regulatory system that is very responsive to the slightest change in settings. The only disadvantage of foreign models, buyers consider a relatively high cost. Thus, the price of particularly powerful models designed to control heavy steel doors can reach 38 thousand rubles.

Russian-made models are also popular and in demand in the domestic market. The devices from the well-known companies Expostroymash Plus and Nikirat are in no way inferior to imported counterparts in their performance characteristics, have a lot of positive feedback and are well bought not only in Russia, but also in neighboring countries. Consumers note the high adaptability of the devices to the Siberian frosts and the possibility of using devices in almost all regions of the country. In addition, there are Russian closers much cheaper than European counterparts, which makes them even more popular and in demand.

Installation

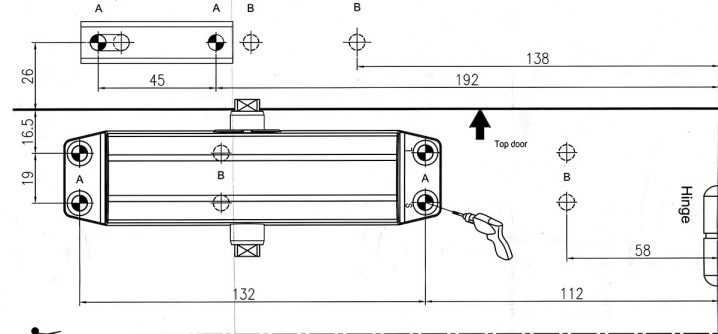

Installation of hidden closers, as well as models on the sliding rod should be done by professionals. Such work requires professional tools and appropriate skills; therefore, self-assembly in the absence of experience can lead to damage to the door and improper installation of the device. However, the overhead devices with a lever arrangement is quite possible to install it yourself. To do this, you must carefully read the instructions and clearly follow each item of the manual, and a few simple recommendations will help to carry out the installation quickly and correctly.

The first step is to stick a diagram on the door (it is usually included in the kit), and in the right places drill holes of a certain diameter. Then, in accordance with the instructions, it is necessary to bait the case on the fasteners, and then tighten the hardware one by one. Drag fasteners highly undesirable. This can lead to the breaking of the thread of the screws and their scrolling. In some cases it is required to replace the self-tapping screws on the kit with more powerful models, and when installing the door closers with plastic doors, it is even possible to replace the screws with screws. In this case, the hardware will have to pass through the fabric and fastened on the reverse side with nuts, wide washers or fixing plates. Otherwise, the screws can simply tear out of the hollow plastic sheet, which will ruin the door.

After the mechanism is fixed, you can proceed to the collection of lever thrust, consisting of two parts connected by thread. The lever is adjusted in length, connecting its halves and exposing a right angle. If you strictly follow the attached scheme, then the difficulties with installation will not arise and the installation of the closer will be quick and easy.

Adjustment

After the closer is installed, it must be adjusted. The method of adjustment depends on the location of the adjusting screws, which can be located both from the end of the case and inside it. Usually, the screws are designated by numbers 1 and 2, where the “unit” is responsible for changing the opening angle of the door relative to the box, which can reach 180 degrees, and the “two” is responsible for the speed with which the door will close. The first is to adjust the opening angle. To do this, set the desired value, which can vary from 90 to 180 degrees, and then proceed to the regulation of the speed of movement of the canvas.

It is made this way: the door is opened at the maximum possible angle that has just been set, and released. At this time, begin to tighten the second screw, achieving a smooth running and stable closing. Usually, the mechanism responds very sensitively to a change in the position of the adjusting screws, after turning it by only a quarter of the canvas, it begins to close very slowly. Some closers have a door lock function, so when adjusting such models, you will need to adjust the lock point when the door is open.

Malfunction rules

Proper installation and correct adjustment allow you to use the door closer for a long time, however, in order for the device to last as long as possible, you need to follow a number of simple recommendations. So, you should not leave the door with the connected door for a long time open. This leads to additional loads on the seals and pistons and contributes to the extrusion of oil from the cylinders. As a result, a quick failure of the device and the need for repair, and sometimes a complete replacement of the device. The exception is hidden floor models, the device of which involves fixing the door in the open position for a long time.

In addition, it is necessary to take into account the change in viscosity of the oil depending on the season. So in the summer months it becomes less viscous and the speed of closing the door increases markedly, in winter, on the contrary, the oil thickens and the door leaf begins to close very slowly. As a result, the room carries significant heat loss and a working closer brings more inconvenience than good. In this regard, it is necessary to monitor the level of oil viscosity and make seasonal adjustment of the speed of closing the door.It is also necessary to regularly lubricate moving parts and ensure that no water gets on the device. Otherwise, the device will quickly rust and become useless.

With careful use and timely service, door closers can last for many years, protecting the door and locking mechanisms from shock loads and greatly increasing the usability of door systems.

How to install door closers with their own hands, see the next video.