Features of the manufacture of wooden doors

Wood is a universal natural material that is used in many areas of modern life. One of the uses of wood is the manufacture of doors. Designs of this substance are durable and sophisticated. It is possible to make such a product independently, but it is important to preliminarily clarify the specifics of the manufacture of a wooden door.

How to make yourself?

The wooden door is a canvas of boards or timber. It is quite possible to make such a construction with your own hands. Before you start making the door leaf, you should stock up with several tools:

- Saw. With its help pruning boards. The best option would be a circular circular saw, which will allow to obtain high-quality and smooth cutting.If this is not, then you can use a hand tool with fine teeth.

- Bulgarian and several types of grinding wheels. Technically polishing home-made products can be done manually, but it is long and inefficient.

- Drill and drills of various sizes. This will allow you to quickly and accurately form the holes of the desired size. In some cases, you may need a screwdriver and screws.

- Milling machine. If the production of the door is done at home, then the manual version will suit you.

- Wood. The type and size of material depends on the specific characteristics of the door you plan to receive. In some cases, use standard boards, and sometimes thick bars.

- Joiner's glue. This substance is used to connect individual boards into a solid and durable system.

From the array

These are the most common options for door leafs. They differ in the use of solid boards, which are interconnected in one design. Step-by-step instructions for the manufacture of solid doors of doors involves the implementation of such sequential operations:

- Initially, cutting boards is performed on individual sizes.Their length should be slightly larger than the doorway. It is necessary in the future to be able to adjust the dimensions more accurately.

- After that, all boards are carefully polished from all sides. Particular attention should be paid to the ends, which should be smooth.

- When all is well, all the elements are glued together. To do this, they are located on a flat sheet of chipboard. Each end is smeared with glue and fits in with the previous one. To fix the entire shield, use clamps, which he clamped.

- After the glue dries, they start the decorative processing of the door leaf. It is thoroughly polished. If you want to create a unique door, then it can be supplemented with carvings or decorative overlays.

- The final stage is the tie-in of the lock and the installation of hinges.

There is a simpler design of this type. It is also made of several planks, but they are already connected in transverse bars. In addition, each element is screwed to the transverse slats, which will allow to obtain a reliable design. To prevent such a door from tilting, another horizontal bar is fastened between the horizontal bars.

But such structures are used as entrance doors in sheds or household premises, as they do not retain heat and over time lose their aesthetics.

Paneled

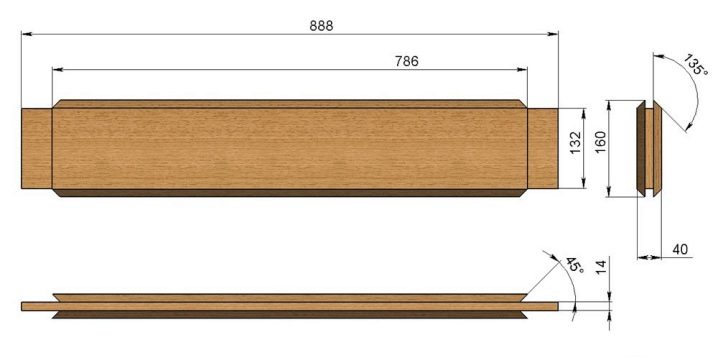

The peculiarity of such doors is that they are assembled from individual boards or bars, and the middle is filled with their thinner versions, glass or plywood. The manufacturing technology of the framed door involves the following operations:

- First of all, you need to cut the blanks for the frame from boards or timber. This design consists of a rectangular canvas, within which there are only partitions, and everything else is filled with other components.

- When the blanks are ready, they are also carefully ground and leveled. Perform such operations only with a dry tree in a dry and warm room. In another case, the tree can get moisture, and then change shape.

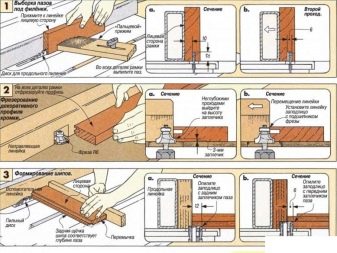

- Next on each board cut grooves. Note that some elements have a spike and the second depressions. This allows you to form a thorn-groove connection. Similarly, from boards form a rectangular frame. It is important to carefully adjust all elements.At this stage, it is also important to cut a slot under the lock.

- After the frame is made, its interior is filled with thinner boards or glass. For this purpose, grooves for these elements are formed on the support boards using a milling cutter and they are also carefully customized. If glass is used, then you need to cut it to the size of the internal opening. It is fixed with the help of wooden beadings from the same tree.

- The procedure ends with the assembly of the entire web and its gluing. To do this, also use a special glue. Boards between themselves are also in a special grip. When the mixture is dry, the canvas is sanded and the glass is installed (if necessary), and then the entire surface is varnished.

Panel doors are complex designs that require a lot of manual work. It is not always possible to make such a product from the first time, since this requires skill and experience in working with various types of wood. These types of door panels are often used as interior elements of the interior.

Another option for wooden doors are panel products. These are the cheapest and simplest designs.To get a similar product, knock down the wooden frame of the timber. After that, its inside is filled with paper or thin strips of wood. Outwardly, all this is sheathed with MDF or particle board.

Products of this type are characterized by simplicity and low strength.

Materials

Technical characteristics of a wooden door depend not only on the production technology, but also on the materials used for this. Today, for such purposes use a variety of different substances:

- Natural array. It is represented by planks and bars, of which then form the frame and all the other elements of the door leaf.

- Decoration Materials. This includes all products obtained from waste wood (veneer, chipboard, etc.). For example, doors are covered with plywood, which reduces the weight of the entire canvas.

- Decorative items. Very often, the door leaf is decorated with a variety of inserts. They are made in most cases from various types of glass or plastic.

But special attention in the construction of wooden doors should be given to the choice of wood species. Today, for these purposes use several types of wood:

- Oak.Differs in durability and durability, and its structure has noble shades. But with a constant change in humidity, oak doors lose their ability to retain heat. Therefore, it is desirable to use them only as interior.

- Ash. The breed also has quality indicators of strength, which are even slightly higher than that of oak. The color shades of this breed can be varied - from pinkish to brown.

- Larch. This type of tree is not afraid of mold, and also does not give in to rotting. On the market there are several types of boards of various species of this wood. One of the disadvantages of larch products is their great weight. Often they are used in a rustic style in a log house.

- Pine. The door of it is the warmest, as this wood has a high thermal insulation. But the designs of pine are not durable and therefore are among the cheapest. To improve this figure, many manufacturers may coat sheets with oak or other hard wood veneer.

- The Red tree. Under this name is hidden several types of wood, such as meranti, nyato, teak, etc.Doors of this material have good strength, since wood has a high density of fibers. The disadvantage of such products is their high price, which is affordable only for a certain category of the population.

What if the wood is swollen?

Many novice joiners in the manufacture of the door using wet boards or perform these operations in a wet room. In this case, the wood picks up moisture and begins to increase in size, which will lead to the unsuitability in the future of the door leaf itself. Therefore, before starting work you need be sure to dry the boards thoroughly, but without using powerful hair dryers.

The best option would be a special drying or fresh air (in the shade).

If the door begins to swell after its installation, then this situation can be corrected in several ways:

- First of all, you need to create a normal temperature and minimum humidity in the room. After some time the boards can dry out and “return” to their place.

- If the design is not restored, then you should try to reinstall or adjust the hinges so that the web easily enters the box.

- The most common option is to change its shape using a planer. For this, the place where the canvas does not close, is pushed a little. Sometimes it is possible to perform such an operation not only with the door, but also with the box itself. But it is desirable to remove the minimum layer, since the wood may eventually shrivel and gaps form in these places.

- Forced drying of the door leaf. But you need to perform this operation only at low temperatures and for a long time. If this is done abruptly, then cracks will simply appear on the boards and the door will become unusable.

Processing options

Wood is not a unique material and has many drawbacks. To get rid of them, wooden doors in the manufacture process in various ways:

- Painting. The most common finish. Both ordinary enamels and clear varnishes are used here. To prevent rotting, the material can additionally be impregnated with special compounds. The technology of their application is quite simple and requires only a uniform distribution of the mixture on the surface of the door. To do this, use conventional rollers, brushes or spray guns.

- Decorating decorative panels. Today it is possible to change the design of the door leaf using veneer. Sheets of this product are made of various wood species. This allows you to give cheaper designs a more noble look. Sheets can be applied both on the sheet itself and on the cashing.

- Warming. A similar approach is used if the doors are placed directly on the street. Insulated structure is able to withstand cold weather, while maintaining the original characteristics. Insulation on the door leaf is applied on top. To do this, on its surface construct a frame of wooden slats. After that, mineral wool, foam or other similar material is placed inside. It is attached with liquid nails. Externally, the system is sheathed with boards or metal, which form a one-piece construction.

The simplest option of warming can be a layer of foam rubber, which is nailed to the door. From above it is sheathed with natural leather or other similar fabrics. In order to keep the canvas attractive, special furniture decorative nails are used.

How to seal the gap?

The gaps in the wooden door are formed in various places, which can lead to the formation of drafts. If these are cracks, then you can try to seal them with different compositions:

- Grout. Apply only to thin layers. In large gaps, they will crumble over time.

- Sealant. One of the most optimal options that is suitable for sealing any types of cracks and crevices. They need to fill consistently to give the opportunity to grab each layer.

If the gap appeared between the box and the door itself, then you can fix it with seals. They are placed on one of these elements so that a seal is formed during closing.

If the number of cracks on the canvas is large, you can reinforce it with a metal sheet, which closes all these shortcomings.

Successful examples and options

The unusual sliding door from a single piece of an array looks very original and harmonizes well with the “aged” wooden floor, but this idea is unlikely to be repeated often.

Dark brown doors in the same style - double-leaf and single-leaf, dilute the white color of the interior, the table and floor vases help them.

The door with a supposedly untreated surface and glass inserts is specially selected for the general style of the room and therefore looks very organic.

How to make a wooden door, see the next video.