Do-it-yourself coupe door installation

To protect one space from another, doors were invented. Many of the designs on the market today can satisfy the needs of any, even the most demanding customer. But there are designs that do not give up their leading position for a long time. These include compartment doors. You can install such doors with your own hands, the main thing is to study their features, types and methods of installation.

Special features

Coupe doors are sliding constructions that have their own characteristics that need to be studied before you start installing the doors yourself.

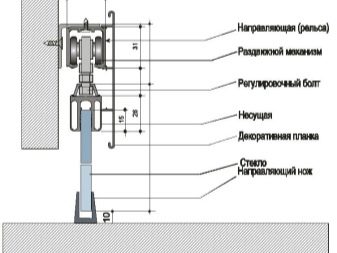

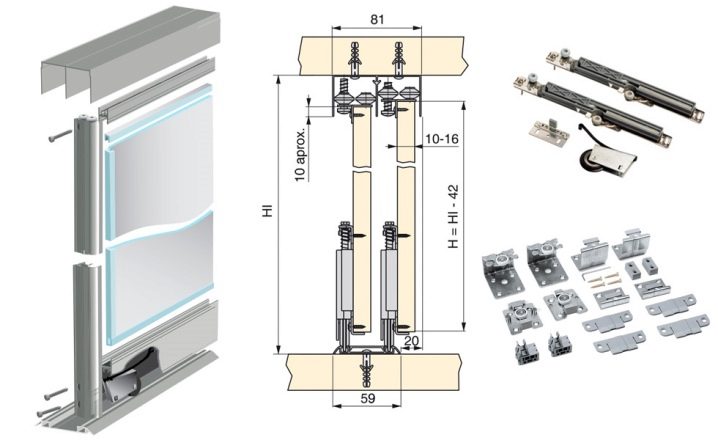

The compartment doors have a simple construction consisting of a door leaf, a roller mechanism and guides.The door leaf moves with the help of rollers along the profile, in which stoppers are installed on each side, limiting the movement of the doors to the set points.

Without a doubt, this design is in great demand, as it has advantages over hinged doors.

Due to the peculiarities of the mounting, the door leaf always moves parallel to the wall, and some models roll back into the built-up niche, therefore there is no dead zone in the corner. Any room with installed compartment doors is visually perceived more spacious than with hinged structures.

The door of the compartment does not just open due to the sudden rush of a draft and it is impossible for her to accidentally pinch a finger, which is important for families with small children.

The design of door panels is very diverse. You can buy a finished canvas, and you can make it yourself. A homemade design will look no worse than the purchased copy. And the installation of compartment doors is not complicated. If desired, the availability of the necessary tools and correctly made measurements even a non-professional will cope with it.

Kinds

There is a classification of compartment doors, due to which they are divided into different types. The classification depends on the place and method of installation, the design and number of door panels.

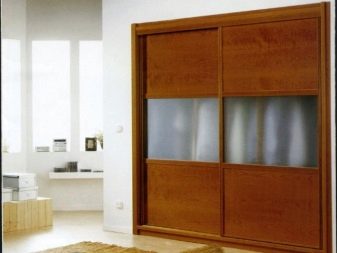

Coupe doors are used in different places. They are installed in doorways in the kitchen, room, toilet or bathroom. With their help, enclose the space, separating one area from another.

Coupe doors are installed in niches using this storage space.

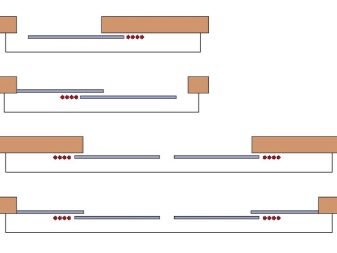

Most often, sliding doors in the home are placed between two rooms. They can move along the wall and have an open structure, or they can be embedded in a niche, and when opened, completely hide inside it. Hidden design requires the installation of the frame and other significant repairs that are carried out before mounting the door.

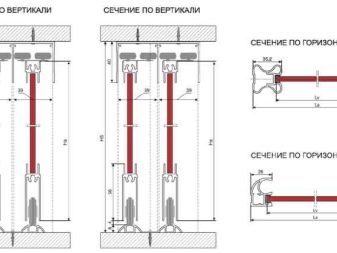

The compartment door is also used in cabinets. Furniture designs have their own specifics. As a rule, such a door moves along two guides and has two pairs of rollers. Some are located at the bottom of the door leaf, and others at the top. Interior compartment doors, in contrast to furniture options, often have one guide - the top one. In this design, it performs two functions: holding the door leaf and providing movement.

In the dressing room you can install any design. It all depends on the area of the enclosed space and the desire of the owners. The surface of the door leaf in the dressing room, as a rule, mirror.

Very often, a dressing room or a wardrobe may have an irregular shape. Then install the door, having a non-standard radius shape. Smoothness of corners and a peculiar curvature of a cloth are characteristic for radial doors. Fixation and movement of unusual doors is carried out along two guides, having the same curved shape and installed both in the upper part and in the lower part.

Materials

To make compartment doors with your own hands, you need to purchase the appropriate materials and choose the design of the door leaf, which can be solid (shield) or panel, consisting of different materials and supported by the frame.

For the manufacture of paintings, you can use solid wood. The choice of breed depends on your preference. Pine is most often used, and the surface is covered with veneer of more valuable species. Both solid canvas and variously shaped panels are made of solid wood.You can use wood as a frame.

When working with solid wood is required not only accuracy and accuracy, but also quite a lot of experience.

A good alternative to solid wood is plywood, which has many advantages. Unlike solid wood, it is much easier to work with. She bends, and therefore to give it the desired shape is not difficult. Plywood doors are resistant to temperature changes, exposure to sunlight, moisture, synthetic detergents. Practical and durable plywood is often used for the manufacture of door panels, not only because of its positive qualities, but also because of a reasonable price.

Slightly lower cost of chipboard, which is also used for the manufacture of door panels. The surface of this material may be covered with film or veneer. When working with chipboard, you must remember that the edge should always be closed, regardless of whether the solid canvas will be used to make a door or a panel, or not. The disadvantage of this material is the presence of harmful resins that are released into the surrounding space when exposed to certain factors.

Glass is also used as a material for the manufacture of door panels. It can be used as a solid canvas, as well as inserts in combination with panels of other materials. The surface of the glass paintings can be decorated with sandblasting, photo printing or engraving.

Instead of glass for the manufacture of the door leaf, you can use lightweight and durable polycarbonate. The doors of it have flexibility, and therefore they are often the basis of radial structures. This material is fire resistant and has a fairly long service life.

As the door leaf is used and the mirror, installed as a separate canvas, and in combination with other materials.

How to calculate the size?

Correct installation requires a thorough preparation, which includes proper measurement of the opening. From the obtained results will depend on the dimensions of the canvas, the method of installation and the number of paintings.

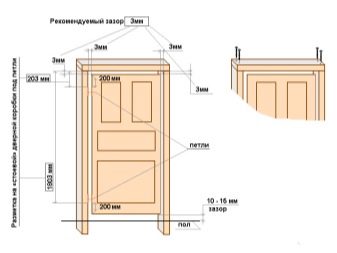

Measurement must start from the height of the opening. Dimensioning is done at several points in increments of approximately 70 cm. As a rule, the measurement is done in the center of the opening, as well as on the left and right side.Height difference should be no more than 15 mm. The minimum value is taken as the base value.

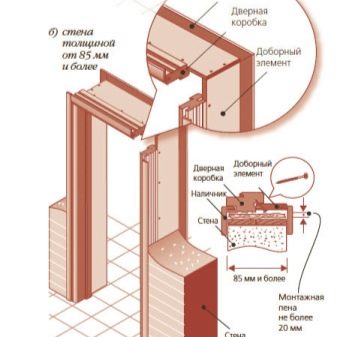

The width is also measured at several points.. Here the main value is the maximum value. Delta should be no more than 20 mm. Similarly, you need to measure the depth of the aperture. This value is required when making the opening box.

If the width of the door opening does not exceed 110 cm, then, as a rule, one door leaf is required, but if it is larger, then you will have to install two doors. The optimal width of the door leaf is in the range of 55-90 cm. Its dimensions should exceed the size of the opening by 50-70 mm.

In addition to measuring the height, width and depth of the aperture, you need to determine the distance from the aperture to the corners (with open installation method). This measurement is necessary to understand whether there will be enough space when moving the door leaf.

The height of the door leaf depends not only on the height of the opening, but also on the method of installation of the mechanism. It can be attached to a bar or a special profile. Profile or timber with compartment mechanism attached directly above the opening or to the ceiling surface.The height of the leaf also depends on the location of the lower guide and the presence or absence of rollers in the lower part of the door leaf.

How to make at home?

In order to make a door structure with your own hands, it is necessary to first determine the material of the door and its structure.

If glass or plastic is planned as a canvas, then it is better to order a ready-made sash, since it will be rather difficult to prepare these materials yourself. Handles and profile frames must be purchased according to the size of the door leaf. Both materials are best suited for installation in the bathroom.

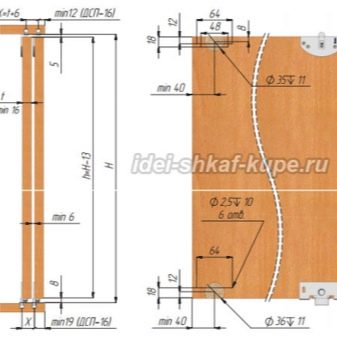

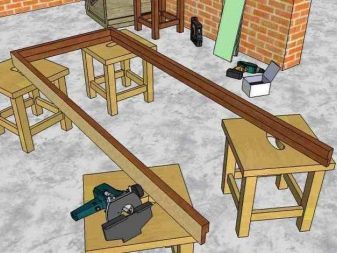

The easiest way to do it yourself is to make the door leaf from untreated MDF or natural wood. For this we need a number of tools: miter saw, drill, mill (for grooves). You will also need to purchase additional materials: lacquer, miter tape, PVC film or veneer to cover the surface, sandpaper in the absence of a grinder. If desired, you can order a finished canvas of the desired size.

First, the canvas is cut to the desired size, and then polished ends.After you can cut a hole for the handle, after making a mark on the canvas. If you plan to install a suspension system, you need to make a groove in the lower part of the canvas, and mark the roller mechanism in the upper part and drill the holes.

Now you need to clean the door leaf from dust. If the work is done with wood, the surface is first treated with impregnation from rotting, and only then varnished. If MDF is processed, then a film or veneer is applied to its surface, which, if desired, can be treated with varnish.

For processing ends use tape. On its inner surface is a special composition, which is activated when heated. It should be attached to the outer ends and iron smooth around the perimeter. The remains of glue are cleaned with sandpaper.

For the combined filling of the door leaf, you can use a combination of a variety of materials. In order to put together all the parts, you will need special profiles that can be purchased at any hardware store. In addition, the need profiles profiles.

Horizontal profiles designed to hold the inserts are cut according to the width of the web, taking into account the width of the handle. Now you can begin to build the web of inserts. If glass or a mirror is used in their quality, then it is necessary to purchase a silicone sealant used to protect the ends. On the inside of the mirror, it is desirable to apply a special film. In the case of breaking the mirror surface, it will not allow the fragments to scatter in different directions.

In order to attach the handle to the inserts you need to make holes in its top and bottom. Two through holes are drilled at the top, and 4 holes at the bottom. The diameter of the holes located on the surface of the handle must be larger than the diameter of the holes located under them. In the upper part of the handle, the holes are drilled with an indent of 7 mm. At the bottom, the first pair is drilled with the same indentation, and the second pair should be located at least 42 mm from the edge.

Now you can begin to build the canvas. Prepared canvases are inserted into profiles. To do this, set the canvas with the end, apply the profile to it and, using a mallet, tapping gently, insert the canvas into the profile groove. We do the same with the other profiles.

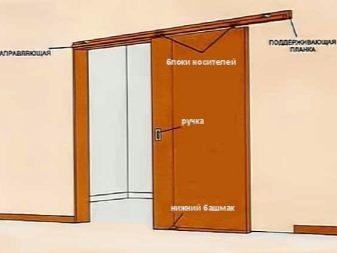

Before installing the door leaf between the rooms, you need to install the box, add-ons (if the box is already open) and prepare the trim. It is better to install them after mounting the door. The design itself is mounted above the doorway with fastening to the wall.

In the drywall wall, the installation of the canvas is made on a metal frame, which must be installed at the repair stage. First, the frame is installed, then the door is mounted, and only then the plasterboard is covered.

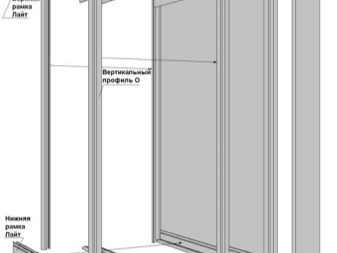

Despite the fact that the system of compartment doors have some differences, the principle of operation and installation remain about the same. Therefore, the step-by-step installation instructions look almost the same for both the hinged system and the system with the lower support.

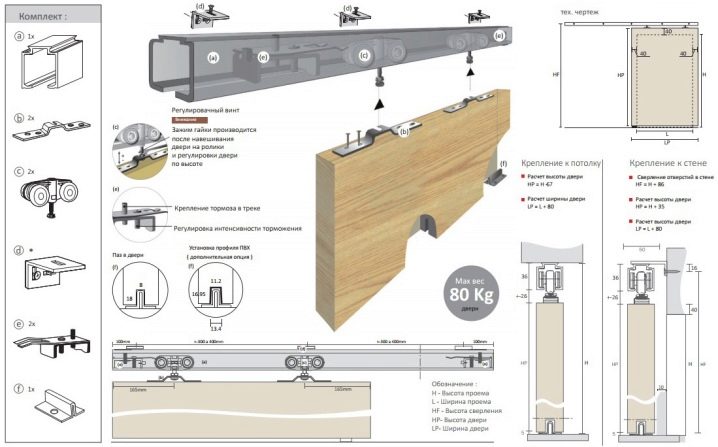

To install the door leaf will need a wooden beam. Its length should be 4 times the width of the web. This is necessary for the free divergence of the doors in different directions.

Installation of the door begins with the mounting bar or a special profile. To the timber with screws, a rail prepared in advance is attached. This prepared structure can be attached either to the wall, or to the ceiling, or to a metal frame. Mounting method depends on the installation site.When installing a door in a niche, the beam is fixed to the ceiling, in the partition it is fixed to the frame, and the wall mounting method is suitable for interior doorways.

For proper fixing on the wall, the canvas is first put in the opening and made a mark, it is indented upwards by 7 cm and a horizontal line is drawn. The prepared timber is screwed to the wall using self-tapping screws strictly horizontally relative to the opening. You can check the position of the beam with the profile using the building level.

The prepared cloth with rollers is put on the rail. The ends of the profile is covered with rubber shock absorbers. In order for the door to move smoothly along a precisely defined path, a flag stopper is installed on the floor.

An open system that provides door movement can be covered with a decorative panel.

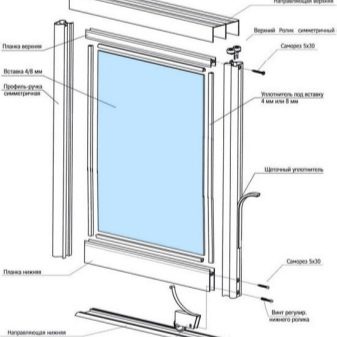

To install a sliding door with a lower support, in addition to the upper rail, a lower profile is installed. The stoppers in this case are located in the lower profile. To install the door, you must first get the upper part of the blade into the upper guide, and then, pressing the lower rollers, install the lower part of the blade on the rail.

Accessories

To date, there is a huge selection of components for the installation of the door-coupe with their own hands.

To install the system with the lower support, you need to purchase a set of guides and rollers, corresponding to the weight and thickness of the installed sashes, handles, a pair of stoppers for each blade, installed in the grooves of the lower guide, and if you want you can buy closers.

For the suspension system, it is enough to choose the upper guide, a pair of rollers mounted on different ends of the web, a pair of flag stops and a handle for the leaflets.

There are some differences between parts designed for a suspension and support system. The upper rail of the suspension system, as a rule, is made in the shape of the letter “P” and contributes not only to the sliding of the canvas, but also keeps it in weight. It accounts for the main load.

As a rule, aluminum is the material of manufacture, but there are pipe-shaped models made of steel. The upper track in the form of a pipe cannot be closed with a false panel, their shape and appearance are an additional decor for the room.

In the support system, the top guide has the shape of a double letter “P” and does not carry the main load. Its function is to maintain the sash in an upright position. The main load in the support system falls on the lower rail. This profile has two parallel gutters intended for the movement of rollers.

Each system has its own set of rollers and stoppers.

Successful examples in the interior

Coupe doors are a universal solution for any room. With their help, you can turn any niche into a comfortable and very functional dressing room. Thanks to them, a big opening looks just great, with the hinged door does not achieve this effect. Without them, not a single built-in wardrobe. The compartment doors help to beautifully and effectively separate one room from another.

See how to install coupe doors by yourself in the next video.