MDF door covers: design features

The desire to protect the home from unauthorized entry into your territory is completely natural. The front door must be reliable and durable. Sturdy metal doors for many decades do not lose their relevance. But if before the appearance of the door was not given due attention, then now every owner seeks to give respect to the entrance to his home respectability and refinement. First of all, the door is the face of the house, the beauty and dignity of the finish of which tells about the taste of the owner.

Special features

Nowadays, it is quite popular to veneer doors with decorative panels.

Covers are made of:

- MDF;

- wood;

- plywood;

- plastic.

MDF panels are widely distributed among consumers, they also have proven to be a beautiful and reliable material.

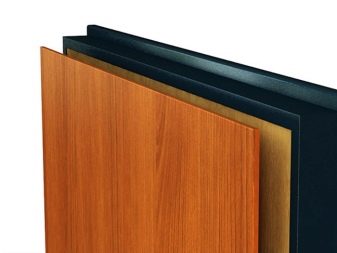

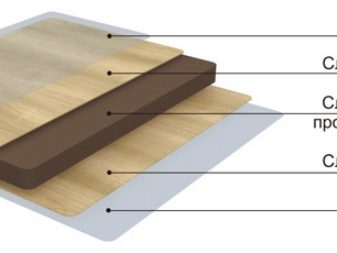

MDF is a fibreboard produced by pressing medium density. If it is simpler, it is crushed sawdust and shavings soaked in resin. Hence the name - the fine fraction, abbreviated MDF. The result is a fairly solid stove.

In the manufacture of linings for doors need a few of these tiles. If an insulating material is laid between them, a panel with enhanced thermal protection properties is obtained.

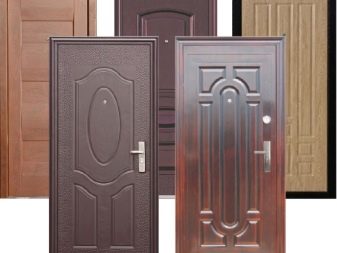

Such linings are called thermopanels and are used mainly for trimming entrance doors, as they help to keep the temperature in the home at a certain level. MDF panels are installed on both entrance and interior doors. They are reveted not only with new, newly installed doors, but also decorate old ones that have lost their appearance. With overlays from MDF it is easy to hide external damages on the door, as well as give it a respectable, refined look.

Properties

No wonder why this material is so popular.

It has such important properties as:

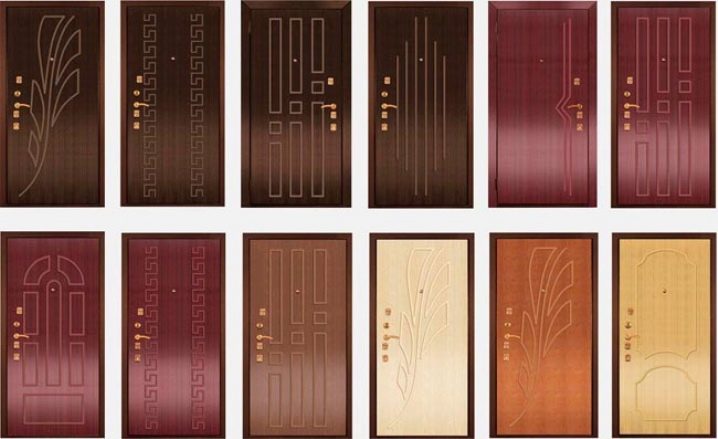

- Beauty. The main advantage of MDF panels is that their coating allows you to simulate any wood species and texture. In addition, a wide choice of colors, from standard, woody to exclusive bright, makes them especially popular among consumers.

- MDF - pretty easy-to-work stuff, it is soft and plastic, which allows you to perform on it absolutely any patterns and ornaments. Milling is very popular now. The surface of the slab is milled before the application of the laminating film or painting.

This makes it possible to put on the plate a relief image, from lines and the simplest geometrical ornaments to the most complex flowery paintings. Embossing is also common.

- Damage resistance and long service life. The material is able to withstand physical stress and damage. Does not fade under the influence of sunlight.

- Fire resistance and moisture resistance. Unlike its fellow - chipboard, does not swell from moisture and does not lose its appearance.

- Soundproofing. The possibility of using mineral wool and other insulating materials improves the insulating properties of the door

- The plating work is not time consuming and expensive.

- Low cost.

At the same time, these panels are made of any sizes at the request of the customer, from typical classical, to non-standard, having exclusive sizes. Decorating a beautiful panel of MDF will easily give the front view of any entrance door.

Kinds

There are several types of manufacturing MDF panels and each of them has certain properties, which significantly affects the place of their further installation.

Laminated

Laminated MDF. The plate is coated with a PVC film laminate. This technology allows you to simulate any texture, although there is a smooth version of the coating. Due to milling, color inserts and mirrors, this type of MDF is very much appreciated by the consumer. The high strength of the material allows it to be used for decades.

Shponirovany

Veneered. Due to the manufacturing technology, in which the surface of the plate is covered with a thin saw cut of natural wood, this type of MDF is the most beautiful in appearance and most natural looking.

The surface obtained with this method of manufacture imitates wood not only in color but also in structure.

Its popularity is due to the noble appearance.The panels covered with an ekoshpon, are suitable for entrance apartment and street doors as on resistance to damages concede only laminated.

Colored

Colored. This type of MDF is suitable for finishing both interior and exterior doors. The surface of the plate is covered with a special paint that is resistant to sunlight and mechanical damage.

Laminate

Coated with laminated plastic MDF. The so-called anti-vandal coating. The most durable coating that can withstand not only UV rays, shocks, but also the effects of chemicals. This coating is considered to be almost perfect in terms of resistance to physical stress. In addition, this coating is the most moisture-resistant, relative to the rest.

DIY restoration

The process of restoration of the door with decorative plates is not that complicated. But small skills with tools will not be superfluous.

First you need to decide on the colors and design, so that your updated door is in harmony with the facade of your home, if you arrange the main entrance. For the correct selection of the top cover is important not to forget about the climatic conditions.When restoring or updating the inner door, it is important that it harmoniously fit into the interior style.

Door cover can be bought ready, however, now the price for individuality of design and housing.

A rich selection of colors, textures and design will allow you to create a panel to your taste, according to your individual project.

For independent work on the door trim panels you need the tools and materials:

- drill;

- screwdriver;

- self-tapping screws;

- glue or liquid nails;

- sandpaper;

- end profile;

- roulette;

- clamps.

Paneling procedure

Before starting the trim it is necessary to remove the door from the hinges, dismantling the accessories, and put them on a flat surface. It is not recommended to carry out all manipulations on weight in order to avoid distortions. If you are replacing the old coating, completely remove it.

Next, you need to sand the entire surface of the canvas. If the door is iron, it is recommended to paint or paste over the vinyl film for a perfect fit of the panel to the door. If the door is wooden, then it is necessary to remove the old paint layer and carefully clean the entire surface.

On the doors it is necessary to outline the places of future fittings, and also to transfer these marks on the panels and drill holes.

Start from the inside of the door. The surface of the door is coated with special glue or liquid nails. The adhesive is applied with waves and the panel is laid. It is important to press it as much as possible. To do this, use clamps or clamps.

Throughout the area, holes are drilled from the outside, with a step of 40 cm. With their help, they will be mounted on self-tapping screws. It is important to choose screws of such length that they do not pass through the lining and do not spoil the decor. Screw them through right into the trim and remove the clips.

Next to install the outer panel. Adhesive composition will need a little more than in the case of an internal card. Fix the panel with clips. Further, the only difference is that it is necessary to drill holes along the perimeter, as close as possible to the edge, in 10-12 cm increments. Screw the screws and remove the clamps.

We close the ends with a decorative corner in the tone of the door, this will hide the caps of the screws. To do this, measure the pagonage door and cut off the necessary slats from the end profile.We install all the fittings and the lock on the door. Hang the door on the hinges.

In the same way we make out and the opening.

When upholstering the door panels of interior doors, several issues arise that will have to be resolved.

Due to the thickness of the lining on both sides, the thickness of the door itself changes. Hinges, as well as the latch will no longer fall into place.

Fittings just have to change, and with them the whole box, as the door will no longer properly "sit" in the door unit.

True, there is an option to install lining with a minimum thickness. These are panels with a thickness of 2-3 mm, but they do not differ in durability and strength. Such panels quickly fail.

If in the process of updating the door you have a question about whether to update the doorway, definitely worth it. Ideal fit the same MDF panels that sheathed the door. The ideal solution would be to perform the slopes and trim from the same material as the door itself. So, the updated door unit will look neat and harmonious.

To update the doorway, it is necessary to inspect it for cracks and crevices and, if they exist, to carry out concrete work.

Then on the surface of the guides are mounted wooden slats. Their installation is carried out using the level. Get the perfect edge when attaching panels can only be using a decorative corner. In order to make the platband as close as possible to the wall, we apply it to the wall and determine the thickness of the gap. If necessary, the corner can be cut and precisely adjusted to the wall.

The first is adjusted and installed with the help of small studs upper slope. Fasten it to the top frame. Then we make measurements to install the slope on the left side. We measure the length from the upper slope to the floor, and the width from the door frame to the outer corners, upper and lower. The slope is fastened with screws, and at the door frame it is better to use small carnations. At the end of this place will be covered with a plank. Then you need to use the grout or putty to eliminate the gaps between the slopes. It remains to attach the trim. We select them in the color of our door.

Below you can see how the restoration / replacement of MDF door panels.