Making metal doors with your own hands

The choice of metal doors on the market is large enough, and everyone can choose the best offer for themselves. But often the high cost of factory products scares away, and its developers cannot predetermine all the needs of the buyer. In addition, the custom-made design of a unique geometric shape or the use of atypical materials can result in a significant increase in costs and time. With independent production, you can be more than ever sure of the quality and perfection of the door you create.

With the availability of suitable materials and tools and at least minimal skills in handling them, you can prepare a good metal door fairly quickly. The main thing is to strictly observe the sequence of technological operations and the requirements for each of them.

Special features

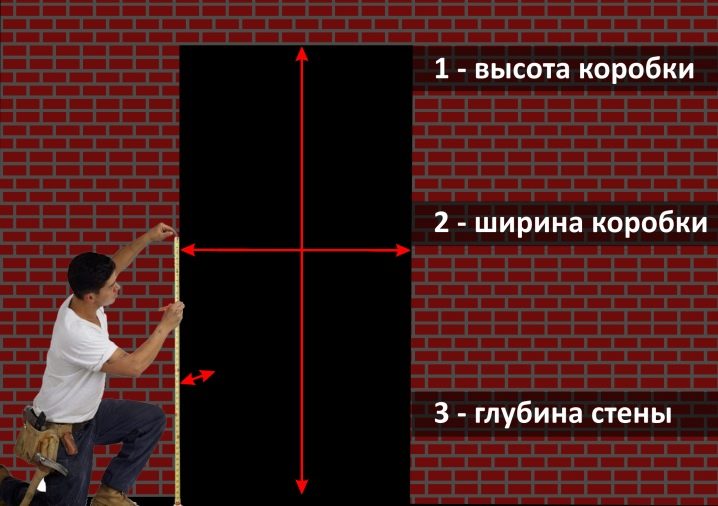

The manufacture of a metal door frame begins only after measurements. A gap of 2 cm is always left on all sides so that the box easily and freely enters the opening. From the canvas to the box, gaps are also needed, and the sheet of metal should slightly go to the edges of the frame. The weld should not be longer than 4 cmAt the same time, at least five joints should fall on each meter. To make loops, you need to take a metal rod with a diameter of 2 cm, which is welded to the box on the one hand, to the canvas with the other. A prerequisite for success and long service homemade door acts careful anti-corrosion treatment.

The choice of materials for the skin and its features vary very widely, in fact, you are limited only by your own stylistic preferences.

How to do it: a step by step process

Assembling a metal door with your own hands will necessarily require the use of:

- Steel sheet (thickness not less than 1.5 mm);

- Metal corner;

- Loops (how many they need, determines the strength of a single loop and the mass of the block);

- Lock, handle and other accessories;

- Surface cladding material;

- Polyurethane foam;

- Anchor bolts and electric drill;

- Welding equipment;

- Welding table;

- Assembly goats;

- Angle grinders with disc on metal.

But this list is only approximate and preliminary, it can be modified and refined depending on which entrance door you need. High reliability ensured only with thick steel sheet or sandwich option, that is, a pair of sheets separated by a warming material.

Iron door must do by exact size. Standard openings in width reach 80-90 cm, in height - 200 cm.

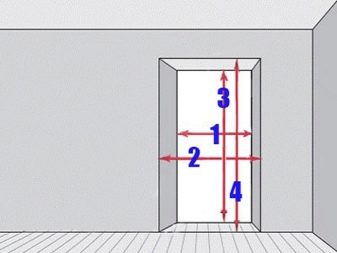

In order to completely eliminate errors in measurement, it is necessary to reach the very foundation of the walls, knocking over layers of decorative coatings on a certain part of them. Or make a cut through the vertical platband with a hammer and chisel. You need to measure on each of the four sides, both inside and outside.

Leaving a gap of 2 cm, do not be afraid - it will help correct the skew of the opening, and when the need for adjustment disappears, it is easily closed with mounting foam. Strictly under the dimensions of the box, they cut a corner, put it on any rectangular plane, ideally on the welding table.If you use goats as a stand, do not forget to check their geometry. Only under the condition that the lengths of the diagonals coincide with each other, can the corners be welded.

In most cases, it is enough to create a construction made of a professional pipe of 1.5 mm or a equal angle of 45x3 mm - a thicker structure will not become genuinely armored anyway, but it will be prohibitively heavy. With a low level of welding skill is to buy a sheet of 0.2 cm, the risk of burning it will be less.

Further, in the profile with the help of the grinder, a cutout is made under the lock. In the frame you need to hammer in wooden slats of a certain length, this will then allow to simplify the lining of the structure. A loop block made of metal profile is welded to the hinges and the box, making the rest of the welding work much easier. Pay attention to the accuracy of the measurements between the loops, they must be the same on the boxes and on the frames, otherwise the installation of the door at the entrance to the apartment will be too complicated.

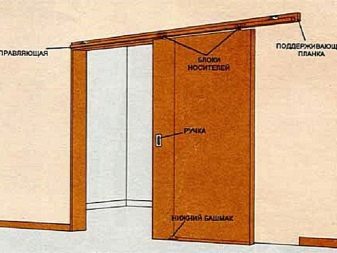

Making sliding doors is not much more difficult than ordinary ones. This solution will save a lot of precious space in small-sized housing.Classic sliding system (coupe) can be suspended, cassette; Some options are equipped with upper and lower guides. It is the latter type that should be recommended to those who do the work themselves, because it is more reliable than others. But you will need to take care about the correct setting and fixing details.

Clearances should be as minimal as possible; fitting should be as accurate as possible. At the bottom they make a threshold or indentation, so that the rail can be mounted.

It will take a lot of time to spend on cleaning the guide, otherwise under the action of small rubbish it will quickly become clogged with dirt and break down.

Suspended systems can be attached to the upper part of the doorway or to the ceiling itself, depending on how high the door and the room are. The canvas in this version is 1-1.5 cm from the wall, and no piece of furniture will be put into this space. False panels masking the upper rails can be installed both on the section along which the door is moving and on the entire span from one wall to another. More time-consuming, but also more interesting from a design point of view option is the placement of a “curb” onperimeter of the room. Such a decision will have to be abandoned if it is not possible to place the guide high enough.

The cassette door can be made if a special design (niche) into which the canvas should be removed is initially provided when creating walls or partitions. You can use the additional drywall unit, but it will absorb 10-12 cm of room space. When in the first place a tight fit of the end of the door when closing and enhanced sound insulation, and the room is large enough, this can be neglected. Unfortunately, even the simplest schemes of sliding sliding doors, created independently, will turn out to be very expensive.

The cascade type differs from the traditional one using not one, but several cloths at once, for each of which a special rail is set aside. If it is necessary to divide the room into two parts, the device should disperse as a partition. The group gathered next to one wall will be able to block the entrance to the room only for the width of a single leaf.

Collecting the product according to the “accordion” scheme is even more difficult. It is not recommended to do it yourself without professional installation skills.In addition, the "harmonicas" almost do not prevent the spread of sounds and heat care.

To install a radial sliding door, you need to build a semicircular wall of plasterboard; it is up to you and only you to install it in the doorway or use it as a full-fledged partition to its full height. At desire it is possible to add such design with the cartridge in which the cloth begins to "hide". Most often it is formed from hollow inside walls. As in the case of the "harmonica", If you do not have enough experience and skill, you should not take on the work.

The easiest way to make a sliding hanging door. Calculate the fittings as they should. It is better to lay an excess margin of safety, rather than face the sudden destruction of your product. The canvas will inevitably be larger than the doorway itself. The length of the upper rail is defined as a double width of 1-2 webs.

Double doors begin to do, as usual - with the measurement of the existing opening. It should be wider than the box, 90-110 mm.

If you need to narrow an unnecessarily large passage, use:

- Lumber;

- Putty;

- Plaster.

By purchasing butterfly loops, you can not screw them into the wall.When hanging the swing door, it is necessary to take into account the level of the floor, horizontal and vertical axes are strictly observed. When gaps appear, they are sealed with foam. Do not forget to carefully remove its surplus.which necessarily falls on the free surface.

Masking the gaps is done with the help of platbands; holes for the installation of handles and locks are made before the final hanging. When the installation is finished, immediately check whether the flaps are evenly positioned, whether they open freely or not. Select the entrance should be a safe lock with a cylinder or suvaldnym device, additional protection against drilling guarantees armored lining. Never place locks on the ends of the doors.such an arrangement would make the home almost defenseless against any intruder.

For insulation of metal doors, it is advisable to use mineral wool, which freely passes water vapor and does not accumulate moisture.

Installation of the door with a window is almost no different from normal work. The necessary opening is easy to cut with a grinder. Be sure to prepare stiffeners, including diagonal.

This opening is filled with a decorative grille, and when the canvas is painted, you can begin to work with glass.

Welding technology

It is easy to weld the metal door itself, but it should be done in small parts. Do not make seams longer than 4 cm. From the beginning of one seam to the beginning of the other one should be exactly 20 cm. The work goes from the center to the edge using the inverse step method and from different sides. While cooking the door at home, take your time take breaks from time to time to cool the product.

Then the workpiece needs to be lifted above the welding table, pieces of pipes and profiles are put under the box. The hinges are made of steel rods with a diameter of 2 cm. In order to work better after they are attached to the box, a ball is placed inside any loop from a bearing. Watch out for so that the axes of the upper and lower loops coincide. The top of the loop is attached to the sheet, and its lower part should be welded to the box.

Mitts should be cut off immediately after the hinges are welded. Entrance doors are perfected by scraping the seams and applying paint. It is possible to insert a lock without any special problems: a fragment is cut from the corner of the frame so that it was possible to introduce constipation without problems, but there was no gap left.After installing the locks mark the holes for fasteners, keys, handles. This markup will help drill out suitable holes.

How to finish?

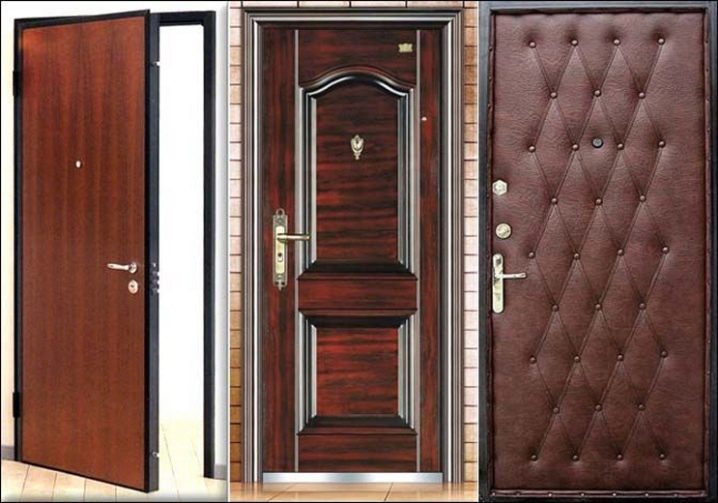

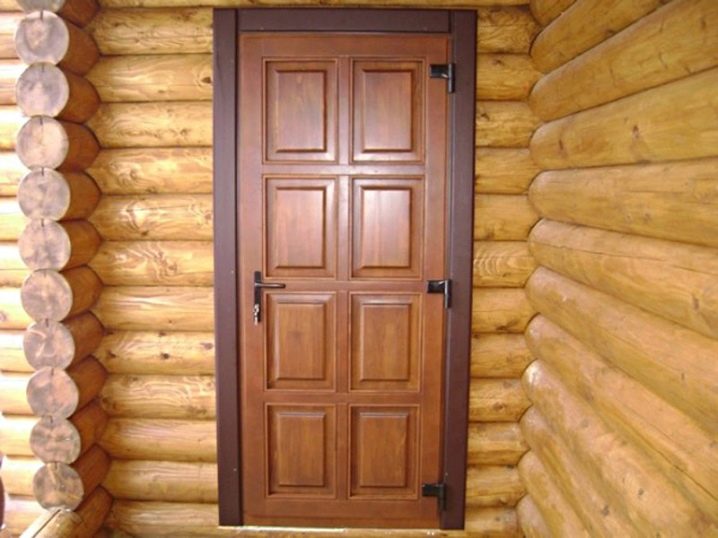

The decoration of the door is able to emphasize the austerity and severity of the forms, or to introduce a feeling of lightness and grace into the space. In both cases, you can use solid wood and veneer. Since self-assembly of doors is designed to save money, then the coating is chosen cheaper, often used warm upholstery from MDF, which is in no way inferior to more expensive products from elite varieties of wood.

An alternative to it is:

- Leatherette;

- Plastic panels;

- Vinyl leather.

Keep in mind that even if the material is chosen for finishing the inside of the entrance door, it must be very resistant to mechanical and temperature effects.

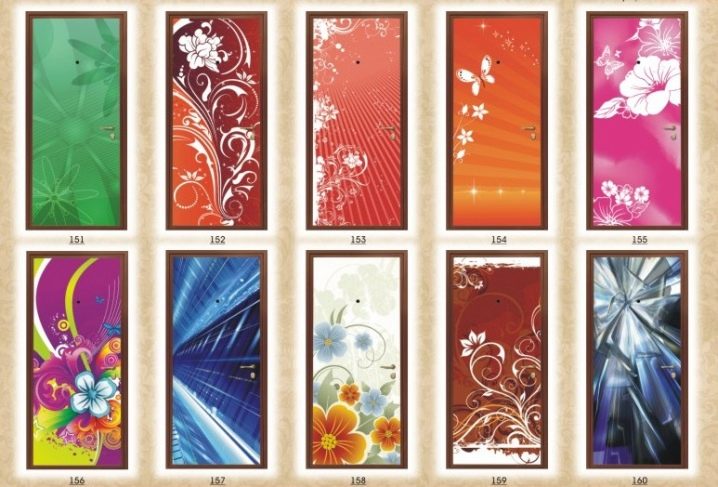

Decor options

Non-standard metal doors must be finished in an original way.

Most often they are:

- Sheathe wooden planks;

- Upholstered with soft materials;

- Glued over with a film reproducing the look of natural wood;

- Just painted in the color vending.

Welded forged parts can look very stylish and attractive.They are able to drastically change the appearance of the whole structure. In any case, regardless of the method of registration, you have to start decorating with a primer and paint.

To decorate the metal door can be used lining or other wooden lining, bolted to the screws. In another embodiment, the fabric is covered with leatherette, hiding a layer of insulating material.

Successful examples and options

Looks good use of steel casing, painted in the color of the main structure. Applying the OSB, you will need to putty the surface, if you want to still stick the film. Grinding will not do anything, no matter how you try to achieve a positive result!

The easiest way to putty a rough coating is not on the door itself, but before it is attached to it.

Beautifully look decorative films that mimic the panel. Never use painted MDF on the outside, it has too little strength. Much better consumer characteristics of laminated panels, which can be with interesting prints or patterns. And if there is free money and you want to get a durable lining, buy oak or birch veneer, beech, mahogany.

How to make a metal door, see the following video.