Slopes for entrance doors

The front door forms the first impression of housing, so it must be both reliable, aesthetically appealing, and perfectly mounted. In this case, the complete assembly cycle includes steps that are often neglected by ignorance. These include the decoration of the slopes of the entrance door, which is necessary not only for the beauty of the design, but also for high-quality operation for a long time.

What it is?

As practice shows, the slopes are often confused with the platbands, since the platbands are their outer, decorative part. By themselves, they carry only an aesthetic function.But the slopes are involved in ensuring tightness, noise insulation and thermal insulation, increase the resistance of the front door to burglary.

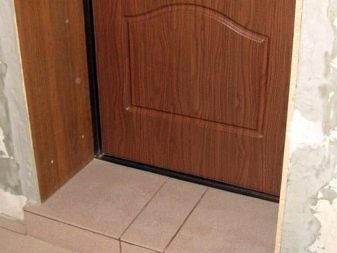

By definition, slopes are the inner and outer parts of the wall that “surround” the door frame. Slopes are also considered to be the left, right, and upper sides of the doorway, in which the door is supposed but not installed. Not all types of doorways have slopes on both sides. Sometimes they may be absent from the outside, but from the inside in most cases.

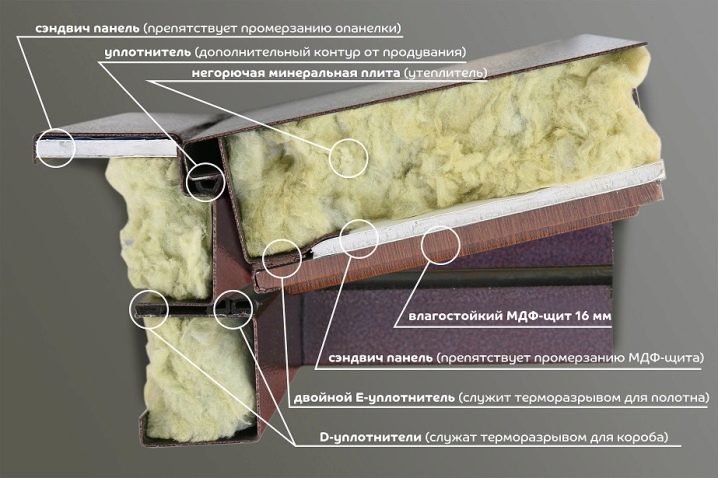

The device of the door slope is quite complicated. High-quality slopes are not just the parts of the wall that protrude beyond the frame, they are the optimal combination of materials, each of which is necessary to perform a separate function. Layered materials on the principle of "puff cake".

The first layer is rough. To create it are used:

- Primer. It is applied to the cleaned surface of the wall as a pre-finish coating. Priming compositions are necessary for leveling the absorbency of the surface, as well as for improved "adhesion" of the following materials to it.

- Styrofoam. This layer is not required, but desirable in cases where the wall must be insulated. This is true for apartments on the lower floors and private houses.

- Plaster. Primer improves adhesion of materials to the wall, but does not level the surface. Plastering is necessary to fill irregularities, depressions or cracks in the wall. This process is the most time-consuming and long and requires certain skills.

Alternatively, you can use a more simple to use material - drywall. This option allows you to quickly prepare the surface for further types of finishes, but it is not suitable in all cases. In the conditions of the Russian climate, it is more often used for decoration indoors or in warm regions with high humidity.

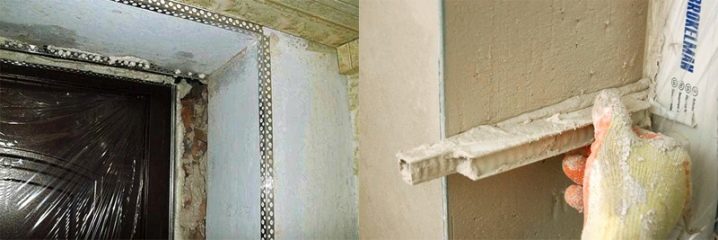

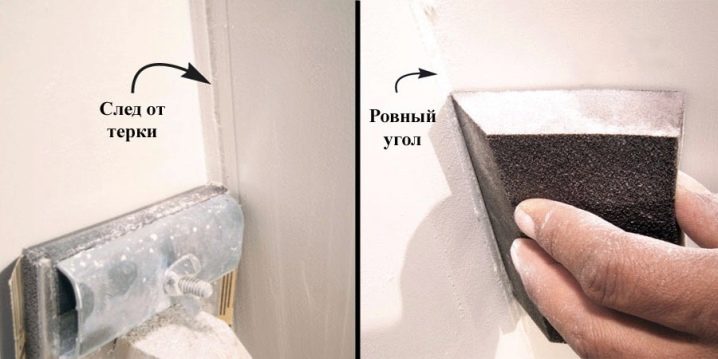

- Reinforcement corners. These thin but durable metal corners are necessary to protect the plaster at the corners of the slopes. The front door is a place with a large cross, and the corners of the opening often touch, hit, scratch. Without proper protection, plastered corners will quickly begin to crumble and lose their presentable appearance.

- Putty. With its help all the shortcomings are aligned after the installation of the corners.Spackling compounds form an uneven layer, so after they dry, the surface of the slopes must be cleaned. For this purpose, fine-grained sheets of emery paper or low-power grinders are used. Furniture is also suitable if it reaches hard-to-reach places.

- Repeated primer before applying a decorative coating.

The second layer - finishing, or facial. There are no strict rules in the choice of finishes. It depends only on individual preferences and financial capabilities. The only condition that must be met is to choose a finish that blends harmoniously with the door leaf and wall decoration.

How to decorate inside the apartment?

Slopes protrude from the outside and inside the door. Accordingly, there are two types of finishes - external and internal. External, as a rule, less variable. The main focus is on the design of the door leaf, and the slopes have something in common with it or with the decoration of the walls. Most often it is practical and concise options that do not attract attention.

Inside the apartment or house, the finishing of slopes becomes part of the interior.She plays a decorative role, so the types of materials and methods of decoration are of great importance.

Finishing of facing materials from the inside can be of the following types:

- Plastering surface.

- Bonding finishing materials.

- Frame covering.

- Coloring.

For the first type, plasterer, primer, water and all the necessary tools are used. This process takes a lot of time, but it makes it possible to putty all irregularities, to insulate the structure, to make the layer of the desired thickness. On top of the plaster, décor is often applied from other materials, but in itself it is already considered to be a finished finish, therefore it refers to the basic methods of repair.

“Clean” slopes after plastering are easy to paint in any suitable color, while they are polished to smoothness or, on the contrary, left to be embossed.

For decorating, you can apply the following materials:

- Ceramic tile (tile). Differs in rigidity, moisture resistance, hygienic, low price and a wide range of colors, shapes and textures. It is easy to take care of the ceramic surface, but the tile may crack or break off due to mechanical damage, and during the replacement process you will have to work hard not to damage the neighboring elements.

The indisputable advantage of the tile - a lot of possibilities for design. The mosaic looks especially original. It can be made from solid tiles of small size or from small pieces. Mosaic fragments are obtained artificially from a tile, cutting it into pieces of the required size, and masters of all hands can use broken tiles for this purpose, which is considered unsuitable. The result is original and unique, and the cost of materials is minimal.

For gluing tiles suitable for any construction glue. Apply it evenly with a plastic spatula, and the seams are rubbed off after a day with a rubber spatula.

- Porcelain tiles. This material is often confused with ceramic tiles. Indeed, in the manufacture of porcelain stoneware used the same composition of the substance as for the tile, but the production technology is very different. As a result, the tile has a colored coating only on top and when chipped becomes ugly, and the ceramic granite has a uniform color throughout the thickness of the slab and the damage on it is less noticeable. Also, its structure is denser, so it is more resistant to damage.Besides the fact that it is moisture resistant, eco-friendly and durable, it also has frost resistance. In appearance, this material is more noble, but the color spectrum is very limited and its cost is higher than on ceramic tiles.

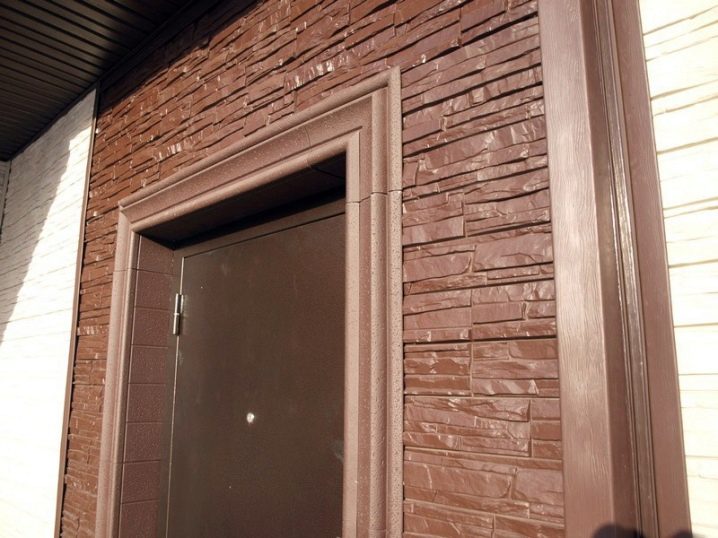

- Decorative rock. It is truly an interior decoration, although it is far from always appropriate and is notable for its high cost. A feature of this material is that it can be used to imitate real masonry. It has an attractive appearance, gives a highlight to the interior, is flawless in terms of performance. The stone does not prick, it is easy to clean, refers to durable and safe materials. For its fixation on the surface of the slopes, building glue is used, but there are also ways to “sheathe” the surface with a decorative stone.

- Wallpaper. Wallpapering is probably the easiest and budget way to decorate. The most convenient way to stick the wallpaper on the slopes decorated with plasterboard. The glue will also “grab” on the plaster, but the surface will have to be leveled very carefully, so that the “bubbles” on the wallpaper will not form.

Given the large cross at the entrance to the room, the wallpaper is better to choose washable and in dark colors.

Sheathe openings with the following materials:

- MDF. Panels of fine fraction are very popular in all types of finishes. They are universal for any interior, look aesthetically pleasing and have a number of advantages: strength, a variety of coatings that mimic different types of wood, ease of installation, improved sound insulation and thermal insulation in the room.

- Chipboard. Finishing chipboard - the easiest way to put in order part of the doorway, if after installing the door it has a deplorable appearance. In this case, do not even need a primer and putty. It is enough to sheathe the surface with even sheets matching the tone and pattern to the door leaf.

- Laminate. Laminate cladding is widespread for two reasons: it is inexpensive and looks an order of magnitude more solid non-laminated materials from recycled wood. The basis of the coating is DVP or chipboard (therefore, “sew up laminated chipboard slopes” means the same as laminate), and on the top it is decorated with a polymer film. The most common option is stylization under the wood of valuable species, but there are other shades in the dark and light palette. It has a number of advantages inherent in all materials based on wood, as well as certain disadvantages.So, among the most common drawbacks is hydrophobia (the material can exfoliate from the water and swell) and average wear resistance.

- Dobor. The lining of the internal slopes from dobor is more a necessity than an element of decor. Endorings are narrow plates of different materials, which are necessary for masking slopes with a width of more than 7 cm. As a rule, they are used in the case when the door and the slopes should be sheathed in the same style and the same materials.

- Drywall The choice of drywall is relevant when you need a quality and budgetary result, which is convenient to work with your own hands. In addition, drywall perfectly aligns the surface for decorative finishes in the future and enhances the insulating properties of the entrance door.

- Plastic. Whatever the universal MDF, laminate and similar materials, plastic door requires the registration of the adjacent space materials based on PVC. The use of sandwich panels is especially popular. They have a variable width - from 5 to 150 cm, which allows you to cover each side of the slope with just one piece.

Product performance is also at an altitude: aesthetic appearance, which persists for a long time, biostability,resistance to humidity and temperature, the presence of air sections inside the panels, which ensure the safety of heat in the house, hygiene.

Modern plastic manufacturing technology guarantees its environmental safety and non-toxicity.

- Siding. Characteristics of siding panels are very diverse, because they are made of various materials - from aluminum to plastic. In the decoration of the slopes used aluminum, copper, wood, basement and vinyl siding.

The best option is vinyl. It is a monolithic PVC panel, the main feature of which is flexibility. It can be given absolutely any shape, ideally adjusted to the corners without joints and gaps. Vinyl is not subject to the processes of decay and burning, is not afraid of water, does not crack when temperature drops, is easily cleaned of contaminants, is of no interest to fungi and insects. The front side of the panels can be monophonic, with a pattern stylized as stone, wood or brick.

Frame lining involves the pre-installation of a metal (aluminum) or wooden profile around the perimeter of the doorway, to which any material is subsequently fastened with self-tapping screws.This method is considered the most time-consuming, since before fastening the profile it is necessary to prime and level the slopes with cement mortar.

Some types of materials (plaster, chipboard, MDF and drywall without decorative coating) are required to be painted to harmonize with the interior of the room.

For these purposes are used:

- Acrylic paints. They are conveniently added to the composition for plastering the surface. This at the same time reduces the number of finishing steps, since surface leveling and painting occur simultaneously, and makes the damage less noticeable, since the entire layer of plaster has been painted;

- Water emulsion. Such paints can be added to the plaster or paint the wall on top of the leveling layer. Using acrylic and water-based paints, it is important to remember that they need to be primed from above, otherwise the surface will get dirty. You can dilute the primer yourself from the PVA and water in a ratio of 1: 5;

- Latex paints can also be used in two ways, but their advantage is that the final primer is not needed. Latex formulations are not hydrophobic and easy to clean;

- Alkyd and oil. These compounds are indispensable in conditions of high humidity. They are more durable and dense, but working with them is more difficult due to the thick consistency and toxic smell.

How to warm?

Thermal insulation and sound insulation are the functions of the entrance door, which are partly dependent on the type of finishing of the slopes. To insulate the room, it is not necessary to run to the store for a heater. First you need to take care of maximum tightness, and you should start from the front door. This will not only increase the level of comfort in the house, but also help in the future to save money on utilities.

Insulation of the slopes from the inside is carried out step by step:

- The choice of materials. The leading positions are occupied by sandwich panels, drywall, foam plastic, mineral wool, polystyrene. Experts recommend choosing polystyrene, which surpasses other materials in many ways. At a relatively low cost, it is capable of thermoforming and vacuum forming, is resistant to moisture and chemical processing, does not smell, is environmentally safe, and is amenable to various types of processing. If there is no polystyrene, it can be replaced with a mineral plate (cotton wool).

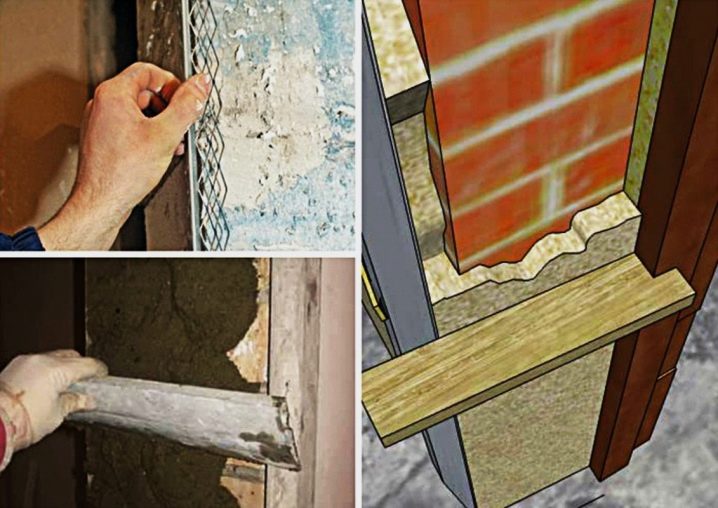

- Preparatory work. They include all measures for cleaning the working surface. It is necessary to cut the mounting foam, remove the old coating, if it is, to eliminate the irregularities as much as possible. After removing the old plaster surface should be removed with a vacuum cleaner and a damp sponge.

- Primer and putty. Priming the surface of the slopes required. This will ensure high-quality adhesion of subsequent layers to the wall, and also minimizes the likelihood of the appearance of fungi and bacteria on the wall. Any soil of deep action will be suitable for this purpose. After applying the surface should be allowed to dry for 3-4 hours. Repeated priming on plaster is permissible.

It is not necessary to putty on the slopes, but it is desirable, especially if the surface has many defects, chips and depressions. All these minor gaps greatly affect the insulating qualities of the entrance door.

- Installation of insulation. At this stage, it is the turn of the warming material. Polystyrene plates and mineral wool are glued with specialized adhesives. Glue is applied with a spatula to the slab, then it is applied to the surface of the slope and adjusted to the level.Glue drying time - not less than a day. After this, the plates are fixed with dowels.

- Fastening insulation. Ideally, polystyrene or mineral plates should be covered with plastic mesh for interior decorating. This will protect against cracks and irregularities in the future. Glue is applied on the mesh with layers, each layer dries to hardness in 6-12 hours.

- Surface alignment. Here again need putty. It is possible to level a surface to 2-3 layers. Then you need to let it dry for the time specified in the instructions on the container, and process it with fine-grained sandpaper. The number of grain on the packaging of sandpaper - not less than 100.

- The final finish. It includes the application of colorless primer followed by painting or any other method of decorating.

It is important to bear in mind that finishing materials have not only their own characteristics that affect the insulation, but also their weight. It is necessary to calculate in advance whether the insulated slope will withstand, for example, the weight of porcelain stoneware or lining or whether paint, plastic or wallpaper should be preferred.

How to make a slope on the front door of the MDF panels with your own hands, see the next video.

Colors

The slopes are a small detail that can both support the style in the interior and completely break out of it. Inappropriate color finish will be an element that violates the integrity of the overall picture, so it is important to correctly choose the color in accordance with the design of the door and finish the walls, floor and ceiling in the room.

The color of slopes directly depends on the chosen material:

- Tree and its derivatives. This group includes all the materials in the production of which one way or another used wood. This includes classic solid wood panels, and lining, and all plates pressed from chips and adhesives, and veneer, and laminate. Accordingly, the color palette is diverse, but does not go beyond the scope of natural colors: pine, spruce, poplar, ash, bleached oak, stained oak, pink oak, light walnut, medium walnut, dark walnut, red maple, mahogany, antique pine, Douglas . Gorgeous colors are collected in a dark palette of natural and synthetic origin: cherry, mahogany, wenge, chocolate, tic, Indiana, macassar, apple locarno.

- Ceramics and stone. The technology of creating these materials allows the use of powder dyes absolutely anyshades. As a result, you can choose ceramics in the color of red brick, granite, zlatolit, slate, natural stone. Also available are brighter colors, both natural and non-pure: shades of green, yellow, red, blue, brown, monochrome palette (black, white, gray), and combined options. The combination is a combination of several colors, often imitating expensive stones: jasper, marble, malachite and others.

- Plastic. Like ceramics, it is available in all colors of the rainbow. In this case, the color may be monotonous, and may be in the form of a picture. Imitation of other materials is popular, for example, drawing under a tree, a brick.

- Siding. It is diverse due to the different materials of manufacture. Copper and aluminum will have metallic shades, vinyl - all colors available for plastics, wood presented in natural colors.

- Paint. Available in any color - from classic white to bright fuchsia. At the same time among the coloring compositions can be found "liquid" gold, silver, bronze.

How to choose the right design?

Registration should correspond to the style of the interior, especially the part of the room where the entrance door is located.Few can boast of the design of the apartment, where everything is designed in the framework of the popular style, but even the interior without complaints, chosen by the household itself, should be harmonious.

Choosing a finish for slopes, you should build on the colors, materials and textures that prevail in the room. So, to maintain a plastic door, you should use siding and a sandwich panel, for wooden - veneer, finishing and laminate, and you can decorate the metal (steel, iron, aluminum) door with paint, artificial stone or plastic with brick imitation.

Beautiful design options

The decoration of slopes in a typical apartment, in a panel or in a private house has the right to be original. Slopes of small width is difficult to make non-trivial. For them, the classic dobor are best suited. But even in this case, there are several design techniques that can make a variety.

First of all, it is the use of dobori under the color of the door, which makes the design whole. In the second case, a game of contrasts is used, when the finishing of the dobor is radically different from the interior of the door shield.Such reception with use of a contrast light and dark scale ideally looks ideal.

Rarely used, but an interesting technique is to elevate the slopes with mirror and reflective materials in the form of a mosaic. It visually "pulls" the doorway in height and width. To focus on the slopes and the opening can be with a stone or textured plaster. But the most popular type of decoration is the stylization of the opening under the arch with the extension of the pattern beyond the edges of the slope.