EP-140 enamel: technical characteristics, colors and application

During construction or repair work, it is often necessary to paint some metal surfaces. The natural color of the metal is not combined with the overall design, and the raw material is exposed to moisture and oxygen. Painted surfaces will look much better and their service life will increase significantly. For painting products from various metals, it is best to use enamel EP-140.

Composition and properties

This enamel is used to paint surfaces and products from a variety of metals: steel, aluminum, titanium, copper, magnesium, as well as their alloys. Before applying the enamel surface must be carefully primed.

EP-140 has a complex composition. It consists of two components that are sold and used only in full. Usually it is a semi-finished enamel and hardener.

This composition can withstand the tundra and taiga climate, it is also adapted to the hot and dry conditions of the steppes, deserts and semi-deserts. However, the best way enamel manifests itself in a temperate climate zone. Coatings treated with enamel EP-140, can be used both at home and in production. Enamel is used for both exterior and interior decorating.

The coating is durable, it is distinguished by high hardness and excellent moisture resistance. Neither oil nor gasoline affects the treated coating.

We should also highlight the enamel silver color: the surfaces processed by it are capable of withstanding temperatures up to 200-250 degrees. Also allocated paint for the processing of the draft metal without pre-priming. The surfaces painted with such enamel are resistant to aggressive chemical environments.

All EP-140 enamels have a long service life. They can be applied in various ways. They have a high drying rate,do not change their properties during hot drying.

Specifications

After drying, the painted surface should look uniform, without any inclusions. It is also necessary to observe that the surface is smooth. For enamels of brown and yellow colors, a small “rash” may appear, which is not a critical fact.

The rate of drying of the enamel depends on the temperature of the room. For example, at temperatures of +20 - +25 degrees, the enamel solidifies in 5-6 hours, and at a temperature close to +90 degrees, in 2-3 hours.

Coatings with enamel applied to them can for a long time not change their properties under the influence of water, oils, gasoline or diesel fuel. Typically, the coating can withstand about an hour of stable exposure to aggressive substances.

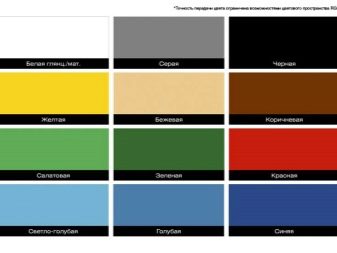

Color solutions

EP-140 enamel has a wide range of colors and shades.

There are a large number of standard colors, the release of which comes in large quantities:

- red;

- yellow;

- Orange;

- blue;

- blue;

- ivory;

- tobacco;

- silver;

- the black;

- white;

- various shades of light gray;

- protective tones.

Scope of use

This enamel is used for finishing works on various metal surfaces. The coloring layer performs both a protective and a decorative function. Often the surface is primed before using the paint, but it is also possible to apply it on rough surfaces.

Before use, you must mix the two components in ratios of 70 to 30 or 75 to 25%. This ratio varies, depending on the color of the enamel. You can find out the exact proportions when mixing on the product packaging. The prepared mixture should be consumed within 5-6 hours.

Enamel can be applied with a brush or roller, or with a pneumatic spray. Work on the application can be performed only at positive temperatures and at a humidity of not more than 80%.

Dye consumption ranges from 70 to 120 g per 1 m2 of surface in one layer. Depends on the nature of the surface, the characteristics of its configuration, the level of skill of the worker, the method of painting and the conditions for applying enamel.

When working with EP-140, it is best to use personal protective equipment. It is recommended to ventilate the room after the work done for a long time. It is necessary to protect the composition from fire.

Benefits

It is necessary to highlight several advantages of the EP-140, which many analogs cannot boast of:

- possibility of use in all climatic zones;

- use in the home and at work;

- painted coatings have increased hardness and strength;

- high resistance to oils and various aggressive formulations;

- different types of enamel have different properties: the composition of silver color is able to withstand high temperatures, other paints have electrical insulating properties.

The enamel EP-140 is very popular due to the wide applications. High technical and operational parameters are the guarantee of the impeccable quality of the dye. The rich color scheme allows you to choose the option that is needed for a particular case.

What is the difference between enamels, paints and varnishes, see below.