Enamel EP-773: technical characteristics and color palette

Successful operation of any metal surfaces depends on the degree of their protection and resistance to external influences. The EP-773 anti-corrosion enamel will help ensure their durability and long service life. After studying the technical characteristics of the material and following certain rules of application, you can create not only reliable, but also a beautiful coating.

Purpose

The composition of the chemical enamel of the EP-773 enamel and the technology of its manufacture are defined by the standards of GOST 23143 83. According to official documentation, the tool is based on E-41 epoxy resin with the inclusion of fillers and various pigments.Paint and varnish products are two-component - the coloring suspension is mixed with an amine type hardener immediately before painting.

The use of the solution due to its protective properties.

It prevents exposure to metal:

- high humidity;

- oil solutions;

- mineral salts;

- combustible mixtures such as gasoline and its analogues.

Anti-corrosive composition is relevant for long-term use of ferrous and non-ferrous metals, as well as for concrete surfaces after the primer. At home, it can be used for processing plumbing equipment, external and internal pipes, various designs and equipment. In addition, it is the most economical option for a protective coating.

Properties

The paint effectively protects metal bases from the thermal effect of alkali vapors of any concentration, atmospheric phenomena, temperature drops, rapid wear due to mechanical loads.

Enamel has the following important parameters:

- creates a matte and semi-matt coating;

- It has a working viscosity of 25-60, which allows it to be applied both manually and by spraying;

- optimum density is achieved in only two layers with a thickness of not more than 25 microns;

- the material has maximum adhesion with metal and is mainly applied to the primer, but can be applied without it;

- final drying takes place within 24 hours, but at a high artificial temperature, the final drying takes only 2 hours;

- the resulting layer has a high elasticity, with bending component of 5 mm;

- per one applied layer consumption per square meter is quite economical and does not exceed 75 grams of coloring composition.

Paintwork product is available in two primary colors. - green and cream, but to order you can pick up any shade of dye. However, it should be borne in mind that when exposed to the same potassium alkali, cream tones are less stable and constitute a time period that is four times smaller than that of enamels of green tones.

After coloring, the color, as a rule, does not deviate from the selected shade, and a smooth film without foreign inclusions is formed on the surface.

Preparation of the solution

If the work is carried out indoors, the container with paint is kept at room temperature for about a day.

For the preparation of the coloring mixture is important the sequence of preparation, respect for proportions and thorough mixing:

- First, you should make sure that the single-component suspension is homogeneous in its structure and volume, it should be thoroughly mixed in order to completely eliminate the precipitation of sedimentary particles;

- then hardener No. 1 of Deta is introduced into the solution, taking into account the proportions indicated in the instructions;

- it is necessary to mix the mixture for 10 minutes until complete homogeneity, and then stand for another 40 minutes and stir again to increase the flow and improve the appearance of the coating;

- after measuring the viscosity for the spray gun (with a nozzle size of 4 mm, it should be no more than 16 s) if necessary, the composition can be diluted with a solvent “P-4”, 646 or toluene;

- mixing is carried out with the help of an auger for paint and varnish materials, a drill or a construction mixer.

If the solution is not homogeneous, and this is sometimes due to stirring in the packing drum, the painted coating in some places can dry out badly. Eliminating this problem is much harder than preventing it.In addition, because of this, the hardener is unevenly distributed, which entails a strong, premature thickening. That is why a special open bath is necessary for stirring.

It should be remembered that it is impossible to carry out staining on wet surfaces. The substrate must be primed, especially when used in a corrosive environment, and must be dried before this.

Metal coating cleaning

This stage is necessary, as it helps the optimum adhesion of the material with enamel.

The following works are envisaged:

- cleansing from scale, rust, dirt and foreign small particles of garbage - for these purposes a rust converter, abrasive cloth, special brushes with wire bristles for metal, sandblasting chambers are used;

- grinding and removal of metallic dust;

- degreasing oil stains and grease contaminants with a solvent.

For further priming, EP-0020 or EP-0010 putty compounds will be required, specially designed for epoxy paint. It is quite enough two layers for the subsequent coloring by enamel. Concrete surfaces are treated with a special composition "Sibton EP-Primer".

Staining rules

In everyday life, brush and roller staining is more commonly used, but for large volumes of work it is more sensible to use pneumatic devices. Painting is carried out at a temperature of from +15 to +35 degrees and moderate humidity up to 80%. In some cases, staining with frost up to -10 degrees is allowed, but mixing is carried out at room temperature. But this is undesirable, since it increases the drying time to a week.

Typically, the enamel "EP-773" is applied in two layers, although it is provided and staining to create a multilayer coating.

Each subsequent application should take place at intervals of one day, since it is during this time that the coating dries completely. By the way, the metal can be dried both naturally and hot using infrared heaters and other devices. Heating should be about +120 degrees.

You should not be upset when a sticky film is found on the treated metal after the final drying - this is not a defect at all, but it appears due to the presence of plasticizers. It is enough to wash the oily layer with soapy water, and this side effect will be eliminated.

When working with paints and varnishes, one should not forget about personal safety measures. It is necessary to carry out the work process in protective clothing, gloves, gas mask or respirator and having a number of necessary fire-fighting tools.

For those who decide to use this composition, we can recommend to buy only high-quality products from a trusted manufacturer, for example, from the PFC Spectr enterprise, which guarantees excellent product characteristics capable of ensuring the continued use of various types of metal structures.

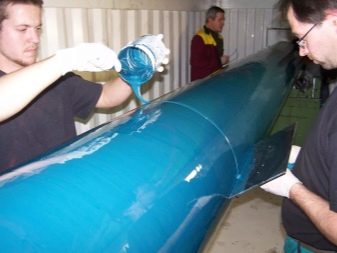

How to restore the old bath using epoxy enamel EP-773, see below.