Enamel HV-785: characteristics, colors and rules of application

Metal parts and structures that are very often used in construction and in industrial production under operation are subject to various negative influences. To protect them, you need a durable and resistant coating: it can provide enamel "XB-785". This product allows you to make the base of the most durable, such materials are of different colors. It should be borne in mind that when using such coatings it is necessary to remember certain rules of application. After reading this article, you will learn all the basic information about these materials.

Distinctive properties of the material

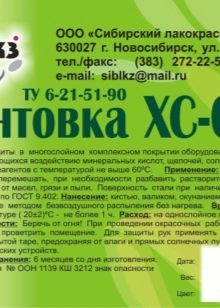

Enamel brand "HV-785" - paint products, the main component of which is chlorinated polyvinyl chloride resin.The composition also includes improving technical characteristics of fillers, plasticizers, solvents of organic origin. The color of the product is directly dependent on the availability of different pigments. It can be white, gray, yellow, black, red-brown.

Material advantages:

- wonderful anti-corrosion properties;

- resistance to salt and alkaline solutions, gases;

- hardness and wear resistance, increased resistance to mechanical loads;

- good adhesion to the bases;

- plasticity of the coating;

- extension of the life of the metal, concrete, reinforced concrete (due to strength and durability).

The enamel is acid resistant, so the material protects the surface by direct contact with various aggressive substances already in the process of their use. At the same time it allows you to get a smooth and beautiful finish.

For multi-layered surfaces that are operated under street conditions, red-brown or black perchlorovinyl enamel “XB-785” is usually used in combination with “XB-784” varnish. It is always applied on pre-grounded bases, including wooden ones.This composition is able to suspend the damaging effects at temperatures not higher than +60 degrees. Light shades of paint are more suitable for the internal processing of coatings, dark - for outdoor use.

Such enamel is used in different areas. It is used in construction, in arranging production plants, to give strength to tanks for chemical mixtures, to increase the service life of industrial, as well as automotive vehicles.

Preparation for staining

The process of staining with this material has its own characteristics. They must be considered in the implementation of finishing works.

First, the surface is prepared:

- metal is cleaned from particles of dust, dirt, corrosion, old paint, grease and oil stains;

- the previous paintwork is removed using a scraper, rust - by using sandblasting, cord-brushes (you can polish the material manually - with abrasives, you can use a rust converter);

- it is important to thoroughly remove dust;

- degreasing is carried out using white spirit, solvent "P-4" or "P-5";

- apply one or two layers of XC-068 primer on a dry surface,"HS-010" or "FL-03K" (depending on wear); it is easier and faster to do this using the pneumatic or airless method.

Then you will need to dissolve the paint to working condition (using solvent "R-4A"). The viscosity of the mixture is checked by the viscometer "VZ-246", it should be 16-22 s. It is not recommended to dilute the enamel with acetone or toluene, as these substances are not part of the material. Otherwise, there is a danger that the solution will collapse.

Mixing is better to implement a construction mixer, it will provide the necessary uniformity. Solvent add no more than 20% to the total enamel volume. If the proportions are different, during further use the coating may peel off.

How to apply?

There are certain painting rules that are important to follow. Considering the following requirements, You can achieve high strength coating and avoid some errors that can adversely affect the result:

- Much depends on the temperature. The application is carried out at +30 degrees and below, the humidity does not exceed 80%.

- For maximum strength, one layer of enamel is not enough.Professionals recommend making several layers. Each previous must dry, after which the next is applied. It takes about an hour to dry.

- Rollers and brushes are used in difficult places, automatic spraying - with a large surface area. So you can greatly facilitate the workflow and save time.

- For cleaning tools, use the same diluents that are necessary for the preparation of the solution.

- When working you need to focus on the standard thickness of the coatings. Primer layer - from 15 to 20 microns, enamels - from 20 to 30 microns (each layer).

- Varnish "XB-784" treated painted with any color of the surface - except those that are coated with black enamel. The thickness of the layer should not exceed 20 microns.

Absolute drying of the coloring composition occurs after 24 hours. It is noteworthy that the consumption per 1 m2 - 120-150 g per layer, you can save a lot. Consumption depends on the structure of the surface, the degree of porosity, total area.

Security

Working with enamel requires adherence to basic precautions. The products are subject to fire, explosive, there is a percentage of toxicity (due to the presence of solvents), so you can not carry out staining near the source of open fire.It is dangerous to inhale the vapors of the solution, and even more so if its particles hit the skin and mucous membranes of the mouth.

To protect yourself from unpleasant health problems, you need to follow important instructions:

- The area in which the painting is carried out must be well ventilated.

- You must use special tools (overalls, rubber gloves, respirators to protect against dust and gas during outdoor work, a gas mask - when applying the solution in enclosed spaces).

- You should have a fire fighting device with you; you should use safe tools.

- In the workplace can not smoke.

In case of fire, it is recommended to use a fire extinguisher., asbestos blanket, felts, foam and water spraying devices. Packing is carried out in plastic or metal containers (weight - 10, 20, 25, 50 or 60 kg). Warranty period of storage - 6 months (with tightly closed lid, away from direct sunlight).

This product has a state certificate of quality and is produced in accordance with existing standards (according to GOST 7313-75). This determines its high quality and necessary operational properties.

The problems that may arise when using paintwork materials are described in detail in the following video.