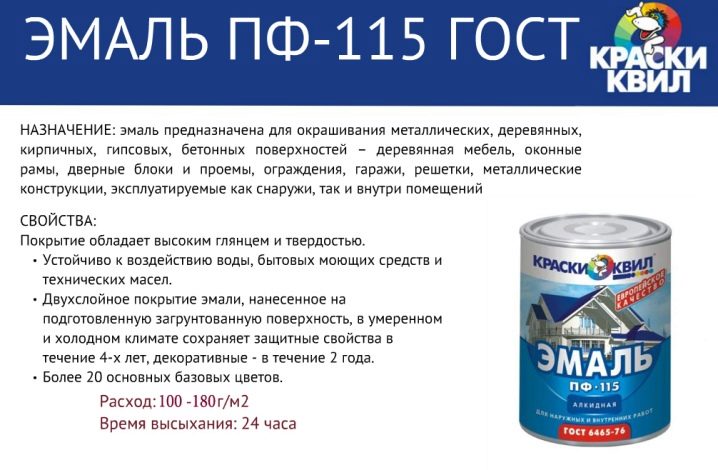

Enamel PF-115: characteristics and application

Weather-resistant enamel paint PF-115 is a universal product, well known to domestic consumers and proven to be a reliable paint and varnish coating with high protective and performance properties. One of the most popular paints and varnishes on the Russian market (enamel coatings) enamels with a pentaphthalic binding base and a wide range of prescriptions began to be produced in the Soviet Union. After the final modernization, which occurred in the 70s of the last century, the improved pefka acquired the highest technical characteristics inherent in this material and successfully passed the test for compliance with the State Standard 6465-76. In this article we will find out what constitutes this protective polymer coating, where and for what purpose it is used.

Special features

Our compatriots at all times preferred to deal with inexpensive, affordable, easy to use, and most importantly, reliable products and things. And if we talk about LKM, then the list of attractive consumer qualities should be supplemented with such a property as universality. All these criteria are satisfied by the enamel paint PF-115, a paintwork material widely used in various industrial sectors and in everyday life.

Its main purpose is to provide anti-corrosion protection for steel structures., railway transport, urban vehicles, agricultural machinery, military equipment, surface parts of self-propelled / non-self-propelled floating structures and other objects, the operation of which involves constant atmospheric effects. However, the scope of this enamel is much wider. It is allowed to use as paint on wood, concrete, foam concrete and reinforced concrete, stone or brick.

Despite the fact that in terms of technical characteristics, many modern analogues significantly exceed the PF-115, it still does not lose its position in the paint and varnish market.Sustained long-term demand for it is due to the optimal combination of price and quality, as well as the fact that over the decades of existence this enamel has repeatedly proved its worth in solving various problems, thereby gaining the trust of a wide range of users.

Advantages and disadvantages

There are many arguments for the use of PF-115.

- Moisture resistant and resistant to weathering. Although some experts are skeptical about the protective properties of pentaphthalic enamel, nevertheless, it is able to take care of your structures, reliably limiting access to precipitation and UV rays.

- Lightfast and durable. The viability of the protective coating is directly dependent on the originality of the formulation and compliance with the technology of dyeing. On average, the shelf life of a coating is 4-5 years.

- It has a low price - this is one of the main advantages of enamel, which often becomes a decisive factor in favor of its purchase, especially when the budget is limited.

- Provides excellent adhesion even when applied to smooth metal surfaces.

- Eliminates significant costs for the preparation of surfaces for painting - another opportunity to save on costly and time-consuming technological procedures.

- Highly elastic and crack resistant.

- High strength and durable, therefore suitable for flooring.

- It is universal in application for external / internal types of works, for painting on metal, concrete, and wood. Since PF-115 is capable of combining well with the listed materials, it will be possible to protect various products with one product, saving on the purchase of specialized formulations for the treatment of surfaces from a specific material.

- It has good decorative properties and allows you to get a glossy, matte, semi-matte surface.

- Easy to use, can be applied using conventional painting tools or special equipment, gives minimal shrinkage. To work with the PF-115 can low-skilled staff.

- It is distinguished by good fluidity, opacity, thixotropy - the ability to reduce viscosity due to mechanical effects and an increase in viscosity in a quiet state.

- Easy to clean with ordinary detergents.

- A wide choice of color solutions, among which there are both classic strict shades and bright, saturated ones, which facilitates the task of selecting the right color for your own needs. In addition to the standard colors of enamels, manufactured according to GOST, you can order a shade of paint according to RAL.

Weaknesses are also present.

- Contents in the composition of components harmful to health. Evaporation of these substances during the drying process is accompanied by a strong odor.

- It has low vapor permeability, which must be considered when painting facades.

- Low chemical resistance to various corrosive media. Therefore, the use of pentaphthalic enamel is limited in some areas of the industrial sector with increased requirements for the quality of protective coatings.

- Fire hazardous

- Increased drying time.

To completely dry, PF-115 takes about a day, which is not always justified in time and, as a result, finances.

When it comes to painting high-rise buildings - water towers, chimneys, or simply the walls of high-rise buildings, industrial climbers are usually involved in the work. The services of such brigades cost accordingly.

In this case, it is most advantageous to paint objects “for one approach”.so time and money is saved. With pentaphthalic enamel, it is impossible to do this, since 24 hours must elapse before applying each subsequent layer. Whereas there are quick-drying enamels, the interlayer drying of which takes only half an hour, for example, Antikor Sprint coating.

In addition, PF-115 does not recommend painting metal structures used in aggressive industrial atmospheres, that is, located directly on metalworking facilities, thermal power plants or close to them, and objects constantly in contact with the aquatic environment - piers. We need more advanced materials than pentaphthalic paint, capable of providing a high degree of protection against corrosion.

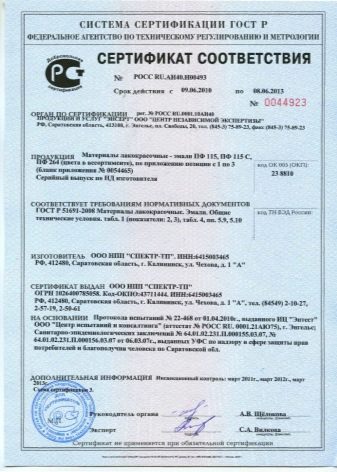

Compliance with GOST

At the very beginning of the article, it was mentioned about such an event in the history of PF-115 as the introduction of the State Standard for this type of paint and varnish products. This pentaphthalic enamel is produced strictly according to GOST 6456 76, applicable to coatings of any color. According to this standard, enamel manufacturers must comply with a number of requirements,concerning quality indicators, technical characteristics, packaging, labeling, transportation of products, warranty obligations of the manufacturer, etc.

The enamel produced according to the original recipe characterizes the formation of a coating with a range of operating temperatures from -50 ° C to + 60 ° C. The duration of the life of a two-layer coating should be at least 4 years without loss of protective properties. The original decorative qualities should be maintained for one year when used outdoors in temperate climates.

Each batch of paint is carefully monitored and supplied with a certificate confirming the quality of the material and its compliance with GOST.

Specifications

PF-115 paint - a type of paintwork material of the alkyd group. Alkyd enamels are traditional paints and varnishes, which use synthetic polycondensation alkyd resins as the basis of the film-forming component. For a number of indicators, they are superior to oil paints with oil-resin bonding bases.

Polyester Resins - Universal Raw Materialswhich are actively used by manufacturers of paintwork materials.The reason for this demand for polyester resins lies in the ability to use renewable natural raw materials and to obtain various compositions of paintwork materials with a certain set of protective, decorative, special properties.

Consider the main components of the composition of pentaphthalic alkyd enamel.

- Film former. This is the main component of paint and varnish, which gives a polymer coating certain properties. The use of pentaphthalic semi-finished lacquer as a binder basis of the polymer coating allows to obtain a high-density film, which is distinguished by good mechanical characteristics, moisture resistance and resistance to constant and short-term effects of atmospheric phenomena.

- Solvents. The solvent is a purified organic liquid, in this case in the form of purified kerosene (White spirit), turpentine or solvent, which bring the film-forming substance to a state of readiness for use and regulate the viscosity of paint and varnish materials.

- Dyes. Conducting finely dispersed insoluble colored powders into the film-former ensures pigmentation of the polymer coating and makes it opaque.To obtain white enamel, manufacturers use titanium dioxide, and for the production of color coatings - chromic anhydride, soot, organic particles. Dyes are responsible for covering the ability of enamel and provide the best decorative coating, making the color resistant and saturated.

- Fillers. They increase hiding power, thixotropy, the resistance of liquid substances to movement, wear resistance, corrosion resistance. The use of barite, calcium carbonate, hydroaluminosilicate, a massive variety of talc - stearin, improves the listed technological characteristics of paint and varnish materials.

- Functional supplements. The use of modifying additives in the form of desiccants, plasticizers and stabilizers solves various problems. Siccativa are organometallic soluble compounds of chemical elements with metal properties and atomic mass above 50. The use of cobalt, manganese, lead and other siccatives accelerates the drying of paint and varnish materials, reducing the duration of film formation.

The addition of plasticizers helps to increase the elasticity of the film and the resistance to sudden changes in temperature.Stabilizers are responsible for the uniform distribution of dyes in the enamel volume and prevent delamination of the polymer coating.

The performance properties of paint.

- Operating temperature range: -35 ° C ... + 60 ° C.

- Hazard Class - 3. As a representative of the group of alkyd enamels, this paint has a high toxicity and fire hazard, therefore when working with it you must be guided by the instructions and follow safety precautions.

- The degree of gloss, extinct photoelectric gloss meter - 50. This type of paint is distinguished by the formation of a smooth smooth glossy coating, eliminating extraneous inclusions.

- Indicators conditional viscosity of the coating, measured by a viscometer, depend on the color. For black, cherry and red coatings range from 60 to 100 seconds, for other colors - 80-120 seconds. A lower viscosity makes it difficult to distribute the enamel with a brush, while a large one makes it necessary to use more solvent to reduce the viscosity of the paint for certain tools.

- The content of pigments and binders (solid non-volatile substances) varies in color and can be 50-68%.

- It dries in a temperature setting of 20 ° C with a humidity of 65-70% per day, with the exception of cherry and red enamels, which have an increased drying time - about 2 days. At low temperatures, the drying time is doubled. Interlayer drying interval is 24 hours.

- T-flexural elasticity (mm) - 1.

- Density characteristics - from 1.2 to 1.4 kg per liter.

- Indicators of impact strength (cm) - 40, which are measured after a kilogram weight is dropped on the painted base. The presence / absence of cracks and dents on the surface is recorded.

- Adhesion ability in points - 1, which is considered the maximum quality indicator of adhesion to the base in accordance with the conventional scale.

- The covering capacity of the dried coating based on the color can be 35-120 g / m2.

- It has a high resistance to static effects of ordinary household chemicals, transformer oils and water.

- Chemical resistance: the film has good tolerability of turpentine, White spirit, denatured alcohol.

- The duration of the storage period for paintwork materials in a sealed industrial warranty box from different manufacturers is 1.5 - 2 years from the date of production.When operating in temperate or cold climates, the coating will last 4 years or more, and in tropical climates at least 1 year.

- Packing: pentaphthalic paints are packed in industrial packaging of various volumes from 0.8 to 60 kg.

Each batch of enamel must be checked in the laboratory for compliance with the quality indicators of GOST.

Among the above parameters, only an estimate of the appearance, flow rate and drying time is available for consumers. Therefore, it is so important to purchase PF-115 produced according to the original recipe in compliance with the requirements of GOST.

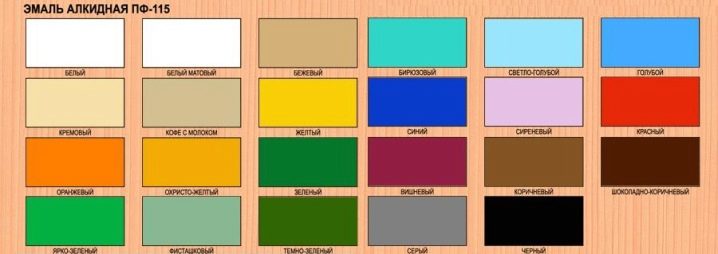

Colors

The range of colors of pentaphthalic paints contains mostly full-color, and shades are presented in limited quantities. After drying, colored enamels can form a film with a glossy, semi-gloss, matte, semi-gloss texture, and the basic white enamel paint forms only a glossy or matte coating.

The color assortment is presented in standard tones:

- yellow, light and pale yellow;

- beige and light beige;

- Orange;

- brown;

- red;

- cream;

- blue;

- blue, pale and grayish-blue;

- turquoise;

- green and dark green;

- pistachio;

- emerald;

- gray, light and dark gray;

- white;

- black and others.

The new color palette is presented in the following shades:

- blue spruce;

- salad;

- fresh greens;

- sesochny;

- greyish;

- turquoise;

- red and blue lilacs;

- chocolate;

- green apple;

- emerald;

- lemon;

- smoky gray.

If there is no desired shade in the line of colors offered by a specific manufacturer, you can use the tinting service and get the desired tone by mixing basic or universal pigments.

The content in the enamel paints of different dyes affects the performance of coatings. The creation of some shades leads to a decrease in the quality of the final product. For example, this applies to cherry, red, black paint, which, for this reason, instead of the highest grade is assigned only the first.

Scope of application

PF-115 refers to alkyd enamels, as evidenced by the letter designation “PF”, indicating the pentaphthalic bonding base. The study of the numbers 115 gives us the following: in the first digit we find out where the paint is applied.Thus, the number 1 indicates that we face an atmospheric paint, which is recommended for use in outdoor work. The subsequent number 15 is the catalog number of the product, so these figures do not contain any practical information.

Although this alkyd paint can boast the widest range of use, it was developed primarily for the anticorrosive protection of metal structures used in natural areas with a temperate, cold or tropical climate.

It is used in the following industries:

- engineering;

- road construction;

- railway transport;

- machine tool;

- aircraft building;

- military industrial;

- manufacture of steel structures.

Due to the intensive drying rate (about a day) and the rapid weathering of the smell, this paintwork is often used during internal work. LKM is also suitable for processing wood, concrete, brick and other surfaces that are adversely affected by weathering, subject to the technology of surface preparation for painting.

PF-115 is considered to be a “popular” product. Various public utilities use this paint with might and main, when there is a need to put in order “non-responsible” objects such as various benches, elements of fences near the entrances, basement doors, protective grills. It is indispensable for painting those products that need not only to provide anti-corrosion protection, but also to give a certain decorative qualities. In addition, the enamel PF-115 often painted wooden frames on the windows or facades, so buildings quickly become well-groomed appearance, and public utilities avoid extra costs.

Most production facilities and warehouses are equipped with full heating systems. Since aesthetics at such facilities plays a secondary role, it is practiced to install a large number of practical heating registers that maintain the optimum temperature in the room. Just them, along with cast-iron radiators, are often painted with pentaphthalic paint, again for reasons of economy.

Manufacturers

PF-115 is manufactured by many Russian enterprises. But the tough competition for consumers has led tothat the domestic market of paints and varnishes was filled with low-quality cheap enamels, produced under the PF-115 trademark, but not according to GOST, but in accordance with TU.

Separate paint and varnish manufacturers practice special marketing solutions., to distinguish their low-quality products from other low-grade products. As a result of a similar marketing policy, a brand of pentaphthalic paint appeared under marking 116 with its other derivatives, such as Ultra, Extra, Super.

When you meet on the shelves of cheap enamel, be sure to be interested in the norms of manufacturing this paint.

Trust deserve only products manufactured in strict accordance with GOST 6465-76, but not with TU - technical conditions of enterprises, most often setting individual quality indicators in order to lower the market price of their products.

We offer to pay attention to reputable manufacturers of paintwork materials with a high rating of reliability among buyers.

Lacra

This is a well-known Russian company specializing in the manufacture of decorative paint products. Universal alkyd enamels "Lakra" have excellent interlayer adhesion, high atmospheric resistance and opacity. The color range has over 40 color solutions.Most of them form a coating with a glossy texture. The guaranteed shelf life of paintwork materials is 24 months.

Prestige

The holding produces paints and varnishes that are of the highest quality in combination with an affordable price. In 2005, the company presented two technological innovations - the budget pentaphthalic paint “Kazachka” and the premium high-quality alkyd enamel paint “Poller”. Both products are manufactured in full compliance with the standards applicable to this group of paintwork materials.

In the line of alkyd enamels, there are many other worthy coatings. This is a super-white PF-115 with a high degree of gloss based on refined clarified lacquer and heat-resistant, anti-corrosion, decorative coating of silver color with natural aluminum powder as a filling fraction, which can be painted radiators, heat pipes, chimneys.

A very interesting option is an eco-friendly acrylic semi-gloss quick-drying universal enamel, which, when applied, begins to smell like a green apple. As the polymer coating dries, the apple smell weakens and disappears.

Tex

One of the largest manufacturers of paint and varnish materials with a wide network of building stores located throughout Russia.

There are several types of PF-115:

- universal alkyd white matte and glossy with the possibility of tinting in the catalog;

- universal glossy colored, which, in addition to wood and metal, you can paint plaster bases, building constructions of drywall, hardboard / particleboard;

- "Fazenda" - enamel, forming a glossy coating, characterized by economical consumption of 1 kg / 6-16 m2 with a single layer of application and resistance to atmospheric phenomena;

- "Optimum" - enamel paints with a drying period of up to 7 hours. Interlayer drying interval - day;

- "Econom" for mass construction and painting of wood and metal structures.

After analyzing the feedback from users of PF-115, it can be concluded that the majority of our compatriots believe that enamel copes with the tasks assigned to it. And almost everyone is satisfied with the price-quality ratio of this product. According to many users, it is necessary to buy “pefku” exclusively from reputable companies that value their reputation and produce enamels from high-quality raw materials, observing all the requirements set by state standards.

PF-115 has more than reasonable priceTherefore, the purchase of cheap paints of inadequate quality is a dubious economy. The use of fakes can provoke allergies and poisoning, albeit to an easy degree, but why such victims. In addition to a strong odor, counterfeit paints dry for weeks, and the coating they form is too fragile and begins to crack in an accelerated mode.

Enamel paint, made according to the original recipe, is still considered by buyers to be a good “folk” remedy, noting the elasticity of the film and its resistance to external factors. Many gardeners are satisfied that with a limited budget, you can quickly upgrade household buildings on the site after the winter or update the old fence cover.

Experienced builders advise not to paint with pentaphthalic paint of a structure exposed to constant sunlight, as it is prone to fading.

For these purposes, it is better to purchase imported enamel that is resistant to UV radiation. There are no complaints about the protective properties of PF-115: this coating is fully capable of protecting concrete, metal or wood from adverse weather effects.

Consumption

The consumption rate of paint on the two-layer paint can be from 100 to 180 g per 1m2 in accordance with the following factors:

- the nature of the base and its absorbency;

- working viscosity of a paint and varnish covering;

- surface treatment method - manual or machine;

- single layer coating thickness;

- selected enamel color;

- the number of applied layers.

For comparison: The consumption of black enamel paint when painting primed metal structures in good weather and using an airbrush will be 50 g / m2 or more, manually - 80 g / m2. And the consumption of white enamel when painting a wooden surface with a brush is about 200 g / m2 or less, and colored - about 110g / m2.

How to breed?

Before direct use, enamel paint is well mixed. The easiest way to do this is with an electric drill with a mixer nozzle. To get a certain working viscosity of paint and varnish materials, it will be necessary to dilute it with a solvent like “Nefras2 A 130/150 (“ Solvent ”), White spirit or a mixture of them, which must be diluted in equal proportions or turpentine. Under the condition of applying electrocolouration - applying paint in a high-voltage electric field, the composition should be diluted with RE-4V / RE-3V thinners.

Usage tips

- To achieve a positive result using enamel paint, it is important to properly prepare the surface for painting. The substrate must be thoroughly cleaned by removing the old coating, dirt, oil, grease, wax, rust, and other contaminants.

- Provided the paintwork is in good condition, the painted surface is washed with soapy water, dried and sanded. The surfaces in oil stains or wax coating are treated with White spirit. Drying wood.

- Plastered and concrete surfaces are dedusted and well dried to avoid peeling of the film, the formation of bubbles, clearly visible on a glossy finish. Dust particles can cause a decrease in both the decorativeness of the coating, and its protective functions - atmospheric resistance and strength.

- Pentaphthalic paints can be stored and transported at a temperature of -30 ° C ... + 35 ° C. Proper storage involves placing hermetically sealed containers with enamel in a dry place with limited access to the sun.

- Optimal conditions for the application of coatings suggest an ambient temperature of 5-35 ° C. The drying time of each layer is a day if the air temperature is up to 20 ° C.The use of fast drying methods is allowed when the coating dries in an hour with a maximum allowable t of 110 ° C.

- Painting work is allowed using ordinary tools - a brush, a roller, by means of pneumatic / airless spraying, spray painting, dipping and electro-painting.

Optimal technologies for painting surfaces from different materials.

- Metal structures. Treatment with a layer of soil on metal GF-0119 / GF-021 / VL-05 / VL-023, similar primers for rusty surfaces such as "Unicor" or a composition that converts rust, followed by a two-layer application of enamel paint.

- Profile timber - 2-3-ply enamel.

- Plastered surfaces, brickwork, concrete slabs, previously painted structures are treated in the same way as profiled wood.

It is necessary to do all the painting work in the production workshopwhere equipped with exhaust ventilation or in a room with good air circulation. Participants of the painting work must have overalls and PPE (personal protective equipment), protecting the skin from contact with paint and respiratory organs from exposure to toxic fumes.

For more information on PF-115 enamel, see the video below.