Elcon heat-resistant enamel: application features

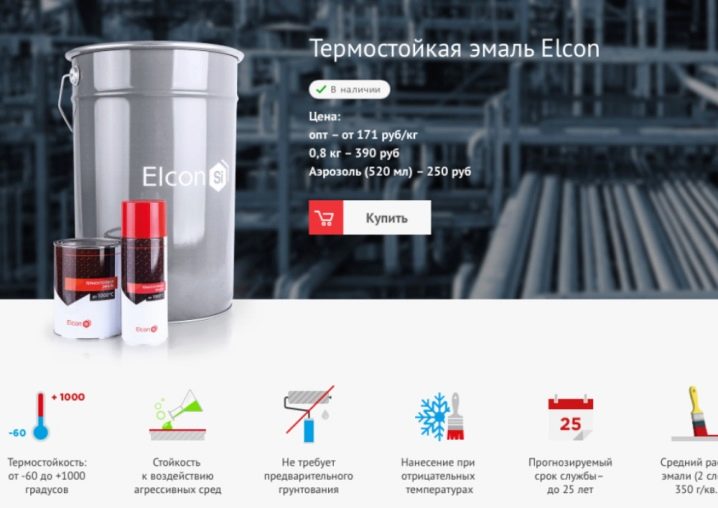

In the building materials market there is a wide range of different paints for completely different surfaces. One of the representatives of this product is Elcon KO 8101 heat-resistant enamel.

Special features

Elcon heat-resistant enamel is specially designed for painting boilers, furnaces, chimneys, as well as various equipment for gas, oil and pipelines, where liquids are pumped at temperatures ranging from -60 to +1000 degrees Celsius.

The peculiarity of the composition is the fact that when heated enamel does not emit toxic substances into the airso, it can be used inside the premises, it can be used to paint various stoves, fireplaces, chimneys.

Also, this paint creates a good protection of the material from the effects of high temperature, while maintaining its vapor permeability.

Other advantages of enamel:

- It can be applied not only to metal, but also to concrete, brick or asbestos.

- Enamels are not afraid of sudden temperature and humidity changes in the environment.

- It is not susceptible to dissolution in most aggressive materials, such as salt solutions, oils, and refined products.

- The service life of the coating subject to the application technology is about 20 years.

Specifications

The heat-resistant anticorrosive Elcon enamel possesses the following technical characteristics:

- The chemical composition of paint corresponds to TU 2312-237-05763441-98.

- The viscosity of the composition at a temperature of 20 degrees is at least 25s.

- Enamel dries up to the third degree at a temperature above 150 degrees in half an hour, and at a temperature of 20 degrees in two hours.

- The adhesion of the composition with the treated surface corresponds to 1 point.

- The strength of the applied layer upon impact is 40 cm.

- Resistance with a constant interaction with water is at least 100 hours, when exposed to oil and gasoline - at least 72 hours. The temperature of the liquid should be about 20 degrees.

- The consumption of this paint is 350 g per 1 m2 when applying the composition to metal and 450 g per 1 m2 to concrete. Enamel must be applied at least in two layers, but the actual consumption can be increased by one and a half times. This should be considered when calculating the required amount of enamel.

- The solvent for this product is xylene and toluene.

- The enamel Elcon has a slightly flammable, flame-retardant composition, when ignited, it practically does not smoke and has low toxicity.

Application features

In order for the coating that forms the enamel Elcon, kept as long as possible, paint should be in several stages:

- Surface preparation. Before applying the composition, the surface must be completely cleaned of dirt, rust and old paint. Then it must be degreased. To do this, you can use xylene.

- Enamel preparation. Paint must be mixed well before use. To do this, you can use a wooden stick or a nozzle mixer for a drill.

If necessary, enamel must be diluted. To give the desired viscosity of the composition, you can add a solvent in an amount up to 30% of the total volume of paint.

After the action with the paint tank should be left alone for 10 minutes, after which you can proceed to painting.

- The process of staining. It is possible to apply structure with a brush, the roller or a spray. The work should be carried out at an ambient temperature of -30 to +40 degrees Celsius, and the surface temperature should be at least +3 degrees.It is necessary to apply paint in several layers, while after each application it is necessary to sustain a time interval of up to two hours for the composition to set.

Other Elcon Enamels

In addition to heat-resistant paint, the product range of the company also contains several products used for industrial and personal purposes:

- Organosilicate composition OS-12-03. This paint is intended for anticorrosive protection of metal surfaces.

- Weatherproof enamel KO-198. This composition is designed to cover concrete and reinforced concrete surfaces, as well as metal surfaces that are used in aggressive environments such as salt solutions or acids.

- Emulsion Si-VD. It is used for impregnation of residential and industrial premises. Designed to protect the wood from ignition, as well as mold, fungi and other biological damage.

Reviews

Reviews of heat-resistant enamel Elcon good. Buyers note that the coating is durable, and it really does not collapse when exposed to high temperatures.

Among the shortcomings, users note the high cost of the product, as well as a high consumption of the composition.

For more information on Elcon heat-resistant enamel, see the video below.