Pile drilling: construction technology

Pile foundations under houses and other structures in many cases are the best solution. But in order for such a construction to serve for a long time and not to fail, it is necessary to carefully drill the notches. This work has many subtleties and nuances that will be discussed in detail in this article.

Special features

Drilling under the piles allows:

- build something in a shorter time;

- reduce the cost of work;

- guarantee the real stability and strength of the building.

Well drilling under piles is really necessary.when it is necessary to build a house in places with increased danger of earthquakes or in the area with low density soil. Such drilling can be done in any season, the type of climate is not important.Such advantages have allowed construction drilling to become one of the leading methods for preparing notches.

Drillers are hired in cases where it is necessary to strengthen the foundation without affecting the characteristics of the buildings that have already been built. Still drilling is able to maintain the slopes in a stationary state.

Instruments

Pile drilling technology can be very diverse. In most cases, vehicles with a wheeled, auger or tracked propulsor are used for this purpose.

To make a well under the pile, use:

- universal drilling rigs for wells;

- pile drilling boring units;

- drilling and crane complexes.

The differences between them in general and between individual models in particular are determined, first of all, by the level of productivity, the specifics of the governing bodies and the size of the wells created. By the cost of work and accessibility for non-professionals it is difficult to find analogues of a manual drill.

Low productivity is justified by the fact that expensive equipment and trained specialists are not needed.But in those situations when the speed is important or the soil is very complex, it is worth using yamobur. Fastening of such devices is made on wheeled and tracked platforms. If conditions are not easy, even highly specialized equipment has to be involved.

The rammer helps to simplify the job alone. The reinforced design of the popular version of "TISE" allows you to make an enlarged heel at the lowest point. As a result, the base goes below the freezing zone, and with the same carrier characteristic, the consumption of the solution is reduced by 3-4 times with respect to alternative technologies. In addition, for the identical properties of the foundation will have to put fewer piles than usual, and their diameter will be reduced.

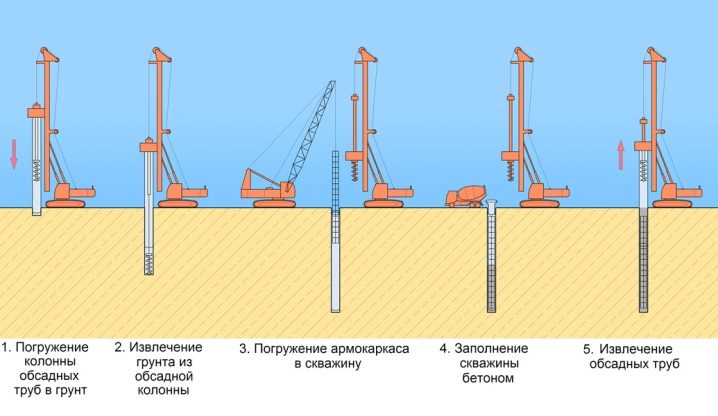

Process steps

To drill a hole with your own hands or with the help of specialists to the desired depth, you must strictly adhere to the technology.

A typical algorithm works:

- installation of drilling equipment and its fixation;

- penetration to the design depth and diameter;

- conservation work using clay solution or casing insertion;

- saturation of the cavity with a solution of concrete.

Experts pay special attention to the fact that both the prepared pit and the concrete poured into it have a short shelf life. According to the generally accepted standard, a maximum of 8 hours should pass from raising a drill to the infusion of the last drop of concrete.

Their requirements are also made for the preparatory work, which is as follows:

- Fertile soil is removed (up to 150 mm over the entire area).

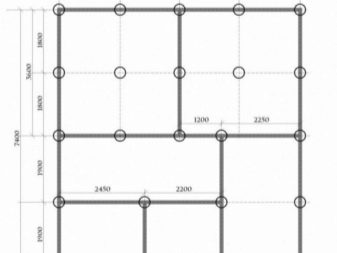

- Planned pile field at the selected mark.

- Mounted fence from strangers.

- The pad is formatted, and then the flatness of the surface is checked again.

- Pillows for the works themselves and the passage of cars fall asleep.

- Route lines are prepared for drilling systems using reinforced concrete slabs.

- Drainage channels are organized.

- Lighting devices are connected (only if it is necessary to drill around the clock or with reduced light day).

- The placement of drilling systems and the required materials and products.

Methods

Rotational drilling of wells consists in the fact that initially they pass the leader part equal in length to the casing section. This method has shown itself very well in a variety of geological conditions, with varying saturation of soils with water.

The use of a typical auger drill (elongated rod with a tip of high strength and screw blades) allows you to quickly raise the crushed soil to the top. The rate of passage of the holes can reach 120 cm per minute. The drilling complex periodically pulls out and raises the working part, freeing it from adhering soil.

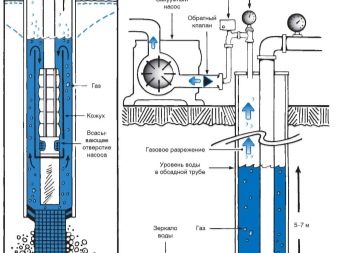

High-quality adherence to technological principles will allow for the working cycle, from one lifting of the drill to another, to form holes up to 10 m in length. Another variant of penetration involves covering the walls of the hole using an inventory pipe formed by single steel sections. Each fragment can reach 6 m in length. Below is a cutting part with teeth made of hard alloys. When the drill moves down, the pile is simultaneously pressed in, it blocks the infiltration of water from the soil and prevents the walls from collapsing.

Having reached the zero level determined by the project of the foundation and SNiP for a specific area, the auger drill is raised to the top. Water that has leaked from the soil into the prepared cavity is removed. But there is immersed reinforcing frame.The final step is the saturation of empty space with concrete.

Another type of drilling is the use of a core auger.which feeds the solution through the cavity in the rod itself. This approach ensures the formation of 400 pog. m. channels within standard 8 hours. In this case, the channels can be of a large diameter (from 50 cm) and reach a depth of 30 m each. It turns out this due to the systematic increase in the length of the screw to the output at a given point. Saturation of the completed cavity with the solution is combined in time with the lifting of the mast, this helps to make an array for stuffed piles. Remember that concrete is forced under pressure and therefore becomes stronger than usual.

If the introduction of a reinforcing cage is envisaged, it is simply pressed mechanically into small wells, and they are embedded in large wells with the help of a vibrating submersible machine. A typical auger works well in dry or almost dry soil. There is no need to prepare and strengthen the internal cavities of the wells.

There are advantages to the approach with the inventory pipe. Only it can form channels with a diameter of 1500 mm in very wet soil and in floating grounds.Wet drilling helps strengthen the casing of a well going through clay or medium-density sand.

It is the wet technique that is considered the least noisy, and it also does not destroy the layers of the soil as a whole. In some places there may be an extension of the channel up to 350 cm, which guarantees the highest stability of the base.

Leader drilling is designed to solve such a problem as the vertical installation of supports in dense ground. It is used in the winter months when the density of the soil is greatest. It is also important that the volume and level of vibration are relatively small.

The lack of "leaders" consists in obligatory preparation for drilling. It is also worth considering that the well will be 30-50 mm smaller than the reinforced concrete structure, reducing the depth - by about 1 m.

Leader drilling is recommended if:

- A layer of high density sand has been detected.

- The top layer of soil is solid.

- The site is located on the permafrost.

- The construction site is abundantly filled with stony ground.

- Piles to lead to great depths.

- The territory is filled with dispersed soil with a very low density.

Test drilling under the laying of piles allows once again to weigh all the subtleties and nuances. In some cases, the error can be very expensive, and it is detected after the completion of all construction work as a whole. Soil properties vary in space over wide limits, and if it is completely solid at 10–15 m, this does not mean that there will be no unexpected phenomena in a particular place. They are and voids, aquifers, loose particles and the departure of a really strong layer to an unusually large depth. Quite often there is such a problem as oscillations of the lines of freezing.

Tips

A manual auger is unacceptable if the depth of penetration of the pile is to exceed 7 m. Simplifying work with gasoline or special equipment, you should strive to reduce the total period of work to a minimum. Even a slight rain or the beginning of snowmelt can bring down a well that has just been prepared at the cost of great efforts.

Remove the soil and reanimate the site does not work, you can only re-drill the hole. The fastest option (although not always acceptable) is screw piles, which simultaneously perform the functions of a drill and a support.

It is recommended to carefully select the configuration of the propeller and the angles of the blades; this will allow the most effective penetration of a specific rock.

Screw piles can even be inserted manually, although specialized devices exist for this purpose. There is no need to level the site, the total duration of work is reduced by 1/5 compared with the installation of concrete supports. Drilling with continuous augers provides a passage of up to 50 m deep, the channel diameter can be from 10 to 80 cm.

When it is required to put bored piles with an extended heel, augers with expanding knives are in demand. When they start the hinge block, they are advanced from the position parallel to the rod, and at the moment of torsion a cylinder is cut in the soil.

The cutting ends of the casing adapt to the situation at the construction site. Through gravel, clay and sand, they go by regular tips, no hard welding of the teeth. Strong clay requires application to cutting fragments of hard alloys. Only grab drilling can be advised where rocky layers alternate with rocky and hard sand.

To keep the bottom of the well, carried out through wet dusty sands, clean, drilling valves and bucket type drills are used.More detailed information on a specific object can be given only by specialists.

The process of drilling and concreting a bored pile with a BAUER BG24H drilling rig is shown in the video below.