How to make a foundation of asbestos cement pipes?

When choosing the type of foundation homeowner must first take into account the characteristics of the soil and the structure itself. Important criteria for choosing one or another base system is price affordability, reducing the labor intensity of installation, the ability to conduct work without the involvement of special equipment. The foundation on asbestos pipes is suitable for "problem" soils, has a lower cost compared to some other types of bases.

Special features

A few decades ago, asbestos-cement pipes were practically not used in private housing construction, which was due, firstly, to the myth of their ecological insecurity at that time, and secondly, lack of knowledge and practical experience in the technology of using this material.

Today, a columnar or pile foundation on asbestos foundations has become quite widespread., especially on soils, where it is impossible to equip the tape base. These soils are primarily clay and loamy, moisture-saturated soils, as well as areas with a height difference.

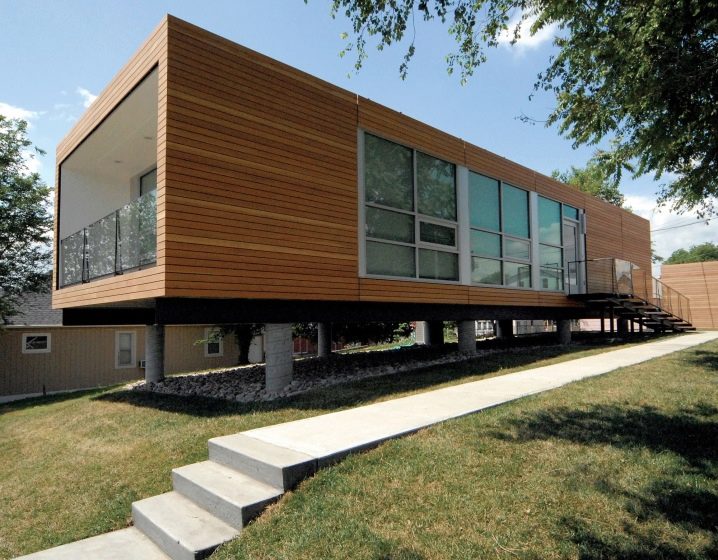

With the help of asbestos-cement pipes, the building can be raised by 30-40 cm, which is convenient for areas located in lowlands, floodplains, and also subject to seasonal flooding. Unlike metal piles, asbestos-cement piles are not prone to corrosion.

Asbestos pipes are building materials based on asbestos fiber and Portland cement. They can be pressurized and pressureless. Only pressure modifications are suitable for construction, they are also used in the organization of wells, boreholes.

Such pipes have a diameter in the range of 5–60 cm, withstand pressures up to 9 atmospheres, are characterized by durability and good hydraulic resistance coefficients.

In general, the technology of their installation is standard - most pile foundations are being installed in the same way.For pipes, wells are prepared, the location and depth of which corresponds to the design documentation, after which they are lowered into the prepared penetrations and filled with concrete. More details about the installation technology will be discussed in subsequent chapters.

Advantages and disadvantages

The popularity of this type of foundation is primarily due to the ability to make a site with a “problem” soil suitable for construction. Asbestos cement pipes can be installed by hand without the involvement of special equipment, which distinguishes them from metal piles. It is clear that this reduces the cost of the object.

The lack of a large amount of ground work, as well as the need to fill large areas with a solution of concrete, cause a lower labor intensity of the installation process and a higher speed.

Asbestos-cement pipes are much cheaper than piles, while they demonstrate better moisture resistance. On the surface does not form corrosion, there is no degradation of the material and the loss of its strength. This allows construction in excessively moisture-saturated soils, as well as in flooded areas.

If we compare the cost of a columnar foundation on an asbestos-cement base with the cost of a tape analogue (even shallow), the former will be 25-30% cheaper.

When using piles of this type, it is possible to raise the building to an average height of 30-40 cm, and with proper load distribution - even up to 100 cm. Not every other type of foundation demonstrates such qualities.

The main drawback of asbestos cement pipes is their low carrying capacity. This leads to the impossibility of using them in the construction of wetlands and organic soils, and also imposes certain requirements for construction. The object should be low-rise of light materials - wood, aerated concrete or frame-type construction.

Due to the small bearing capacity, it is necessary to increase the number of asbestos-cement pipes and, accordingly, wells for them.

In contrast to metal counterparts, such supports are characterized by the absence of an “anchor” property, and therefore if non-compliance with the installation technology or errors in calculations when heaving the soil, the supports will be squeezed out of the ground.

Like most pile houses, objects with asbestos-cement foundations are built without a basement. Of course, with a great desire, it can be equipped, however, it is necessary to dig a pit (to build a powerful drainage system on moisture-saturated soils), which in most cases is irrational.

Calculations

Construction of any type of foundation should begin with the preparation of project documentation and drawing up drawings. They, in turn, are based on data obtained during geological surveys. The latter suggest a laboratory analysis of the soil in different seasons.

To obtain information about the composition of the soil and their features allows the drilling of a test well, due to which the stratification of the soil, its composition, the presence and volume of groundwater becomes obvious.

The key to a solid foundation is an accurate calculation of its carrying capacity. The supports of pile foundations should reach solid layers of soil that lie below the level of its freezing. Accordingly, for such calculations, you need to know the depth of soil freezing. These are constant values that depend on the region, they are freely available in specialized sources (Internet,official documentation of bodies regulating construction rules in a particular region, laboratories producing soil analysis, and so on).

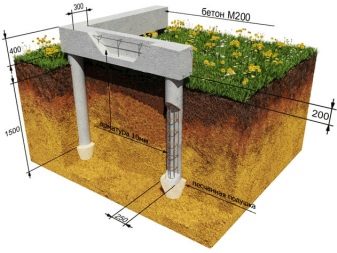

Having learned the necessary coefficient of frost penetration, another 0.3–0.5 m should be added to it, since it is precisely such asbestos-cement pipes that project above the ground. Usually, this is a height of 0.3 m, but when it comes to flooded regions, the height of the above-ground part of the pipes increases.

The diameter of the pipes is calculated based on the load indicators that will affect the foundation. To do this, find out the specific weight of the materials of which the house is built (they are set out in the Building Code). In this case, it is necessary to sum up not only the weight of the materials of the walls, but also the roof, cladding and thermal insulation coatings and floors.

Weight per 1 asbestos-cement pipe should not exceed 800 kg. Their installation is required around the perimeter of the building, at the points of increased load, as well as at the intersections of the load-bearing walls. Installation step - 1 m.

After receiving information about the specific gravity of the material, an additional 30% is usually added to this value in order to obtain the coefficient of the total pressure of the house in use on the foundation.Knowing this number, it is possible to calculate the number of pipes, a suitable diameter, and also the number of valves (at the rate of 2-3 rods per support).

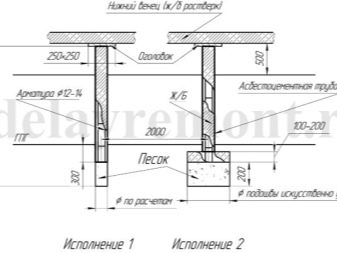

On average, for frame buildings, as well as non-residential facilities (gazebos, summer kitchens), pipes with a diameter of 100 mm are used. For aerated or log houses - products with a diameter of at least 200 -250 mm.

Concrete consumption depends on the diameter of the support. So, about 0.1 cubic meters of solution is required to fill 10 m of a pipe with a diameter of 100 mm. For a similar filling of a pipe with a diameter of 200 mm, 0.5 cubic meters of concrete are required.

Installation

Installation must necessarily be preceded by soil analysis and drafting, which contains all the necessary calculations.

Then you can start preparing the site for the foundation. First of all, it is necessary to remove garbage from the site. Then remove the top soil layer of the soil, level and tamp the surface.

The next step will be the marking - according to the drawings at the corners, as well as at the points of intersection of the supporting structures, pegs are driven in between which the rope is stretched. Upon completion of the work, you should make sure that the resulting “pattern” complies with the design one, and also double-check the perpendicularity of the sides formed by the corners.

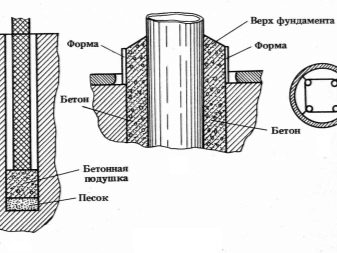

After the marking is completed, proceed to the drilling of pipes. For work use the drill, and at its absence dig deepenings manually. Their diameter is 10-20 cm greater than the diameter of the supports. Depth - 20 cm more than the height of the underground part of the pipe.

This "stock" is required to sleep a layer of sand. It is poured to the bottom of the depression about 20 cm, after being tamped, moistened with water and crushed again. The next stage is the primary waterproofing of pipes, which involves the lining of the bottom of the well (on top of the compacted sand "cushion") of roofing material.

Now the pipes are lowered into the recesses, which are leveled and fixed with temporary supports, usually wooden. When pipes are immersed in soils with a high level of moisture along the entire length of the underground run, they are covered with bitumen waterproofing mastic.

Concrete mortar can be ordered or prepared by hand. Mixed cement and sand in proportions of 1: 2. Water is added to this composition. It should make a solution, the consistency of a flowing dough. Then 2 parts of gravel are introduced into it, and it is still well mixed again.

Concrete is poured into the pipe to a height of 40-50 cm, and then the pipe is raised by 15-20 cm and left until the solution hardens.This technology allows you to create a "base" under the pipe, thereby increasing its resistance to soil heaving.

When the concrete solution hardens completely, the walls of the pipe are waterproofed with roofing felt. Between the walls of the recess and the side surfaces of the pipe fall asleep river sand, which is well tamped (the principle is the same as in the arrangement of the "pillow" - pour sand, tamp, pour water, repeat the steps).

Between the pipes tighten the string, once again convinced of the accuracy of the level and proceed to the reinforcement of the pipe. For this purpose, several rods are connected with transverse wire jumpers, which are lowered into the pipe.

It now remains to pour concrete solution into the pipe. The use of a vibratory pile driver allows to eliminate the preservation of air bubbles in the thickness of the solution. If it is not there, pierce the filled solution in several places with reinforcement, then close the resulting holes on the surface of the solution.

When the solution gain strength (about 3 weeks), you can begin to level the aerial part of the bases, their waterproofing. One of the positive features of these supports is the ability to speed up the process of preparing the foundation. As is known, for a full set of strength concrete needs 28 days.However, pipes fringing the concrete play the role of permanent formwork. Thanks to this, further work can be started already in 14-16 days after pouring.

Between themselves, the supports can be connected by beams or unite a monolithic slab. The choice of a particular technology is usually based on the materials used.

Beams are used mainly under frame and brick houses, as well as small buildings for household purposes. For houses made of aerated concrete or arbolit, a grillage is usually poured, which is additionally reinforced. Regardless of the chosen technology, it is necessary to connect the reinforcement of the pillars with the power element of the base (beams or reinforcement of the grillage).

Reviews

Consumers using the foundation on asbestos-cement pipes, leave mostly positive reviews. Homeowners note the availability and lower cost of the house, as well as the opportunity to do all the work with their own hands. As in the case of casting monolithic or slab base, you do not need to order a concrete mixer.

For clay soils in the northern regions, where there is a strong swelling of the soil, residents of constructed houses recommend increasing the support step, be sure to make them with the expansion below and increase the number of reinforcement.Otherwise, the soil pushes the pipe.

From the video below you will learn about the advantages of a foundation made of PVC pipes, asbestos or metal.